Patents

Literature

42results about How to "Short crushing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

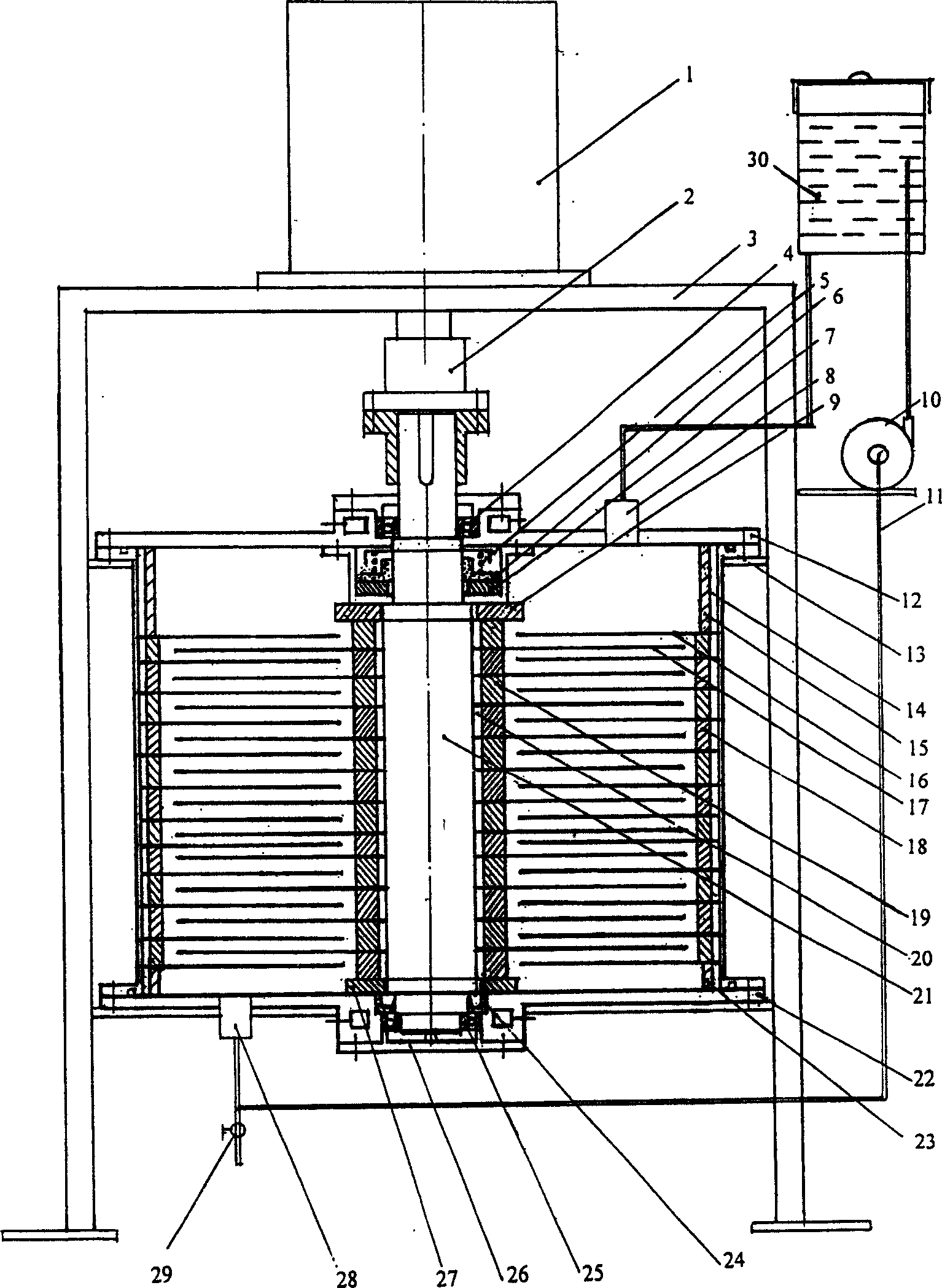

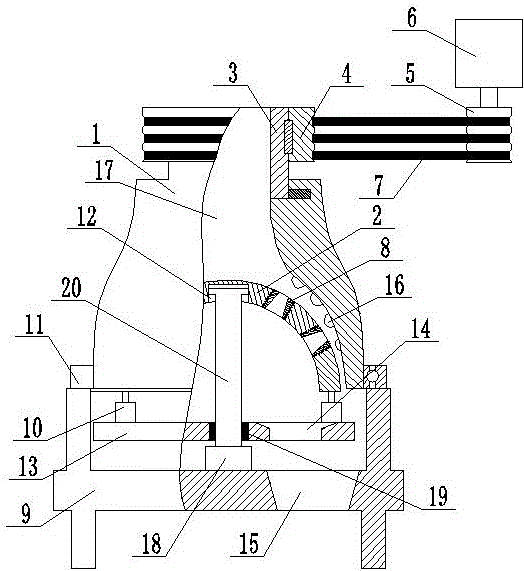

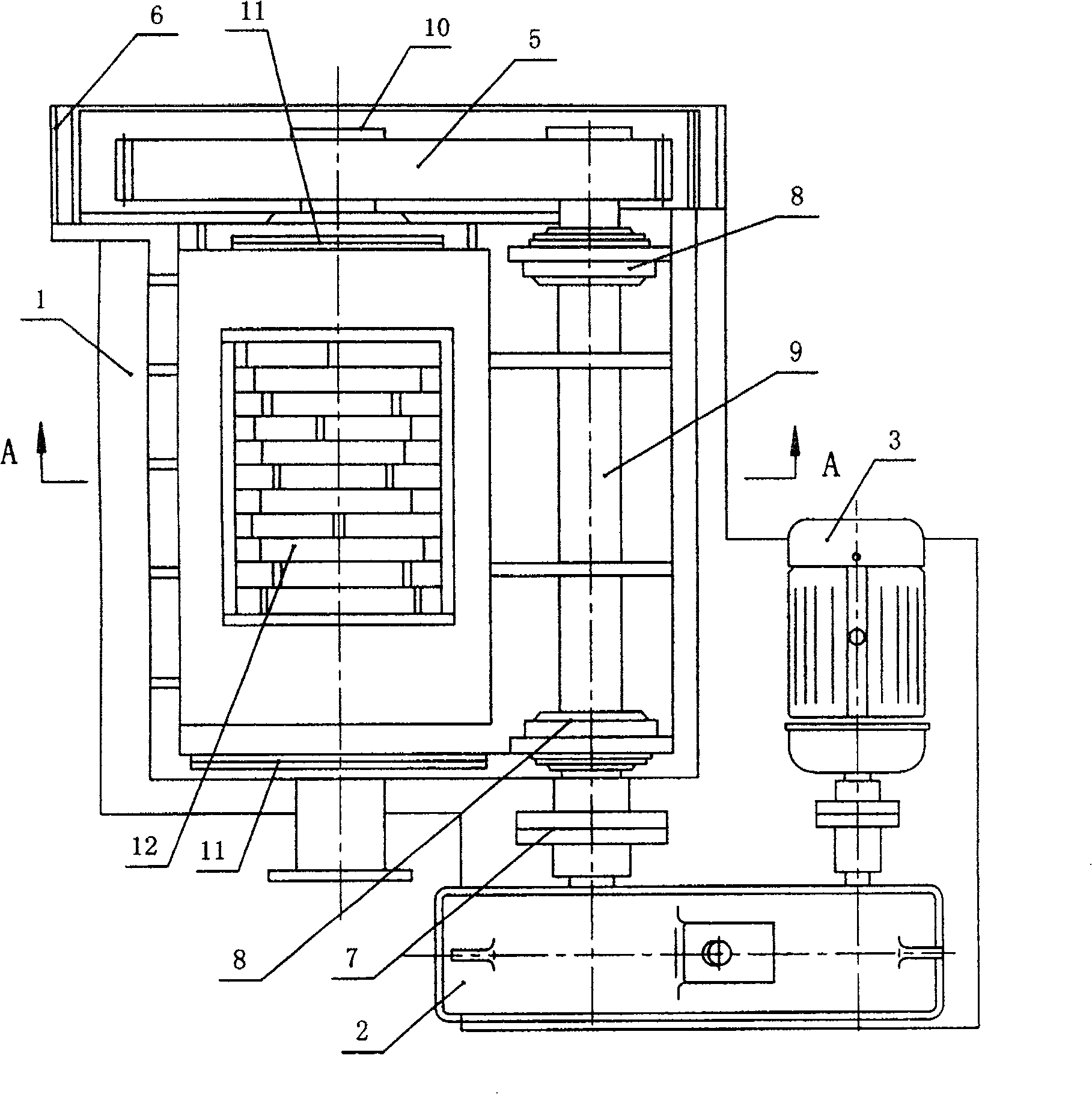

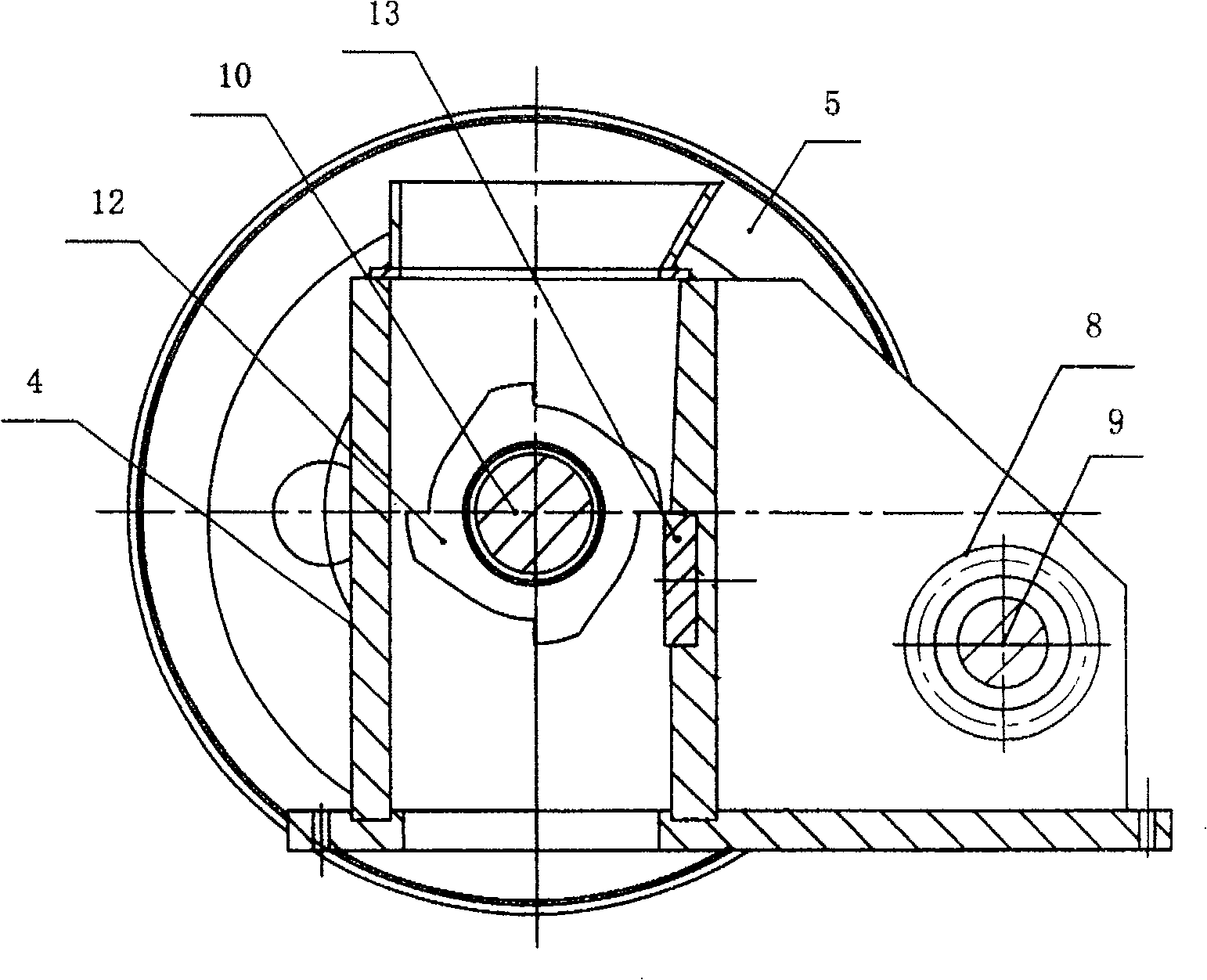

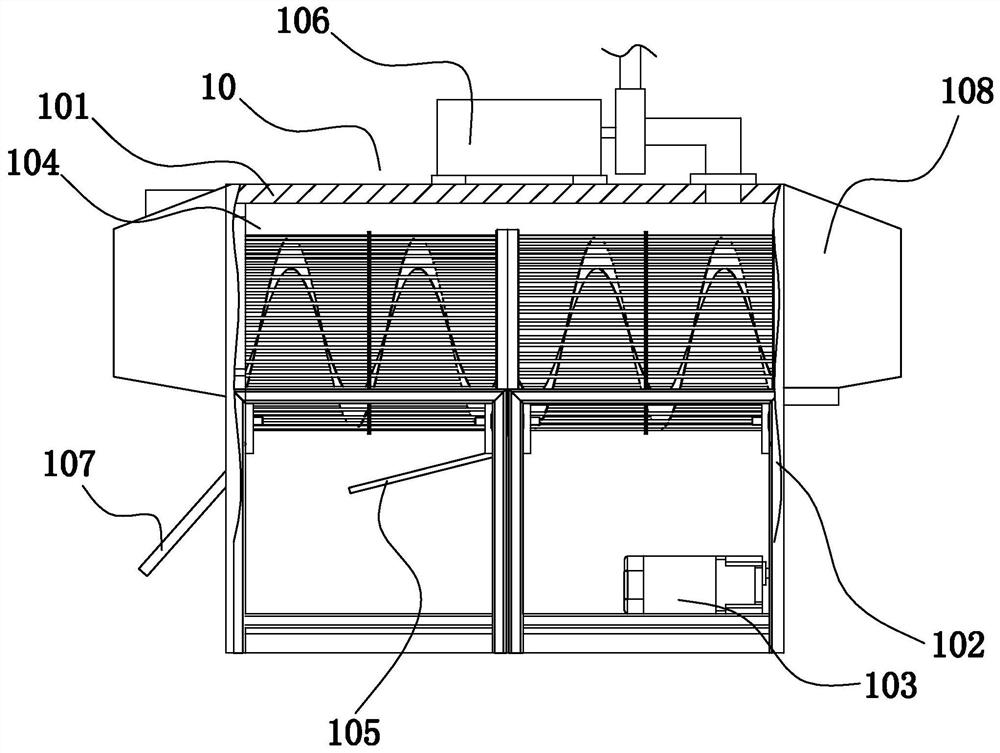

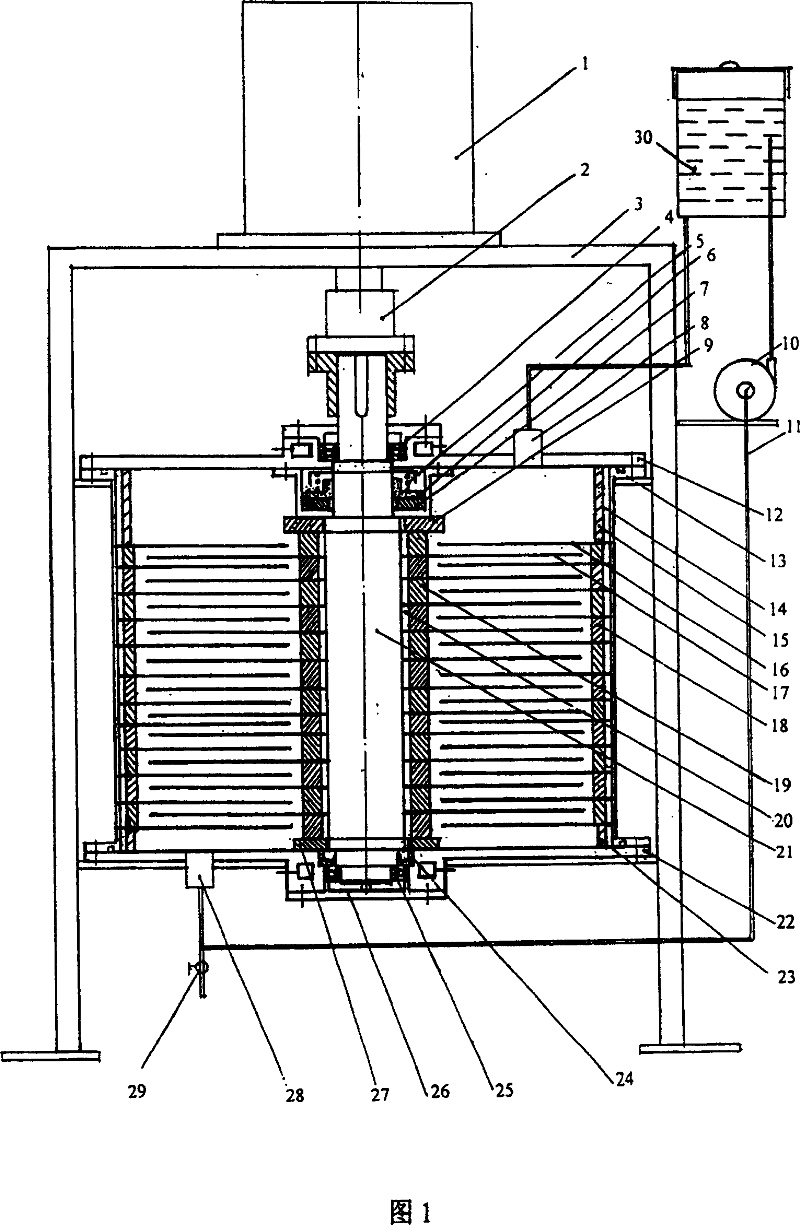

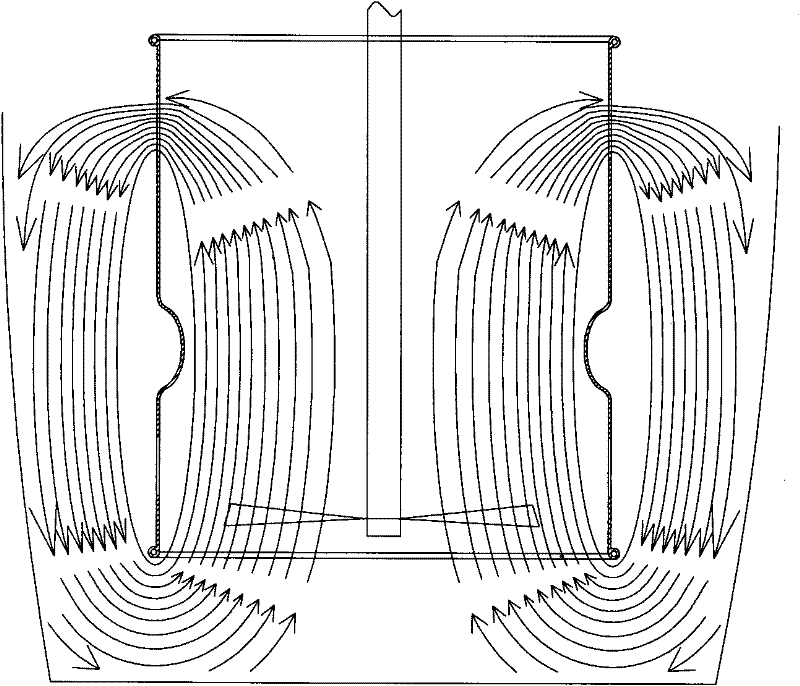

High speed interlayer shearing crusher for nano powder

InactiveCN1600438ASolve the problem of excessive noiseReduce noiseGrain treatmentsNanoparticleElectric machinery

A high-speed interlayer-shearing pulverizator for preparing nanoparticles is composed of high-speed motor, supporting frame, movable and fixed sealing plates, gas or liquid circulating pump, main cylinder, multi-hole static plates, multi-hole moving plates, oil sealing, feeding tank, discharging valve, etc.

