Patents

Literature

52results about How to "Strong crushing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crusher

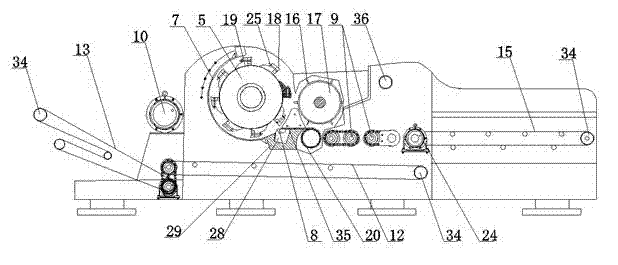

InactiveCN102806126AHigh cutting forceSmooth crushing processGrain treatmentsAgricultural engineeringStructural engineering

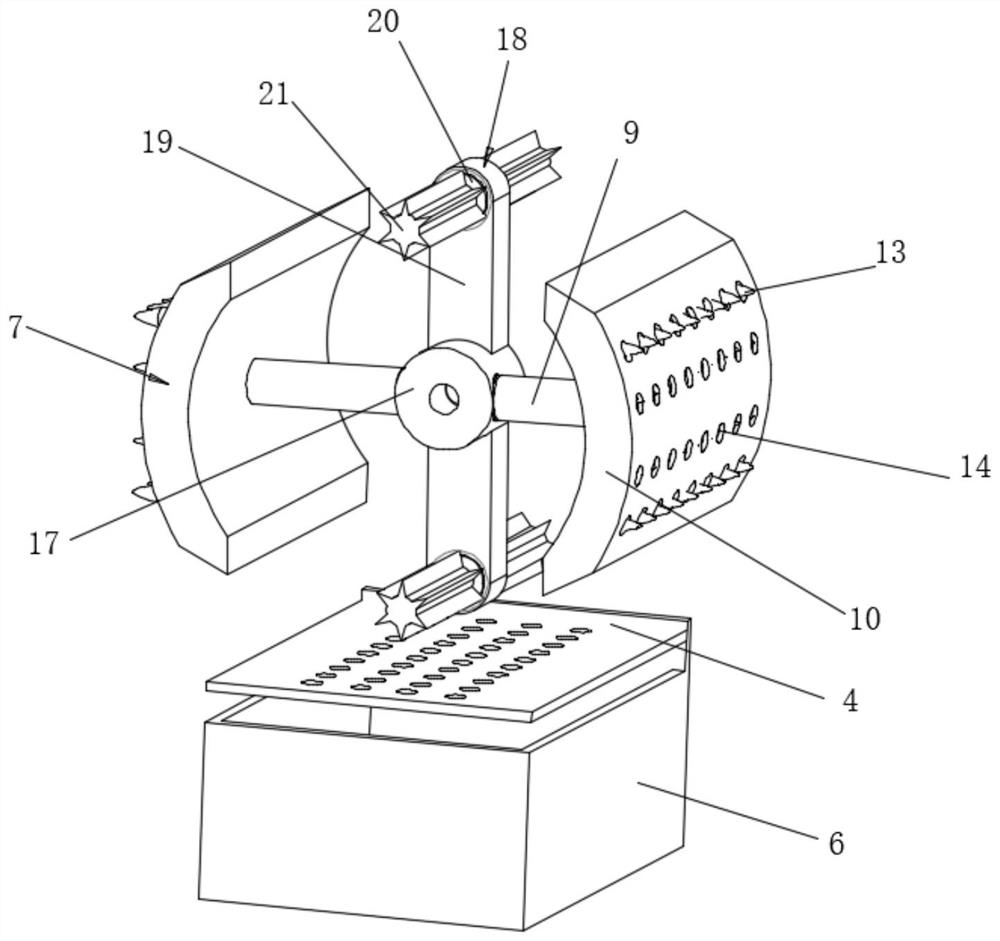

The invention discloses a crusher. The crusher comprises a charging device, a discharging device, a feeding device and a crushing device; the feeding device consists of feeding rollers and a material poking roller; the crushing device consists of a rotor, a fixed cutter and a filter screen; the circumference of the rotor is provided with fly-cutter seats; the included angles between the adjacent fly-cutter seats are equal on the circumference; fly-cutters are fastened on the fly-cutter seats through bolts; gaps are reserved between blades of the fly cutters and the fixed cutter; the fixed cuter is fastened on a fixed cutter beam by a bolt through a pressing plate; the fixed cutter beam is connected with the feeding rollers through a feeding transition plate; and the feeding rollers are parallel to each other, and the rotation directions of the feeding rollers are consistent with each other; and the material poking roller is fixed on a material fixing roller cover in which a hinge is taken as a rotation center. The crusher is high in crushing efficiency, low in energy consumption, and good in effect of crushing wood, core wood, cotton straw and other biomass, is suitable for crushing municipal solid waste and industrial refuse simultaneously and runs stably.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

