A method of using a hydraulic screw type cabin bottom cleaning machine

A technology of spiral and bottom cleaning machines, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficult manual cleaning, hidden safety hazards, and heavy labor, and achieve simple structure, reduced labor, and high work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

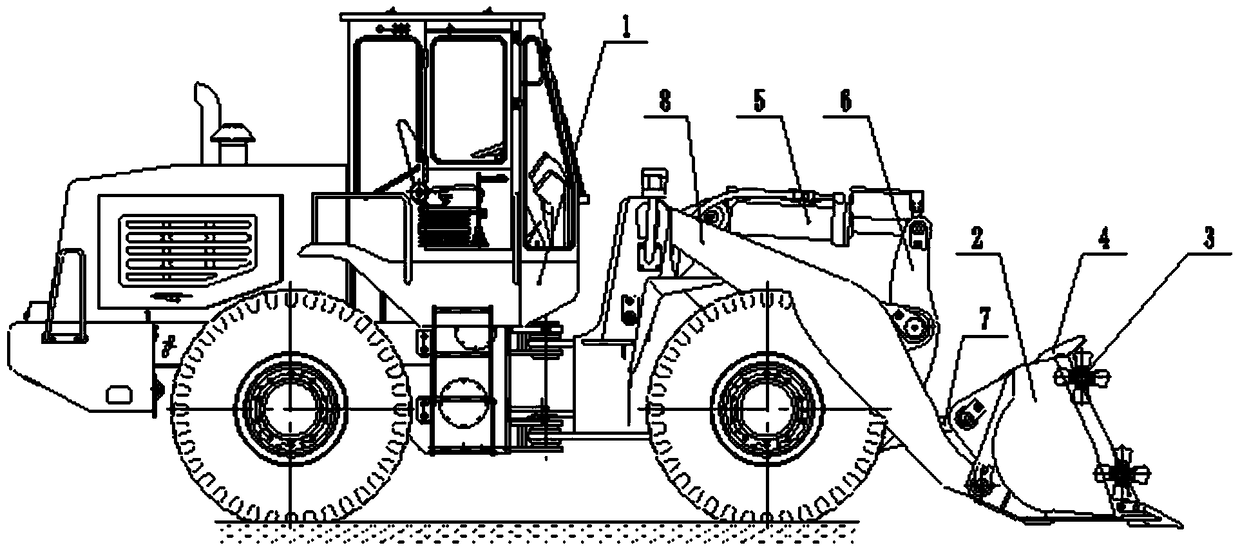

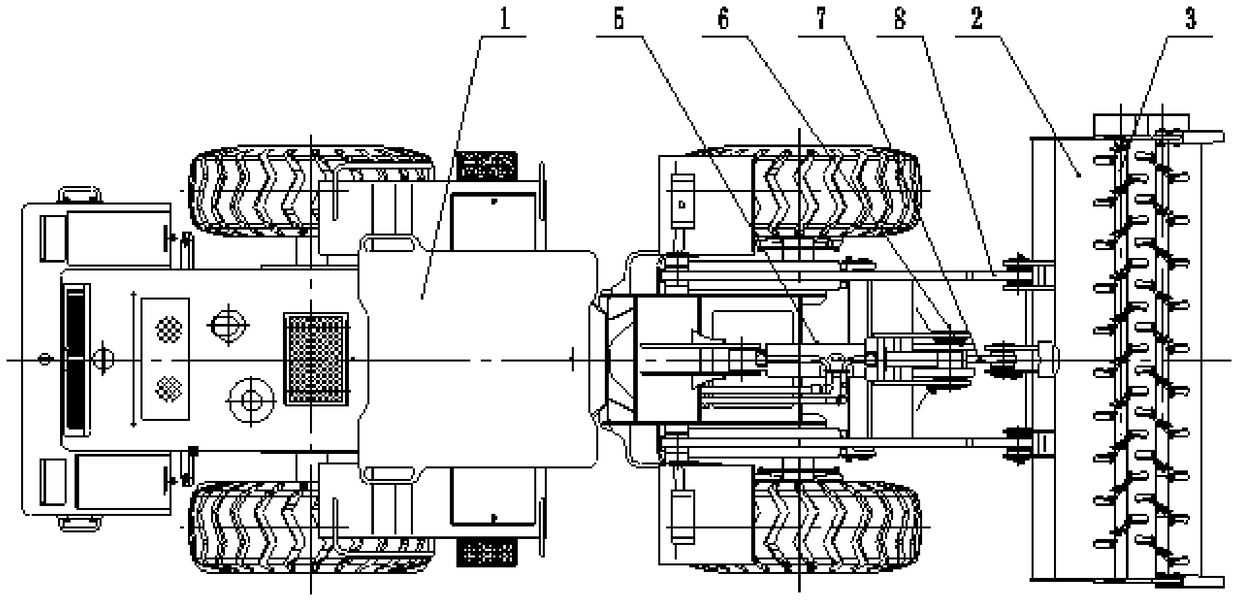

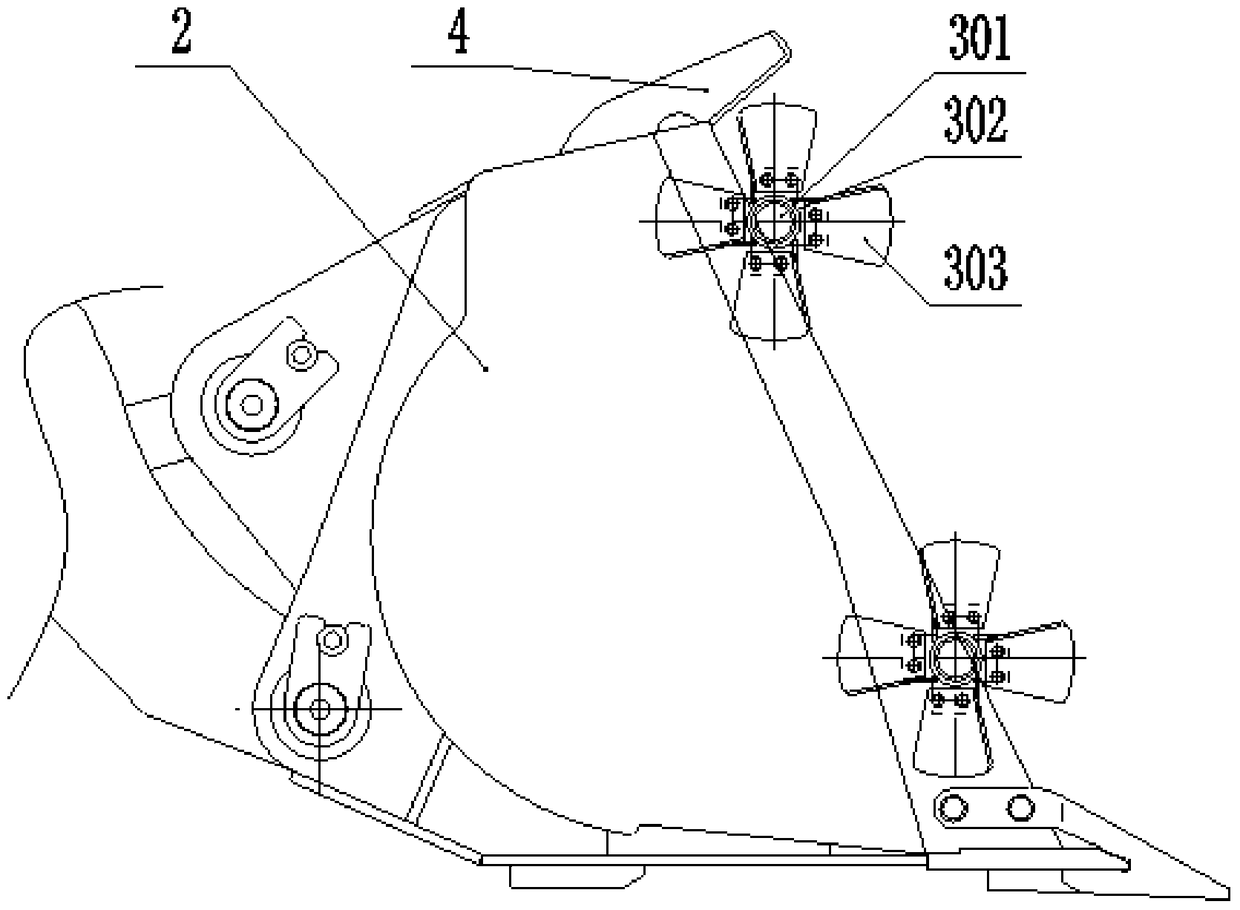

[0038] like figure 1 , figure 2 , image 3 and Figure 4As shown, a hydraulic screw type tank bottom cleaning machine in this embodiment includes a main engine 1 and a bucket 2; wherein, the main engine 1 can be a loader, a scraper, an excavator or other equipment capable of installing a bucket 2 In this embodiment, the main engine 1 adopts a loader, which has the advantages of fast operation speed, high efficiency, good maneuverability, light operation, etc., and the main engine 1 is equipped with a boom oil cylinder 5, a boom 6, a small arm 7. Support arm 8 and support arm cylinder; one end of the boom 6 is hinged to one end of the forearm 7, and the other end of the boom 6 is connected to the body of the main engine 1 through the boom cylinder 5, and the middle part of the boom 6 is connected to the body of the main engine 1. The body of the main engine 1 is hinged, the other end of the small arm 7 is hinged to the bucket 2; one end of the support arm 8 is hinged to the...

Embodiment 2

[0044] The basic structure of the hydraulic screw type cabin bottom cleaning machine of this embodiment is the same as that of Embodiment 1, the difference is that: the blade surface of the crushing blade 303 forms an acute angle β with a plane perpendicular to the axis of the rotating