Owner:UNIV OF SCI & TECH BEIJING

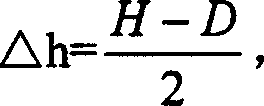

Reuse method for plastic handset sheathing material

InactiveCN1836874AAvoid damageReduce performanceSolid waste disposalPlastic recyclingEngineering plasticEngineering

The method of recovering plastic cellphone casing material belongs to the field of waste electronic product recovering and reusing technology, and aims at ensuring the pollution-less development of electronic industry. The plastic cellphone casing material recovering process includes the following steps: eliminating metal wires and brass parts from the casing, sorting into PC and PC+ABS, sand blasting to eliminate surface coating and adhered parts, crushing and sieving, gravitational sorting to separate metal from non-metal material, recovering metal material, cleaning non-metal material, adding small amount of assistant and extruding to pelletize or into plastic product. The method of the present invention has high production efficiency, high performance of the recovered material, low cost, and less pollution.

Owner:BEIJING UNIV OF TECH

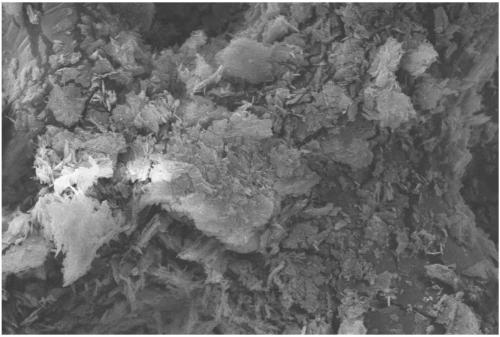

Chitin crushing method

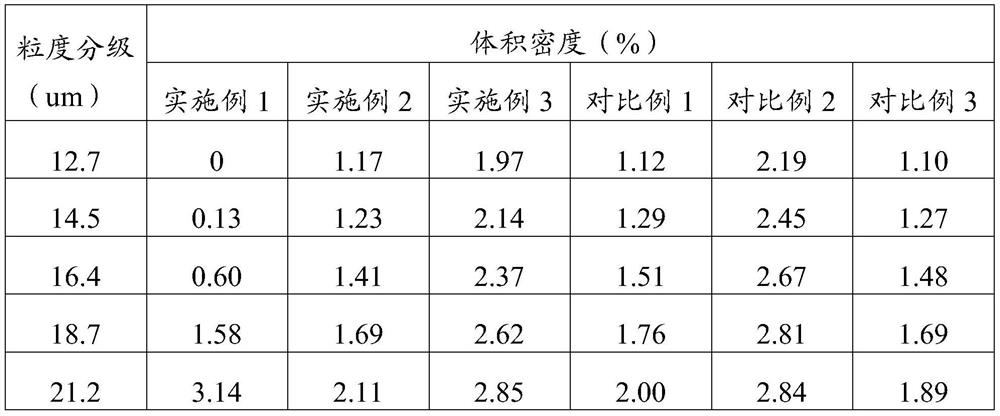

InactiveCN104117418AReduce crushing timeShort crushing timeGrain treatmentsPhysical chemistryCrystal structure

The invention belongs to the technical field of crushing, in particular discloses a chitin crushing method. The overspeed refrigeration is performed for selected chitin packaged in vacuum; the temperature of the overspeed refrigeration is in a range of -35 DEG C to -30 DEG C, and the time of the overspeed refrigeration is 5-10 min; and the chitin after the overspeed refrigeration can be crushed after being stored at the low temperature below -18 DEG C, or can be directly taken out from the package to be crushed in a frozen state. The method shortens the crushing time, enables crushed particles to achieve a powder state, cancels a procedure that in the prior art, crushed raw materials need to be dried before storage, optimizes the process flow, saves the energy consumption, and achieves high efficiency and speediness. Through the analysis and the test, the morphology, molecular structure, crystal structure and thermal property of the chitin are not obviously changed due to the low-temperature condition and mechanical effect of the crushing after and before the overspeed crushing; the dissolving property is prominently improved; and the application range is widened.

Owner:SOUTH CHINA AGRI UNIV

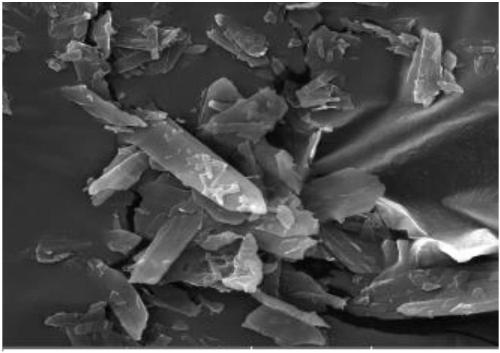

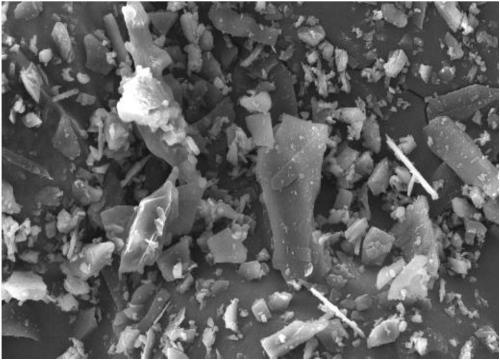

Preparation method of paliperidone palmitate

ActiveCN109400602ASmall particle sizeAvoid damageOrganic chemistryPaliperidone PalmitateCrystallization

The invention belongs to the technical field of medicines and relates to a preparation method of paliperidone palmitate. The method disclosed by the invention comprises the step of precipitating paliperidone palmitate in a mixed solvent of dichloromethane and n-heptane. Paliperidone palmitate particles obtained by the invention are small in particle sizes, flaky, easy to homogenize and grind, andshort in grinding time, have little damage to instruments and equipments, and are short in crystallization time, high in yield and free of solvent residues and particularly suitable for needs of industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD +1

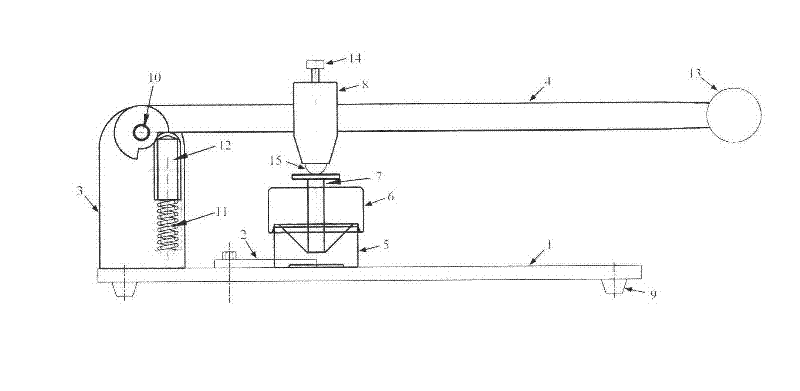

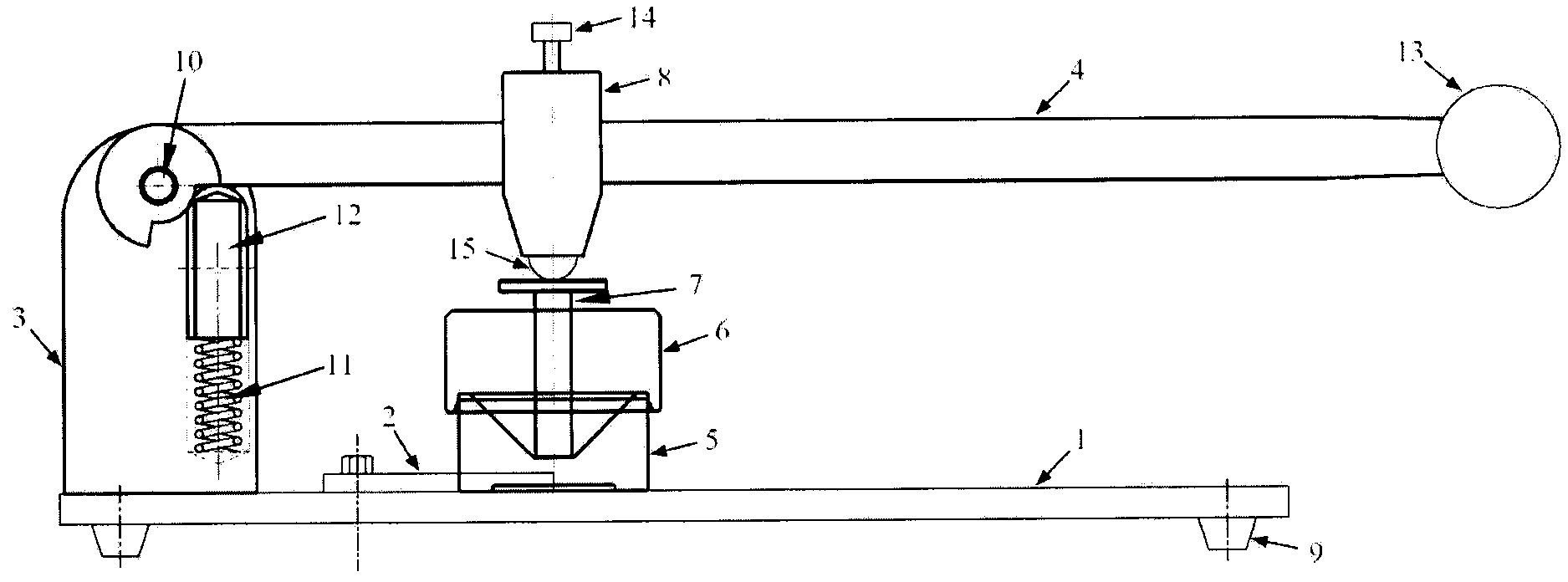

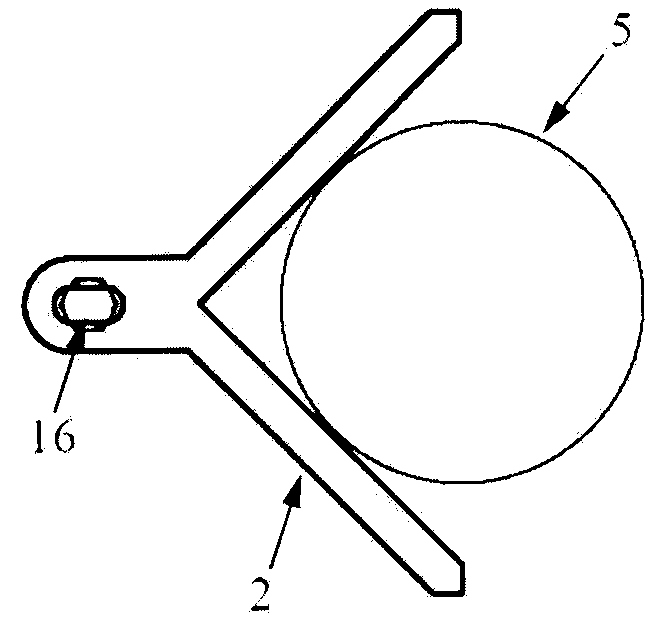

Liquid nitrogen medium/low-temperature crusher for biological sample

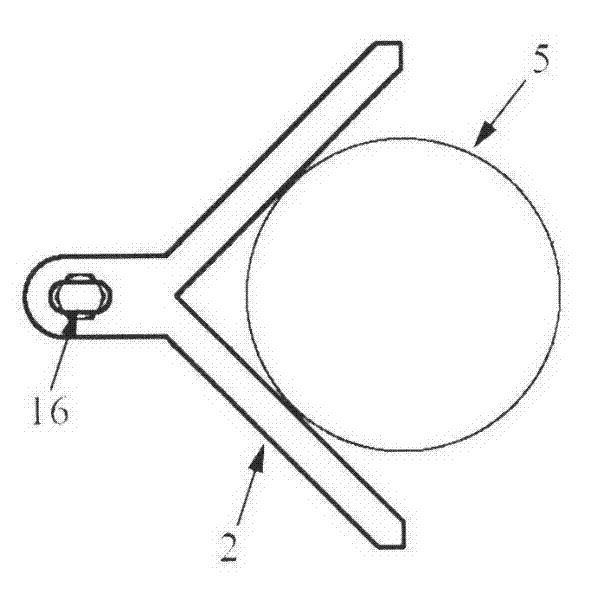

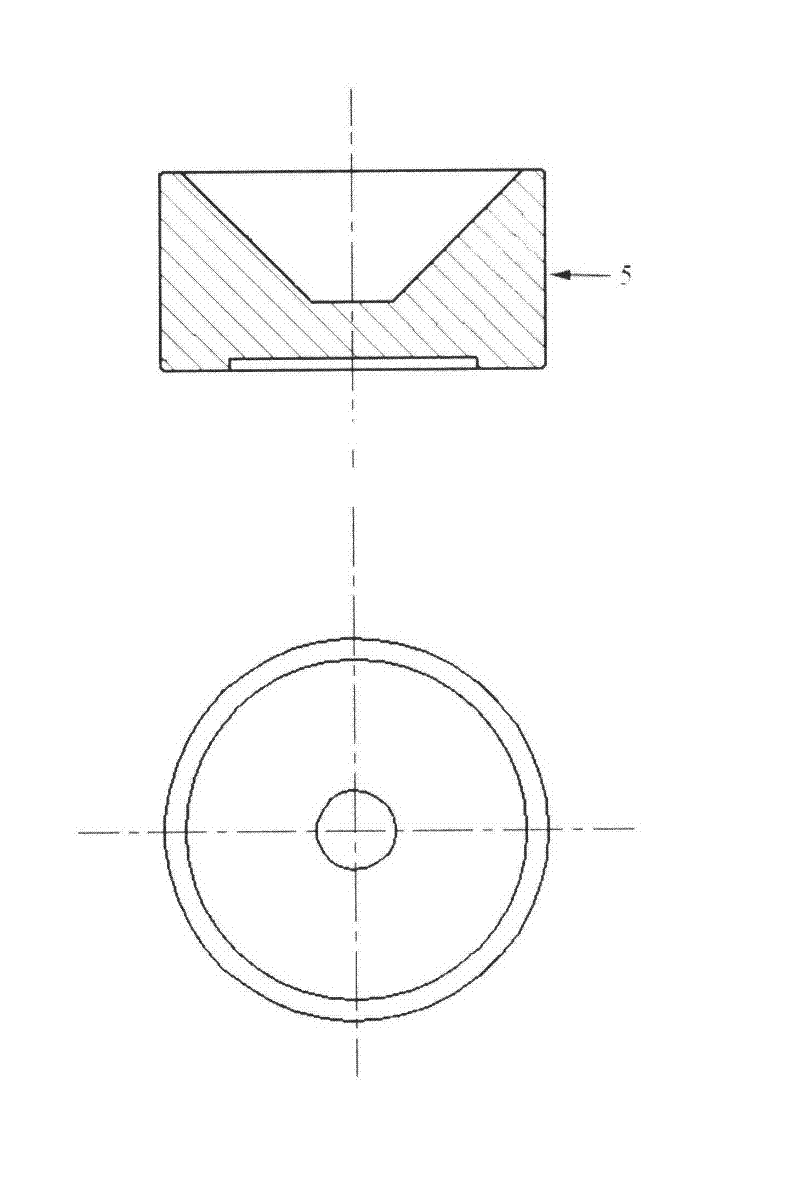

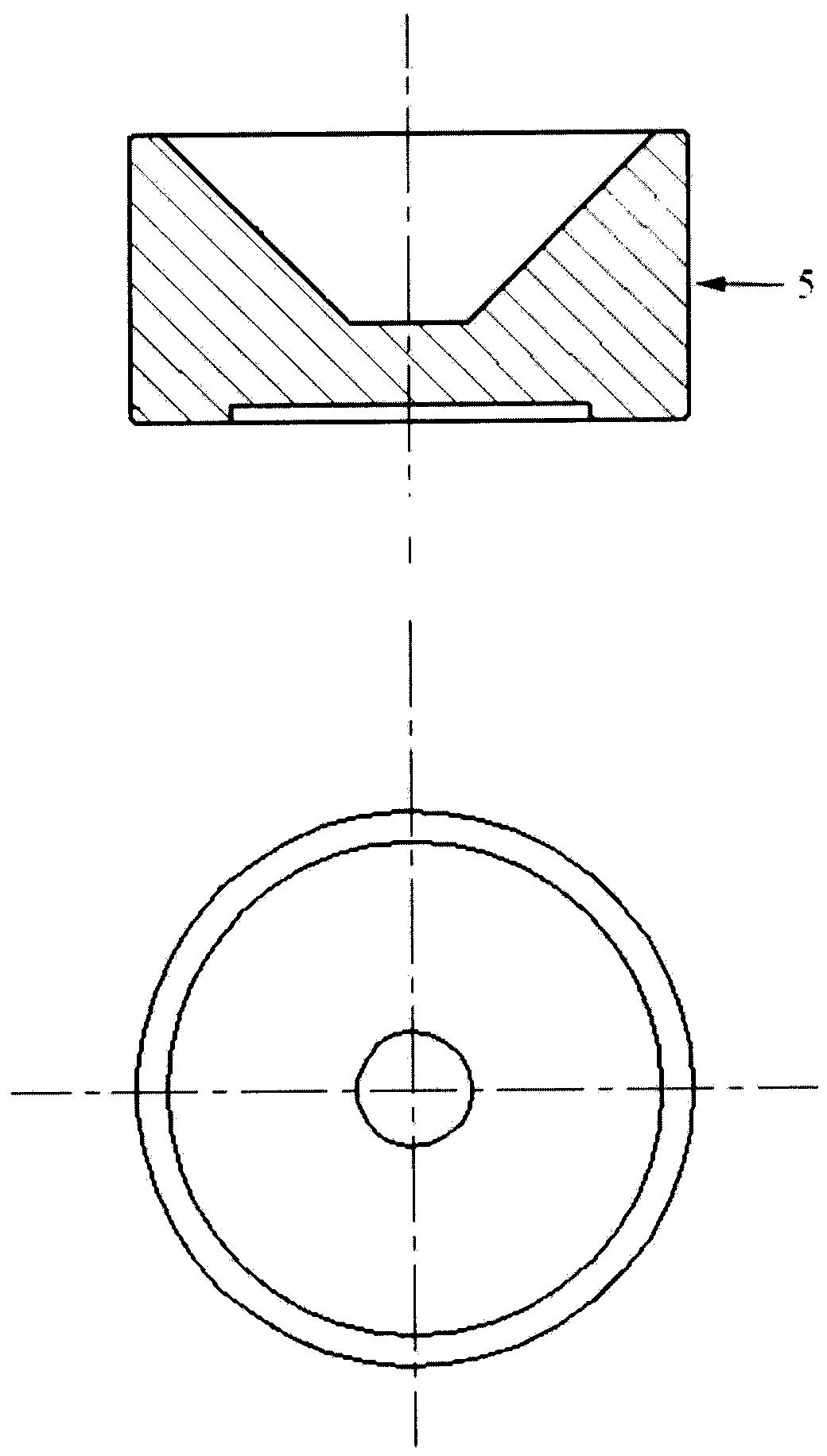

InactiveCN102519773AEasily brokenReduce lossesPreparing sample for investigationCircular discCrusher