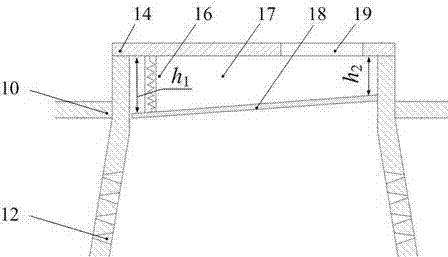

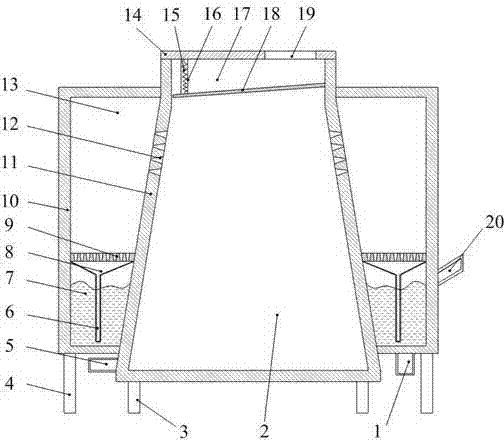

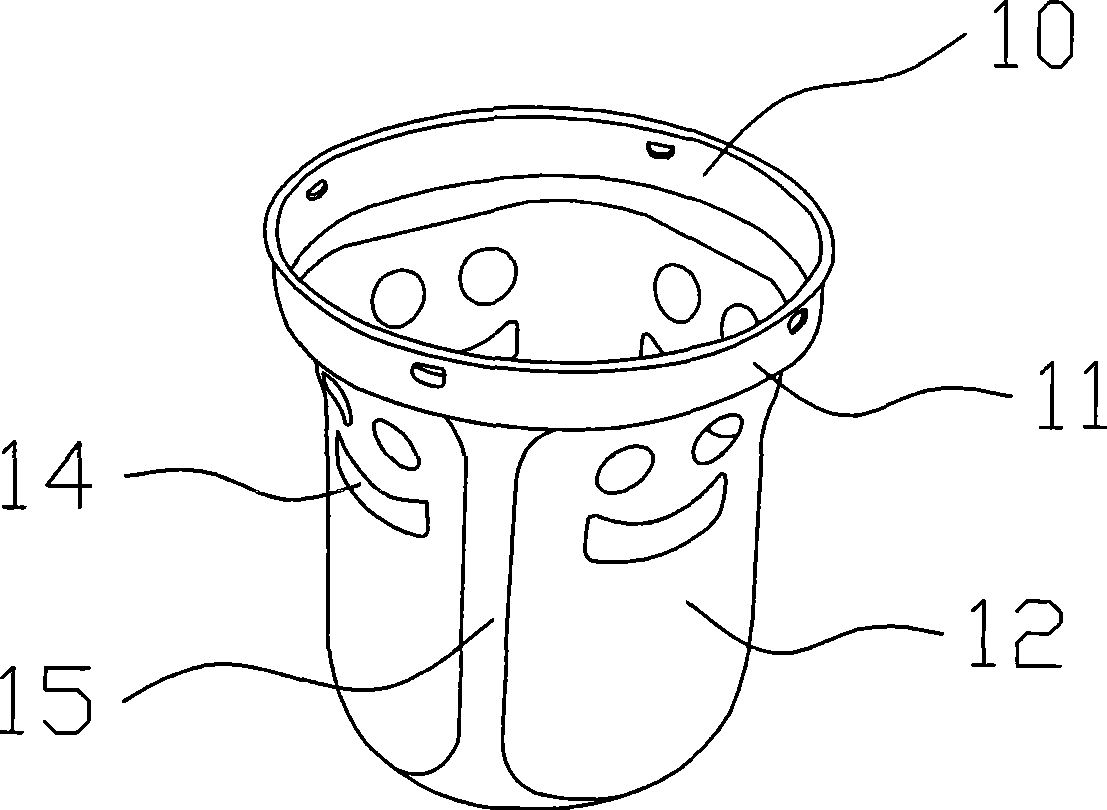

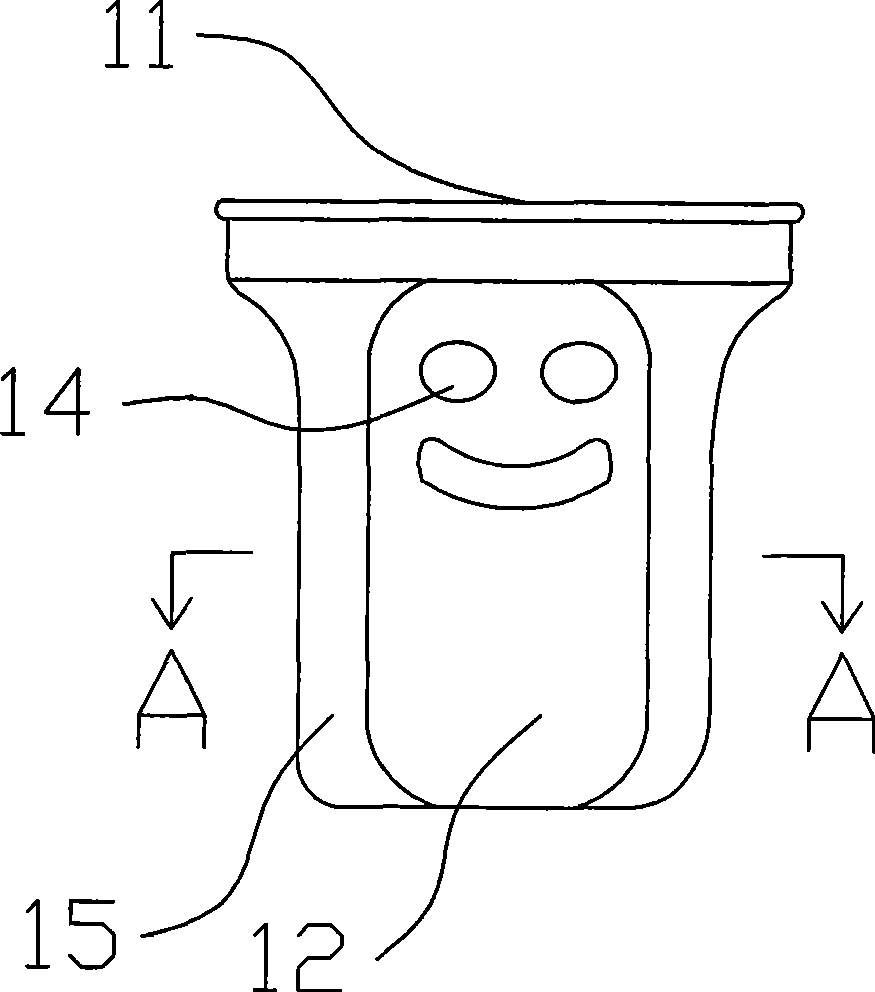

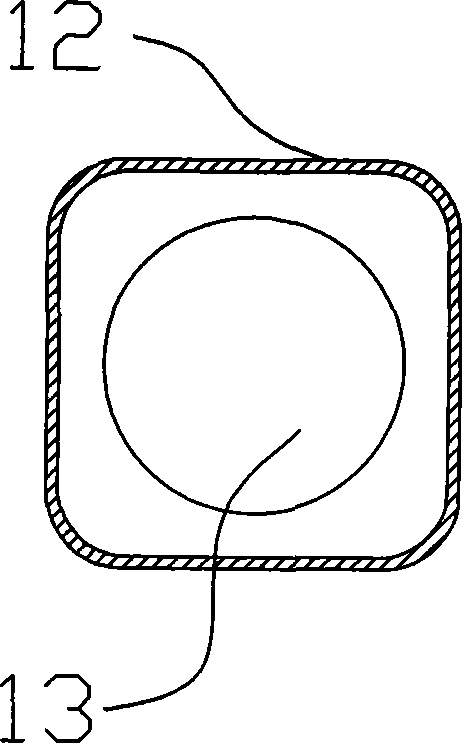

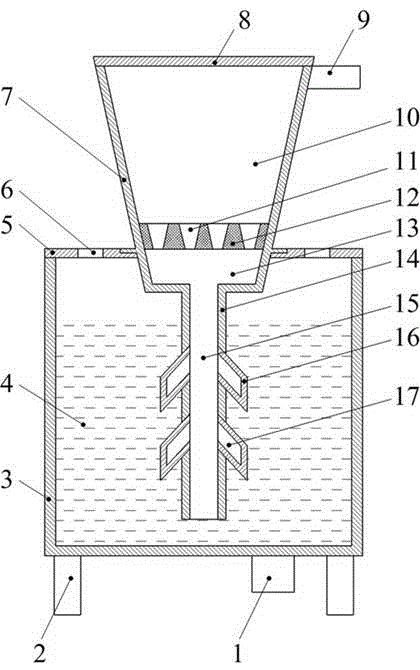

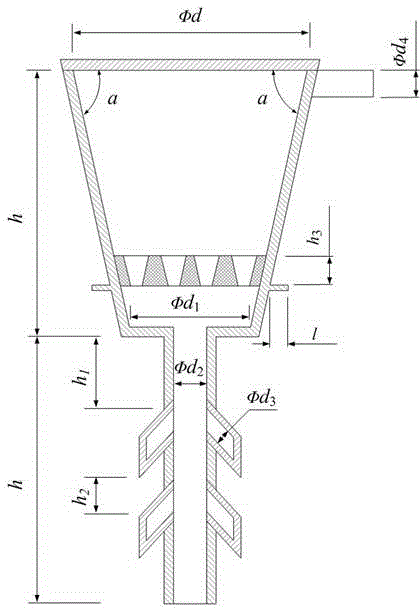

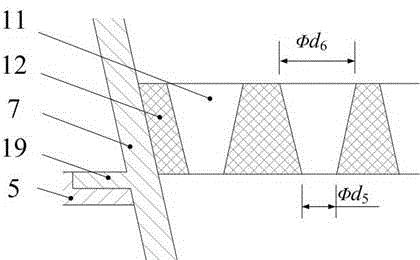

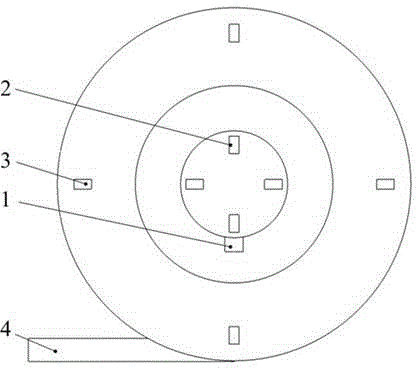

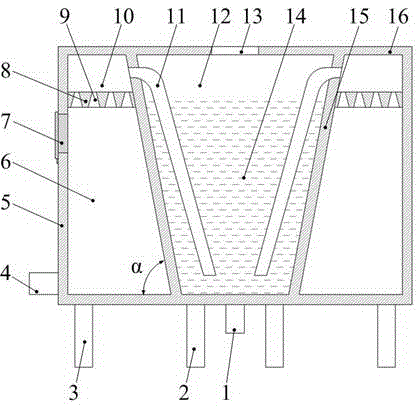

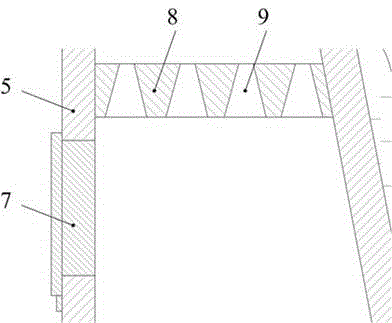

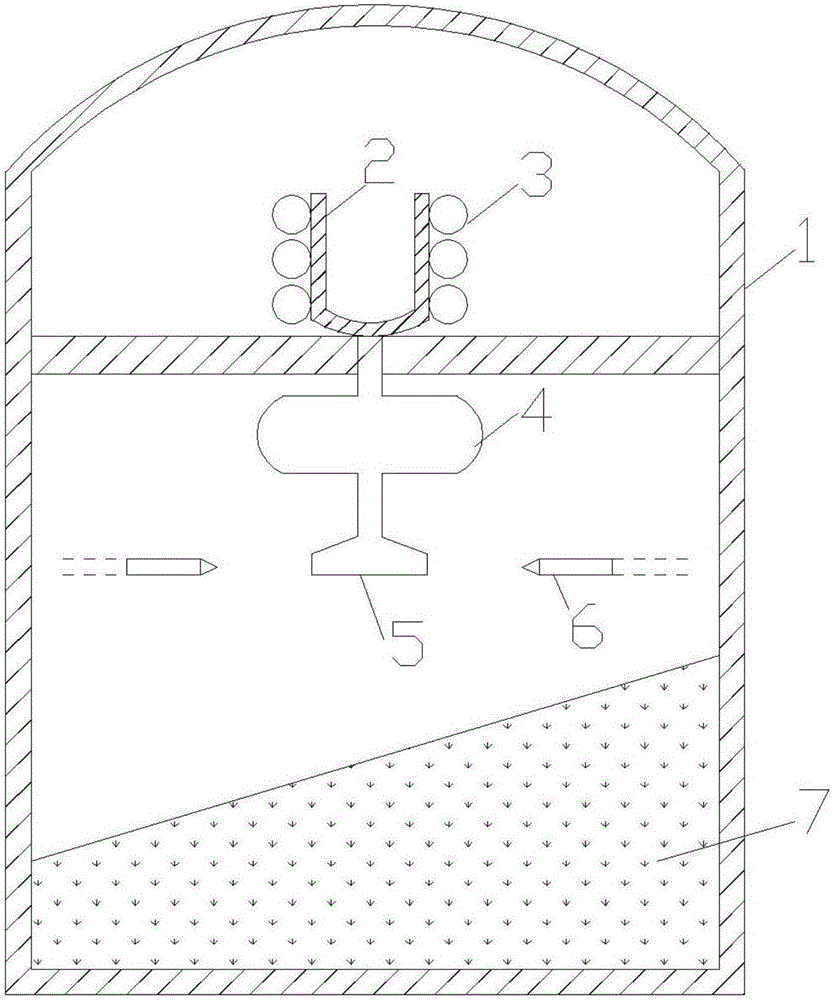

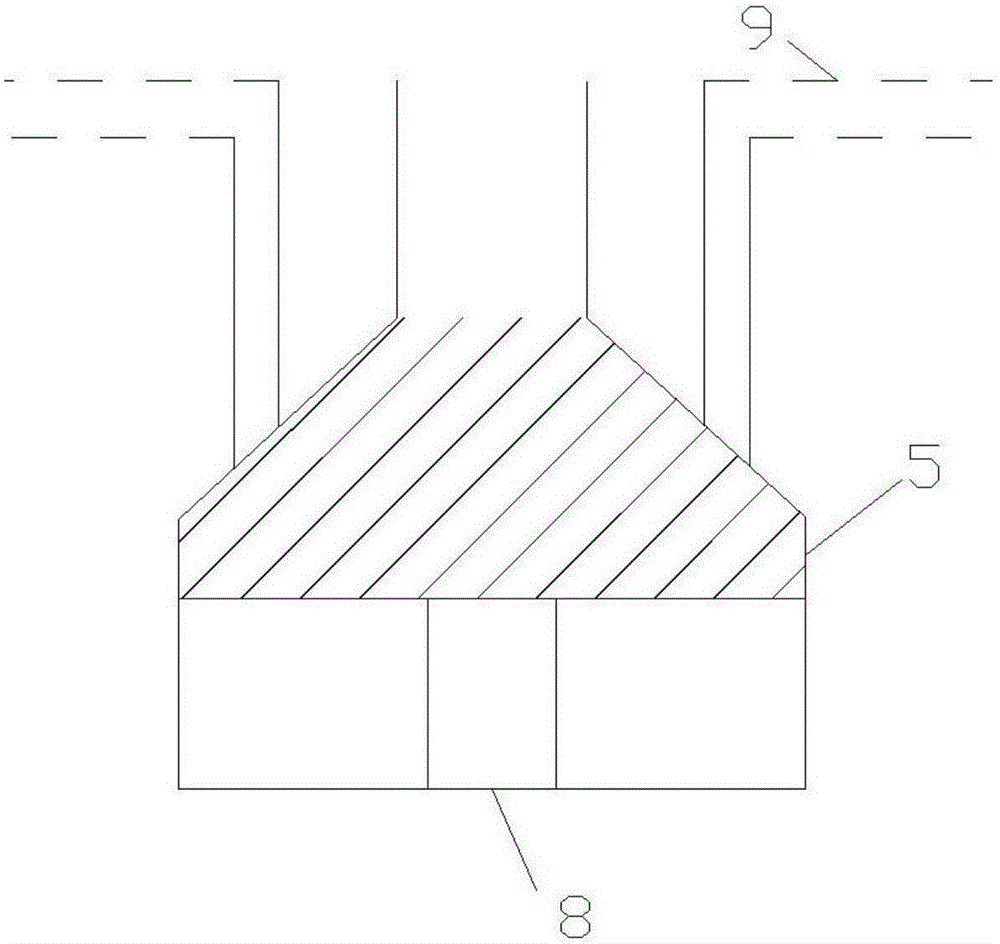

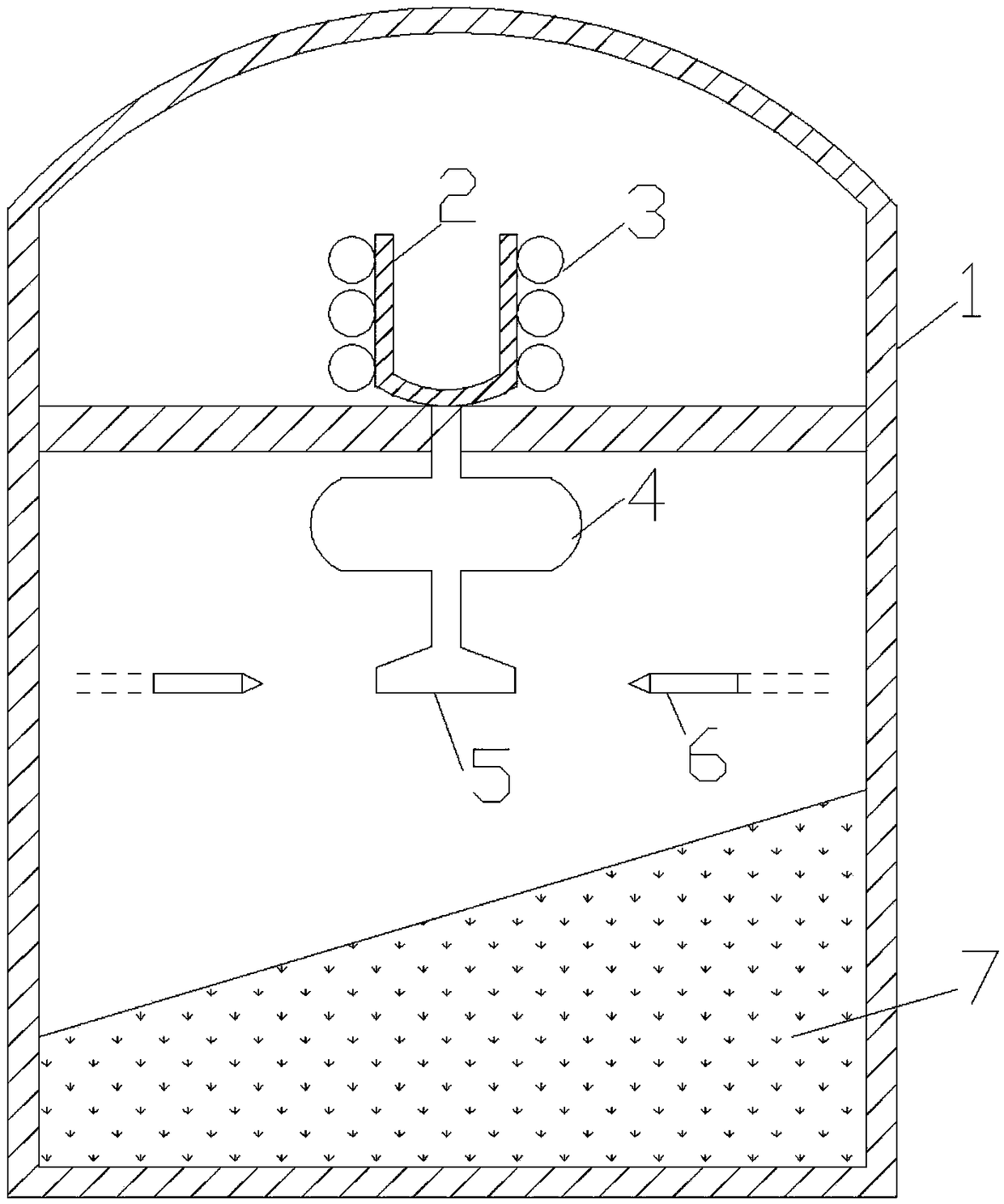

Pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown

InactiveCN104727173AGuaranteed stabilityEliminate shakingRaw material divisionLiquid stateLiquid water

The invention provides a pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown. The pulping device mainly comprises a feeding device, a vortex breakdown device and a liquid pulp generating device and is characterized in that solid and liquid are separated, air vortex breakdown is conducted firstly, and then broken materials are mixed with liquid water to form pulp. According to the pulping device, feeding amount control and sealing are achieved through a buffering and sealing plate and a spring, tangential feeding of air is achieved and loop current is formed through an air inlet tangent to the outer edge of the bottom of an inner conical cylinder, rotational flow is accelerated twice through a tapered primary vortex breakdown area and an oblique secondary vortex breakdown area, the broken materials are screened twice and blockage prevention is achieved through circular truncated cone-shaped holes in a primary filtering device and a secondary filtering device, and mixing and stirring of solid and liquid are achieved through a broken material delivery pipe.

Owner:UNIV OF JINAN

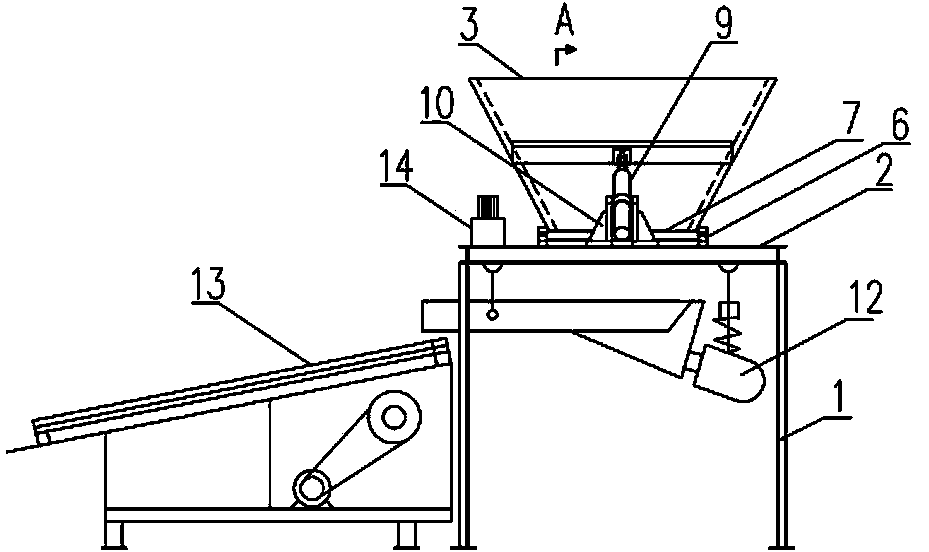

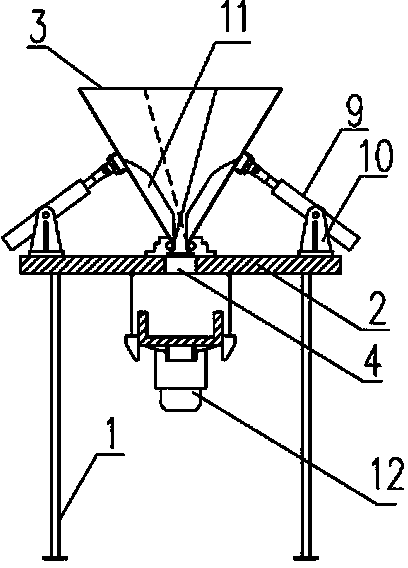

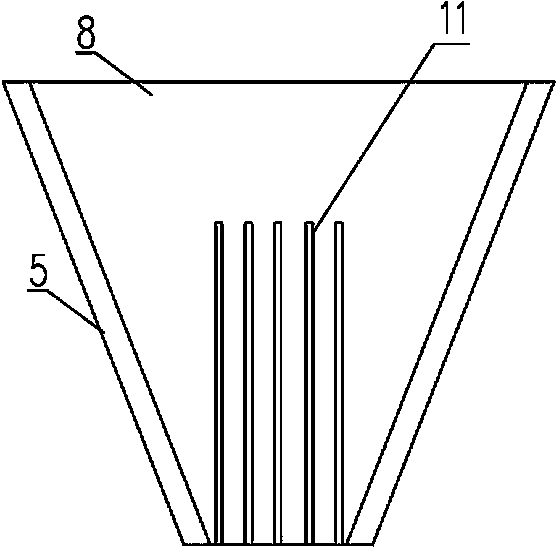

Crushing and screening integrated conveying device for resin wheel cold storage material

ActiveCN104307613AWithout compromising intrinsic qualityRealize intelligent crushingGrain treatmentsHydraulic cylinderGrinding wheel

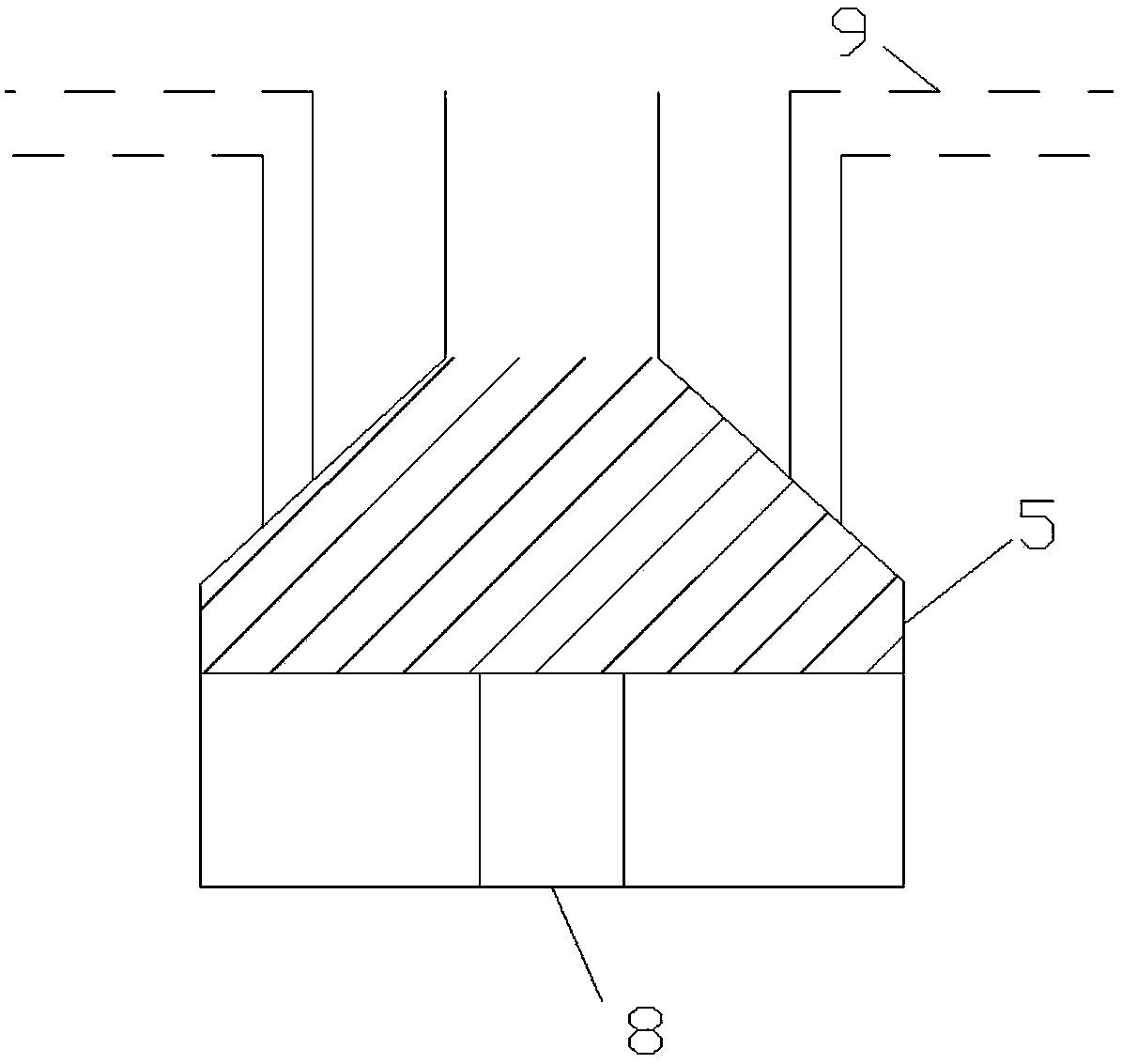

The invention discloses a crushing and screening integrated conveying device for a resin wheel cold storage material. The crushing and screening integrated conveying device comprises a hopper arranged on a rack working platform, wherein the hopper consists of two inverted conical tank-shaped shells; the notch of one of the two inverted conical tank-shaped shells is inserted into the notch of the other inverted conical tank-shaped shell in a sliding manner; the bottom sides of the two inverted conical tank-shaped shells are respectively fixed with corresponding rotating shafts; the outer surfaces of bottom tank plates of the two inverted conical tank-shaped shells are respectively hinged to piston rods of hydraulic cylinders; the bodies of the two hydraulic cylinders are respectively fixed with the working platform through hinged supports; a plurality of crushing plates are respectively fixed on the inner surfaces of the bottom tank plates of the two inverted conical tank-shaped shells; an electromagnetic vibration feeding machine is hung below the discharge hole of the working platform; the discharge hole of the electromagnetic vibration feeding machine is joined with a shaking sieve below the discharge hole. The crushing and screening integrated conveying device has the advantages that integrated functions of crushing, screening and conveying are achieved, and intelligent crushing, screening and conveying of the resin wheel cold storage material are achieved.

Owner:SIPPR ENG GROUP

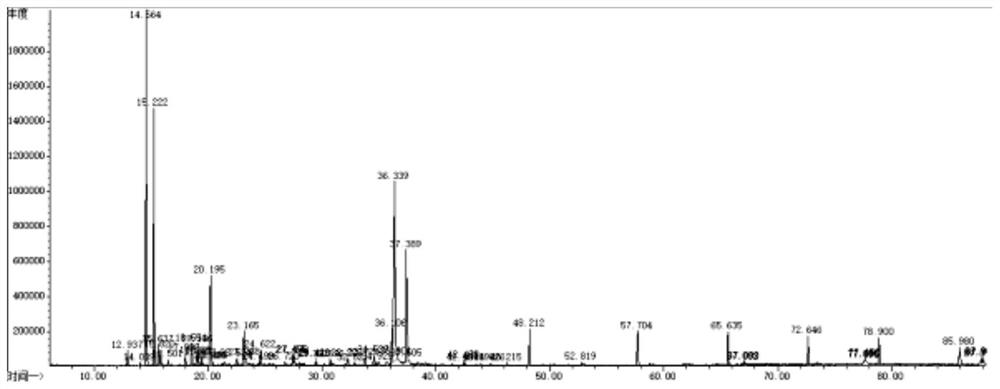

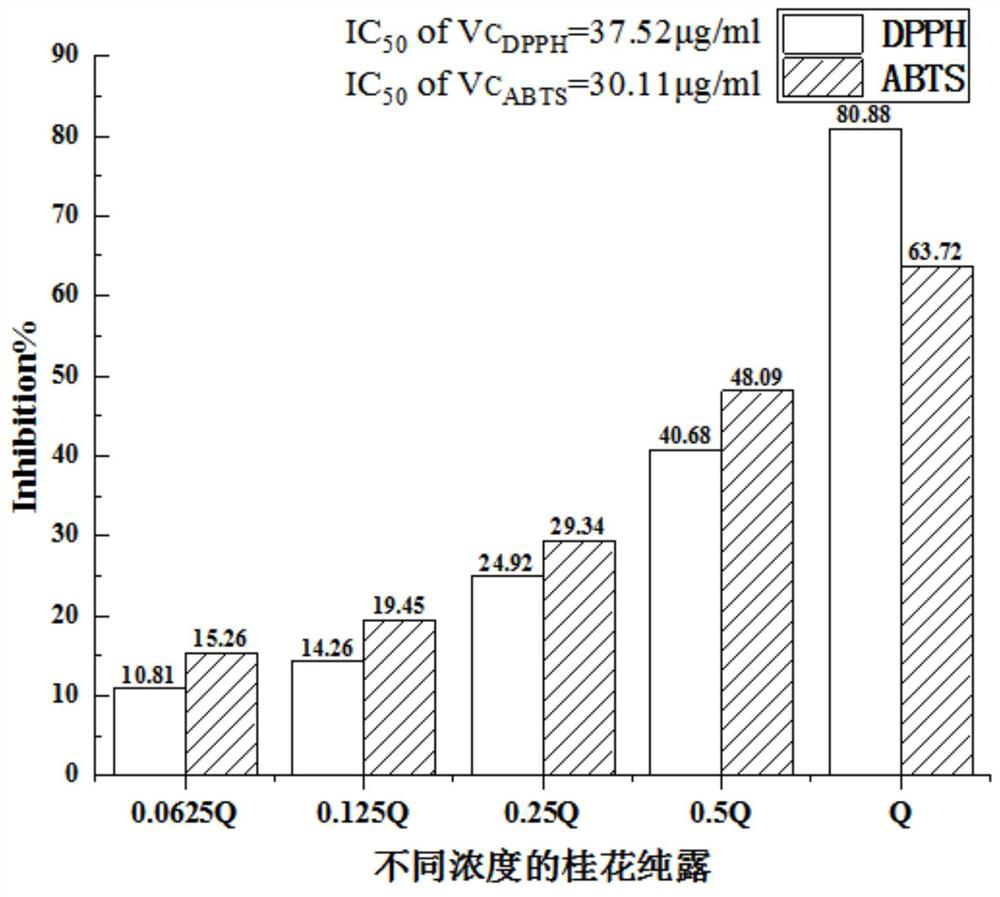

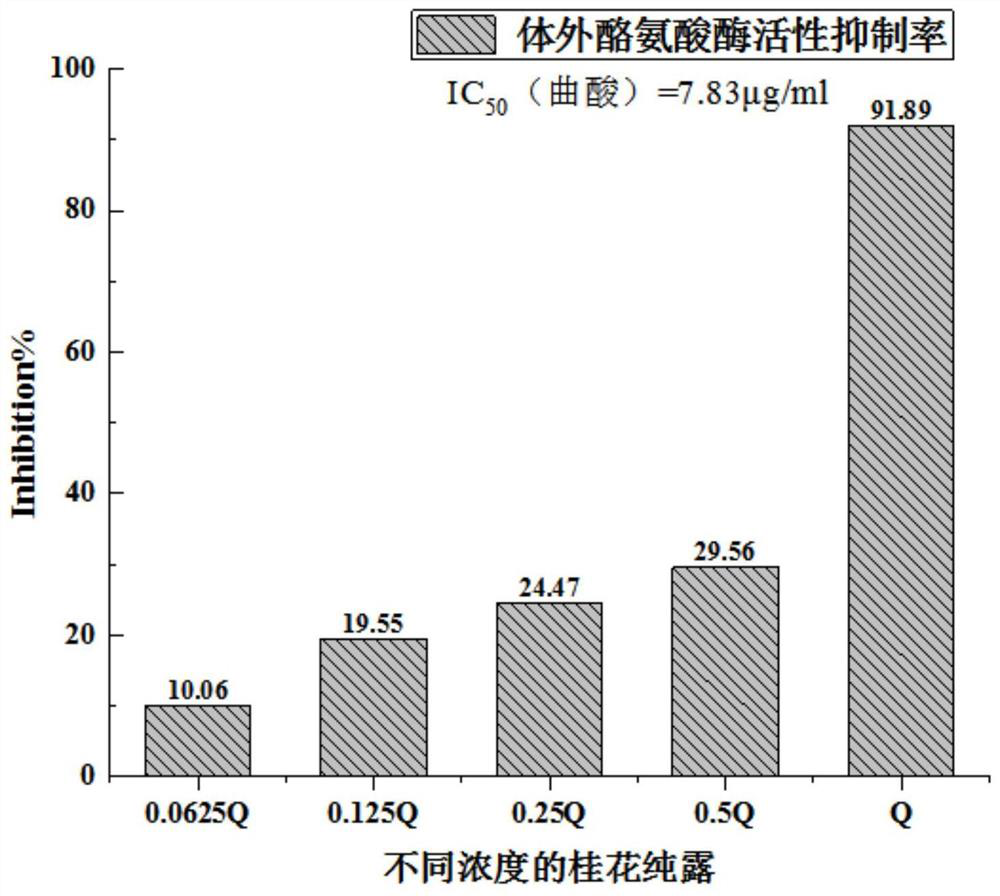

Extraction process for ultrasonic-assisted flash extraction of sweet osmanthus hydrolat and activity determination method