shaft 301, and the acute angle β It is 25 °, that is, the helix angle is 25 °, and its crushing force is slightly smaller than that of Example 1, but the single crushing area is larger. A method of using a hydraulic screw type cabin bottom cleaning machine, which is the same as Embodiment 1, except that: during the crushing process, the flow rate of the hydraulic motor 304 controls the rotational speed νr / min of the rotating shaft 301 to satisfy ν=λβ, wherein, λ is a constant coefficient with a value of 2.5-3, β is the helix angle of the crushing blade 303 expressed in degrees, and β takes a value in the formula, then in the present embodiment, the value of ν is 62.5-75r / min; When crushing withi...

Embodiment 3

[0046] The basic structure of the hydraulic screw type cabin bottom cleaning machine of this embodiment is the same as that of Embodiment 1, the difference is that: the blade surface of the crushing blade 303 forms an acute angle β with a plane perpendicular to the axis of the rotating shaft 301, and the acute angle β It is 30 °, that is, the helix angle is 30 °, and its crushing force is also slightly smaller than that of embodiment 2, but the single crushing area is also larger than that of embodiment 2. A method of using a hydraulic screw type cabin bottom cleaning machine, which is the same as Embodiment 1, except that: during the crushing process, the flow rate of the hydraulic motor 304 controls the rotational speed νr / min of the rotating shaft 301 to satisfy ν=λβ, wherein, λ is a constant coefficient with a value of 2.5-3, β is the helix angle of the crushing blade 303 expressed in degrees, and β takes a value in the formula, then in the present embodiment, the value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com