The invention belongs to the field of biomedical instruments and relates to a liquid nitrogen medium / low-temperature crusher for a biological sample. The liquid nitrogen medium / low-temperature crusher comprises a bottom plate, a limiting fork, a stand column, a lever, a sample cup, sample cup cover, a sample pressure head, a horseshoe-shaped cushion block and a pressurizing slider. A use method of the liquid nitrogen medium / low-temperature crusher comprises the steps of: placing the biological sample at the bottom of the sample cup, pouring liquid nitrogen, covering the sample cup cover, placing the sample pressure head into a hole in the center of the sample cup cover, meanwhile, placing the horseshoe-shaped cushion block so as to erect a circular disc shaped structure on the upper end of the sample pressure head on the horseshoe-shaped cushion block, suspending the sample pressure head in the liquid nitrogen to decrease the temperature of the sample pressure head, removing the horseshoe-shaped cushion block after the temperature of the sample pressure head is decreased, lowering the sample pressure head onto the biological sample, moving the sample cup, the sample cup cover and the sample pressure head to lean against the limiting fork on the bottom plate, and forcibly pressing the lever to transfer the pressure of the lever by the pressurizing slider on the lever to the biological sample in contact with the lower end of the sample pressure head via the sample pressure head, thereby crushing the low-temperature solid-state biological sample in the liquid nitrogen.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

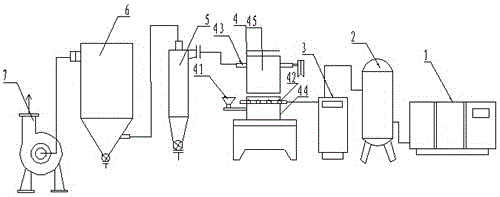

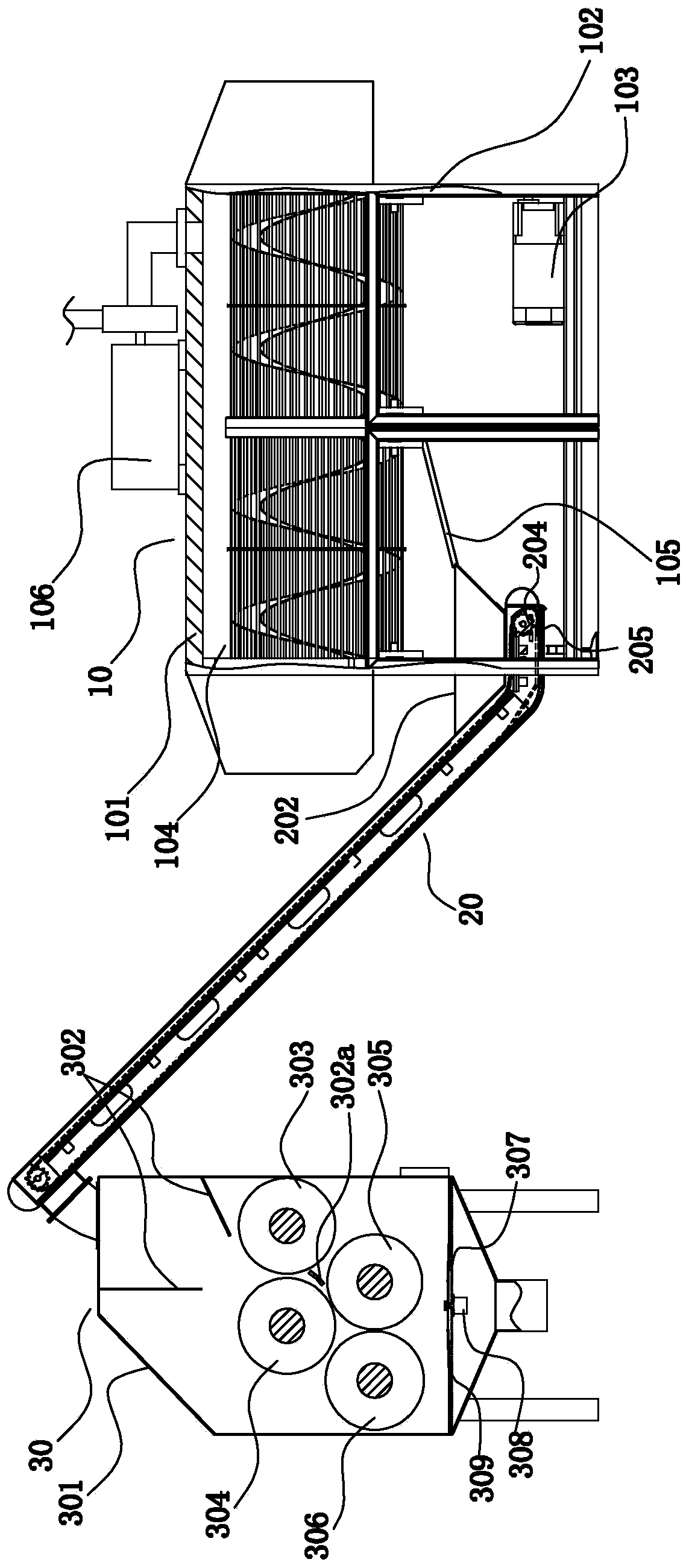

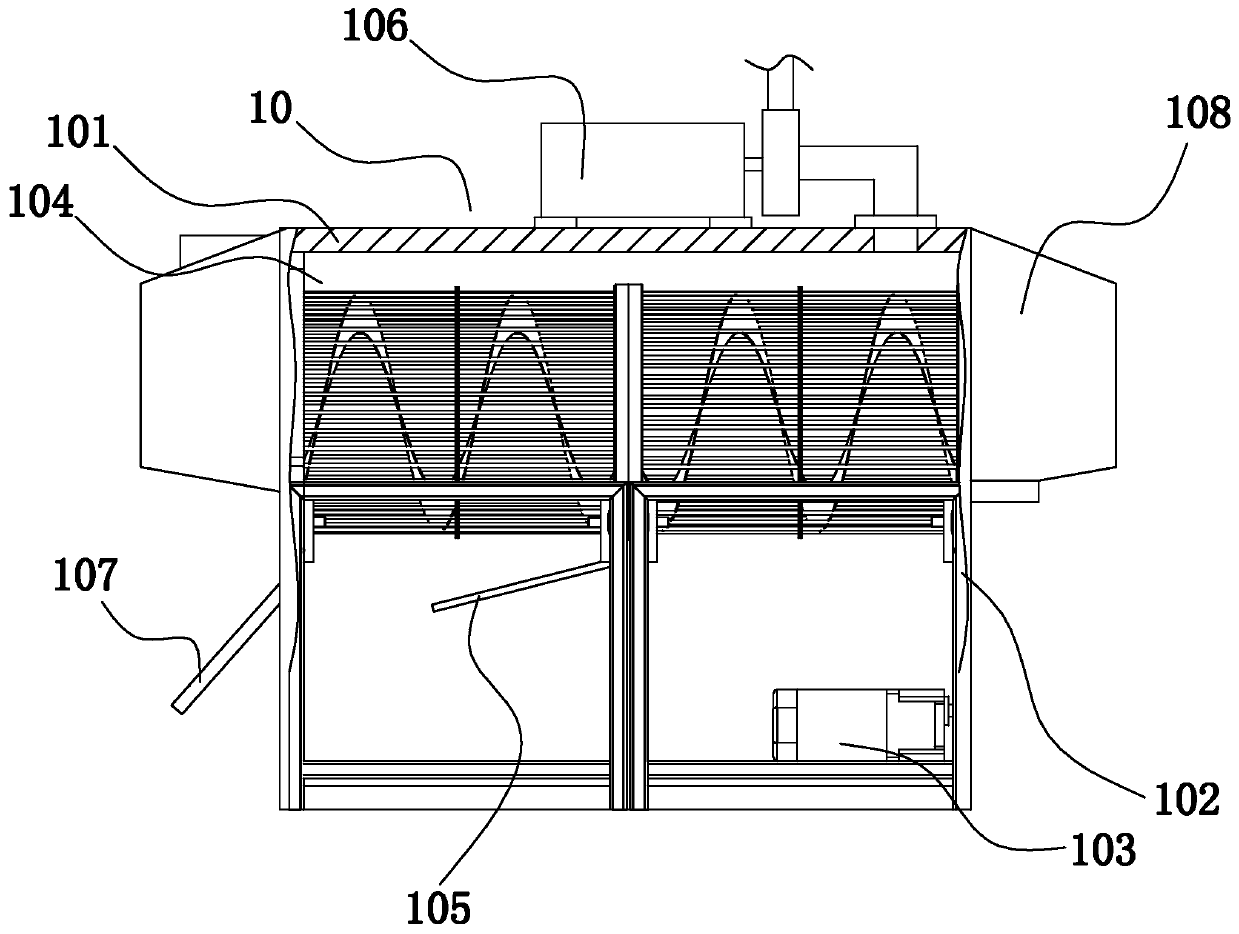

Fluidized-bed airflow pulverizing system

The invention discloses a fluidized-bed airflow pulverizing system. The fluidized-bed airflow pulverizing system comprises an air compressor, an air storage tank, an air freeze dryer, a fluidized-bed airflow pulverizer, a cyclone separator, a catcher and an induced draft fan which are connected through pipelines. The fluidized-bed airflow pulverizer comprises nozzles, a pulverizing chamber, a raw material inlet, a raw material outlet and a classification chamber. The fluidized-bed airflow pulverizing system has the beneficial effects of being short in pulverizing time, simple in structure, convenient to operate and maintain, small in occupied area and low in energy consumption.