PendingCN113075016AStrong crushing forceIncrease added valuePreparing sample for investigationColor/spectral properties measurementsCytotoxicityPlant cell

The invention discloses an extraction process for ultrasonic-assisted flash extraction of sweet osmanthus hydrolat and an activity determination method. The method comprises the following steps: soaking osmanthus flowers in a saline solution, performing ultrasonic treatment after flash crushing, adding water for direct distillation, and receiving osmanthus hydrolat, wherein the sweet-scented osmanthus hydrolat is aromatic water with rich sweet-scented osmanthus fragrance and terpene component smell, is prominent in sweetness after being aged, and has pleasant fruit sweetness like peaches. According to the method disclosed by the invention, more active substances in petals are brought into a solution through the strong crushing force of the flash extractor, the cavitation effect generated between the rotary vane and liquid and the crushing effect of ultrasonic waves on plant cell walls, so that the additional value of osmanthus fragrans products is improved; in addition, an in-vitro and cell whitening experiment, an antioxidant determination method and experimental data of the sweet osmanthus hydrolat are provided, and it is proved that the sweet osmanthus hydrolat is extremely low in cytotoxicity and has antioxidant activity and whitening activity.

Owner:SHANGHAI INST OF TECH

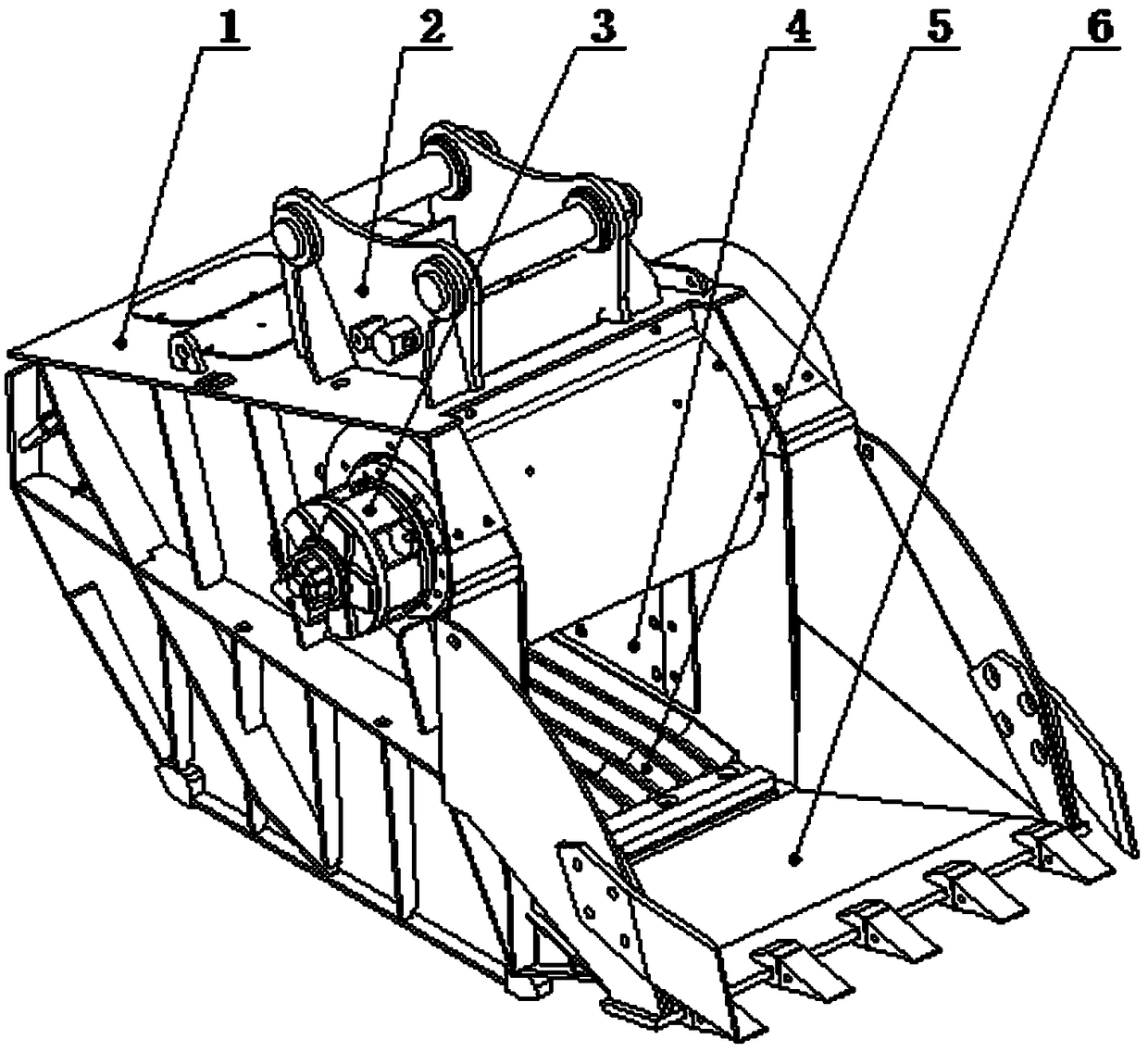

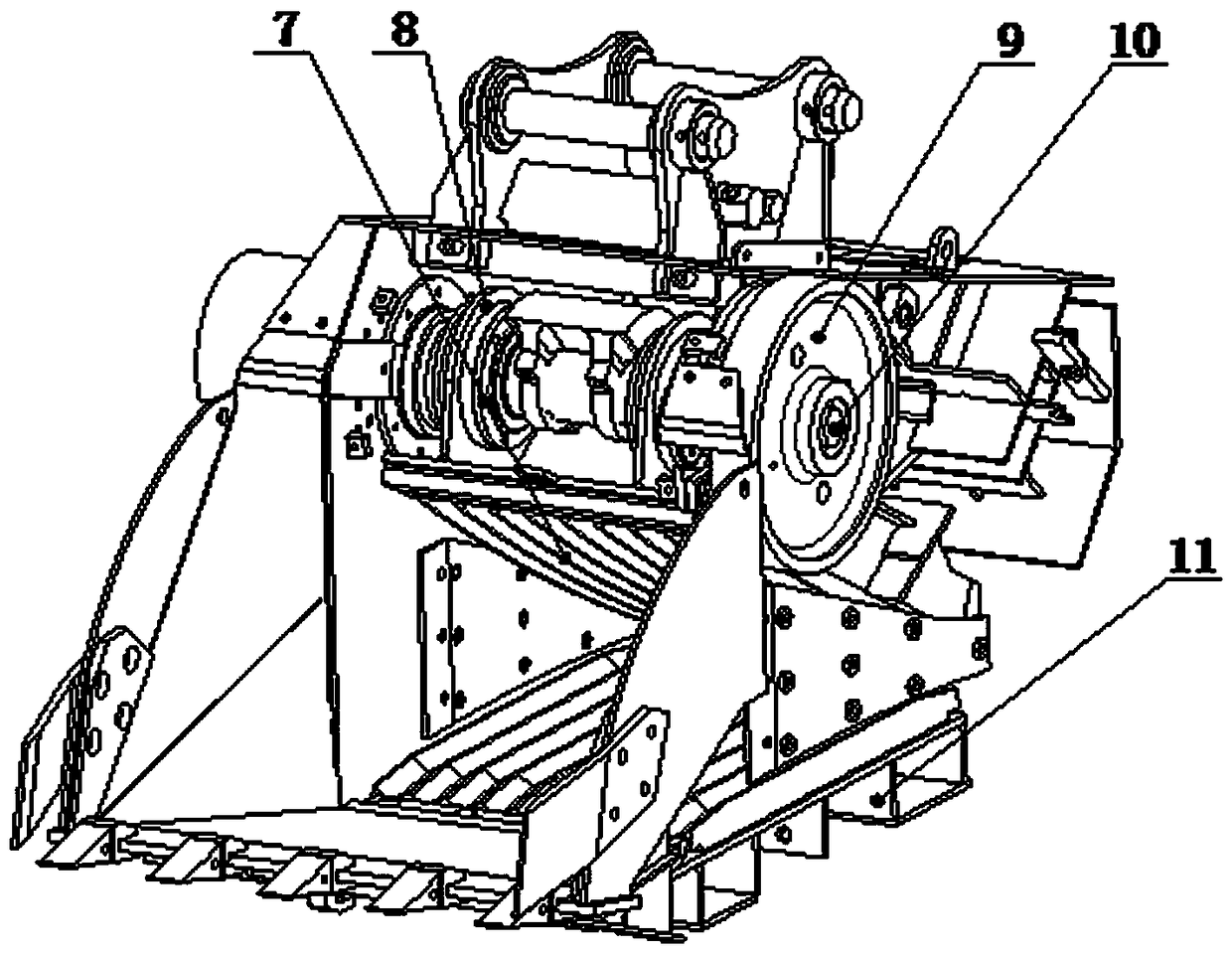

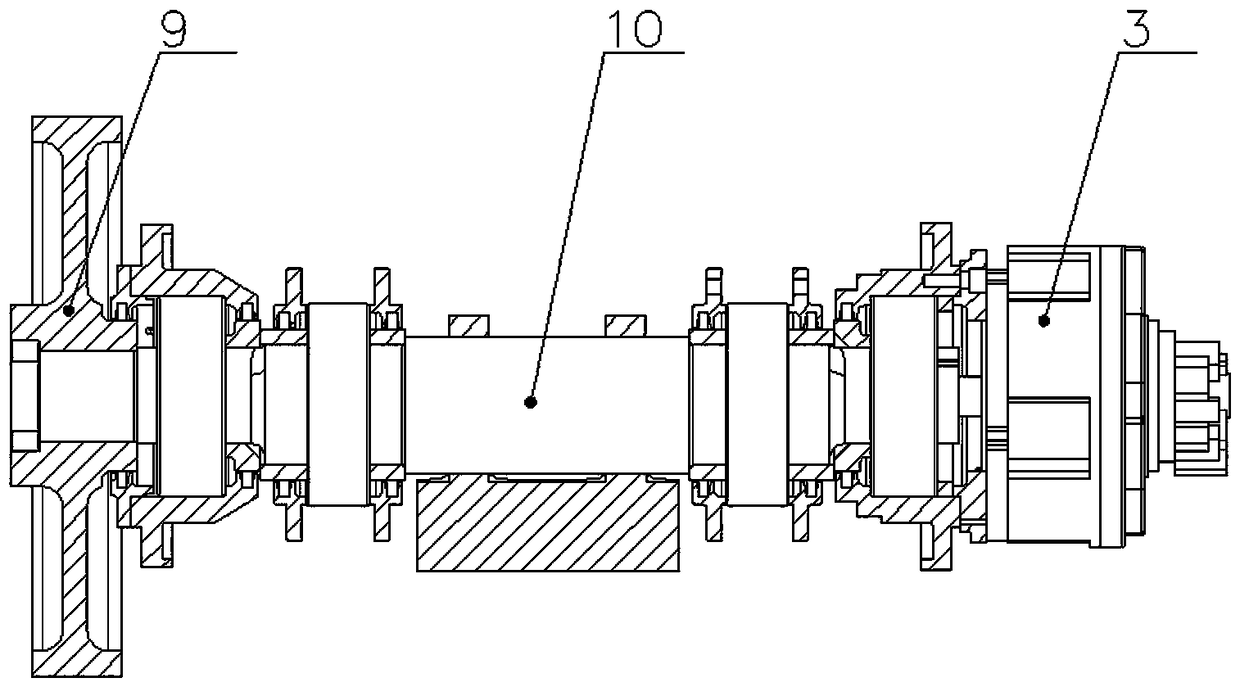

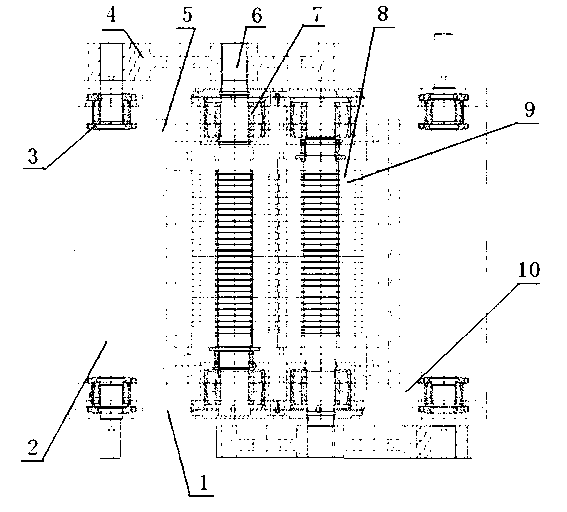

Hydraulic crushing bucket

PendingCN108411971ASimple structureImprove crushing effectSoil-shifting machines/dredgersHydraulic motorReciprocating motion

The invention discloses a hydraulic crushing bucket. The hydraulic crushing bucket comprises a main body. A joint is welded on the main body. The main body can be reliably installed on a loader or anexcavator through the joint. The main body comprises a crushing mechanism and a transmission mechanism. The crushing mechanism comprises a fixed jaw plate and a movable jaw plate. The fixed jaw plateis fixedly connected to the inner side of a main body bottom frame. The movable jaw plate is arranged on the other opposite side of the fixed jaw plate, and the movable jaw plate and the fixed jaw plate form a big-end-up crushing space. The transmission mechanism comprises a hydraulic motor, an inertia wheel, an eccentric shaft and an installation fixing piece. The hydraulic motor rotates to drivethe rotation of the eccentric shaft so as to drive the reciprocating motion of the movable jaw plate. By the adoption of the scheme, the crushing bucket can be reliably installed on an excavator or aloader for use, can carry out crushing work in any occasion and is small in size, light in weight, convenient to move, large in crushing force, easy to operate and low in cost.

Owner:南阳红阳远大重工有限公司

Choked flow cover for food processing machine

InactiveCN101433436AIncrease speedIncrease the relative speed differenceBeverage vesselsFood preparationChoked flowEngineering

Owner:田莉

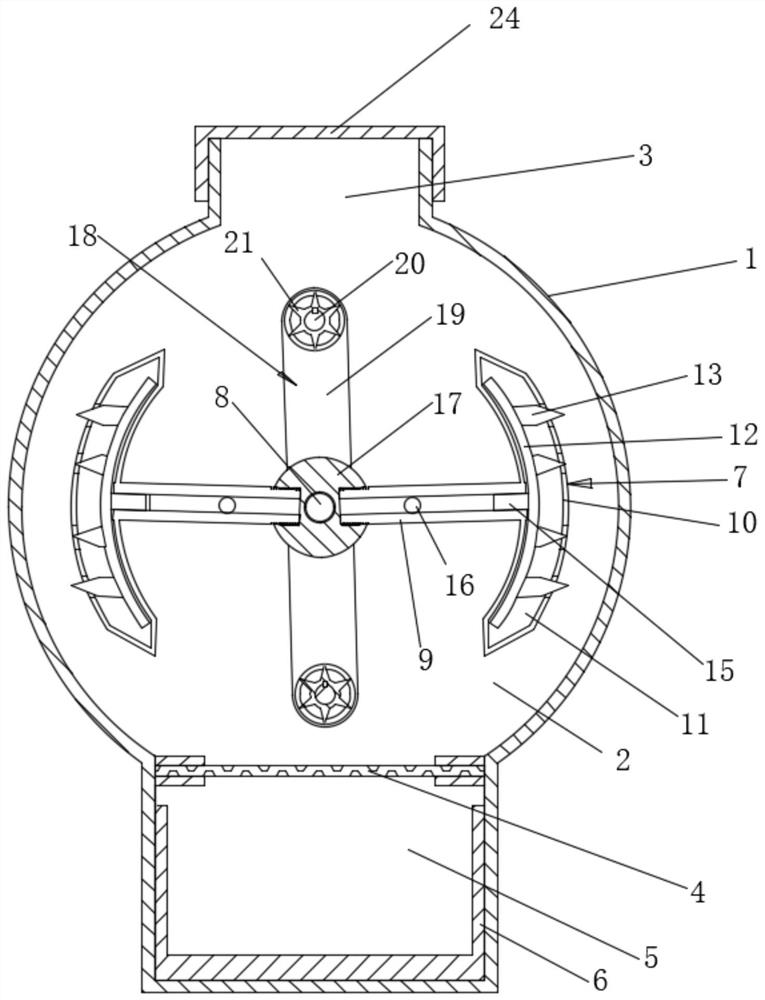

Material-fluid separation pulping equipment using airflow eddy kinetic energy

The invention discloses material-fluid separation pulping equipment using airflow eddy kinetic energy. The material-fluid separation pulping equipment mainly comprises an airflow eddy crushing device and a pulp generation device. The material-fluid separation pulping equipment is characterized in that the material-liquid separation includes that using airflow eddy kinetic energy to crush the material and mixing with liquid water to generate size. The material-fluid separation pulping equipment realizes the minimum energy-loss gas circulation through a gas inlet pipeline tangential to the edge of the outer side of the upper end of a conical material cylinder, realizes acceleration rotational flow and increases the airflow eddy crushing force through the conical material cylinder, realizes the crushed material sieving through a crushed material filtering device and realizes to quickly mix and stir to generate uniform pulp through a main crushed material conveying pipe, a branch crushed material conveying pipe and a liquid barrel.

Owner:UNIV OF JINAN

Eddy kinetic energy gas flow material smashing and material-liquid separation pulping device

InactiveCN104818635AGuaranteed stabilityEliminate shakingPaper recyclingRaw material divisionLiquid stateLiquid water

The invention provides an eddy kinetic energy gas flow material smashing and material-liquid separation pulping device. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device mainly comprises an eddy material smashing device and a liquid pulp generation device. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device is characterized by achieving material-liquid separation, using eddy kinetic energy gas flow to smash materials firstly, and then mixing the smashed materials with liquid water so as to generate pulp liquid. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device achieves tangential entering of gas and generates loop currents through a gas inlet pipeline tangent to the outer side edge of the bottom of an outer cylinder, achieves the purposes of increasing eddy kinetic energy in an eddy material smashing area and improving gas flow agitation efficiency in a liquid and material mixing area through an inner cylinder, achieves smashed material screening and blocking prevention through an inner cone hole, and achieves material and liquid mixing and stirring through a smashed material conveying pipe.

