Crusher for titanium sponge

A crusher and titanium sponge technology, applied in the field of machinery, can solve the problems of crushing oxygenation, yellowing of sponge titanium appearance products, high crushing efficiency, and achieve the effects of large crushing force, easy crushing particle size and short crushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

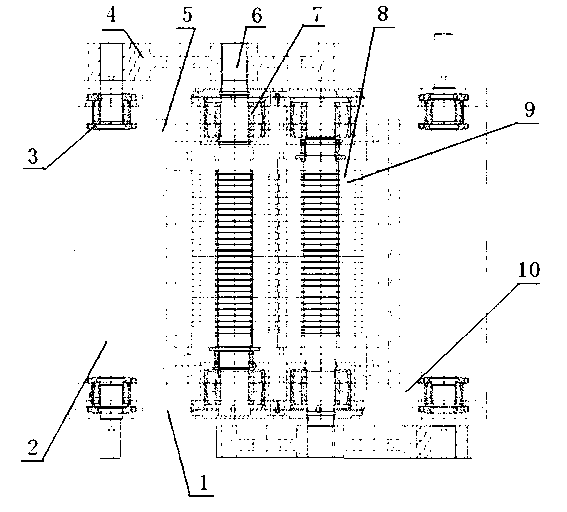

[0012] Such as figure 1 As shown, a crusher for sponge titanium is mainly composed of a base 1, a body, a drive shaft 2, a gear 4, an inner lining plate 11, a rotating shaft 6, a main blade 8, and a secondary blade 9. The body is composed of a support plate 10. The side plate 5 and the inner lining plate 11 are composed and set on the base 1. There is a discharge port on the base 1. The feed port is set above the body. The rotating shaft 6 is set on the support plate 10 through the rotary bearing 7. In the machine body, the rotating shaft 6 is connected with the drive shaft 2 through the gear 4, and the drive shaft 2 is set on the support plate 10 through the drive bearing 3 arranged on the support plate 10, and the other end of the drive shaft 2 is connected with the motor, each of which rotates Main blade 8 and auxiliary blade 9 are arranged at intervals o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com