Owner:太仓市友联干燥粉碎设备有限公司

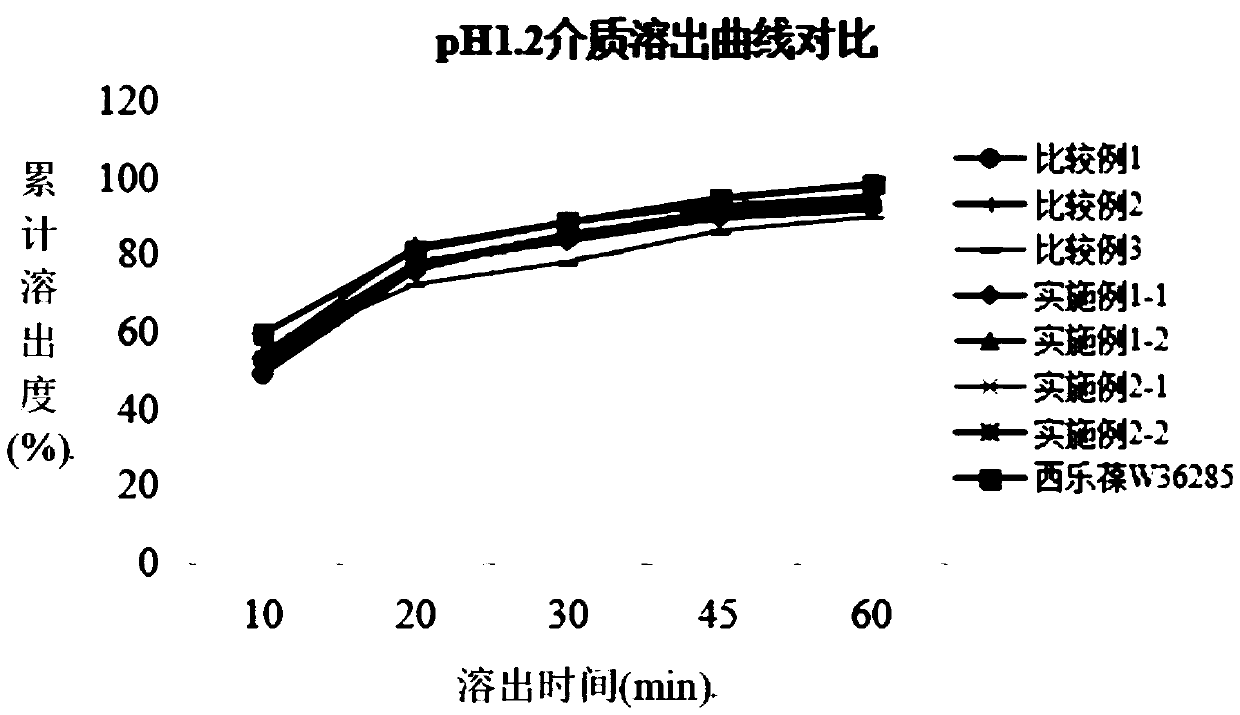

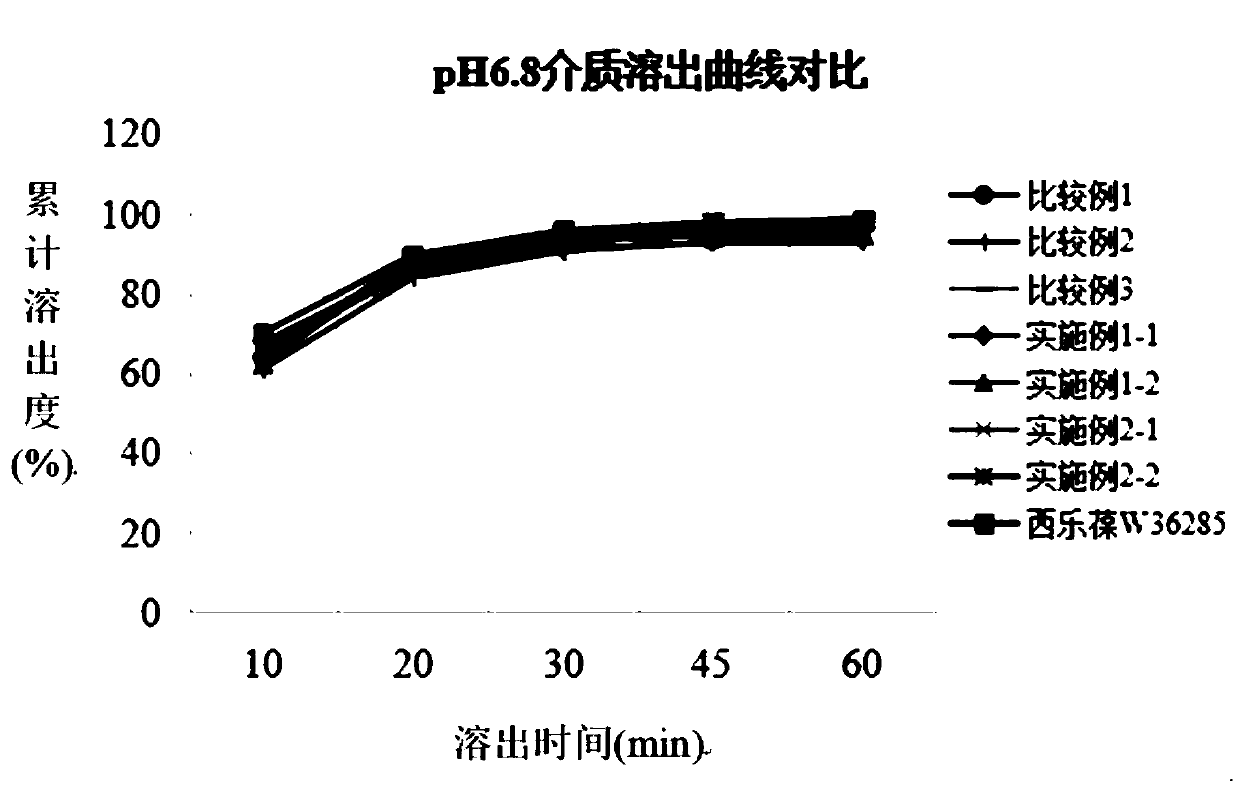

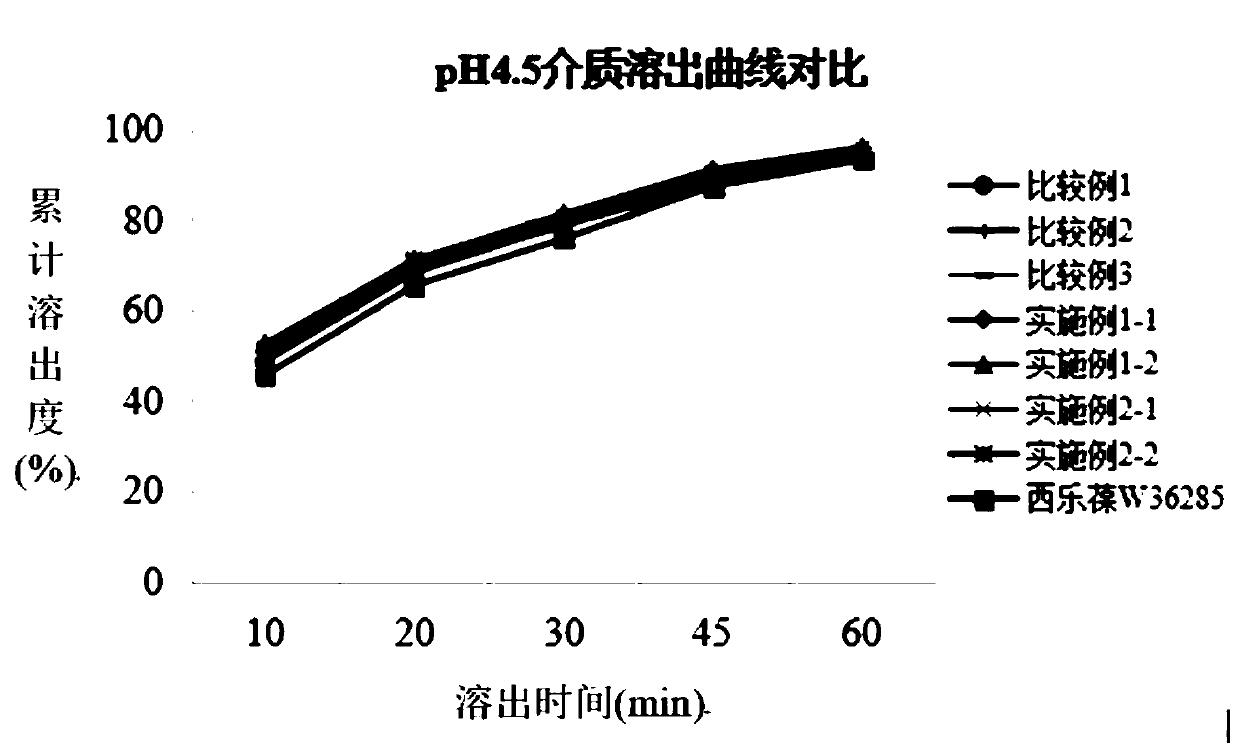

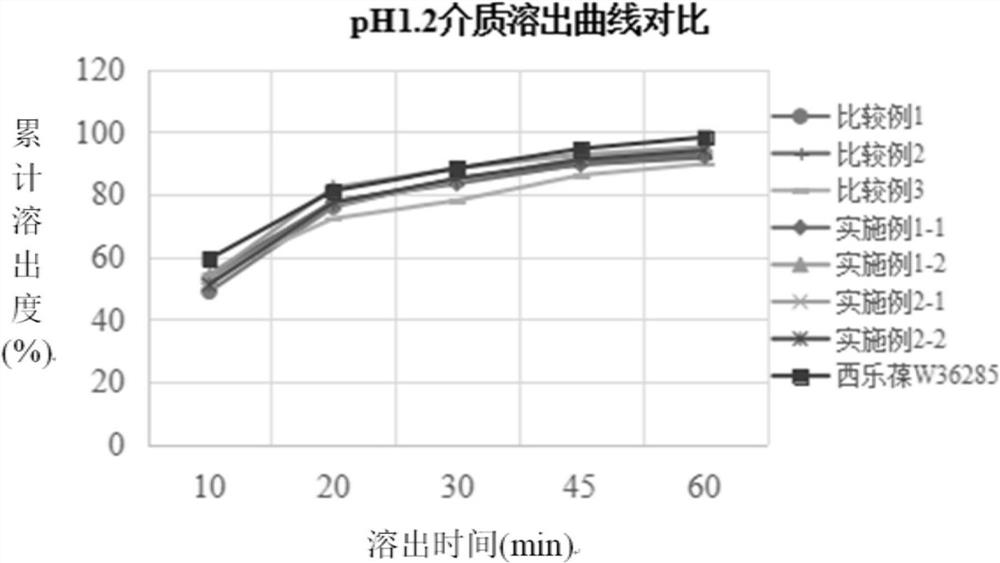

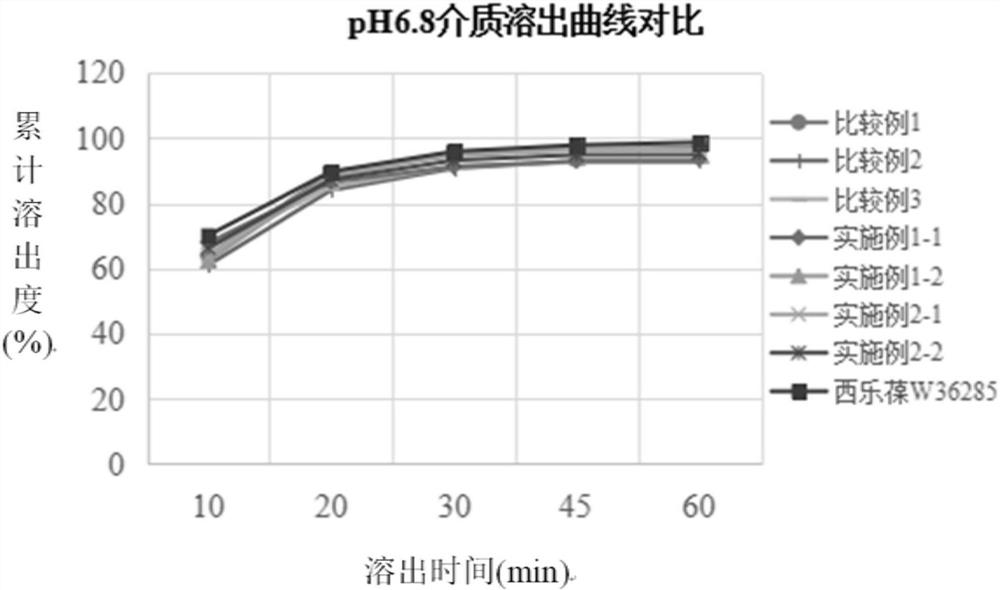

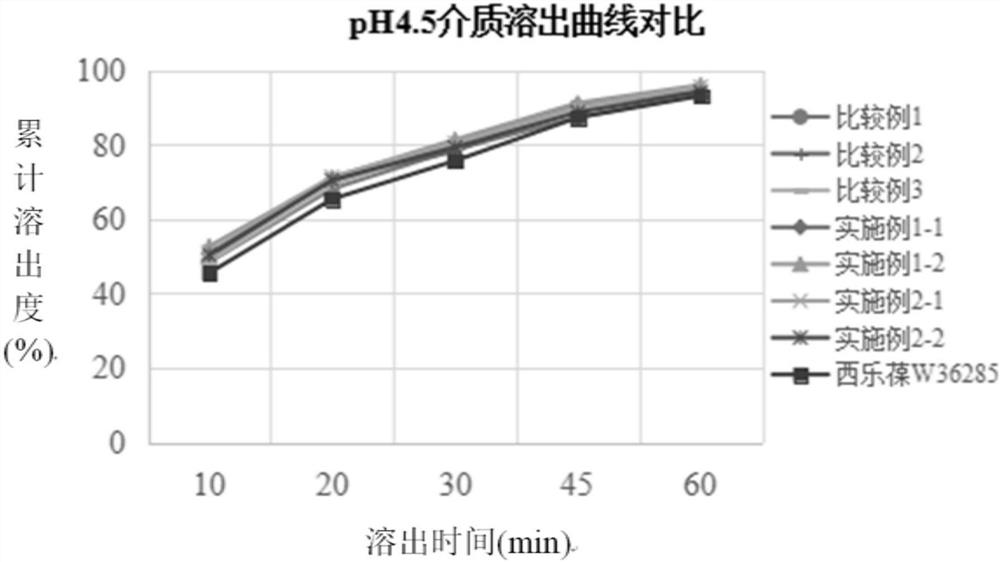

Solid dispersion method of celecoxib and preparation method of celecoxib capsules

ActiveCN110604722AEffective dispersionHigh densityOrganic active ingredientsPowder deliveryLACTOSE MONOHYDRATEMechanical milling

The invention provides a solid dispersion method of celecoxib and a preparation method of celecoxib capsules, and the solid dispersion method comprises the following steps: mixing the celecoxib with pharmaceutical adjuvants to obtain raw and auxiliary material mixed powder, and carrying out ultramicro jet milling and / or mechanical milling on the raw and auxiliary material mixed powder, wherein thepharmaceutical adjuvants at least comprise lactose monohydrate and lauryl sodium sulfate. The solid dispersion method disclosed by the invention not only overcomes the characteristic of poor preparation of a celecoxib preparation, but also solves the problem of slow dissolution of the celecoxib, and the preparation is good in stability, so that the preparation is consistent with an original developed preparation (Celebrex) in prescription and dissolution, and the quality consistency and bioequivalence of the celecoxib preparation and the original developed preparation (Celebrex) are ensured.