Owner:UNIV OF JINAN

Crushing machine

PendingCN107051630ASmall sizeExtended service lifeOpen-pit miningGrain treatmentsMoving jawReciprocating motion

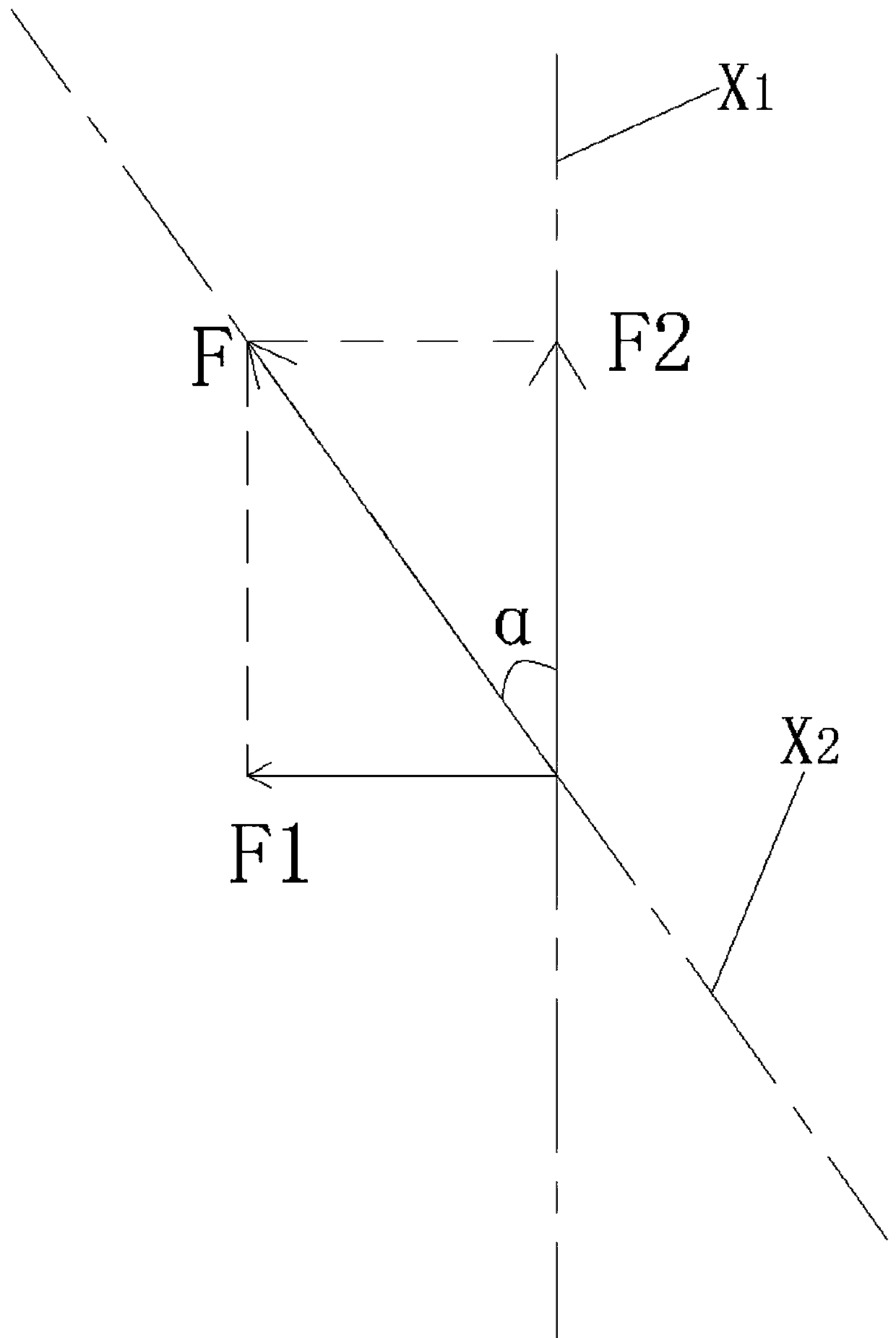

The invention provides a crushing machine. The crushing machine comprises static jaws and moving jaws, wherein the static jaws are oppositely fixed and arranged in a downwards inclined manner from an inlet to the back, the moving jaws are installed above the static jaws through eccentric shafts which are fixed relative to the static jaws, and the moving jaws are opposite to the static jaws and are arranged in a basically horizontal manner; and more than two eccentric shafts are arranged, all the eccentric shafts are arranged at intervals in the horizontal swing direction of the moving jaws, and all the eccentric shafts have the same eccentric direction and eccentric distance. The crushing machine further comprises a driving device used for driving all the eccentric shafts to synchronously rotate, and the moving jaws are driven by the eccentric shafts to move in a reciprocating manner. Due to the fact that more than two eccentric shafts are utilized for driving the moving jaws, acting force on the moving jaws is dispersed to the eccentric shafts, and then acting force borne by each eccentric shaft is greatly reduced; and therefore, the diameter of the eccentric shafts can be decreased, and the size of the crushing machine can be decreased. Due to the fact that the acting force borne by the eccentric shafts can be reduced, the eccentric shafts are not prone to be damaged, and the service life of the crushing machine is prolonged.

Owner:NENGCHENG GRP

Double-roll crusher

The invention discloses a double-roller crusher, which belongs to the field of mining machinery. The roller crusher includes a body, a motor, a transmission, a roller shaft and rollers, and the body is provided with a roller shaft and rollers; The shaft device is connected with the transmission, and the transmission is connected with the roller shaft; the roller shaft and the roller are connected by splines; the roller shaft includes the driving roller shaft, the driven roller shaft 1 and the driven roller shaft 2, and the corresponding roller shaft is provided with a driving roller 1. Passive roller 1 and passive roller 2; the body is provided with a feeding port, and a screen is provided in the feeding port. Through the above structural design, the uniformity of the particle size of the material crushed by the crusher and the crushing efficiency of the crusher are effectively improved.

Owner:张荣斌

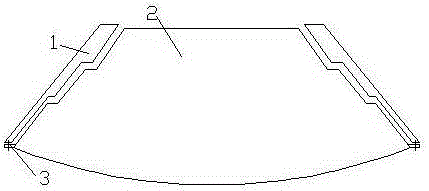

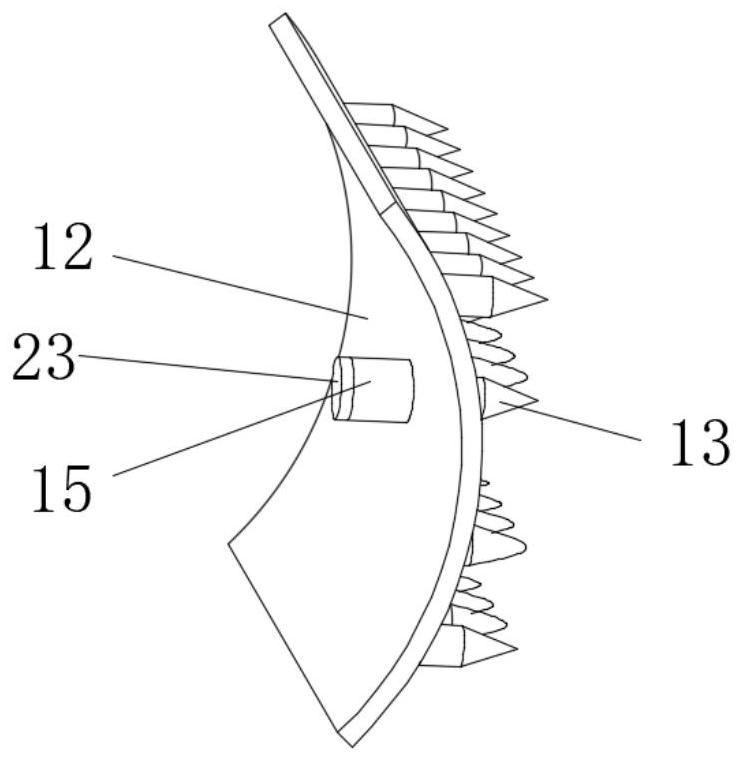

Movable cone of inertial cone crusher

The invention discloses a movable cone of an inertial cone crusher. The movable cone comprises a cone cover and a cone body, wherein the cone cover is a cone of which the inside is vacuumed; reversed steps are arranged on the inner conical wall surface of the cone cover; the step surfaces of the reversed steps are horizontal; obverse steps are arranged on the outer conical wall surface of the cone body; the obverse steps on the outer conical wall surface are matched with the reversed steps on the inner conical wall surface of the cone cover; and the diameter of an inner conical wall surface circle of the cone cover is larger than the diameter of an outer conical wall surface circle of the cone body at the same horizontal position. The technical aim of the invention is to provide the movable cone of the inertial cone crusher which is characterized in that the cone cover of the movable cone can be changed; by adopting the movable cone of the inertial cone crusher, production cost can be reduced; and crushing force of the crusher cannot be lowered.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Atomization preparation device for TiAl powder

The invention discloses an atomization preparation device for TiAl powder. The atomization preparation device comprises a furnace body, a smelting chamber, an atomization chamber and a collection chamber. The bottom of a smelting chamber crucible is connected to a liquid storage bag through a flow guide pipe. The bottom of the liquid storage bag is connected with a centrifugal nozzle through a flow guide pipe. The centrifugal nozzle is in a disc shape and is 10 cm in diameter. Four liquid discharge outlets are formed in the outer side of the centrifugal nozzle symmetrically and are 3 cm in diameter. The open direction of the liquid discharge outlets is the normal direction of the disc. A pulse-pressuring gas pipe is arranged above the centrifugal nozzle and is connected with a gas source. A control system controls the gas source to conduct pulse type pressuring on melt in the centrifugal nozzle. Four inert gas nozzles are arranged around the centrifugal nozzle correspondingly. The direction of the inert gas nozzles directly faces the throwing-out direction of melt at the liquid discharge outlets during rotation of the centrifugal nozzle. The collection chamber is arranged below the atomization chamber and is internally provided with a cyclone separator and an ultrasonic vibrating screen. Through the atomization preparation device, the crushing effect is improved, and the uniformity of powder is improved.

Owner:泸溪县安泰新材料科技有限责任公司

Atomizing preparation method of TiAl powder

The invention discloses an atomizing preparation method of TiAl powder. The method comprises the steps that vacuumizing and heating melting are conducted, and then a melt is introduced into a centrifugal nozzle; the centrifugal nozzle starts to centrifugally rotate, and argon is ejected through an inert gas nozzle simultaneously; meanwhile, a control system controls a solenoid valve at a liquid drainage port in the centrifugal nozzle to be switched on and switched off in a pulse manner, so that the melt is thrown away in a pulse manner, and a liquid flow ejected each time is rightly opposite to the ejection direction of atomized gas; frontal impact of the melt and the atomized gas is achieved, the melt is crushed into minute droplets under the action of airflow, and the minute droplets are cooled and solidified into fine powder; and the fine powder enters a collecting chamber, and then the fine powder is collected after being separated through a cyclone separator and sieved through a vibrating screen.

Owner:YANGZHOU FEILING ALLOY TECH CO LTD

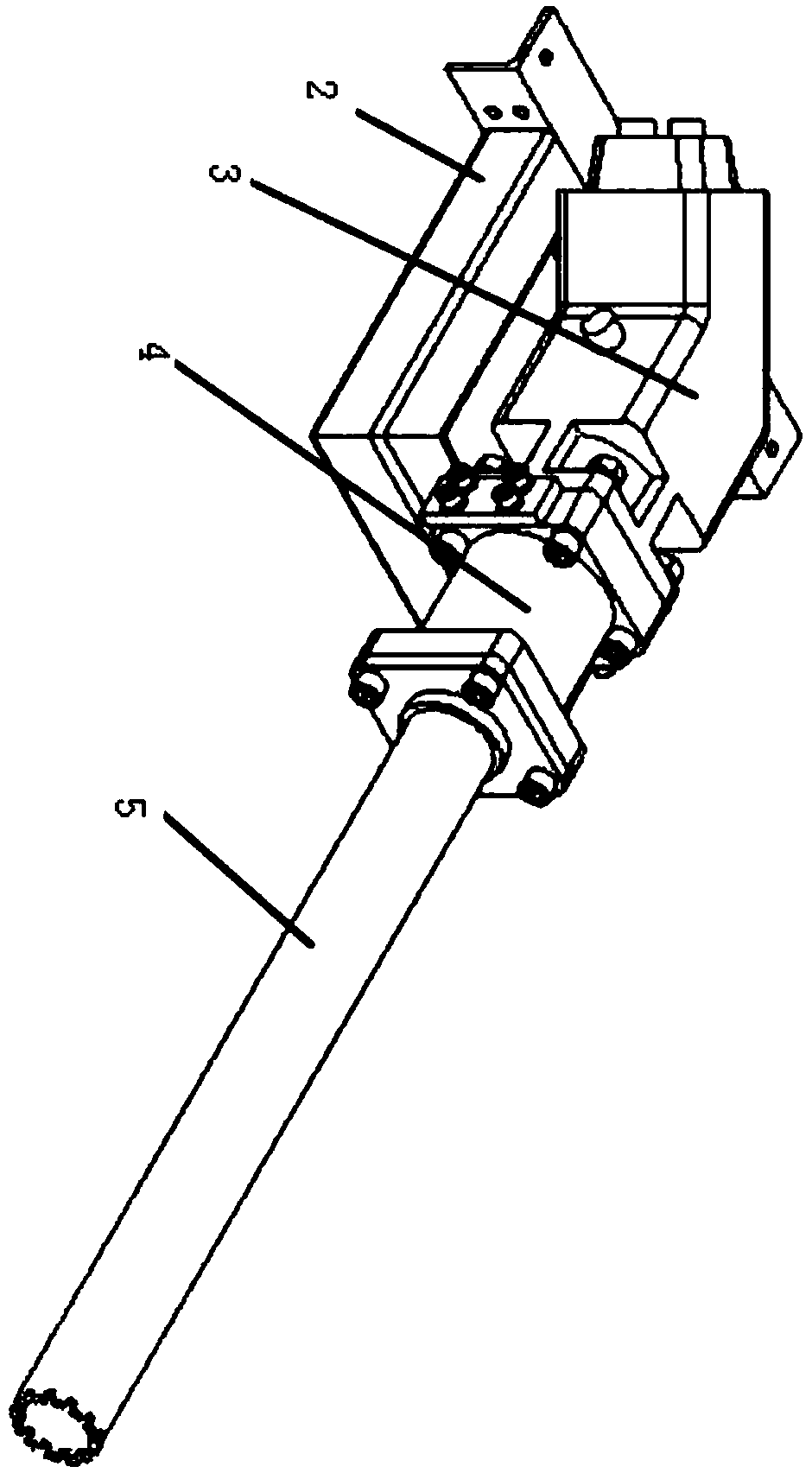

Underwater robot portable horizontal-direction geological sampling drilling tool

PendingCN108386188AImplement sampling workStrong crushing forceDirectional drillingBorehole/well accessoriesOcean bottomHydraulic motor

The invention discloses an underwater robot portable horizontal-direction geological sampling drilling tool. The underwater robot portable horizontal-direction geological sampling drilling tool comprises a connecting base, a hydraulic motor, a transmission unit and a drilling and sampling unit; and the connecting base is provided with the hydraulic motor and the transmission unit, and the hydraulic motor is connected with the drilling and sampling unit through the transmission unit. The underwater robot portable horizontal-direction geological sampling drilling tool has the beneficial effectsthat seabed special landscape body geological sample taking operation is implemented, and the drilling tool has been applied to capturing in-situ samples of cavity walls of a certain sea area.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Special-shaped ore grinding medium

InactiveCN105327749AGood turning effectReduce overgrindingGrain treatmentsStress concentrationPoint contact

The invention relates to a novel ore grinding medium. A special-shaped ore grinding medium uses a spherical ore grinding medium as foundation; three spherical gaps with the same section circles are cut in the surface of the special-shaped ore grinding medium at intervals; values of diameters D of the section circles are between zero and a sphere radius R, that is, D is bigger than 0 and not bigger than R; and values of distances L from the circle centers of the section circles to the sphere center are FORMULA. The ore grinding medium is combined with advantages of the spherical medium, embodies better rotating performance of the spherical medium in the ore grinding process, adopts the point contact crushing, and is strong in crushing force; planes formed by cutting the surface of the medium are in surface contact with ores in the ore grinding process, so that excessive crushing can be relieved; and the ore grinding medium surface has the point contact crushing and the surface contact crushing. As the spherical surface of the surface of the medium has the stress concentration, the ore grinding medium is obvious in coarse ore crushing effect in the ore grinding process; and the plane of the medium surface can selectively grind coarse ores to protect fine ores so as to achieve the purposes of relieving excessive ore grinding and improving the ore grinding product quality.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Scale removal spray liquid on surface of steel tube

InactiveCN101974309AStrong crushing forceReduce pollutionOther chemical processesAcid washingHigh pressure

The invention discloses scale removal spray liquid on the surface of a steel tube, and relates to the technical field of production of the seamless steel tube, in particular to spray liquid for removing scales on the inner surface and the outer surface of the seamless steel tube. The spray liquid consists of water and garnet abrasive, wherein the particle diameter of the garnet abrasive can be 50 to 100 meshes. Because the garnet has a sharp angular appearance and can still keep the sharp angular appearance after being crushed, the garnet has extremely strong crushing force to the scale. The spray liquid is jetted to the surface of the steel tube by high pressure to remove the scales on the inner surface and the outer surface of the steel tube through high-pressure washing, so that the steel tube from which the scale is removed can be directly delivered to a user for use. The spray liquid completely substitutes the conventional acid washing process in the production of the cold-drawn seamless steel tube, so that the pollution is reduced and the cost is lowered.

