Multistage extraction unit for animal and plant raw materials, and method and application thereof

An extraction device, animal and plant technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of difficult extraction, low extraction efficiency, large volume, etc., and achieve high crushing efficiency and filtration efficiency. and the effect of improving leaching efficiency and improving leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

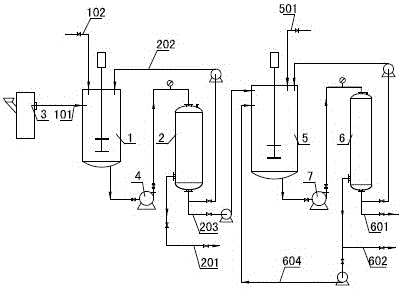

[0039] refer to figure 1 , the multi-stage extraction device for animal and plant raw materials includes an extraction tank 1, a membrane filter 2, a pulverizer 3 and a concentrated liquid membrane separation device, and the extraction tank 1 is connected to the pulverizer 3 through a raw material delivery pipe 101 1. The first pump 4 is connected to the inlet pipeline of the membrane filter 2, and the permeate outlet of the membrane filter 2 is connected to the permeate output pipe 201; The liquid return pipe 202 is connected with the extraction tank 1 and connected with the concentrated liquid membrane separation device through the concentrated liquid delivery pipe 203 . The concentrated liquid separation device comprises a leaching tank 5 and a filter membrane separator 6, the leaching tank 5 is connected with the inlet pipeline of the filter membrane separator 6 by a second pump 7, and the concentrated solution outlet of the filter membrane separator 6 is connected to the ...

Embodiment 2

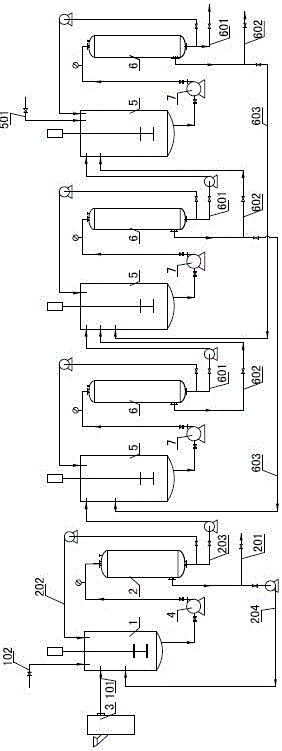

[0043] refer to figure 2 , this embodiment includes the above structure, the difference between this embodiment and embodiment 1 is: there are multiple concentrated liquid membrane separation devices, and the multiple concentrated liquid membrane separation devices are along the concentrated liquid conveying direction, from the upper level to the lower level It is arranged in multiple stages, and the adjacent concentrated liquid membrane separation devices are connected through the concentrated liquid feeding pipe 601 and the permeate liquid feeding pipe 602 respectively; in the adjacent concentrated liquid membrane separation devices: the lower concentrated liquid The permeate outlet of the membrane separation device is connected to the leaching tank 5 of the upper concentrated liquid membrane separation device through a countercurrent pipeline 603 .

[0044] There are various designs for the solvent replenishment tube 501: refer to figure 2 , it can be designed that only ...

Embodiment 3

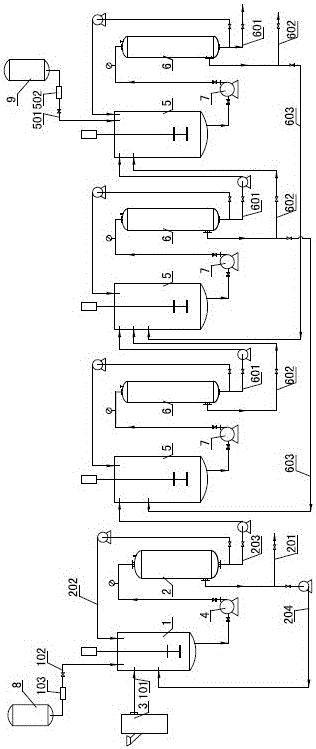

[0047] refer to image 3 , the present embodiment except including all structures of embodiment 2, difference is: comprise solvent storage tank 8, extraction tank 1 is connected with solvent storage tank 8 through solvent delivery pipe 102, is provided with temperature regulator 103 on the solvent delivery pipe 102 and valves. It includes a solvent supplement tank 9, the liquid inlet end of the solvent supplement pipe 501 is connected to the solvent supplement tank 9, and the solvent supplement pipe 501 is provided with a temperature regulator 502 and a valve. Including the permeate return pipe 204, the permeate outlet of the membrane filter 2 is connected to the extraction tank 1 through the permeate return pipe 204, and the permeate return pipe 204 can return the low-concentration permeate to the extraction tank 1, until the permeate concentration reaches a higher value, the permeate return pipe 204 is closed, and the high-concentration permeate is discharged from the perme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com