Owner:SHANDONG CHUANGXIN PHARMA RES & DEV

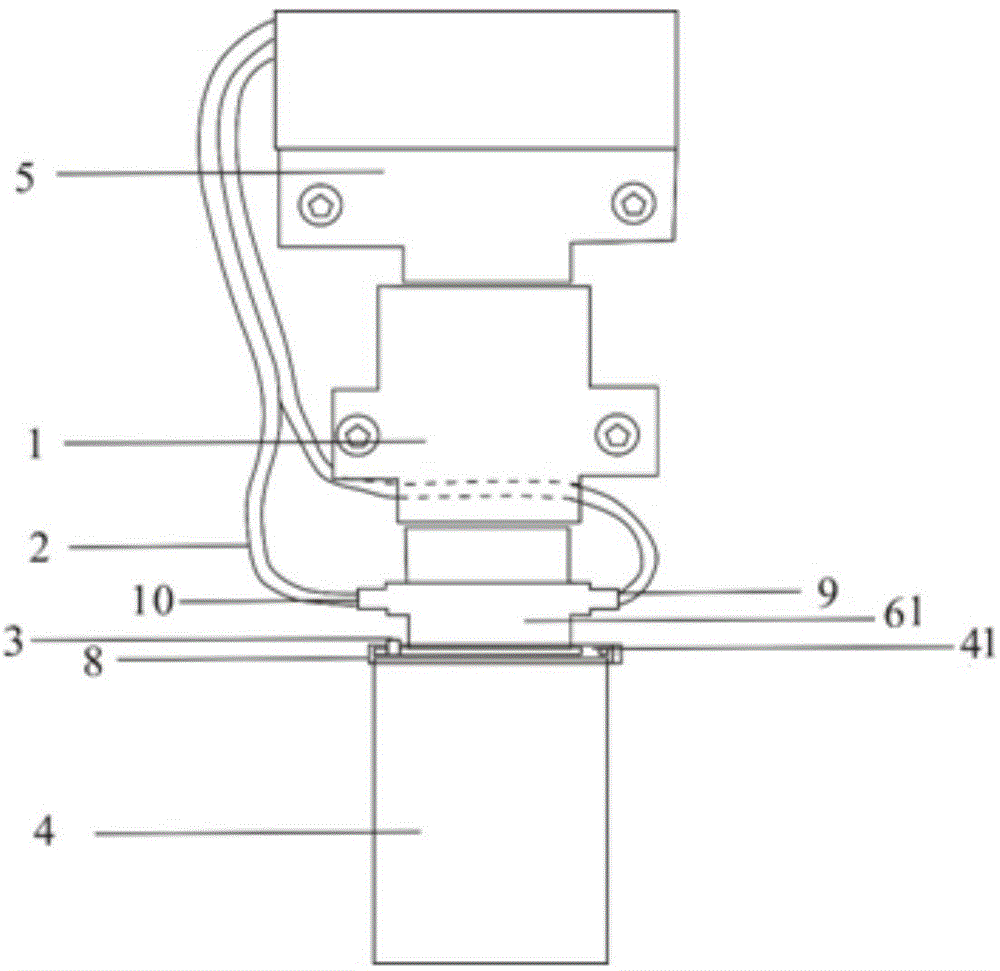

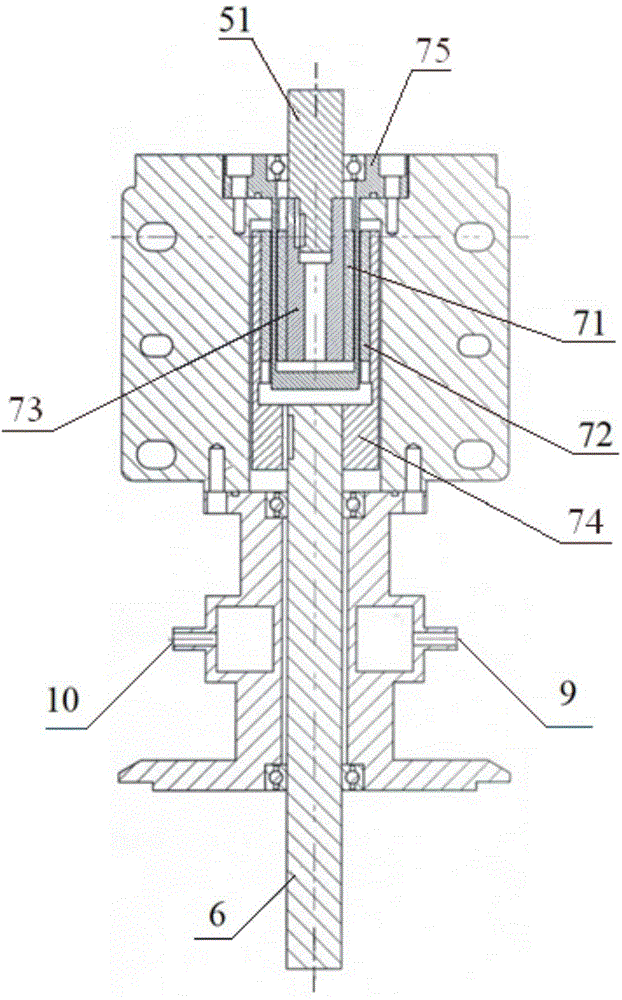

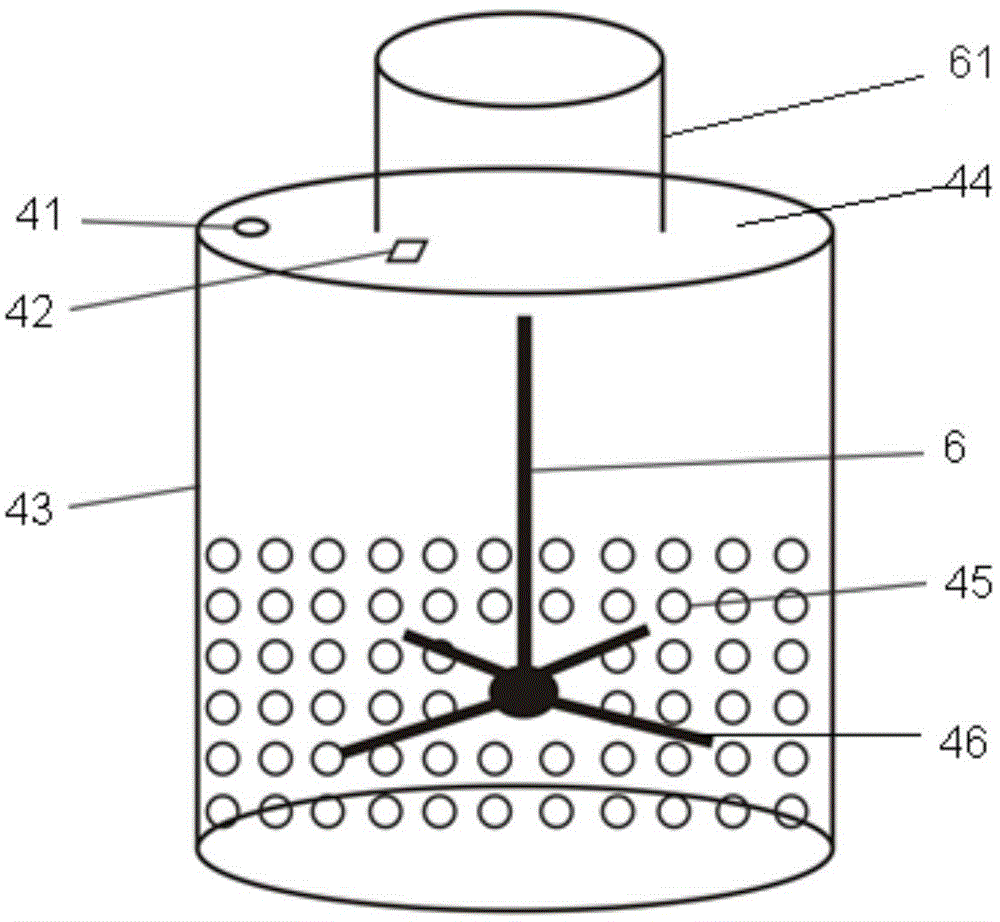

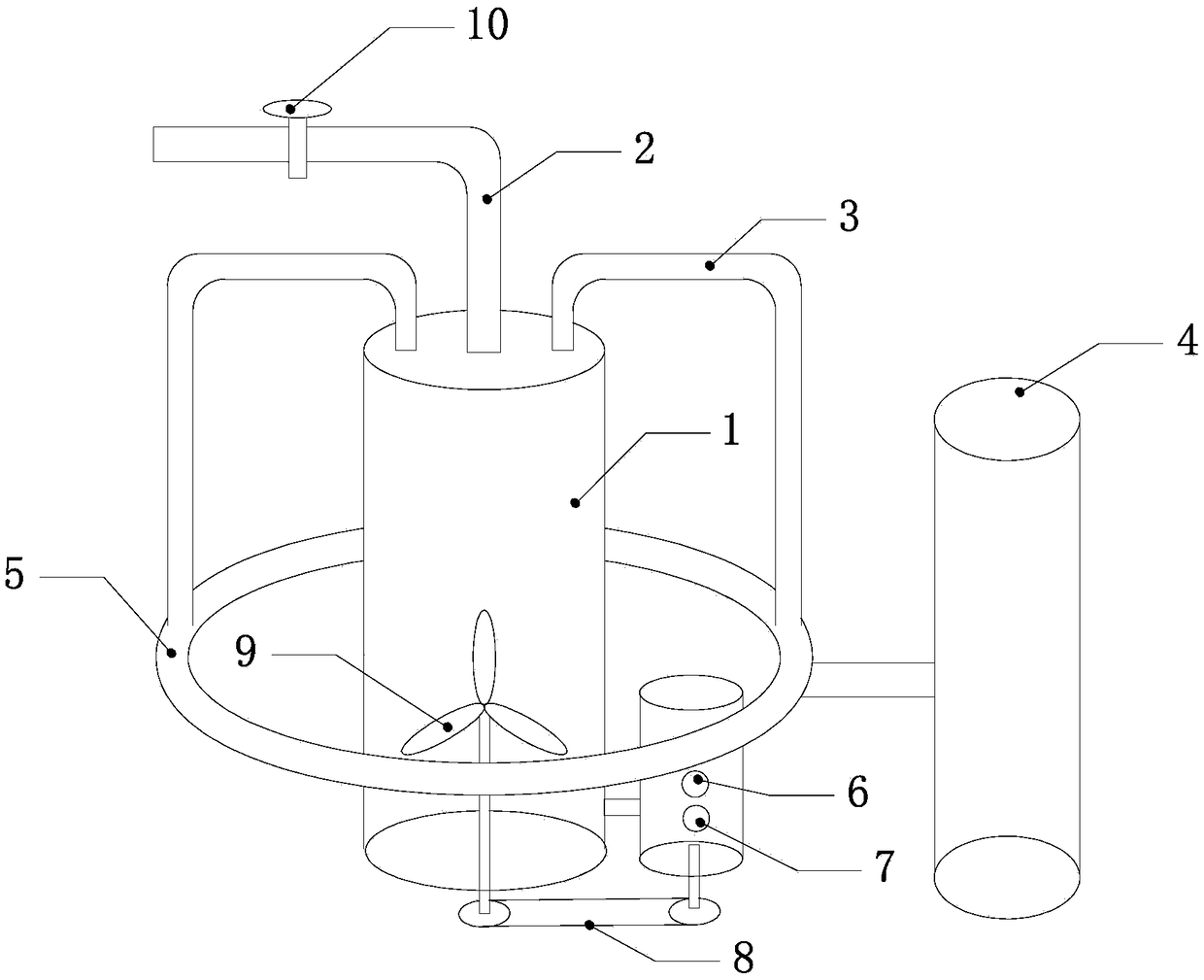

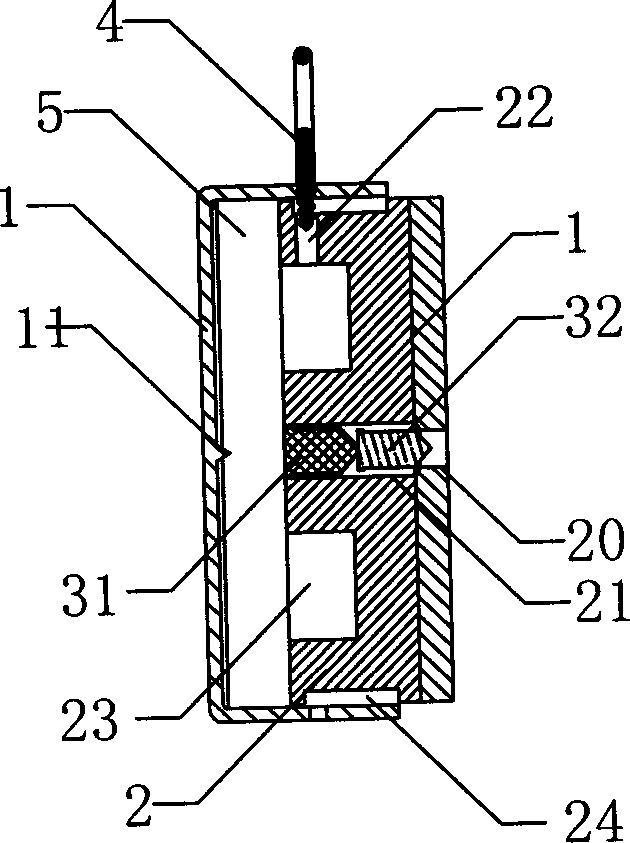

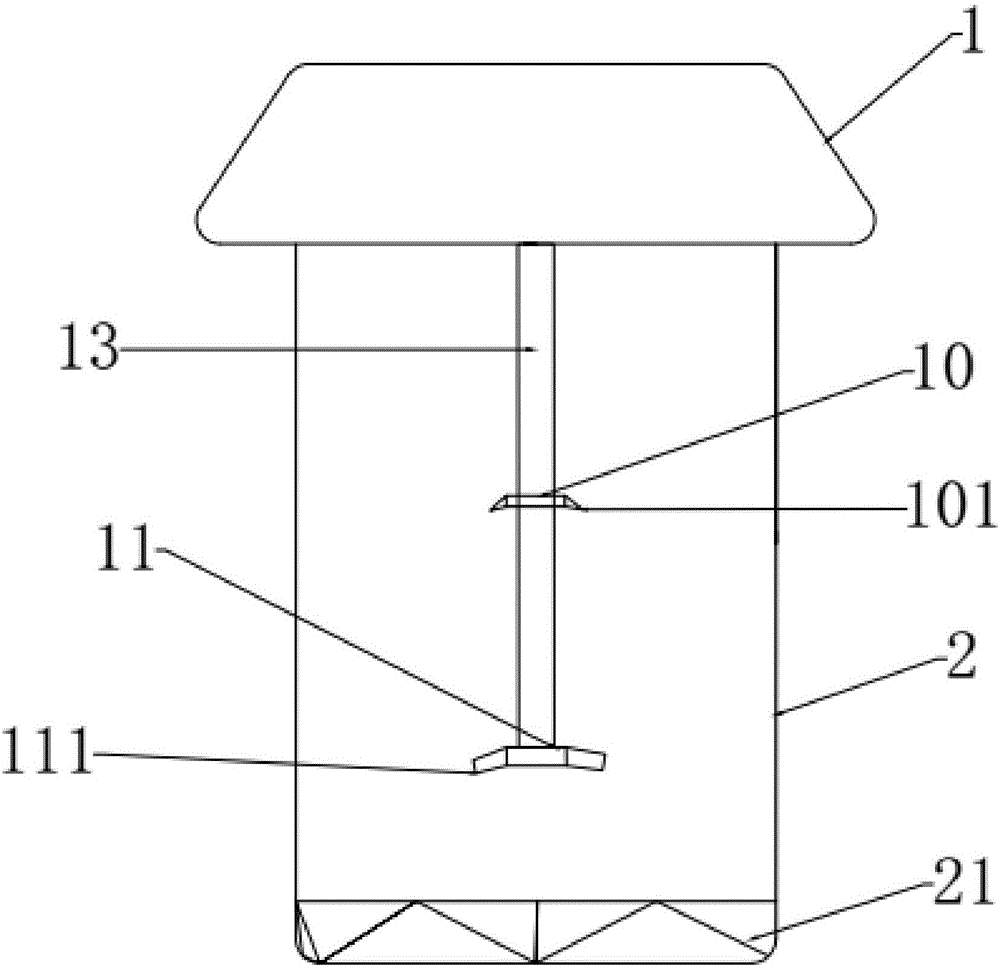

Airtight pulverizer and application thereof

ActiveCN104923352AAchieve airtightnessImprove experimental test accuracyGrain treatmentsMagnetic rotationCoupling

The invention discloses an airtight pulverizer and application thereof. The pulverizer comprises a sample smashing tank and a non-contact type torque transmission system. The non-contact type torque transmission system comprises a motor, a magnetic rotation shaft and a magnetic transmission coupler. The motor is connected with the magnetic rotation shaft and drives the magnetic rotation shaft to rotate through the magnetic transmission coupler. A shell is arranged outside the magnetic rotation shaft. The lower end of the magnetic rotation shaft extends out of the bottom of the shell and extends into the sample smashing tank. A stirring piece is arranged in the sample smashing tank. The magnetic rotation shaft is connected with the stirring piece and drives the stirring piece to act. The sample smashing tank is connected with the shell of the magnetic rotation shaft in a sealed mode. According to the pulverizer, through the magnetic transmission technology, the external torque transmission efficiency is kept, good sealing, enough power, high efficiency and good effects are achieved when a sample is smashed, operation is easy and convenient, and the airtight pulverizer is suitable for practical use. The gas content of a rock sample can be measured through the pulverizer.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

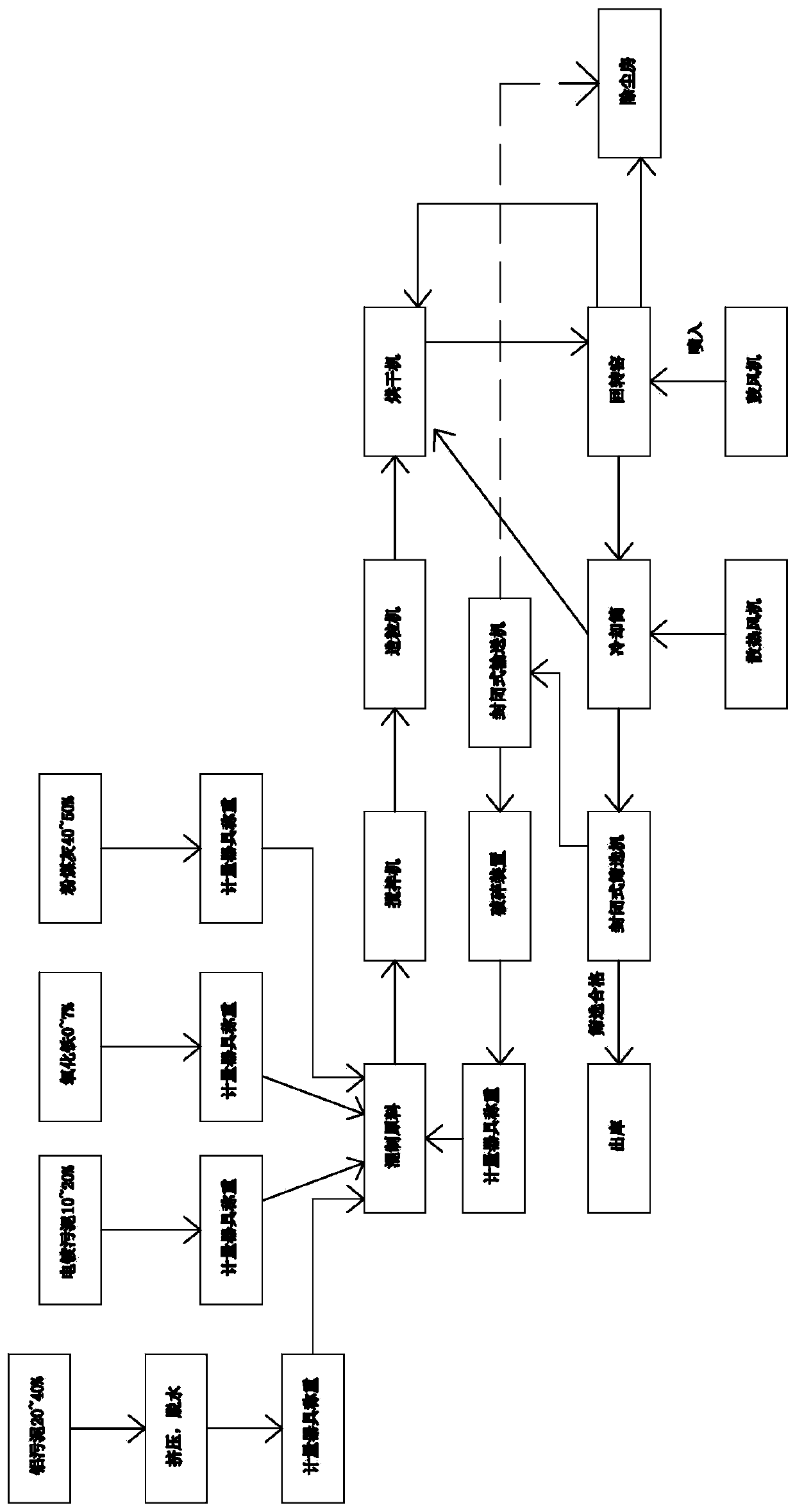

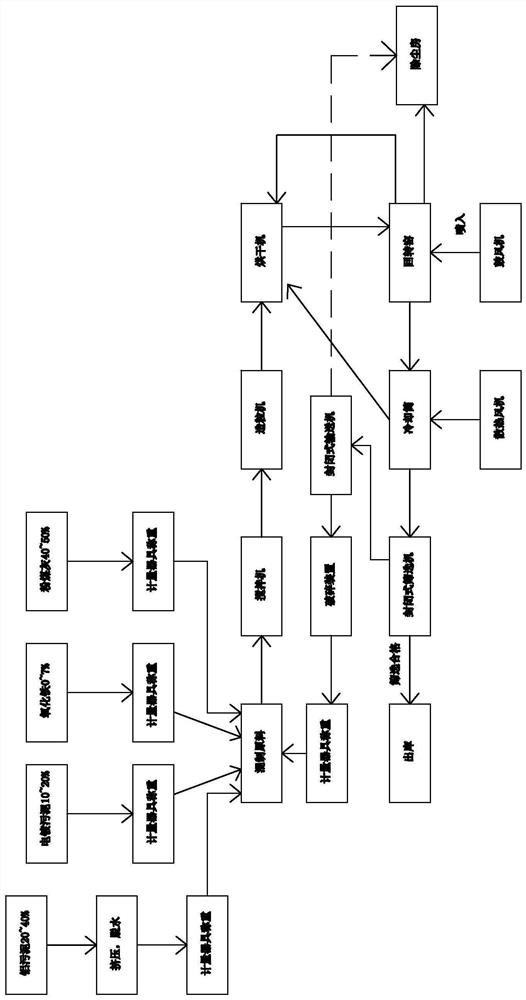

Preparation method of aluminum sludge ceramsite

The invention relates to the technical field of sludge waste utilization, and particularly relates to a preparation method of aluminum sludge ceramsite. The aluminum sludge ceramsite comprises following raw materials: electroplating sludge, aluminum sludge, iron oxide and fly ash. The preparation method comprises following steps: stirring raw materials by a stirrer, conveying the mixture into a granulator; then conveying the mixture into a dryer, conveying the ceramsite raw material into a rotary kiln for roasting; grading and screening by a closed screening machine; conveying waste materialsand ceramsite with a size smaller than the standard size to a crushing device by a closed conveyor; forcibly crushing the ceramsite by a crushing device, screening, conveying the powder to a mixed rawmaterial storage tank, weighing the powder by a gauge, and mixing the powder with the mixed raw materials. The wastes are reproduced and utilized, and the prepared ceramsite can be applied to roadbed materials, concrete aggregates and the like, and is wide in application range. The mixed material is formed and made into blocks; after the ceramic manufacturing, the broken ceramsite is crushed, conveyed and recycled by utilizing a crushing device, through advanced processing, the recycling rate of waste materials is increased, and the production benefit is further improved.

Owner:FUJIAN MINFA ALUMINUM

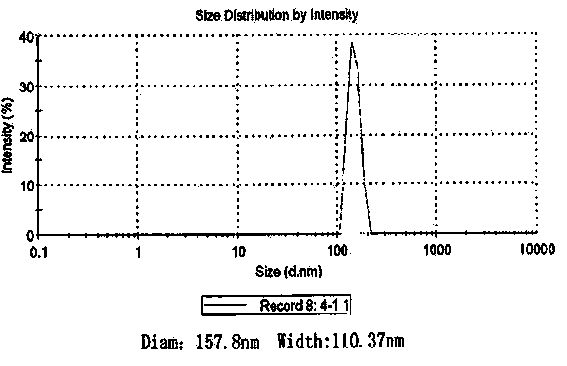

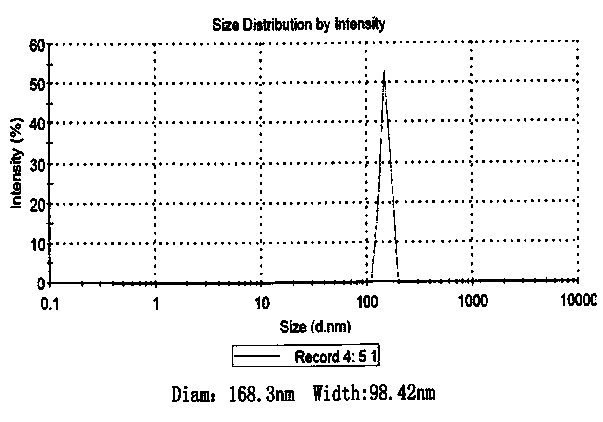

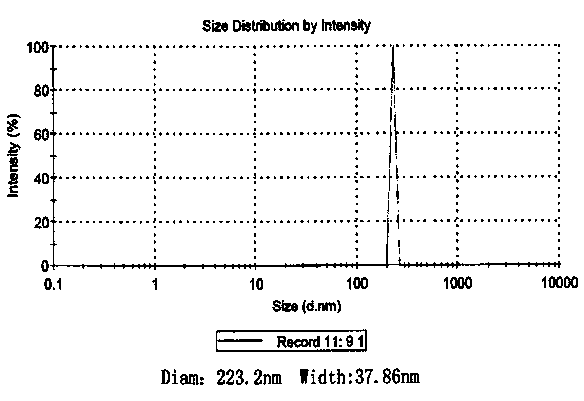

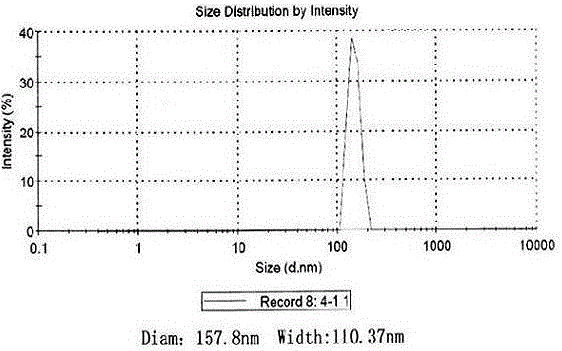

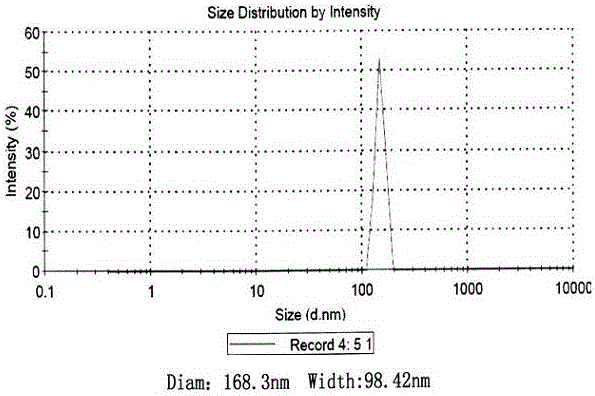

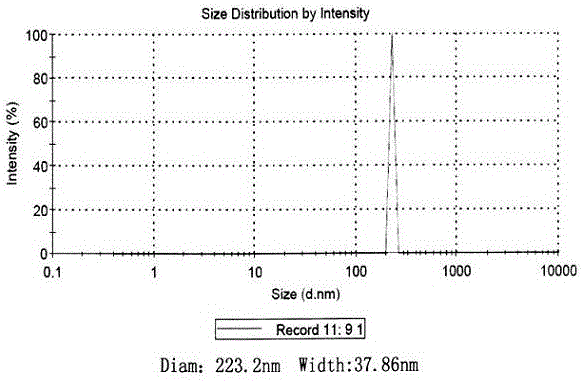

Technology of preparing nanometer traditional Chinese medicine material by liquid-phase shear dispersion

ActiveCN103623012AImprove bioavailabilityGuaranteed full powderUnknown materialsFood preparationTraditional Chinese medicineLiquid phase