Owner:江苏诚德钢管股份有限公司

Efficient well hole trimming tool

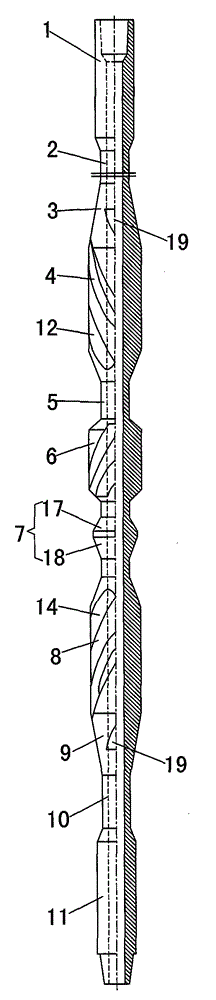

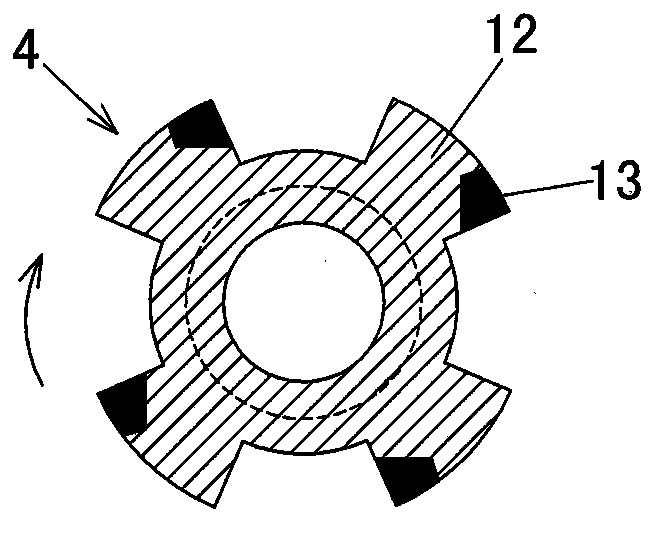

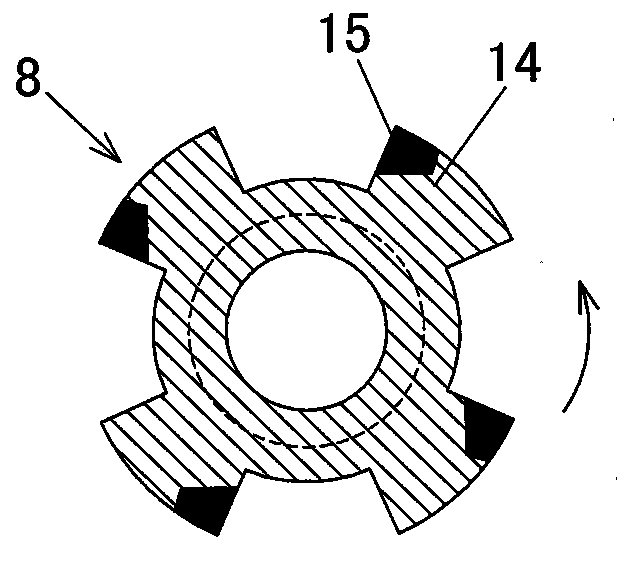

ActiveCN105888592AHigh efficiency in repairing the well wallEasy to carryBorehole/well accessoriesWell cementingEngineering

The invention discloses an efficient well hole trimming tool which comprises an upper cutting section. The lower end of the upper cutting section is connected with a lower cutting section through a first connecting section in the axial direction, the upper end of the upper cutting section is connected with a first connector for being connected with a well pipe string, the lower end of the lower cutting section is connected with a second connector for being connected with the well pipe string, and the cross section diameter of the first connecting section is smaller than that of the upper cutting section and that of the lower cutting section. The efficient well hole trimming tool is beneficial to well hole quality, ensures casting running and well cementing operation and is also beneficial to efficiency improvement and shortening of a drilling period.

Owner:XINJIANG GRAND OILFIELD TECH

A kind of atomization preparation device of nickel aluminum powder

The invention discloses an atomizing preparation device of nickel aluminum powder. The atomizing preparation device comprises a furnace body, a smelting chamber, an atomizing chamber and a collection chamber. The bottom of a smelting chamber crucible is connected to a liquid storage bag through a flow guiding pipe, the bottom of the liquid storage bag is connected with a centrifugal spray nozzle through a flow guiding pipe, the centrifugal spray nozzle is of a circular arc shape, and the diameter is 20 cm; the outer side of the centrifugal spray nozzle is symmetrically provided with two liquid discharging openings, the diameter of the liquid discharging openings is 2 cm, and the open direction of the liquid discharging openings is the tangent line direction of the circular arc; a pulse pressurizing air pipe is arranged above the centrifugal spray nozzle, the pulse pressurizing air pipe is connected with an air source, and a control system controls the air source to perform pulse type pressurization on melt in the centrifugal spray nozzle; the periphery of the centrifugal spray nozzle is correspondingly provided with two inert gas spray nozzles, and the direction of the inert gas spray nozzles is opposite to the tossing-out direction of the liquid discharging opening melt generated when the centrifugal spray nozzle is rotated; the collection chamber is arranged below the atomizing chamber, and the collection chamber is internally provided with a cyclone separator and an ultrasonic vibrating screen. By means of the atomizing preparation device, the crushing effect is improved, and the uniform degree of the powder material is improved.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV +1

Stirring sand sucking pump

InactiveCN107461360AExtended service lifeImprove adsorption capacityPump componentsPump installationsSpiral bladePulp and paper industry

The invention discloses a stirring sand sucking pump. The stirring sand sucking pump comprises a sand sucking pump shell part and a stirrer, wherein the sand sucking pump shell part comprises a motor, a motor rotor shaft and a sand sucking pump shell; the motor is positioned in the sand sucking pump shell; in a sand sucking port at the lower end of the sand sucking pump shell, the motor rotor shaft is connected with the stirrer; the stirrer comprises a connecting shaft fixedly connected with the motor rotor shaft; the connecting shaft is connected with spiral blades, and is also connected with three layers of stirring discs; and the radiuses of the upper and lower layers of stirring discs are both larger than the radius of the middle layer of stirring discs. The stirring sand sucking pump realizes looseness of gravels in water through the spiral blades, and realizes stirring of the gravels through the stirring discs so as to conveniently absorb the gravels. The spiral blades are higher in cutting force or crushing force, and are provided with wear resisting layers for improving the wear resistance; preferentially, the stirring discs are produced by ceramic materials to achieve wear resistance; and convex teeth can be replaced when being badly worn.

Owner:XUZHOU NORTHERN PUMP CO LTD

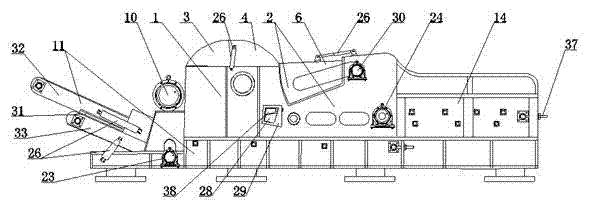

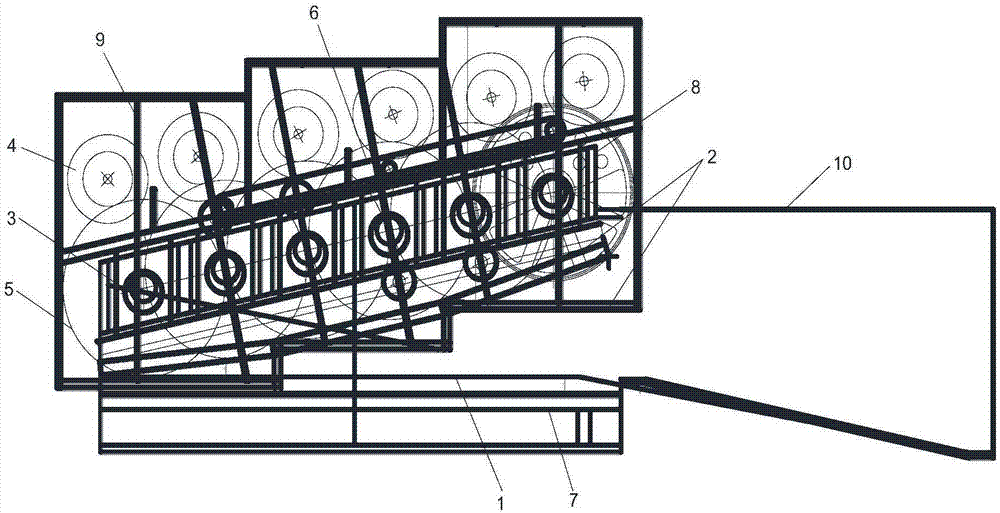

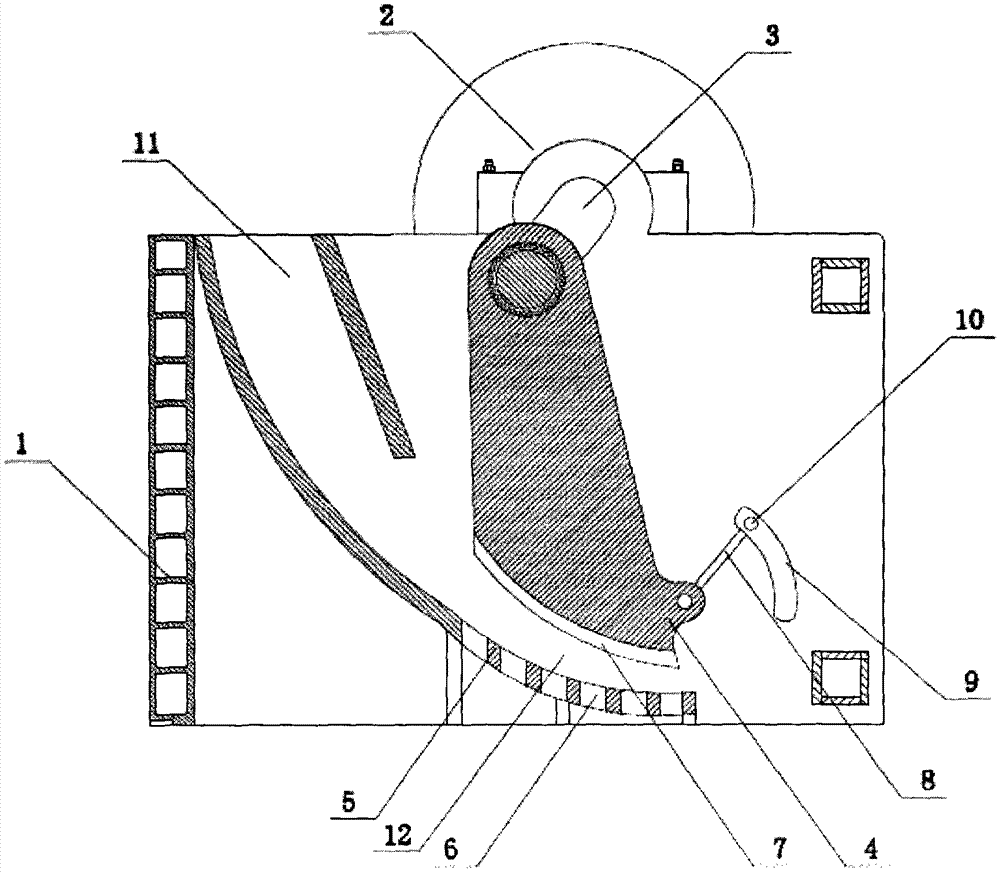

Multifunctional breaking machine

InactiveCN103721779AWith secondary crushing functionStrong crushing forceGrain treatmentsEngineeringCrusher

The invention discloses a multifunctional breaking machine which comprises a machine frame and a transmission device, wherein a front crank-rocker mechanism and a rear crank-rocker mechanism are arranged on the machine frame and connected with the transmission device; a side breaking pair forming a side breaking cavity is arranged on the side of the front crank-rocker mechanism; a bottom breaking pair forming a single bottom breaking cavity is arranged at the lower part of the rear crank-rocker mechanism, and the side breaking cavity is communicated with the single bottom breaking cavity; or two bottom breaking pairs forming two bottom breaking cavities connected in sequence are arranged at the lower parts of the front and rear crank-rocker mechanisms, and the side breaking cavity is communicated with the two bottom breaking cavities. The multifunctional breaking machine provided by the invention is small in occupied area, low in manufacturing cost, power-saving and convenient to manage and use.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

