Movable biomass compact molding apparatus and molding roll

A molding equipment and biomass technology, applied in the field of molding rollers, can solve the problems of poor mobility, short service life, and high energy consumption, and achieve the effects of simple equipment, reduced energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

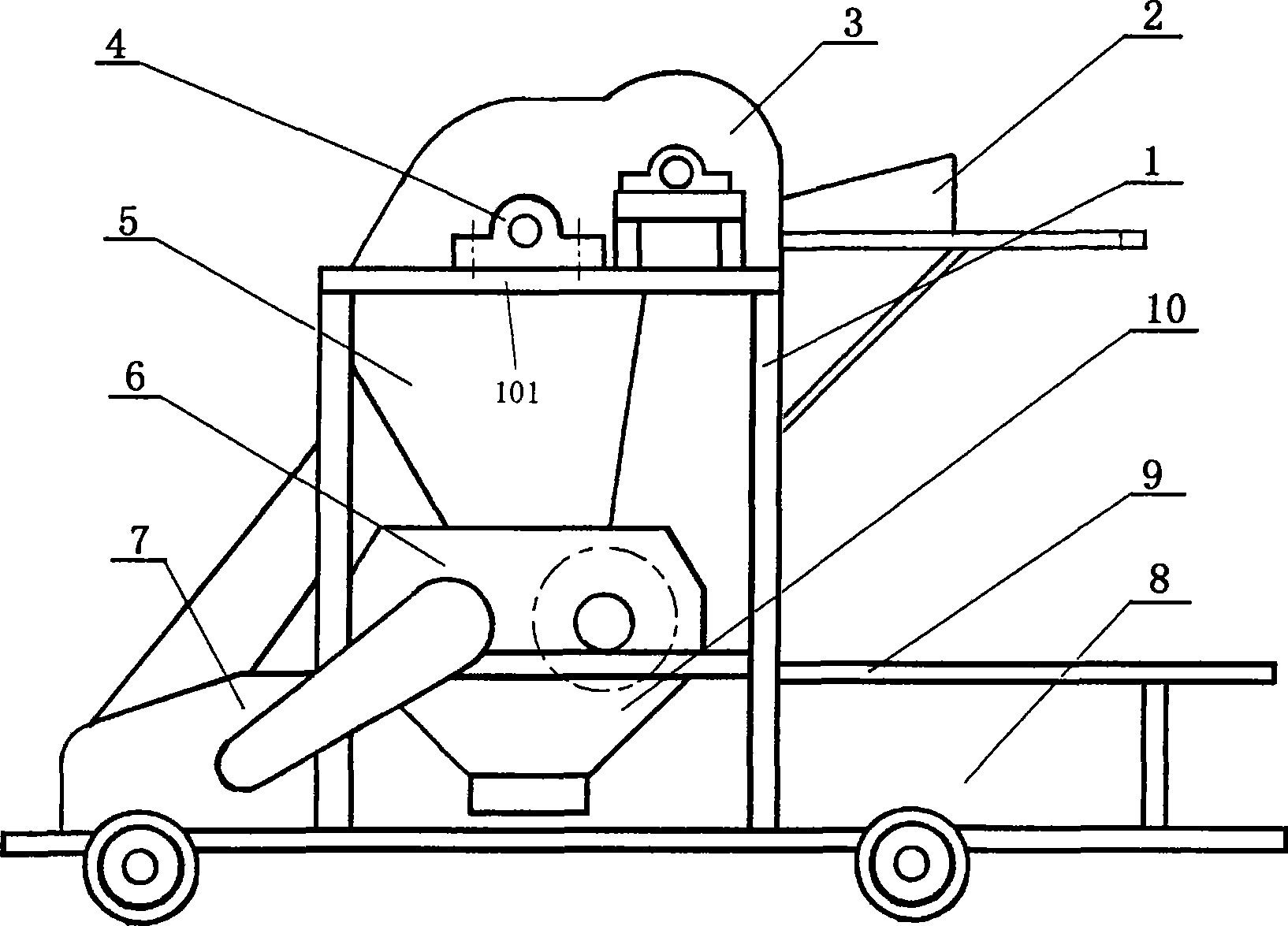

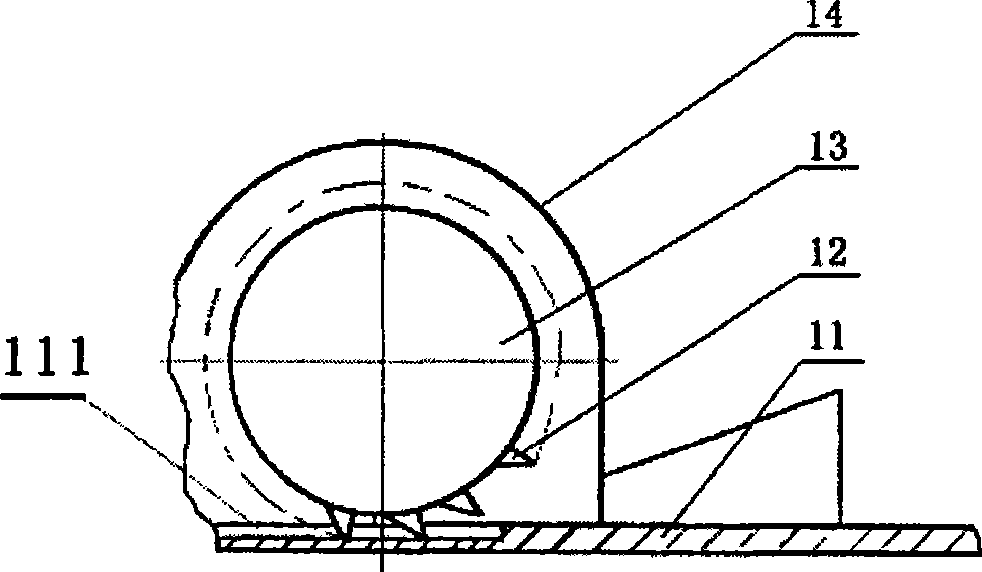

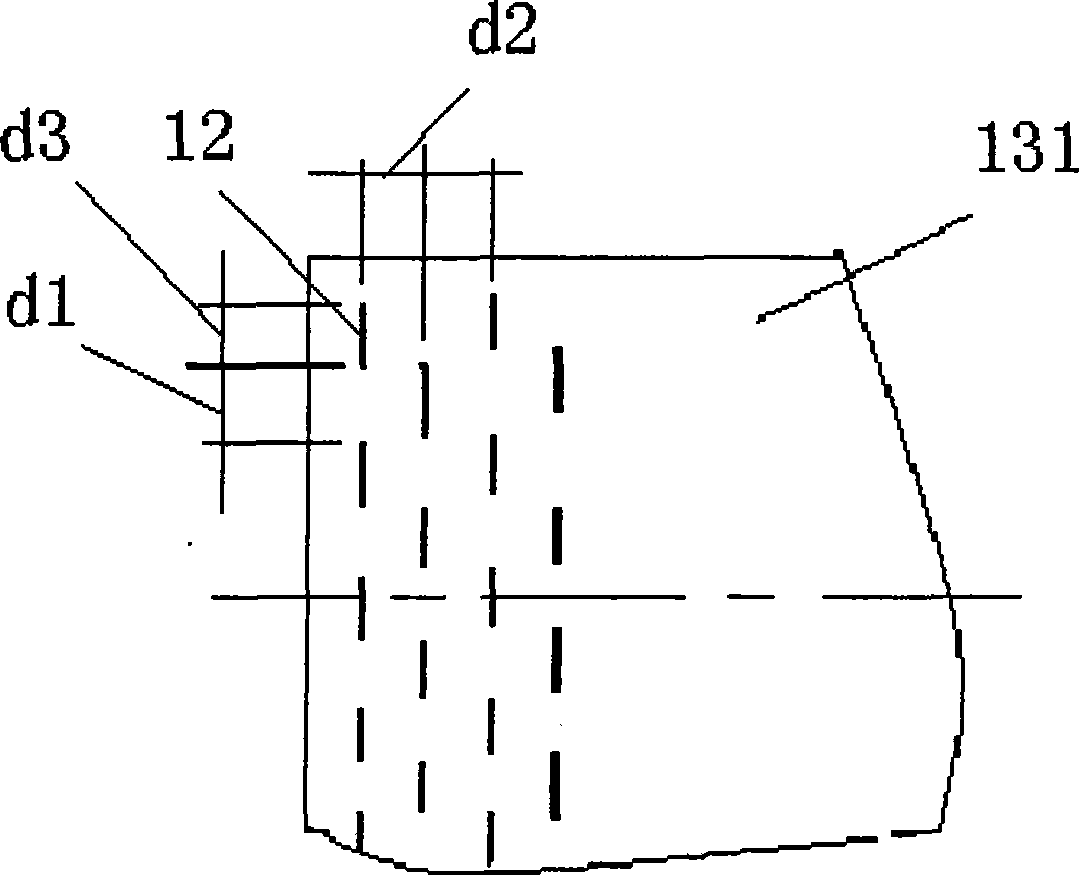

[0050] A specific example of the biomass compact forming processing equipment provided by the present invention is used for crushing corn stalks. The processing process includes several steps of pre-crushing, crushing and roller forming of raw materials; the pre-crushing step is divided into flattening and splitting. There are two sub-steps. In the pre-crushing step, the biomass raw material is first flattened and then split longitudinally; then, in the following crushing step, the thin strips of biomass Send it to the crushing mechanism for horizontal cutting; then, pass the cut and crushed debris through a sieve, and the qualified debris falls into the roller forming machine for compression and compact molding to produce biomass with a certain density Granular product output.

[0051] This processing method can be used as figure 1 shown in a complete set of equipment. It comprises a frame 1 on which frame wheels 8 are fixed. A motor 05 or a diesel engine is fixed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com