The invention discloses a technology of preparing a nanometer traditional Chinese medicine material by liquid-phase shear dispersion. According to the technology, a traditional Chinese medicine material is used as a raw material, and the nanometer traditional Chinese medicine material having a particle diameter of 50-300 nm is rapidly prepared by utilization of a high-shear dispersion smashing technology. The traditional Chinese medicine material can be prepared into solid nanoparticles and also can be prepared into nanometer traditional Chinese medicine suspension.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

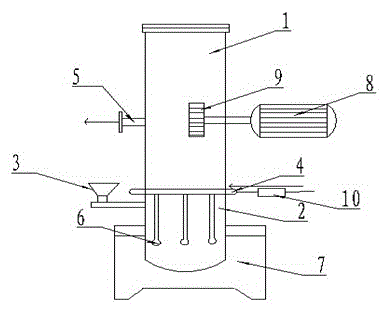

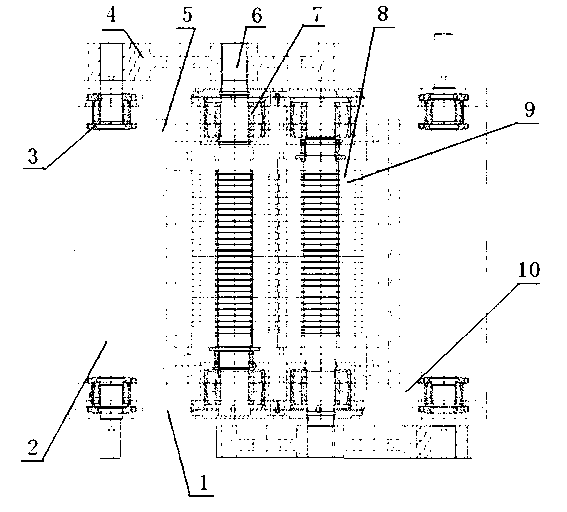

Multi-cylinder hydraulic cone crusher

InactiveCN106111246AIncrease frictionShort crushing timeGrain treatmentsHydraulic cylinderCrushed stone

The invention relates to a multi-cylinder hydraulic cone crusher. The multi-cylinder hydraulic cone crusher is characterized in that a material inlet is formed in the upper end of an upper conical lining disc; a hollow shaft is arranged on the oil inlet; a large belt wheel is fixed on the outer end of the hollow shaft; a small belt wheel is arranged on a forward-rotation motor; the large belt wheel is connected with the small belt wheel through a belt; the lower end of a lower conical lining disc is fixedly provided with multiple hydraulic cylinders which are arranged uniformly; the lower ends of the hydraulic cylinders are fixedly provided with a rotation plate; a bearing and a leaking hole I are arranged on the rotation plate; a leaking hole II corresponding to the leaking hole I is formed in a support; a reversed-rotation motor is fixed on the support; one end of a rotary shaft is fixed on the reversed-rotation motor; the rotary shaft is sleeved in the bearing; and the other end of the rotary shaft is vertically and movably arranged in a guide hole. According to the multi-cylinder hydraulic cone crusher, the upper conical lining disc and the lower conical lining disc simultaneously rotate in opposite directions, so that the friction force of the crusher is increased; the time for crushing stone materials is shorter; and crushing efficiency is improved to a great extent.

Owner:CHENGDU DAHONGLI MACHINERY

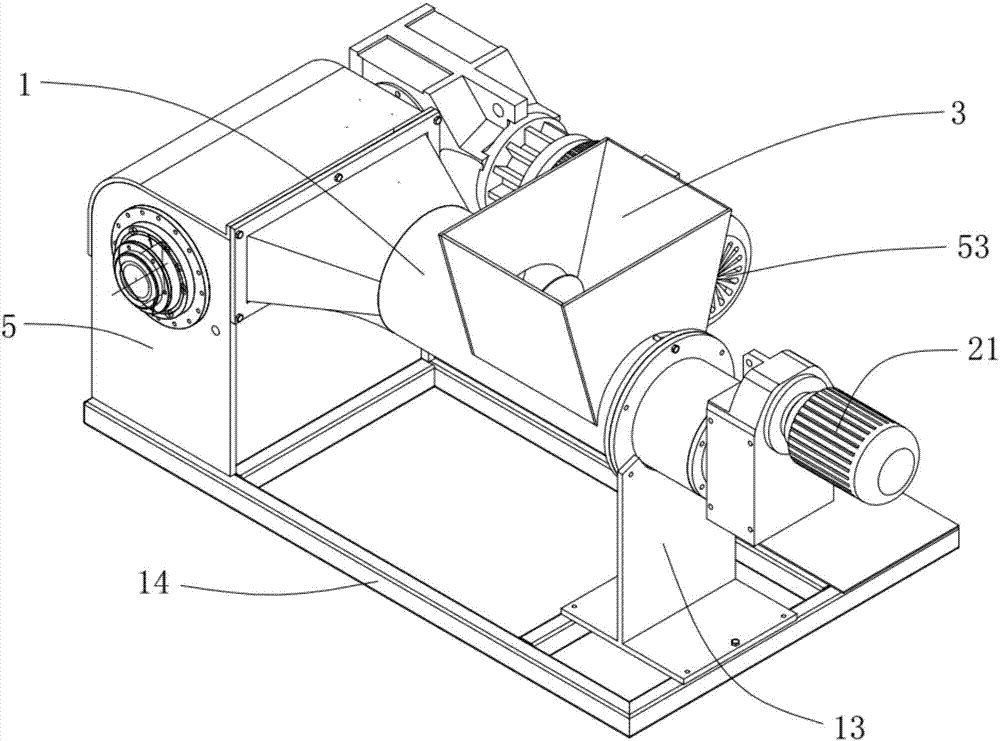

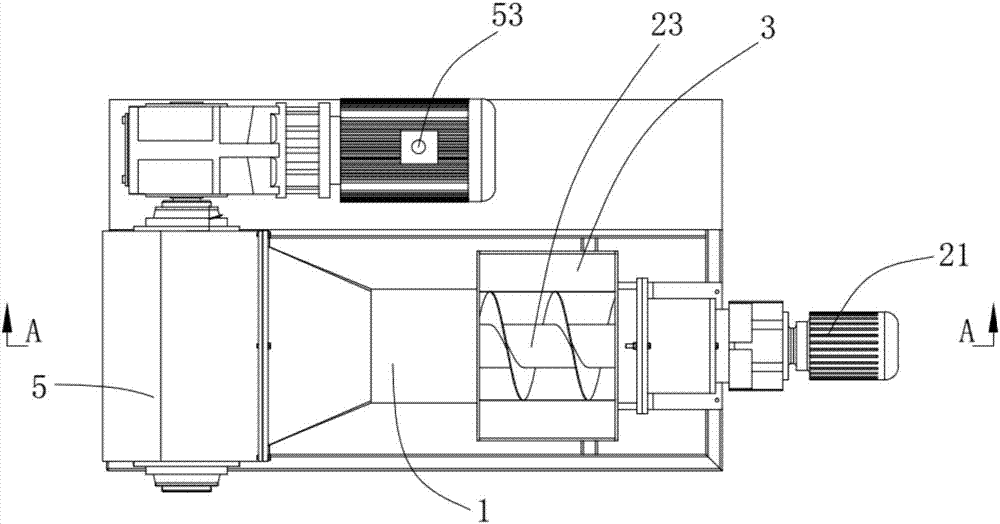

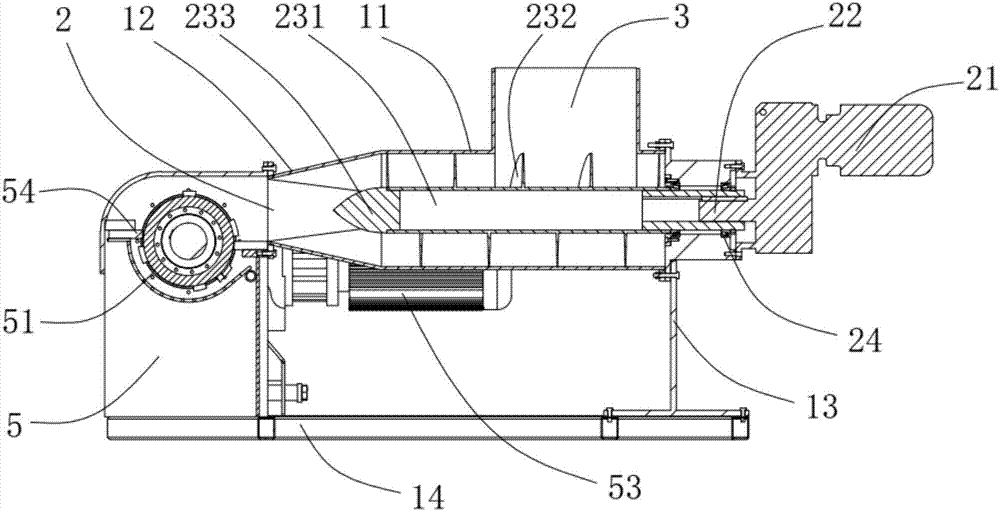

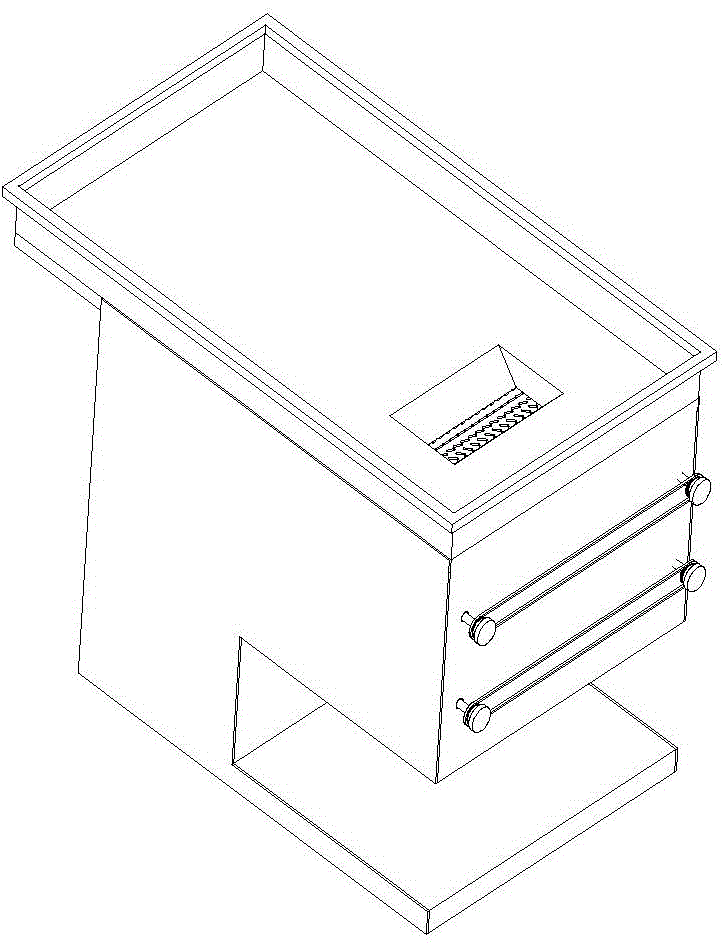

Crushing machine

The invention relates to a crushing machine processing device, in particular to a spiral feeding type fine crushing machine. The crushing machine comprises a spiral machine barrel provided with a discharging opening, a feeding opening is formed in the upper portion of the spiral machine barrel, a gear motor is arranged at the back end and is fixedly connected with a spiral conveying shaft inside the spiral machine barrel, the spiral conveying shaft comprises a screw and a paddle wound around the screw, and at least a part of the paddle is located below the feeding opening; a guide head is further arranged at the end of the spiral conveying shaft, during matching, the screw and the paddle wound around the screw are arranged in a cylindrical inner cavity of a feeding section, and the guide head is arranged in the cylindrical inner cavity of a guide section; and a crushing device is further connected to the discharging opening and comprises a crushing cavity and a crushing cutter arranged in the crushing cavity. Constant-speed feeding can be guaranteed; and continuous feeding is carried out through the screw, and traditional feeding discontinuity is avoided. Dust flying at the feeding opening during transferring is avoided while spiral material transferring is carried out.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

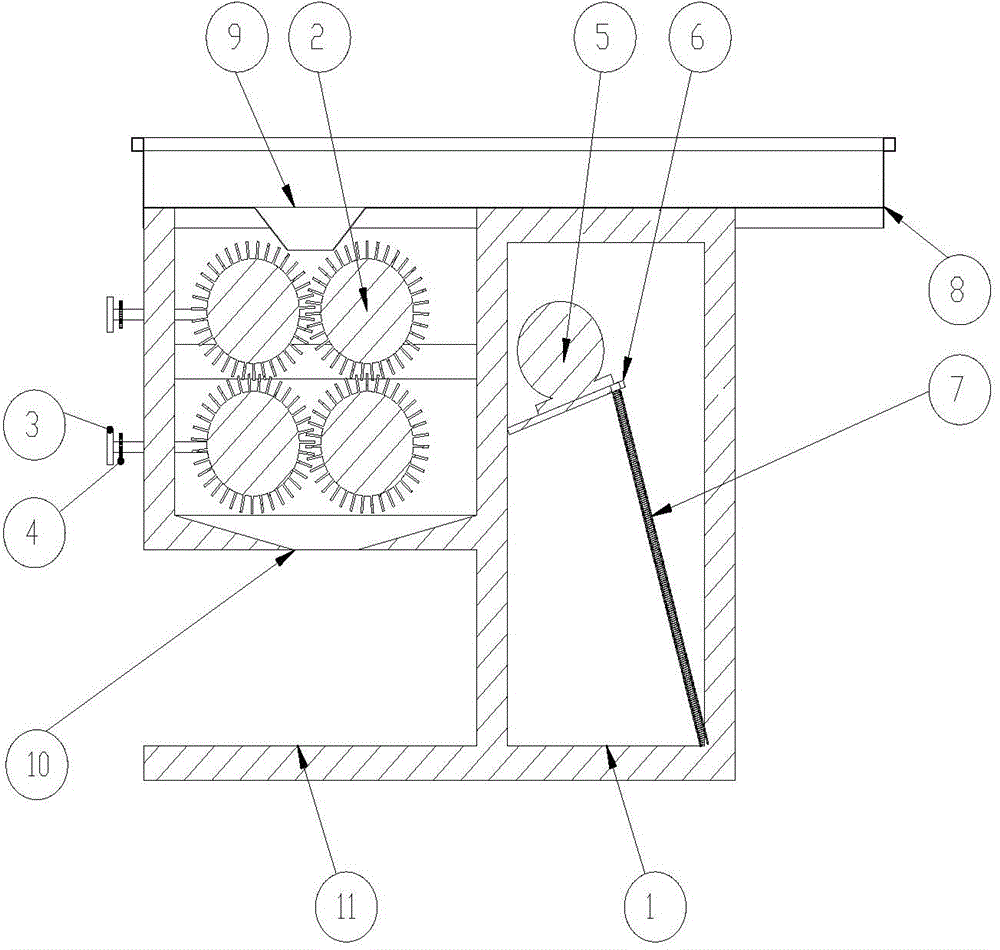

Full-automatic meat shredding machine

The invention discloses a full-automatic meat shredding machine which comprises four needle tooth rollers in two layers, wherein each layer comprises two needle tooth rollers; a motor is arranged on a supporting table and drives the needle tooth rollers to rotate in a meshed manner; a feeding opening and a discharging opening are respectively formed in positions, which correspond to the middle parts, of the upper and lower layers of needle tooth rollers. The full-automatic meat shredding machine shreds meat through a roller needle with the two layers of longitudinal and transverse needle tooth rollers; the shredding time is short; meat can be thoroughly shredded, and shredded meat can be formed for one time; the time and the labor are saved; the efficiency is obviously improved by over 40 percent.

Owner:大连拓新能源有限公司

Preparation method of spirulina protein powder

InactiveCN108794565ASimple processHigh nutritional valuePeptide preparation methodsHigh energyHigh pressure

The invention belongs to the technical field of biochemical separation and purification, and relates to a preparation method of spirulina protein powder. The method comprises the following steps: firstly crushing spirulina powder, uniformly mixing the spirulina powder with 8 to 10 times of water, and then laying spirulina powder fluid into a high pressure homogenizer to perform homogenizing treatment on the fluid, so as to release spirulina protein subjected to wall breaking, pressing the spirulina protein subjected to wall breaking to form protein fluid, unfreezing and extracting the proteinfluid, laying the protein fluid to an air flotation separation and purification device to perform purity extraction, and finally drying the purified protein fluid, so as to obtain the spirulina protein powder. The method solves the problems of long process route, long extraction period, high energy consumption and low production efficiency of a preparation method of spirulina protein powder in theexisting prior.

Owner:胡梦丽

Airflow crushing device of fluidized bed

The invention discloses an airflow crushing device of a fluidized bed. The device comprises a supporting base and a body. A grading cavity, a crushing cavity, a raw material feed inlet, a raw material discharging port, a compressed air annular pipe and high-pressure nozzles are arranged on the body. The compressed air annular pipe surrounds the body of the airflow crushing device of the fluidized bed and is connected with the high-pressure nozzles of the airflow crushing device of the fluidized bed through a guide pipe. The airflow crushing device has the advantages of being short in crushing time, simple in structure, low in noise and free of vibration, and is low in energy consumption. Compared with airflow grinding of other types, energy can be saved by one third.