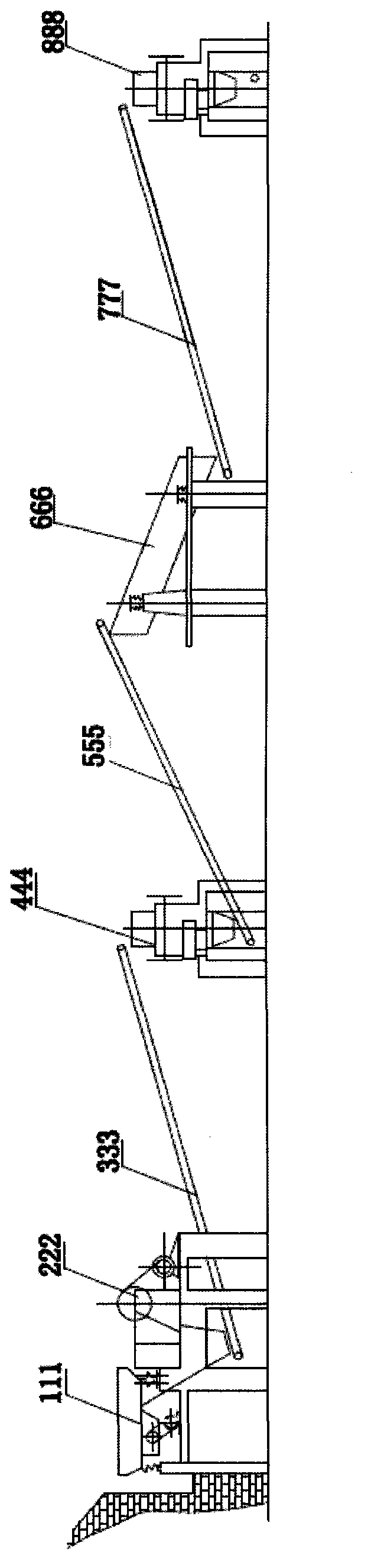

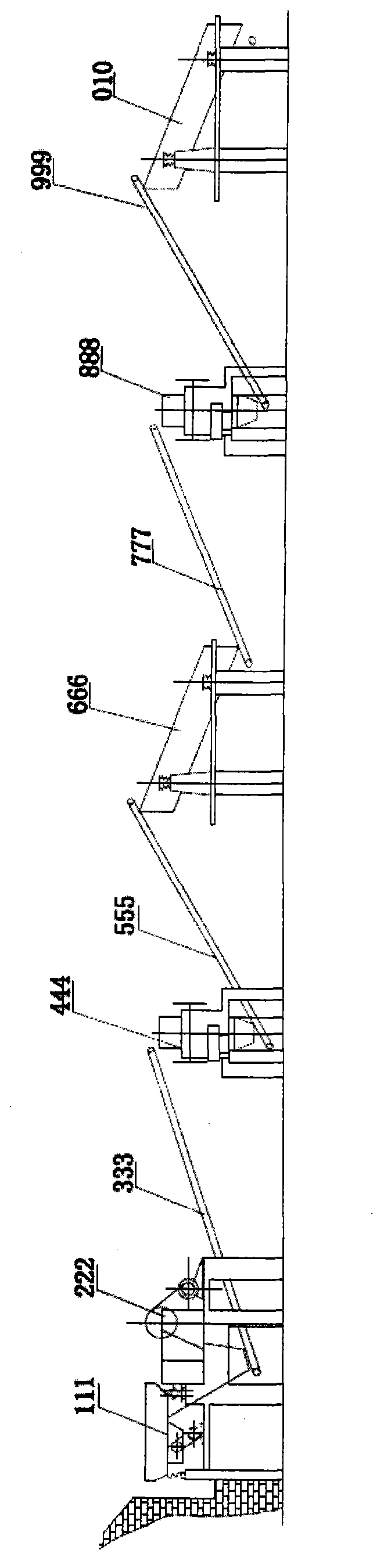

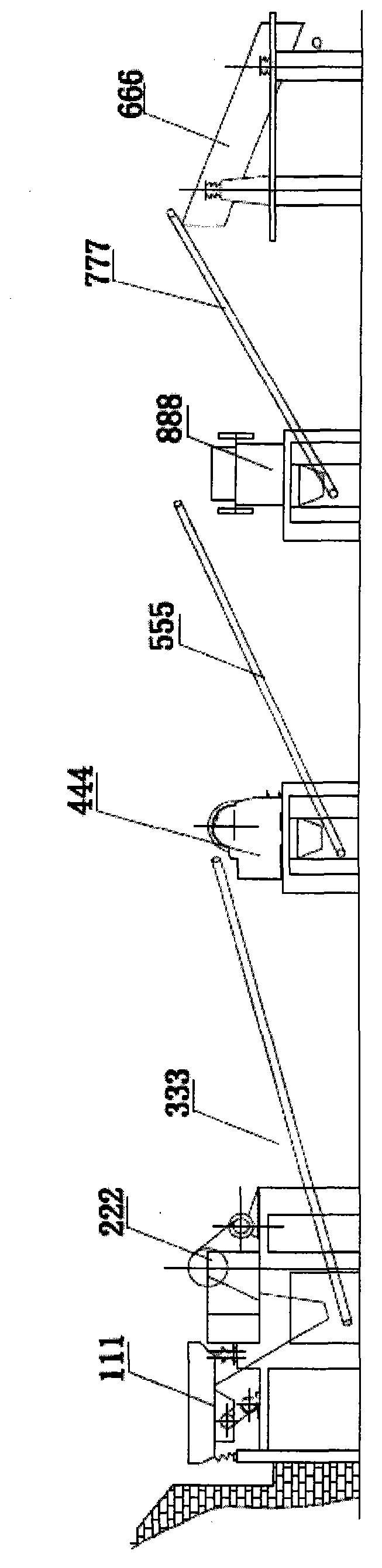

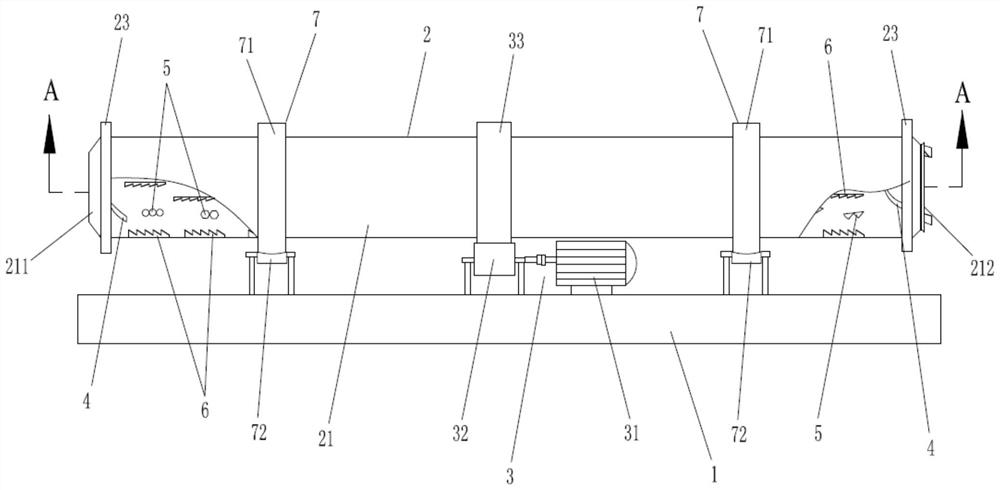

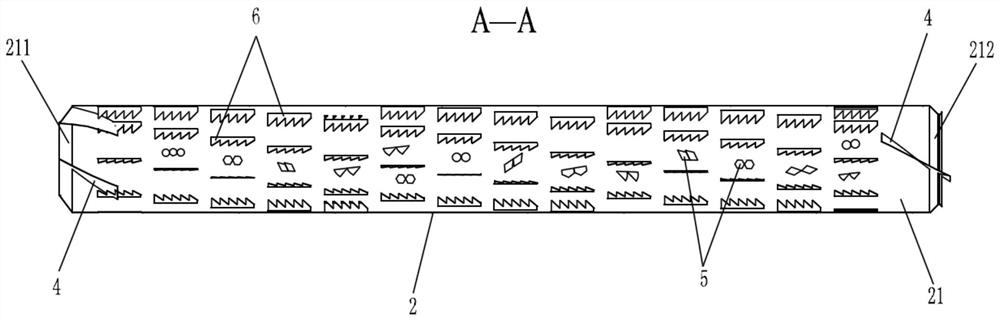

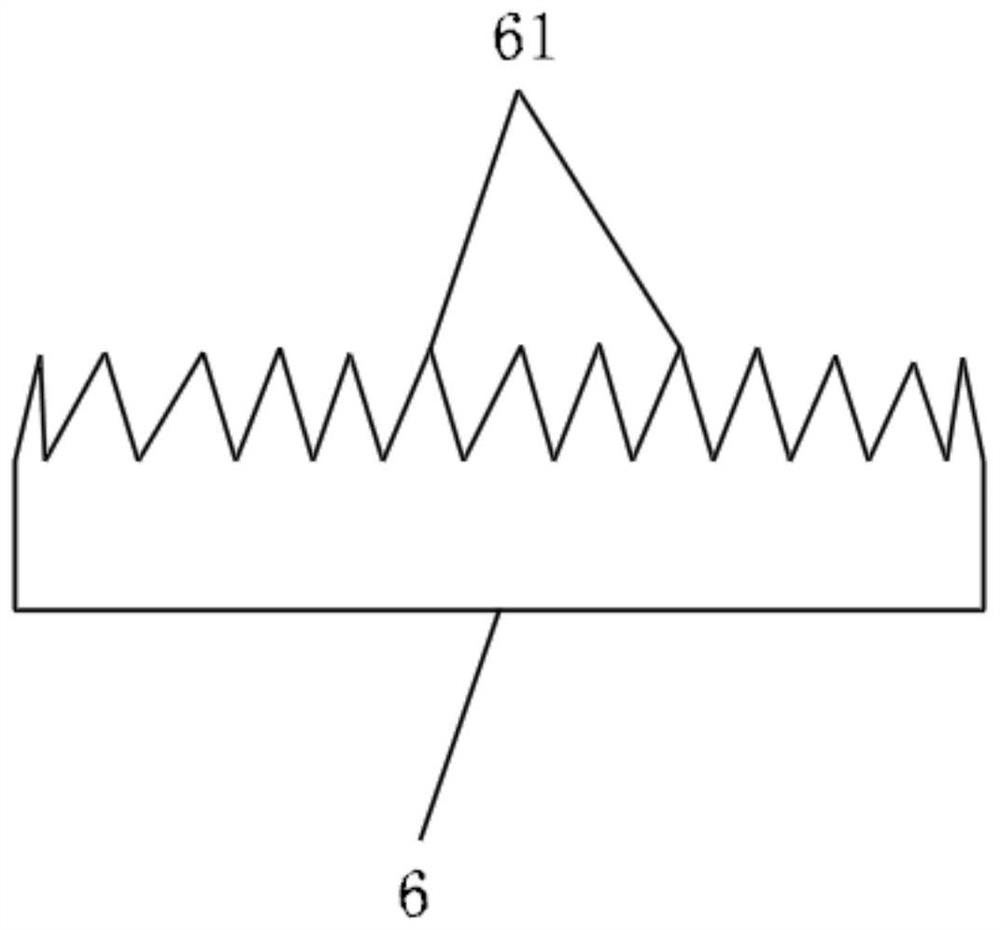

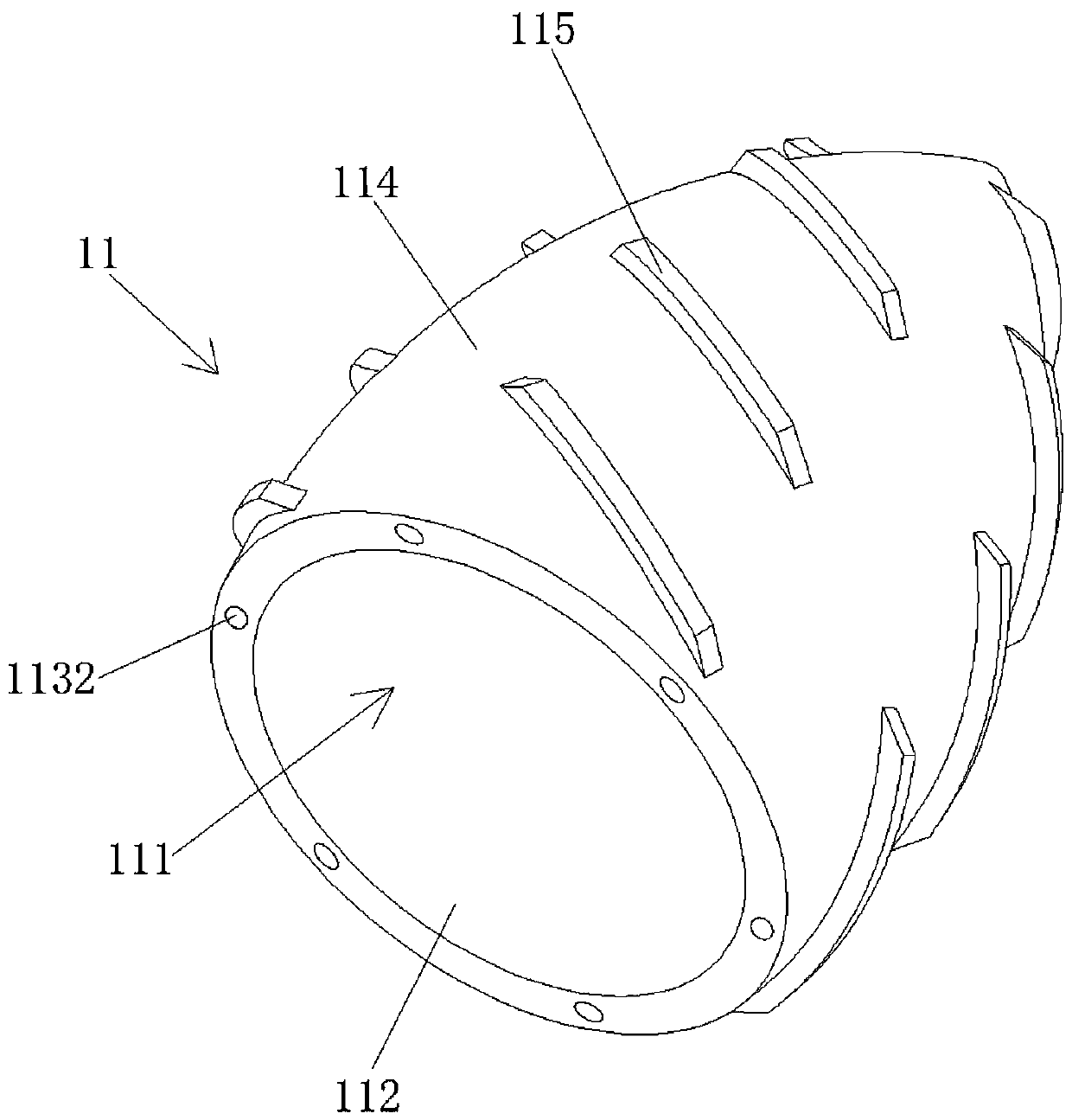

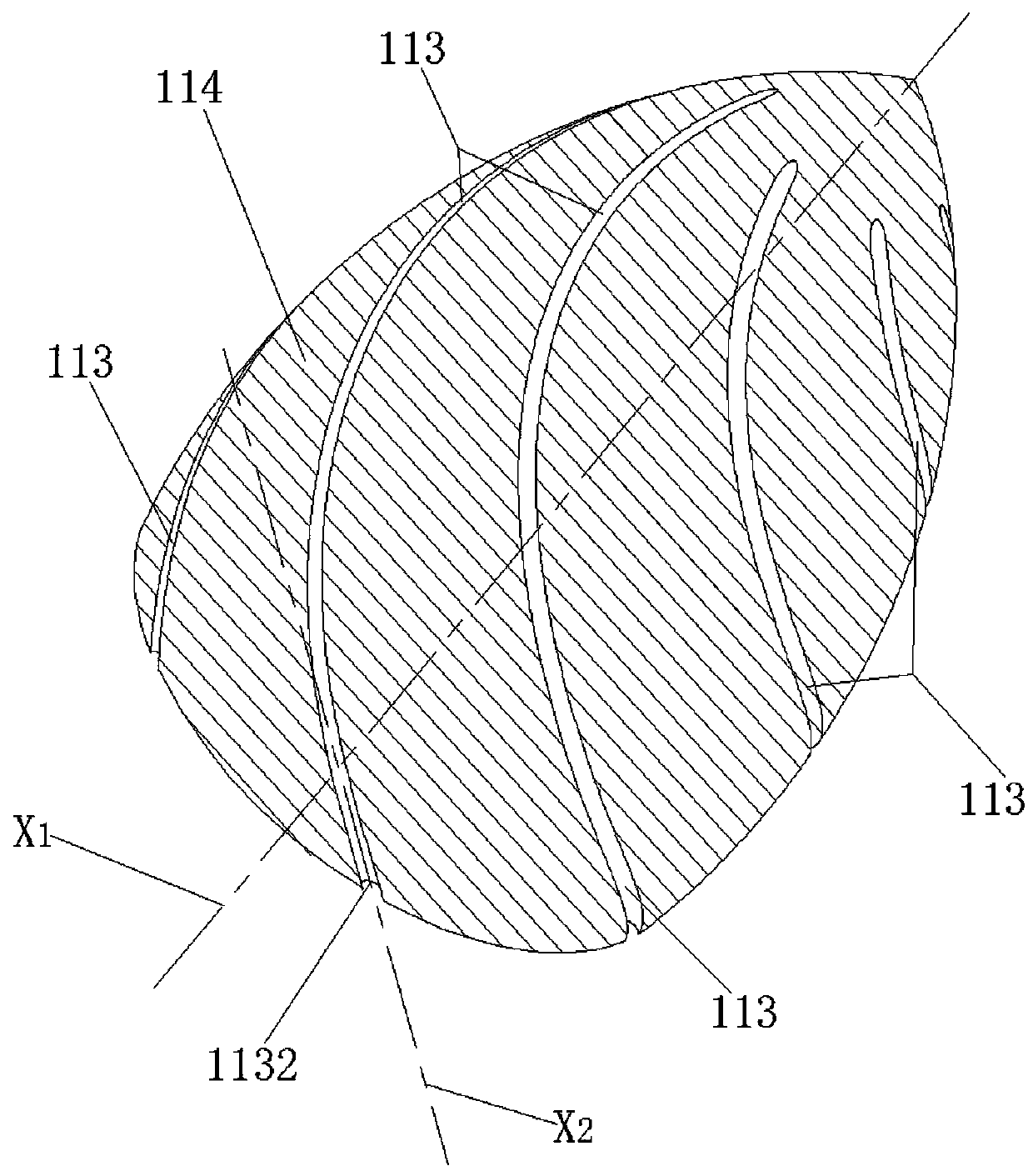

Household garbage selective crushing device

ActiveCN113926545AImprove classification efficiencyImprove processing efficiencySolid waste disposalGrain treatmentsStructural engineeringOrganic matter

The invention relates to the technical field of environmental protection equipment, in particular to a household garbage selective crushing device which comprises a base, a drum arranged on the base and a driving mechanism. The drum comprises a drum body and a spiral guide plate arranged on the inner wall of the drum body, a feeding port and a discharging port are formed in the two ends of the drum body, the feeding port and the discharging port are each provided with a guide plate, and the feeding port is further provided with a zymophyte liquid adding device; the device further comprises a crushing body combination used for crushing household garbage, the crushing body combination comprises a plurality of cutting bodies and a plurality of crushing bodies in different shapes, the cutting bodies and the crushing bodies are welded to the inner wall of the drum body and arranged at intervals, and each crushing body comprises a combination of at least two or more of a sphere, a conical body, a polyhedron and a special-shaped body; and a plurality of sawteeth are arranged on the surface of each cutting body. The device can selectively and quickly crush and pulpify kitchen garbage and paper garbage which are difficult to separate in mixed household garbage, and eliminate peculiar smell of organic matters such as the kitchen garbage, so that the treatment process is greatly simplified, and the cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Rotating obstacle clearing drill bit

The invention discloses a rotating obstacle clearing drill bit. The rotating obstacle clearing drill bit comprises a drill bit body, a high-pressure water containing cavity is formed in the drill bitbody, multiple spiral water channels which are communicated in a cut-through mode along the cavity wall from top to bottom are arranged in the cavity wall of the high-pressure water containing cavity,and each spiral water channel comprises a water inlet and a water outlet, so that high-pressure water in the high-pressure water containing cavity enters the corresponding spiral water channels through the water inlets and flows out of the water outlets to exert forward driving force and rotating turning force to the rotating obstacle clearing drill bit. By arranging the spiral water channels, the rotating obstacle clearing drill bit rotatably advances at a high speed in a water drainage pipeline, and then the water drainage pipeline blocked by waste blockages can be dredged; and by arrangingblades used for cutting and crushing the blockages in the water drainage pipeline on the outer surface of the drill bit body, the rotating obstacle clearing drill bit has the high crushing capabilityon large soft waste blockages and hard waste blockages in the water drainage pipeline and can smoothly dredge the water drainage pipeline for the water drainage pipeline difficult to dredge.

Owner:郑州中原科技工程研究院有限公司

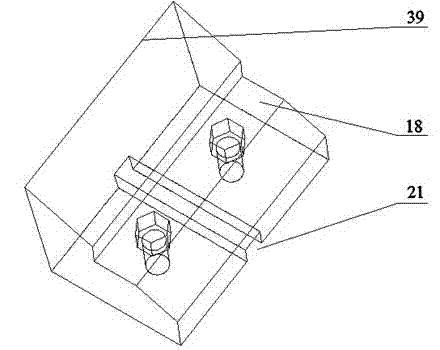

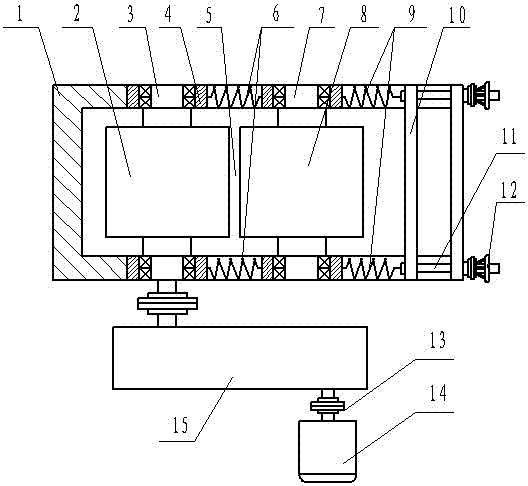

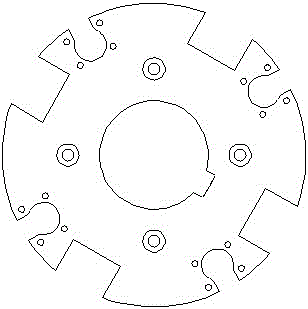

Crusher for titanium sponge

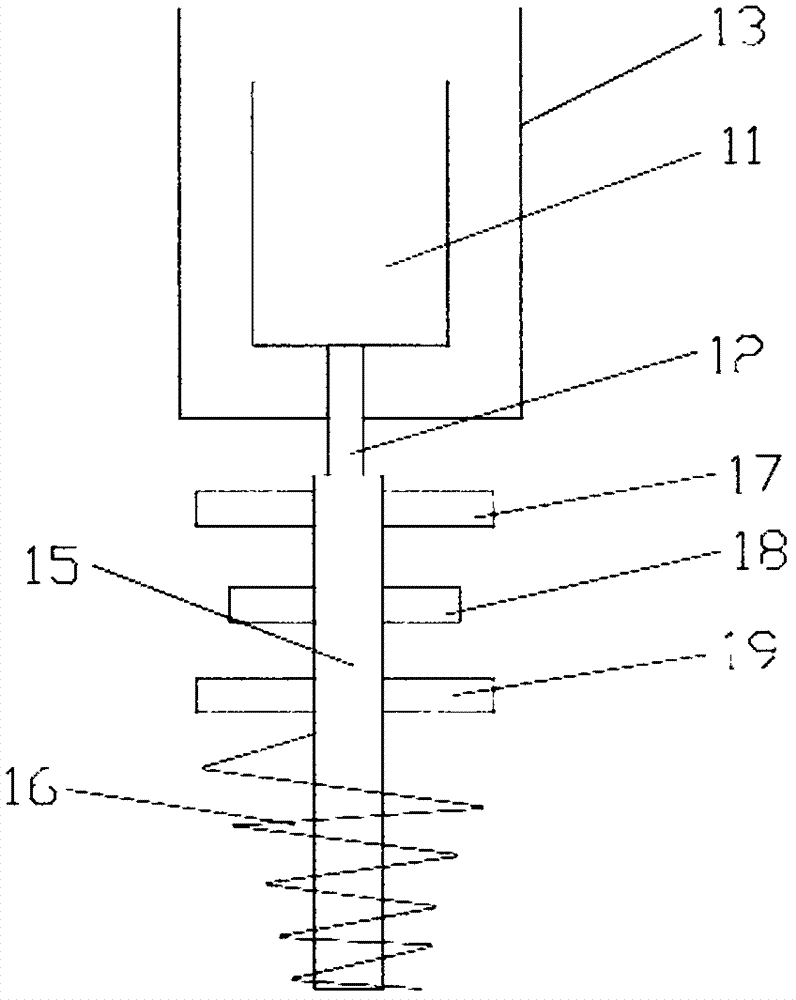

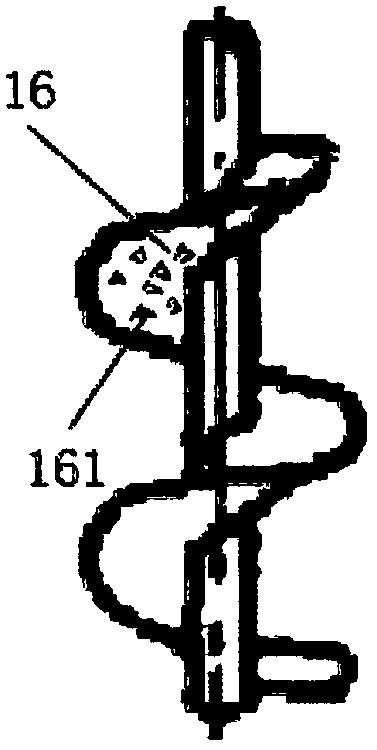

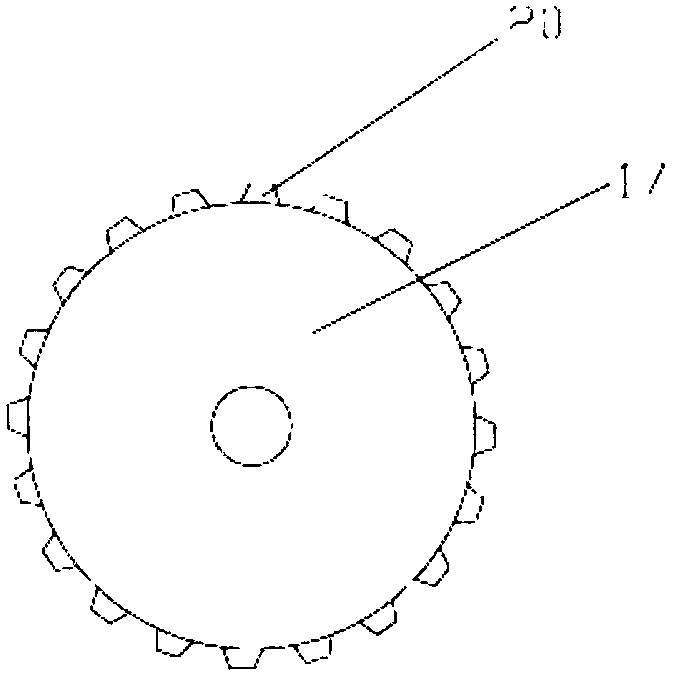

InactiveCN102989563AStrong crushing forceImprove efficiencyGrain treatmentsProduction lineDrive shaft

The invention discloses a crusher for a titanium sponge. The crusher is mainly composed of a base, a machine body, driving shafts and gears and the like, wherein rotating shafts are arranged in the machine body through a swivel bearing arranged on the supporting plate, the rotating shafts are connected with the driving shafts through the gears, and the driving shafts are arranged on the supporting plate through a driving bearing arranged on the supporting plate; and the other end of the driving shafts is connected with a motor, each rotating shaft is provided with a main blade and an auxiliary blade in an interval manner, cutter teeth on the periphery of the main blades and the auxiliary blades are distributed by an involute curve, the main blades and the auxiliary blades are arranged in an interval manner, the diameter of each auxiliary blade is less than that of each main blade, and each main blade of the rotating shaft is connected and corresponding to each auxiliary blade on the other rotating shaft. The crusher provided by the invention has the advantages that the crush capacity is large, the efficiency is high, the crush time is short, the labor intensity is low, a product is not easy to become yellow, the crush granularity is easy to control, and the crusher is particularly suitable for automatic crush serial production lines.

Owner:ZUNYI TITANIUM

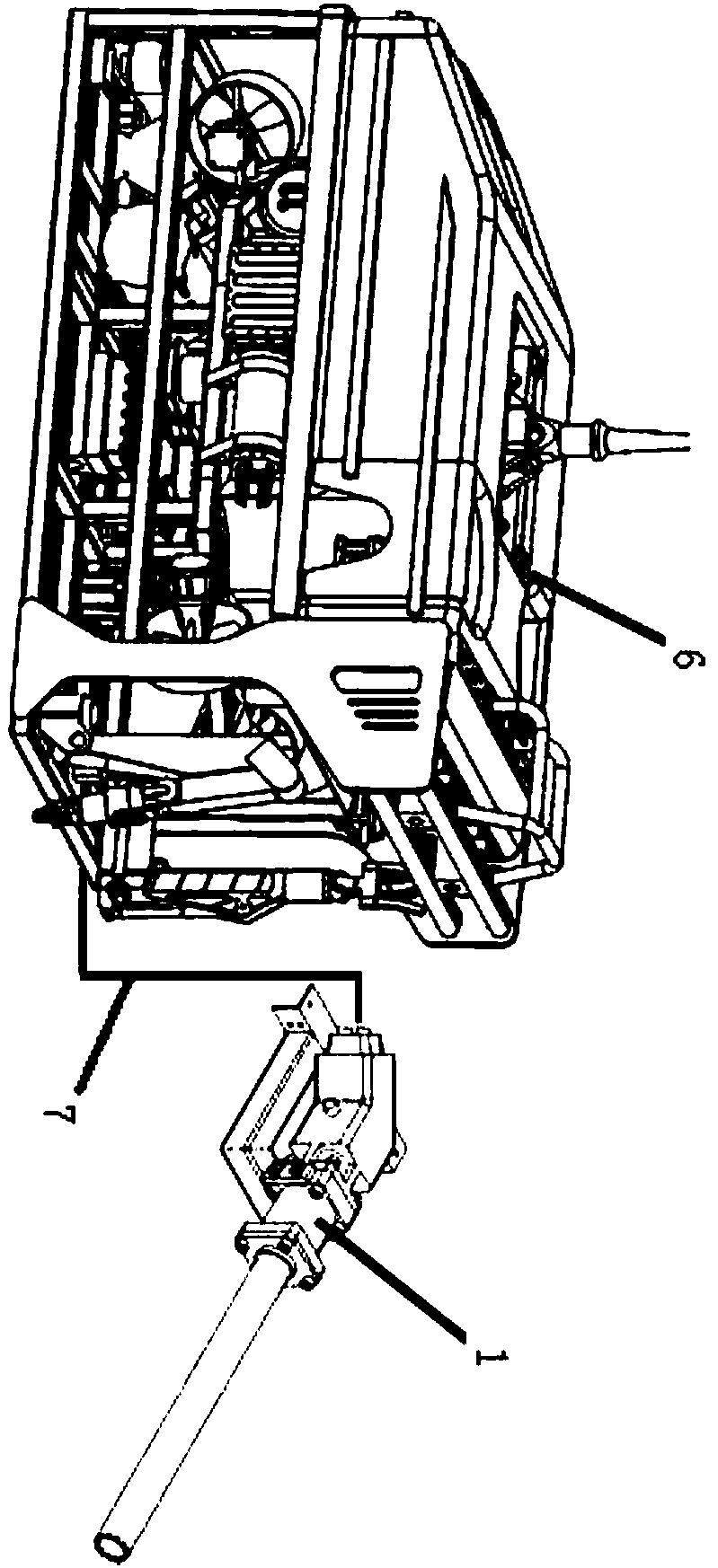

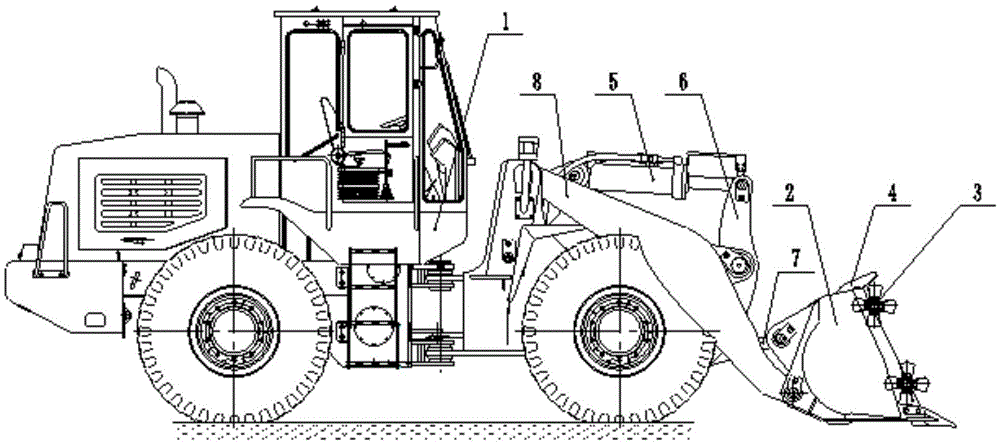

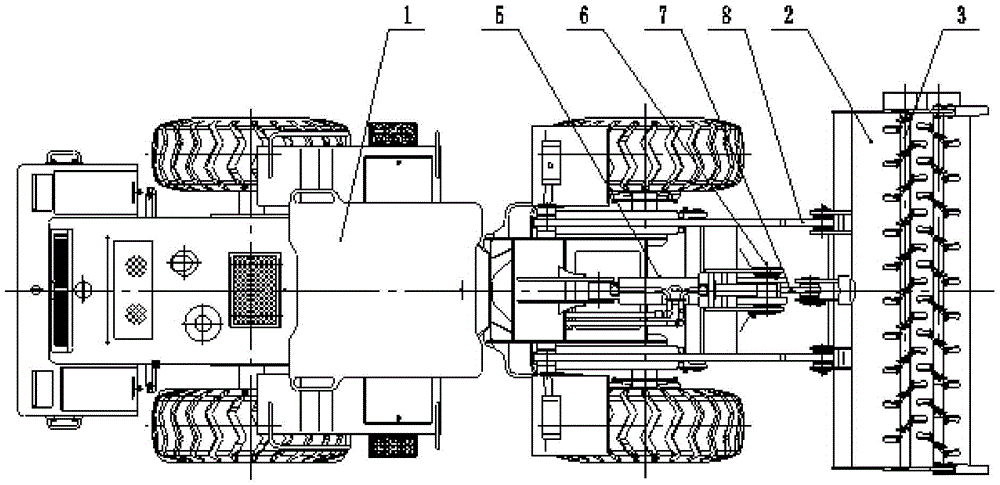

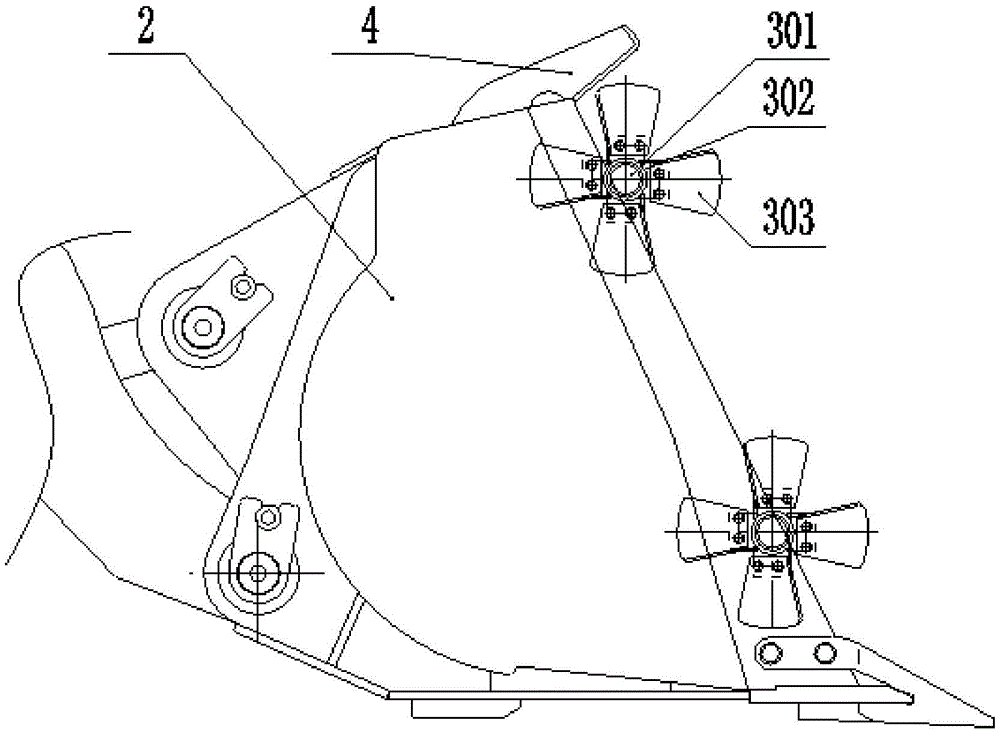

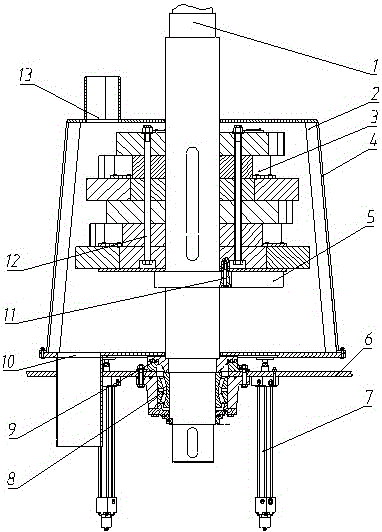

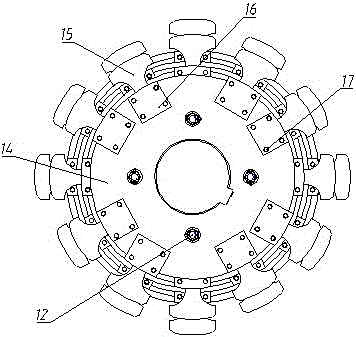

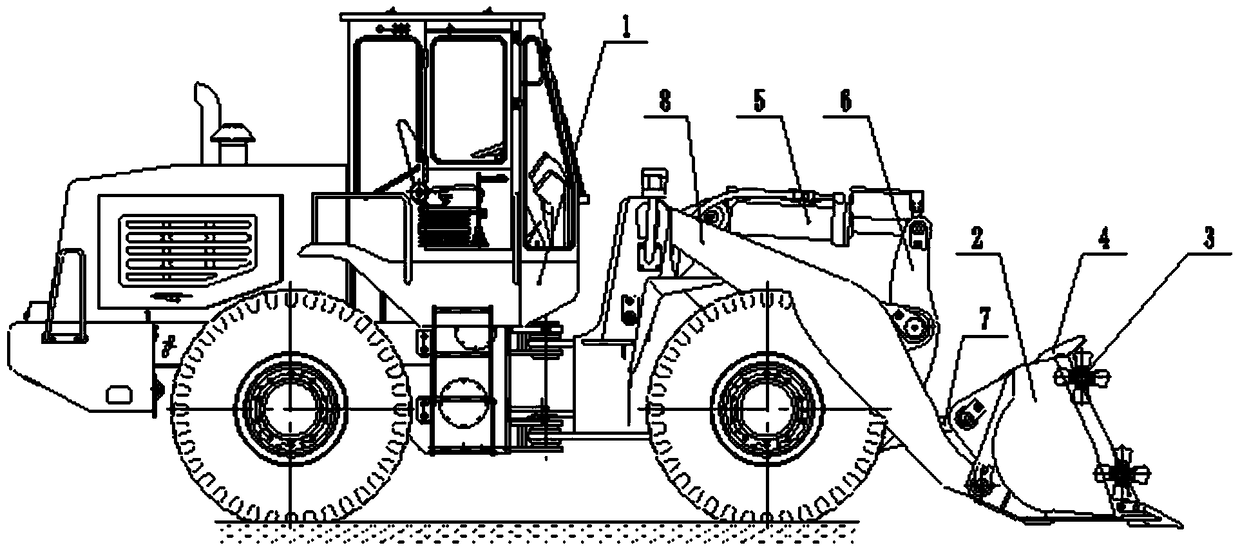

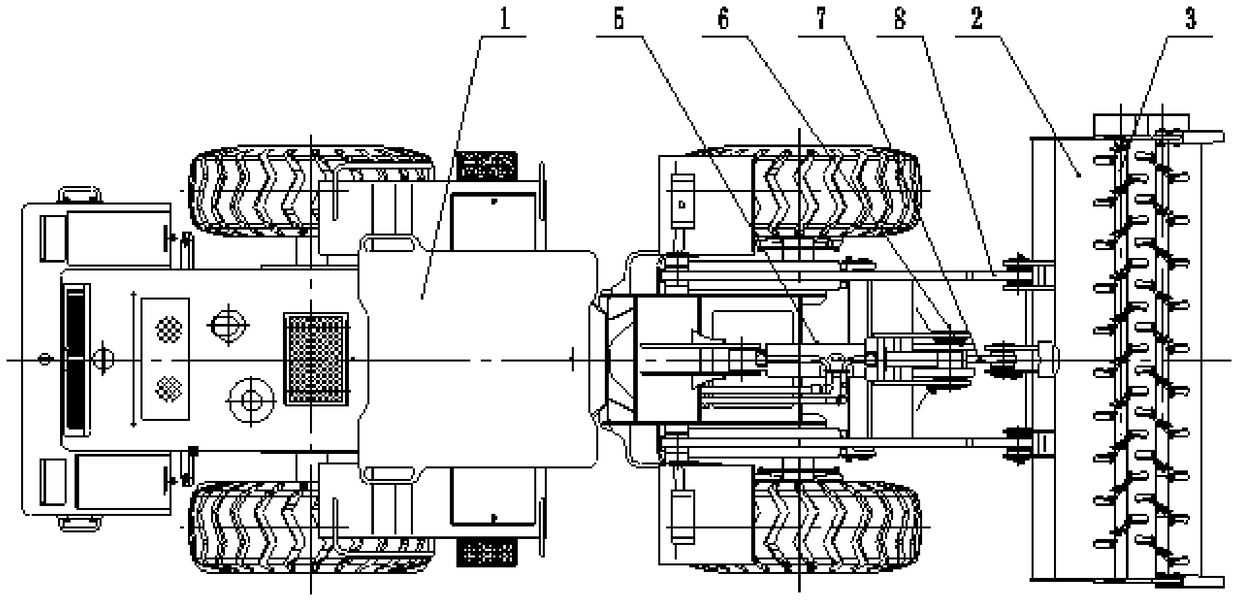

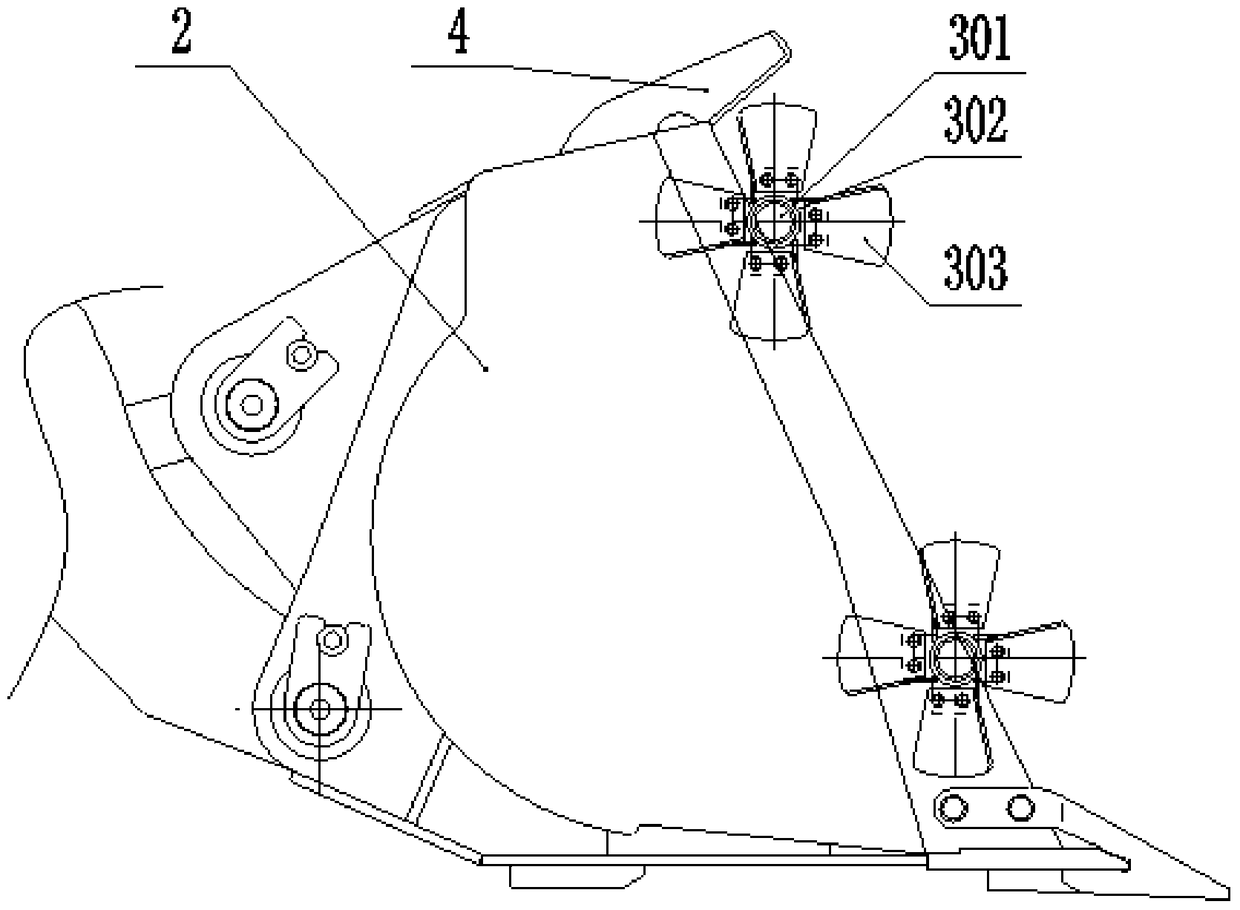

Hydraulic screw ship cabin bottom cleaning machine and application method thereof

ActiveCN105523397ACause damageExtended service lifeLoading/unloadingHydraulic motorMarine engineering

The invention discloses a hydraulic screw ship cabin bottom cleaning machine and an application method thereof, and belongs to the technical field of crushing and transportation of mineral aggregates. The equipment comprises a host machine; the host machine is a loader, a scraper or an excavator, and is provided with a bucket; the bucket is provided with a hydraulic crushing device; the hydraulic crushing device comprises a rotating shaft and a hydraulic motor; the rotating shaft is arranged in the bucket, and is provided with a crushing blade; and the hydraulic motor is arranged on the outer side surface of the bucket, and drives the rotating shaft to rotate. The equipment integrates crushing and loading , can crush and clean mineral aggregates bonded at the bottom of a ship cabin, is simple and compact in structure, high in working efficiency, excellent in effect, free of dead angles and capable of continuously operating, needs no laborers to perform crushing operation, largely reduces the labor capacity, decreases the labor cost, and prevents the generation of accidents; and in addition, the crushing operation poses no damage to a ship body, so that the service lifetime of a ship is prolonged.