Owner:太仓市友联干燥粉碎设备有限公司

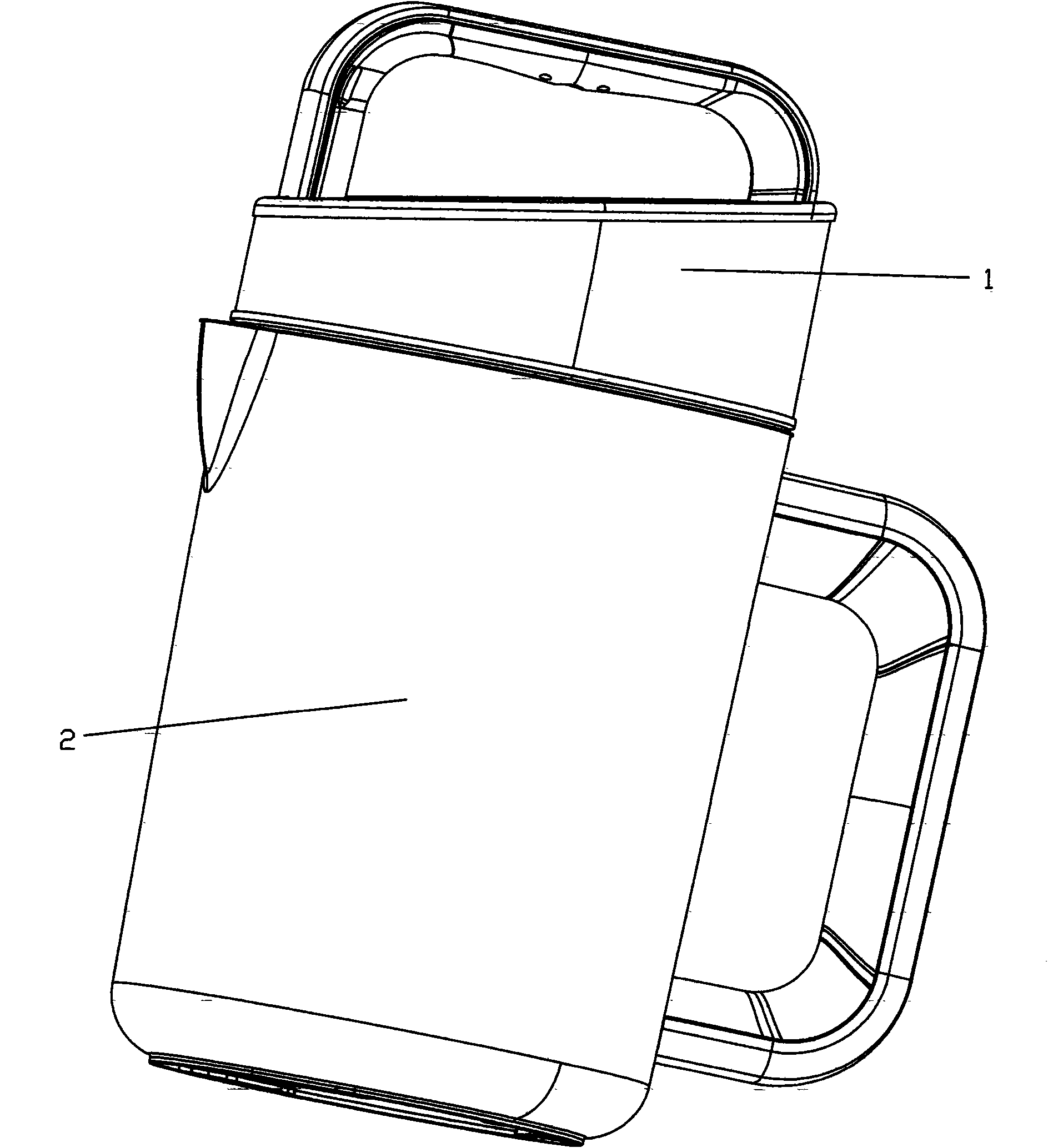

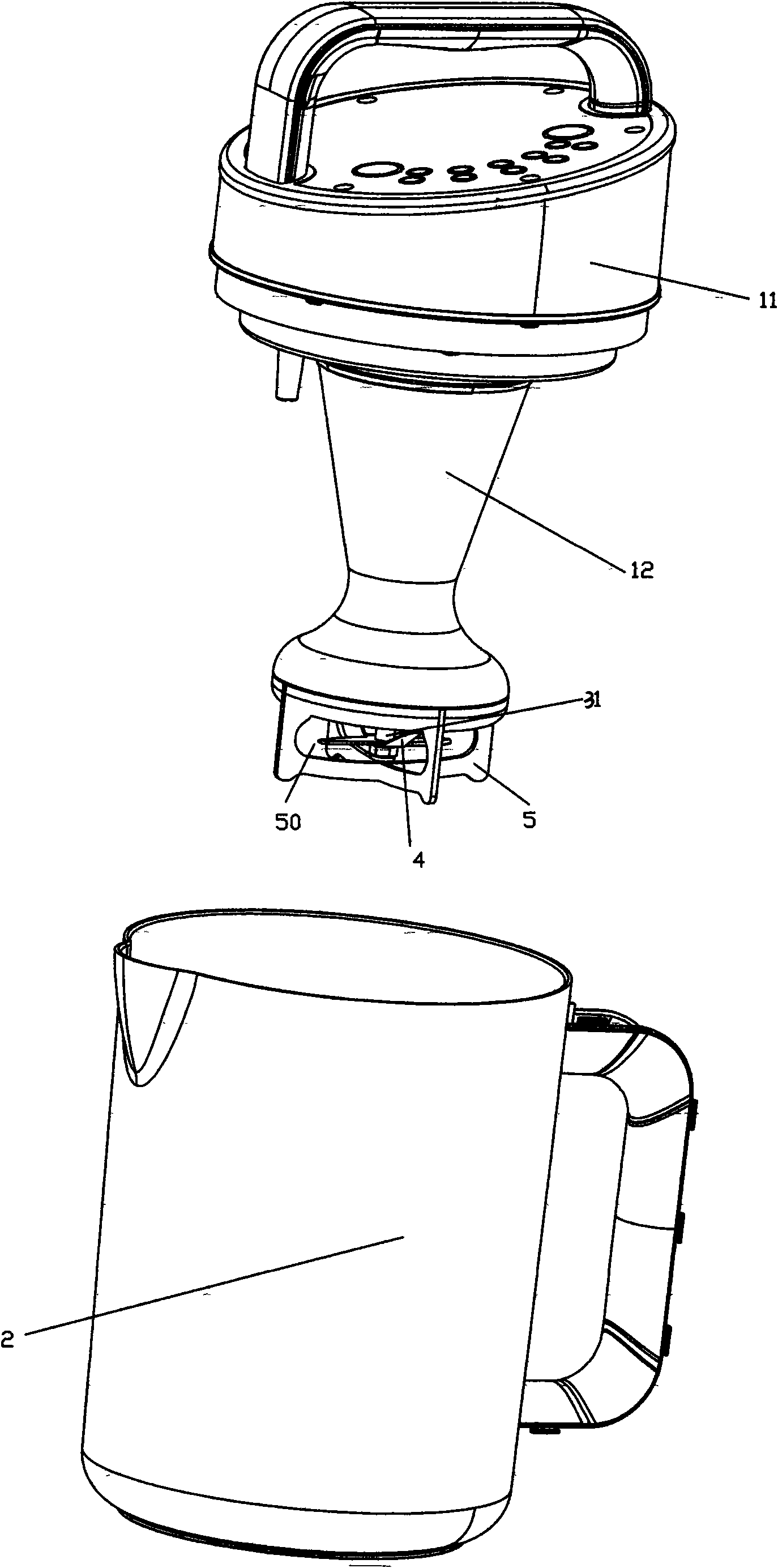

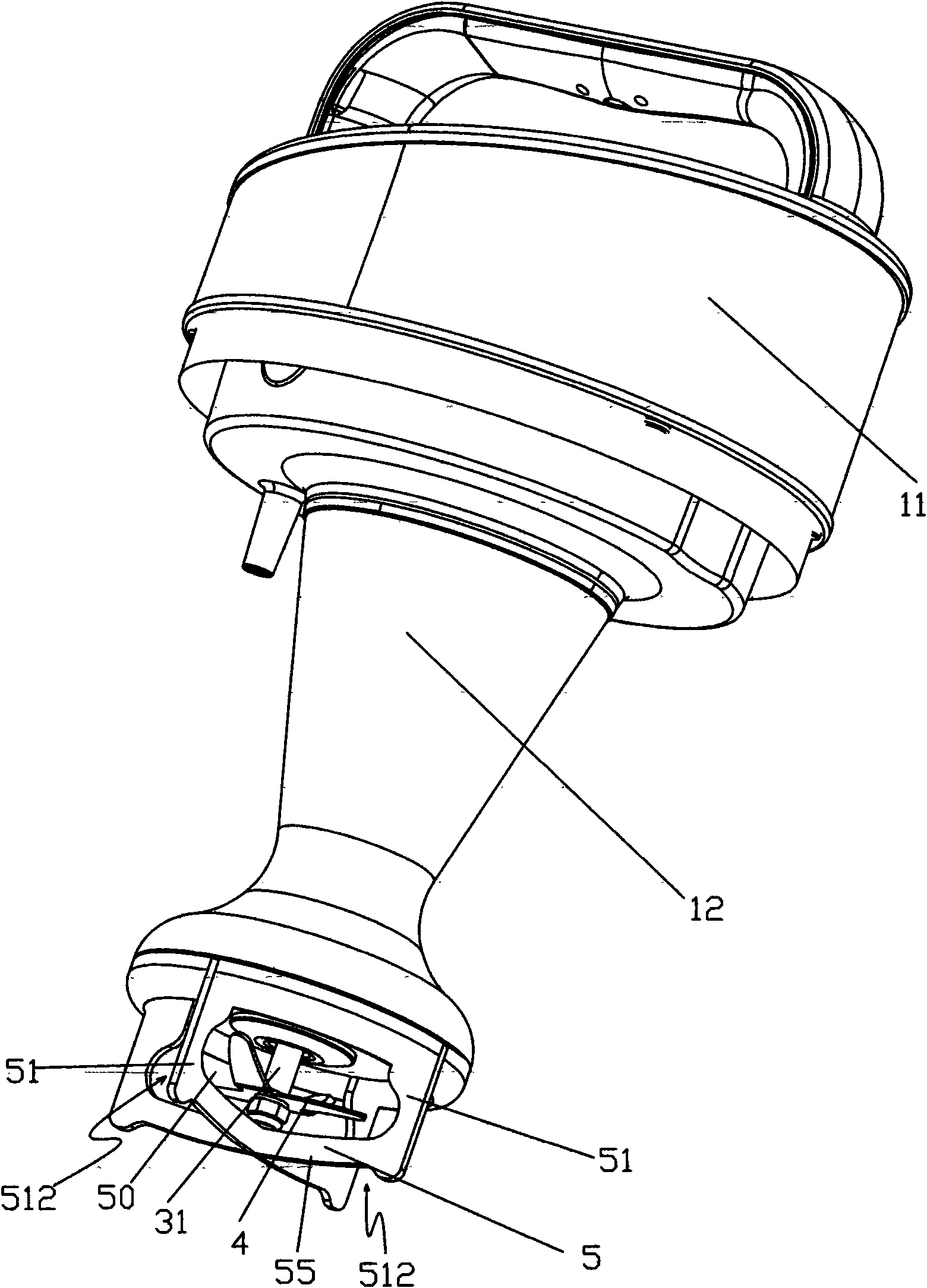

Soybean milk machine

ActiveCN102007971ADelicate tasteAct as a spoilerBeverage vesselsMilk substitutesElectricityDrive shaft

The invention discloses a soybean milk machine. The soybean milk machine comprises a machine head and a barrel body, wherein a control circuit board and an electric motor are arranged in the machine head; the machine head comprises a machine head upper cover and a machine head lower cover; and the lower end of the electric motor transmission shaft of the electric motor extends out of the machine head lower cover and extends into the barrel body, and is provided with a pulping tool. The soybean milk machine is characterized in that: a spoiler is arranged between the machine head lower cover and the inner bottom of the barrel body; a spoiling space is formed in the spoiler; and the pulping tool 4 extends into the spoiling space. The spoiler is arranged between the machine head lower cover and the inner bottom of the barrel body, and comprises two or more spoiling plates and spoiling ribs which are connected to the lower ends of the plurality of spoiling plates. Both the spoiling plates and the spoiling ribs of the spoiler can perform spoiling function, after the spoiling effect is strengthened, the pulping effect is further improved, and the pulping time can be greatly shortened, so that the pulping time is short in the process of producing soybean milk, time and electricity are saved, and high-quality soybean milk with fine and smooth mouthfeel is produced.

Owner:ZHONGSHAN MESTER IND

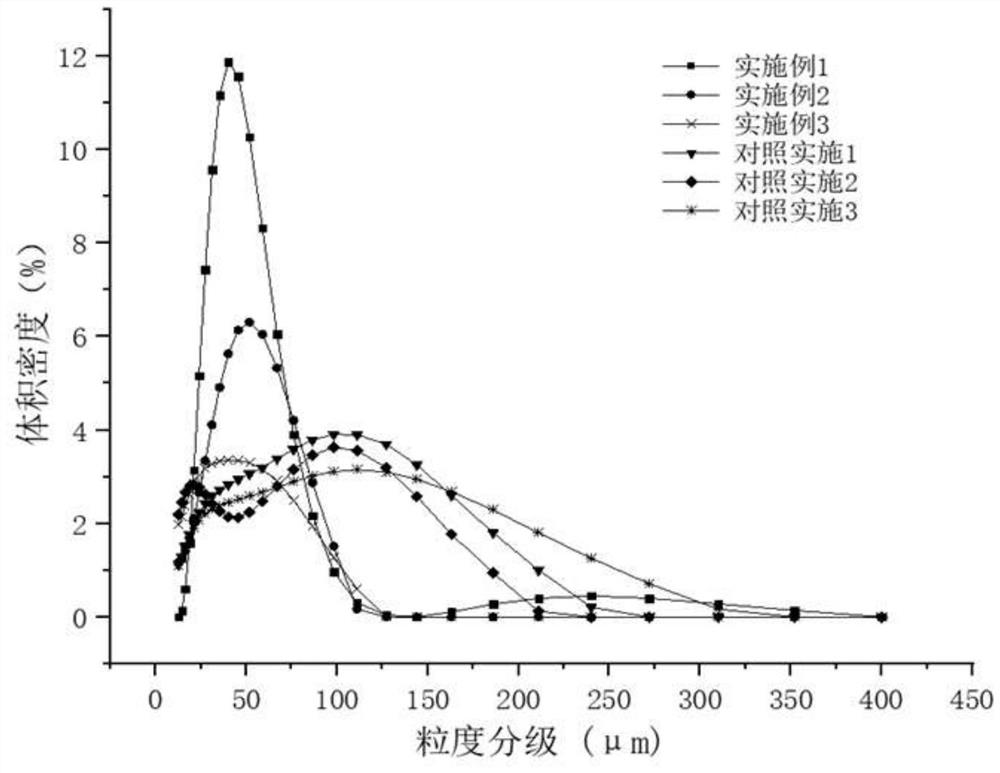

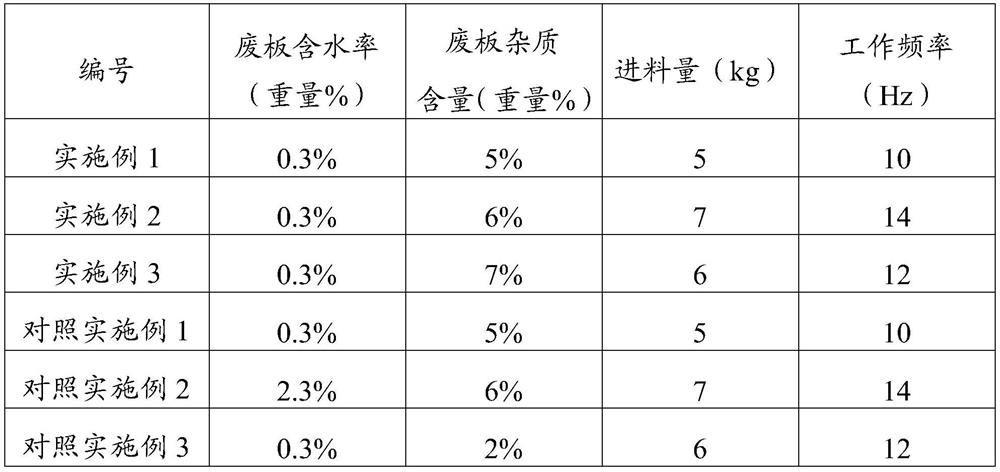

Preparation method of gypsum board coagulant and gypsum board coagulant prepared by preparation method

InactiveCN111606592AAchieve recyclingLow costSolid waste managementProcess engineeringWaste material

The invention discloses a preparation method of a gypsum board coagulant. The raw material of the coagulant is waste generated during gypsum board production; the gypsum board coagulant is prepared after the waste is sent into an impact mill to be crushed. The invention also discloses application of the gypsum board coagulant prepared by the preparation method of the gypsum board coagulant in a gypsum board. According to the preparation method of the gypsum board coagulant provided by the invention, the waste is used as the raw material of the coagulant, so that the cyclic utilization of the waste is realized, the cost is saved, benefits are brought to a factory, and the requirements of environmental protection are met; the gypsum board coagulant prepared by utilizing the impact mill is smaller in volume weight and particle size distribution and larger in specific surface area, so that the coagulant has a better coagulation accelerating effect to meet production requirements.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