Owner:南通卓效自动化有限公司

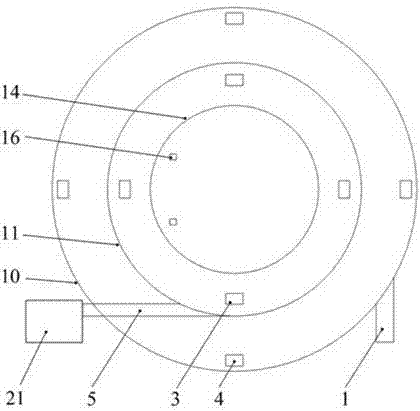

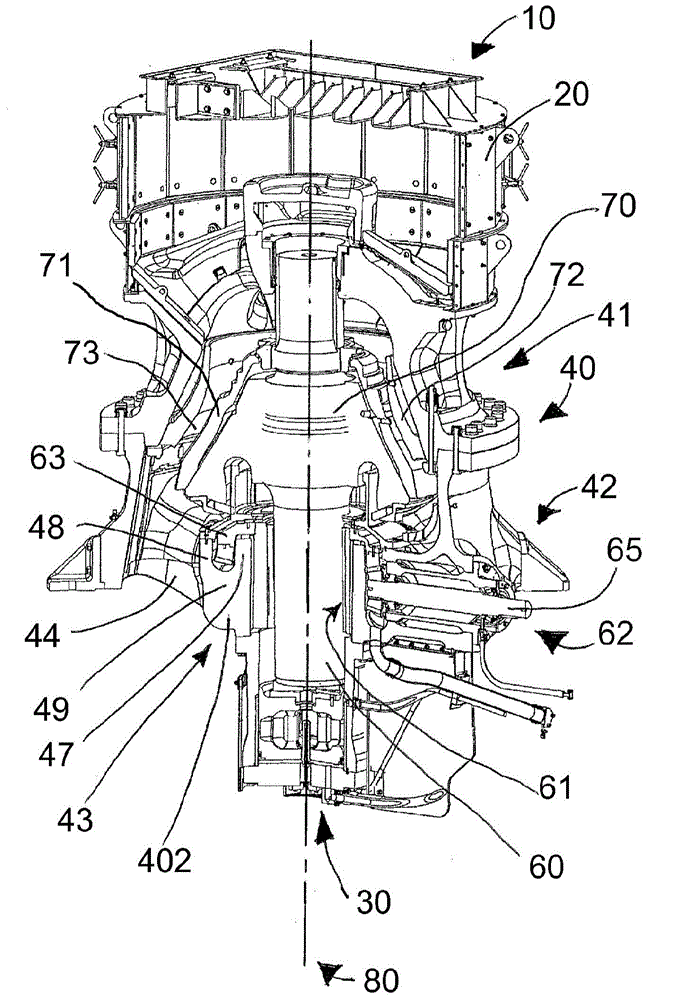

Multi-stage cone cavity fixed hammer crusher

The invention relates to a multistage conical cavity fixed hammerhead crusher. Multiple layers of cutterheads are arranged on the main shaft of the conical crushing cavity from the top to bottom in a tower shape. Each layer of cutterhead is fixedly provided with a plurality of hammerheads. A substance, which enters the crushing cavity from the top of the crushing cavity, is punched by the hammerheads arranged on the cutterheads that rotate in a high speed and are perpendicular to the main shaft, and extruded and grinded by the hammerheads and cavity wall into powder. The hammerheads on the cutterhead are staggeredly arranged, so that a plurality of hammerheads can be arranged in the same descending path so as to increase the punching frequency on the substance. The space between the hammerheads and the cavity wall becomes narrower from the top to the bottom and can be changed by changing the height of the machine. The substance is grinded in each stage during the descending process, and is finally discharged out of the crusher when the particle size of the substance is equal to the distance between the hammerhead in the lowest stage and the cavity wall.

Owner:TONGJI UNIV

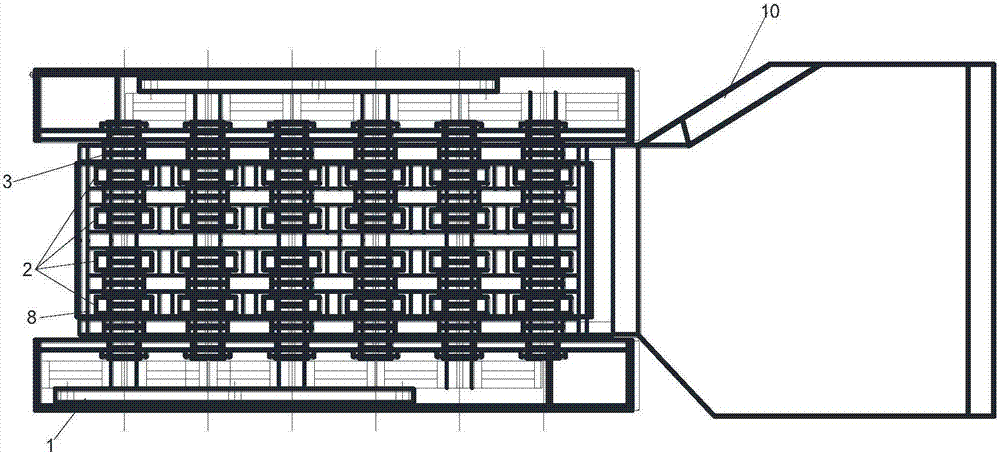

A hammer crusher

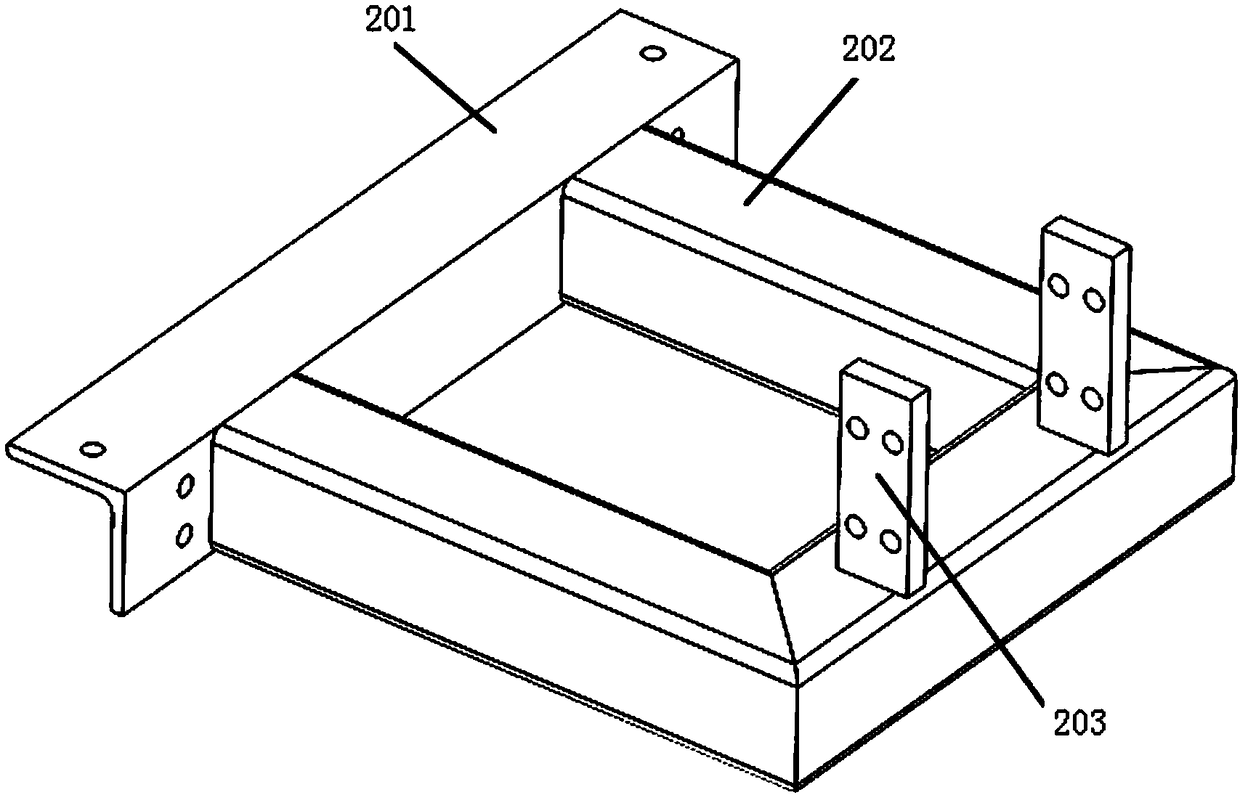

InactiveCN103041901BImprove adaptabilityStrong crushing forceSievingScreeningProduction linePunch press

A single-machine crushing production line, comprising a crushing mechanism, a base (2), a shaking chamber (4) and a gantry (3); the base is disposed on the gantry via an elastic supporting mechanism; the crushing mechanism, the base and the shaking chamber are integrated from top to bottom; the base is also provided with a material feeding chamber (7) on the upper side; the outlet of the material feeding chamber corresponds to the crushing chamber inlet of the crushing mechanism; the inlet of the shaking chamber body corresponds to the crushing chamber outlet of the crushing mechanism; and the shaking chamber body is provided with a sieve therein. In the crushing production line, the crushing mechanism shares an eccentric shaft with the material feeding chamber and the shaking chamber; the single-machine crushing production line completes the whole material feeding process, crushing and sieving, and utilizes the vibration generated by the crushing movement of the crushing mechanism to feed and sieve the material, thus reducing energy consumption in the material feeding, conveyance and sieving process.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

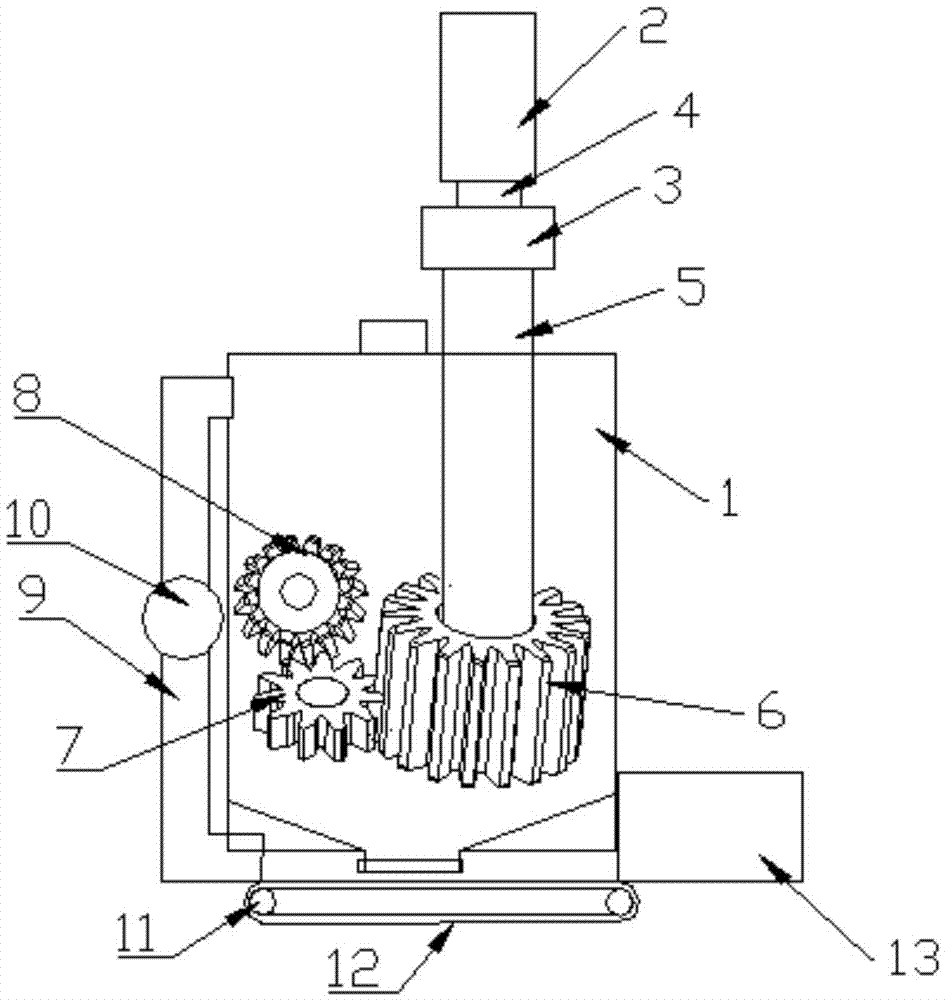

Crushing device

InactiveCN106861813AGood crushing effectSimple and efficient operationGrain treatmentsElectric machineryEngineering

The invention provides a crushing device, which includes a box body, a rotating shaft, and a first gear. The rotating shaft is driven to rotate by a motor. The other end of the rotating shaft is connected to the first gear. The feeding port of the box body Located in the middle of the top of the box, the discharge port of the box is located in the middle of the bottom of the box, and a second gear with the same axial direction as the first gear is provided near the first gear, and the second gear is in the same direction as the first gear. The first gear is meshed, and a third gear perpendicular to the axial direction of the second gear is arranged above the second gear, and the third gear is meshed with the second gear; A conveyor belt is provided at the bottom of the box, and a return pipe and a collection box are respectively provided on both sides of the conveyor belt. The present invention utilizes the rotating first gear to drive the second gear, and the second gear drives the third gear to form a strong rotational force, and the fast rotating sawtooth produces a great crushing force on the material, and the crushing effect is more obvious.

Owner:TIANJIN ZHENBANG AQUACULTURE

A variable torque type traditional Chinese medicine pulverizer

ActiveCN111957390BIncrease the momentary impact forceStrong crushing forceSievingScreeningMechanical engineeringChinese herbology

The invention discloses a variable torque type traditional Chinese medicine pulverizer, which comprises a box body, a pulverization cavity is arranged inside the box body, and a sieve plate is plugged into the bottom of the pulverization cavity of the box body, and the box body is in the Located below the sieve plate, there is an open drug receiving cavity at the side end, and a drug receiving box is arranged in the drug receiving cavity; a variable torque crushing mechanism is arranged in the box, and symmetrically arranged The inside is a pair of hollow central columns, each of which is provided with a hammer at the outer end of the central column, and the outer end of the hammer is provided with a channel that communicates with the movable chamber and corresponds to the impact block one by one. hole, the back of the impact sheet is provided with a push column extending into the inner cavity of the central column, and the central column is provided with an impact ball sliding along the inner cavity of the central column. The invention adopts a variable torque type crushing mechanism to crush the Chinese herbal medicines, effectively reduces the abrasion of hammer blades in the crushing process, and has the characteristics of good crushing effect.

Owner:WENZHOU UNIVERSITY

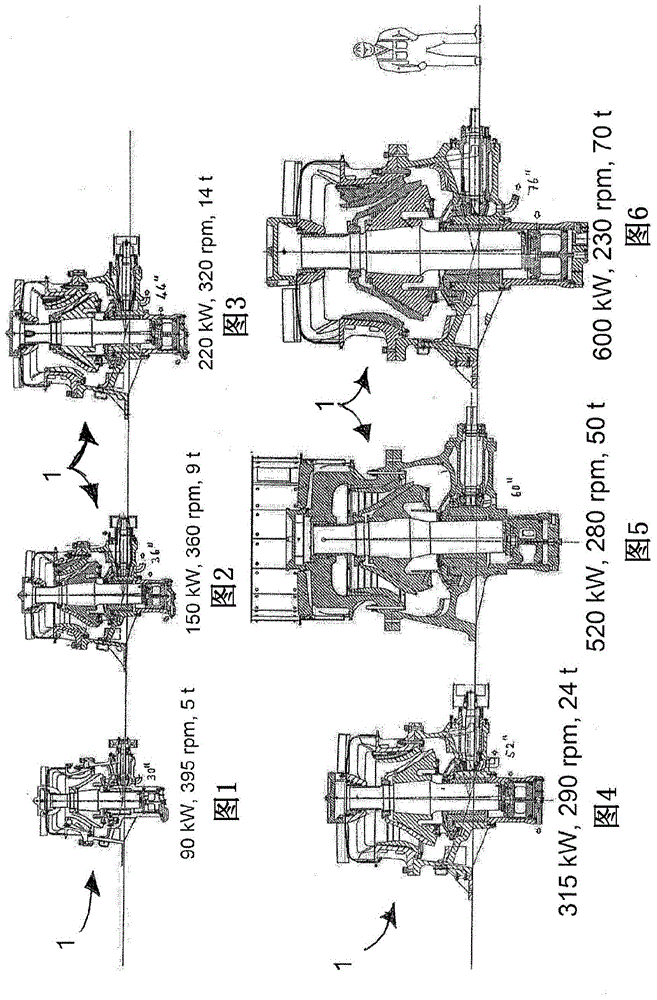

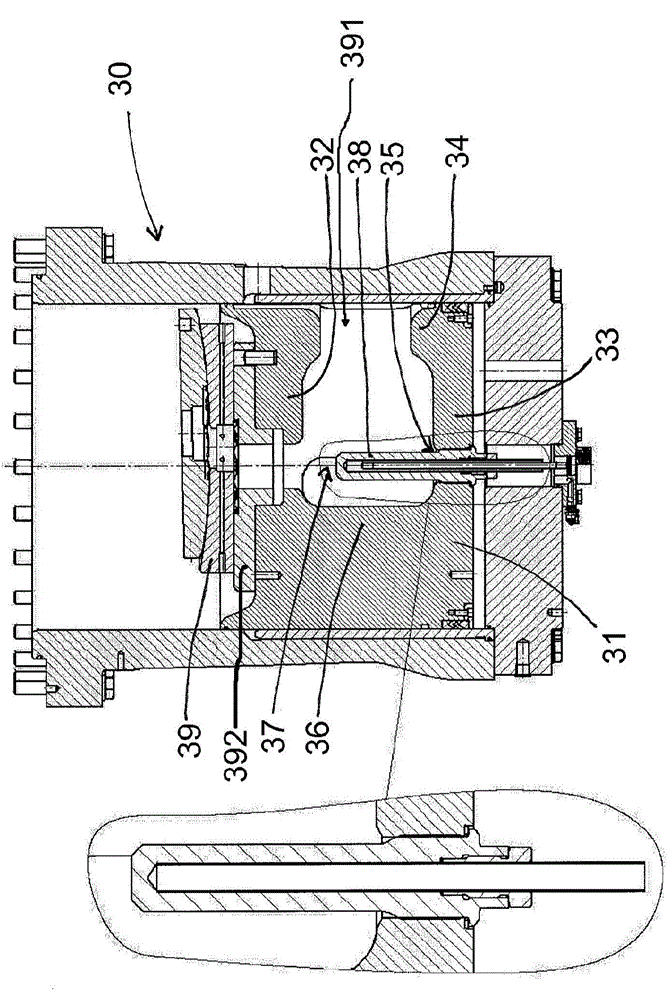

Gyratory crusher with piston

InactiveCN103608112AReduced external dimensionsStrong crushing forceGrain treatmentsEngineeringCrusher

A piston (31) for a gyratory crusher; which piston is cylindrical and hollow and comprises a piston wall (34), a piston top (32) and a piston bottom (33), which piston wall comprises at least one opening (391) leading into an inner chamber of the hollow piston, which piston wall comprises an outer sliding surface and an inner chamber surface. Said piston further comprises at least one supporting structure (36) connecting the piston top (32) and the piston bottom (33).

Owner:SANDVIK INTELLECTUAL PROPERTY AB

A method of using a hydraulic screw type cabin bottom cleaning machine

ActiveCN105523397BCause damageExtended service lifeLoading/unloadingHydraulic motorTransportation technology

The invention discloses a hydraulic screw ship cabin bottom cleaning machine and an application method thereof, and belongs to the technical field of crushing and transportation of mineral aggregates. The equipment comprises a host machine; the host machine is a loader, a scraper or an excavator, and is provided with a bucket; the bucket is provided with a hydraulic crushing device; the hydraulic crushing device comprises a rotating shaft and a hydraulic motor; the rotating shaft is arranged in the bucket, and is provided with a crushing blade; and the hydraulic motor is arranged on the outer side surface of the bucket, and drives the rotating shaft to rotate. The equipment integrates crushing and loading , can crush and clean mineral aggregates bonded at the bottom of a ship cabin, is simple and compact in structure, high in working efficiency, excellent in effect, free of dead angles and capable of continuously operating, needs no laborers to perform crushing operation, largely reduces the labor capacity, decreases the labor cost, and prevents the generation of accidents; and in addition, the crushing operation poses no damage to a ship body, so that the service lifetime of a ship is prolonged.

Owner:南通卓效自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com