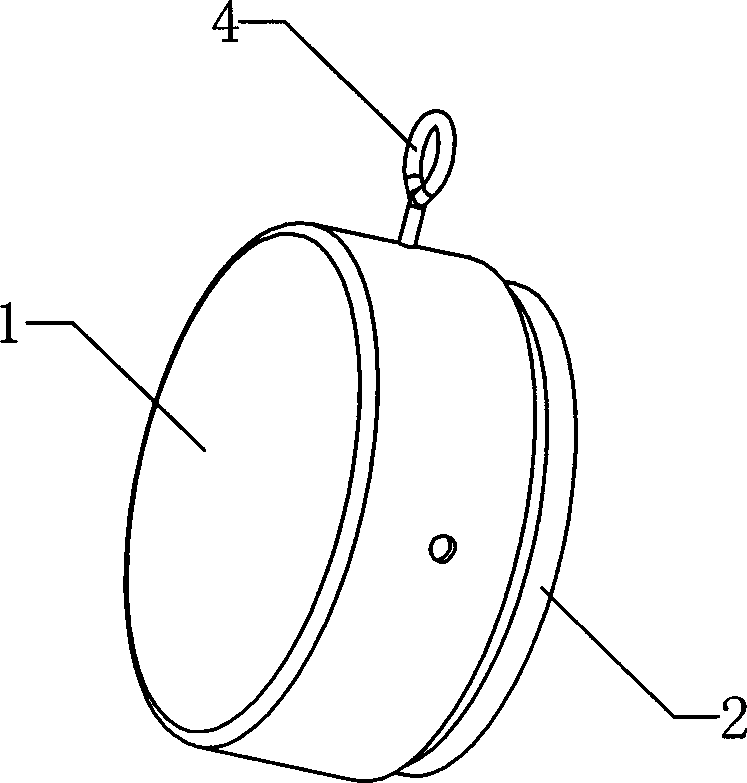

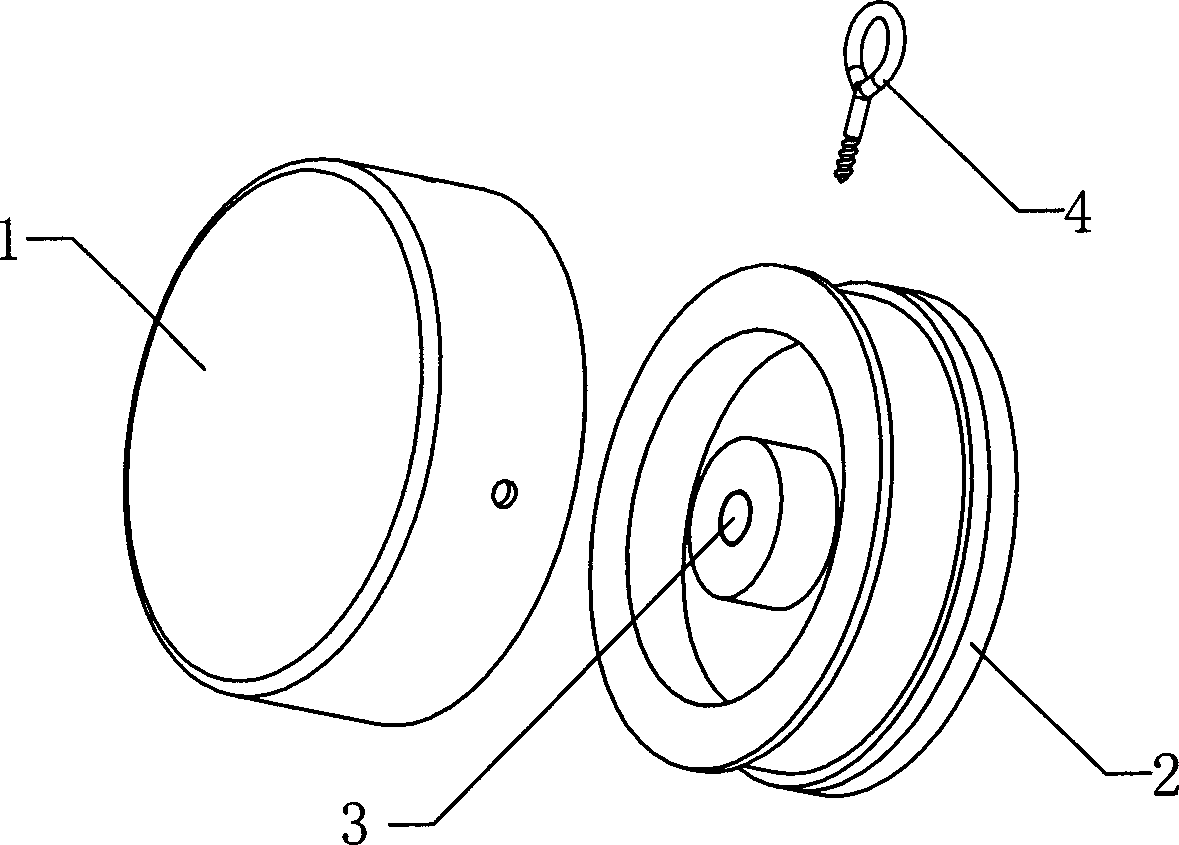

Glass smashing device for emergent escape

ActiveCN103157201ABig impactIncrease the probability of emergency escapePedestrian/occupant safety arrangementBuilding rescueEscape rateEngineering

The invention discloses a glass smashing device for emergent escape. The device comprises a cylindrical cover body and a cylindrical internal piece, wherein an opening is formed in one end of the cylindrical cover body, and the cylindrical internal piece is arranged in the cover body in a sliding mode. A nail point is arranged on the inner surface of the end portion of the cover body in a protruding mode. A through hole is formed in the position, corresponding to the nail point, of the internal piece. A nail component which can be abutted against the nail point position is arranged in the through hole. An inner flange is arranged at the tail end of the through hole. The glass smashing device for the emergent escape is small in size, light in weight, capable of being fixed on the surface of glass directly and short in smashing time, the glass can be smashed when the device beats the glass, and therefore the escape rate in emergency circumstances can be increased greatly.

Owner:丘学文

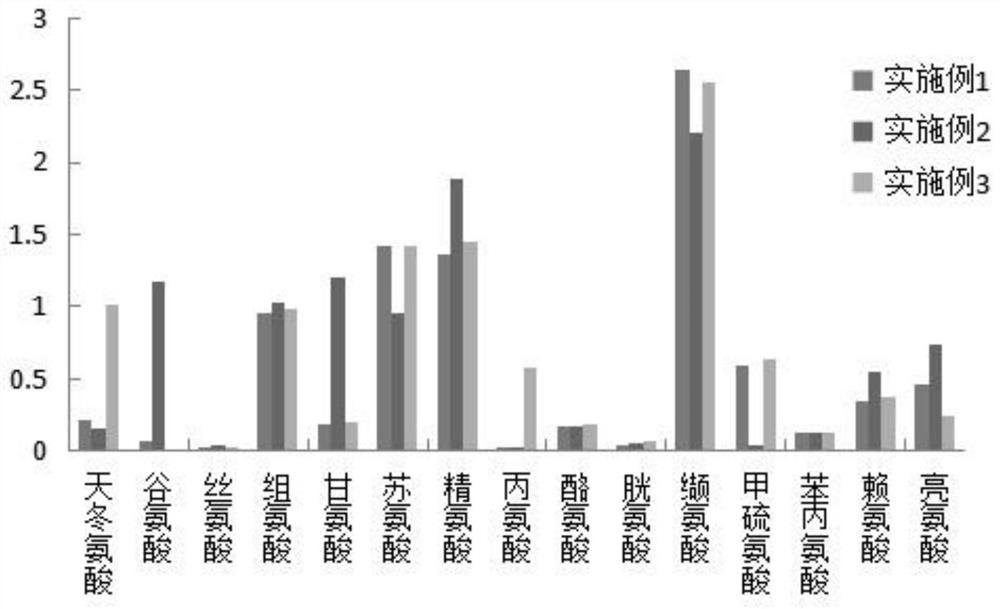

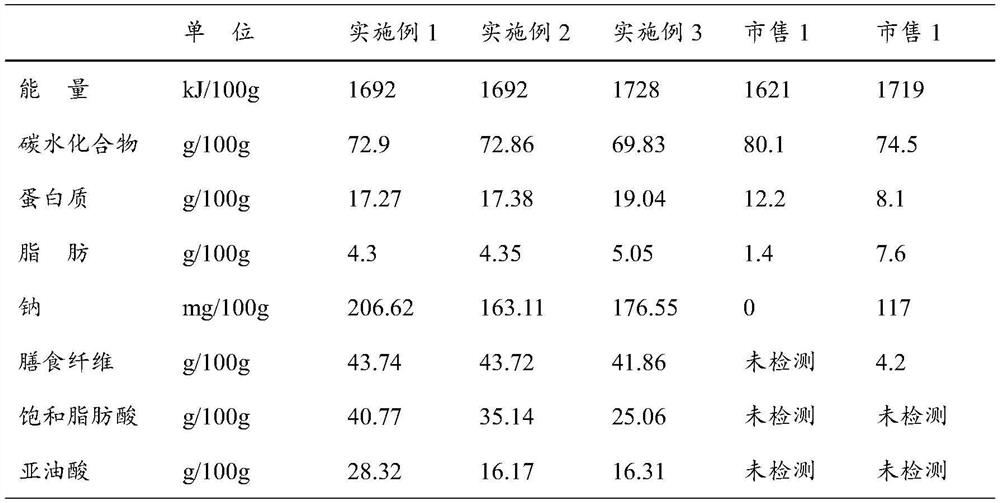

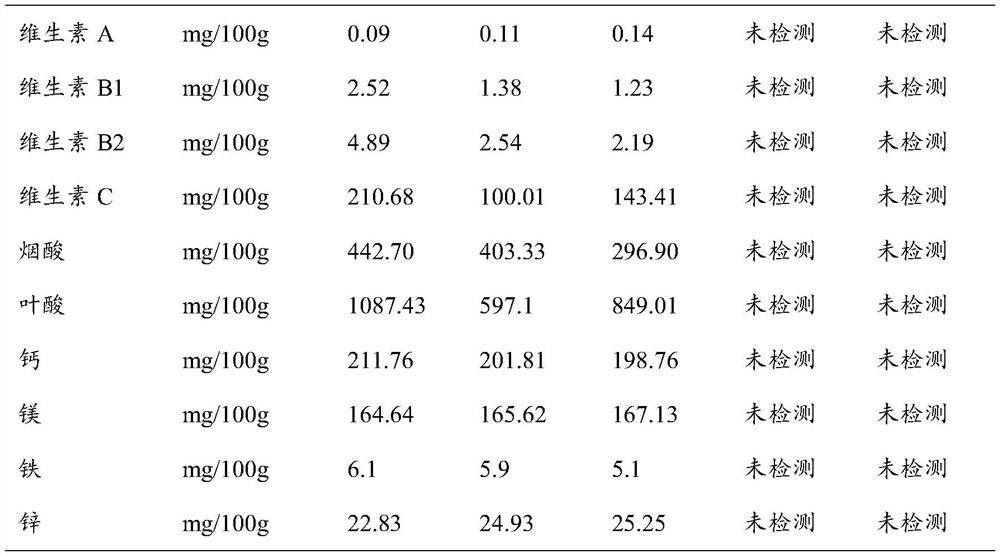

Meal replacement powder containing agriophyllum squarrosum as well as preparation method, edible method and application thereof

InactiveCN112189842AHigh protein contentIncrease satietyFood ingredient functionsBiotechnologyPumpkin seed

The invention relates to the field of food processing, in particular to meal replacement powder containing agriophyllum squarrosum as well as a preparation method, an edible method and application thereof. The meal replacement powder comprises the following components by mass: 18-24 parts of agriophyllum squarrosum powder, 12-20 parts of soybean protein isolate powder, 12-20 parts of whey proteinpowder, 1-5 parts of inulin, 1-5 parts of coix seed powder, 1-5 parts of red bean powder, 1-10 parts of stir-fried white kidney bean powder, 3-5 parts of konjaku flour, 1-5 parts of Chinese wolfberrypowder, 1-5 parts of Cistanche powder, 1-5 parts of oat powder, 2-10 parts of quinoa powder, 1-5 parts of corn grits powder, 1-5 parts of melon seed powder, 1-3 parts of perilla seed powder and 0.2-0.5 parts of sesame powder. The meal replacement powder provided by the invention is a meal replacement product which is low in carbohydrate content, high in protein content, good in satiety and good innutritional function, which can meet the needs of weight control group or special group (diabetes patients).

Owner:宁夏农林科学院农业生物技术研究中心

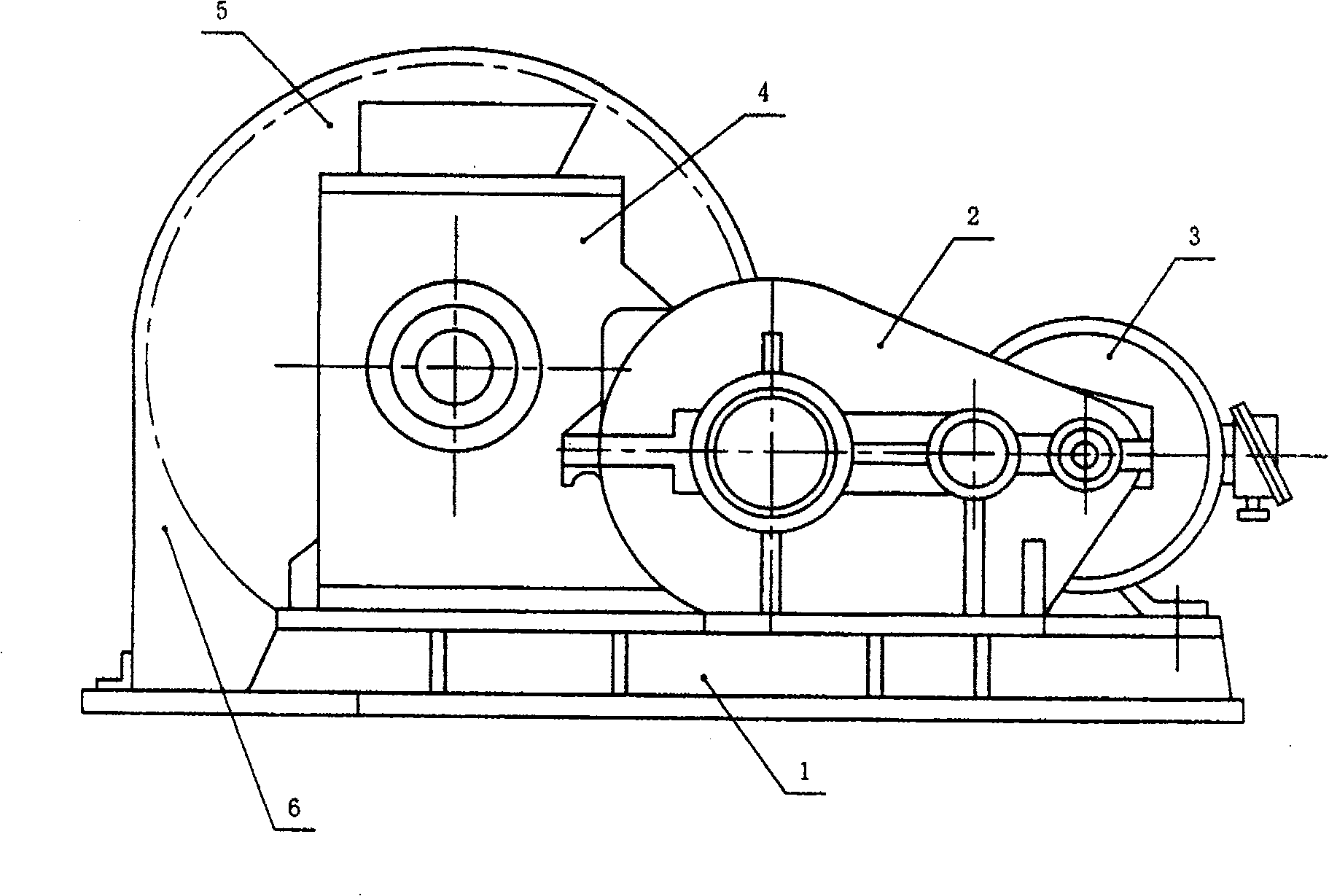

Compression shearing type crusher used for titanium sponge

The invention relates to a compresso-crushed crusher processing titanium sponge. The invention is characterized in motor on the device connecting with decelerator, decelerator connecting with coupler, coupler connecting with one side of drive axle on bearing block located on hull, the other side of drive axle equipping gear pair, gear pair connecting with one side of axle on bearing block located on hull, axle equipping rotating knife and one side of hull equipping dead knife. Driven by axle, rotating knife starts to rotate and drive titanium sponge to be squeezed at the edge of dead knife, so that titanium sponge is processed according to presetting grain size. The invention has the advantages of high efficiency, low energy consumption, convenient maintenance and long durability.

Owner:ZUNYI TITANIUM

A kind of preparation method of aluminum sludge ceramsite

The invention relates to the technical field of sludge waste utilization, in particular to a method for preparing aluminum sludge ceramsite. , and then transported to the dryer, and then transported the ceramsite raw meal to the rotary kiln for roasting. After being classified and screened by the closed screening machine, the waste and the ceramsite smaller than the standard size were transported to the crushing device through the closed conveyor. , use the crushing device to crush and sieve and then transport it to the storage tank of the mixed raw materials, and then weigh and mix the mixed raw materials with the measuring instrument, and recycle the waste materials. The produced ceramsite can be used in roadbed materials, concrete aggregates, etc. It is widely used; the mixed materials are formed into agglomerates. After the sludge is processed, the ceramsite fragments are crushed, transported and recycled by the crushing device. Through further processing, the recycling rate of waste can be enhanced and the production efficiency can be further improved.

Owner:FUJIAN MINFA ALUMINUM

Method for detecting content of trehalose in artemia eggs

ActiveCN101793884ACompletely brokenShort crushing timeComponent separationPreparing sample for investigationEgg cellOrganism

The invention relates to a method for detecting the content of trehalose, in particular to a method for detecting the content of the trehalose in artemia eggs, which belongs to the technical field of biochemistry. The method for detecting the content of the trehalose in the artemia eggs comprises the following steps: crushing cells by ultrasonication; treating the crushed cells; and detecting by a thin-layer chromatography. The detecting method of the invention utilizes ultrasonication to crush artemia egg cells, and detecting the content of the trehalose by the thin-layer chromatography qualitatively and quantitatively. Compared with the traditional method, the method for detecting the content of the trehalose in the artemia eggs has the advantages of simple pretreatment, audio-visual and obvious results, rapid and convenient detection and the like.

Owner:QILU UNIV OF TECH

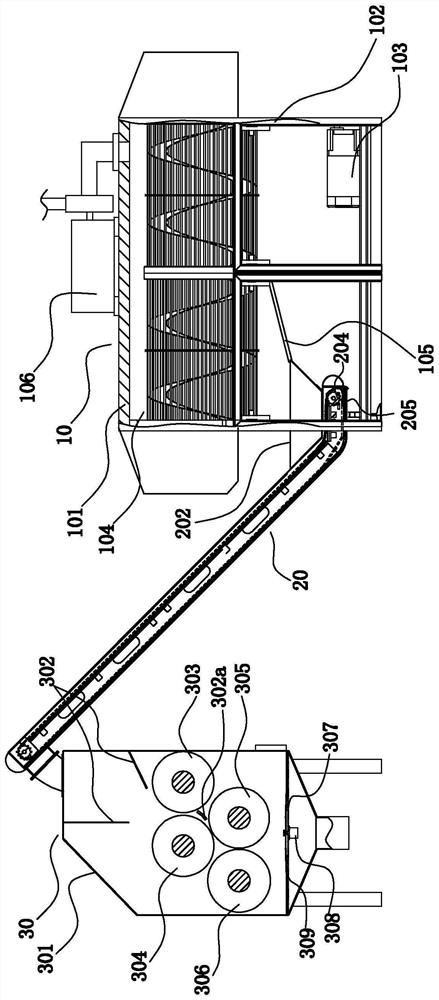

Crusher for titanium sponge

InactiveCN102989563AStrong crushing forceImprove efficiencyGrain treatmentsProduction lineDrive shaft

The invention discloses a crusher for a titanium sponge. The crusher is mainly composed of a base, a machine body, driving shafts and gears and the like, wherein rotating shafts are arranged in the machine body through a swivel bearing arranged on the supporting plate, the rotating shafts are connected with the driving shafts through the gears, and the driving shafts are arranged on the supporting plate through a driving bearing arranged on the supporting plate; and the other end of the driving shafts is connected with a motor, each rotating shaft is provided with a main blade and an auxiliary blade in an interval manner, cutter teeth on the periphery of the main blades and the auxiliary blades are distributed by an involute curve, the main blades and the auxiliary blades are arranged in an interval manner, the diameter of each auxiliary blade is less than that of each main blade, and each main blade of the rotating shaft is connected and corresponding to each auxiliary blade on the other rotating shaft. The crusher provided by the invention has the advantages that the crush capacity is large, the efficiency is high, the crush time is short, the labor intensity is low, a product is not easy to become yellow, the crush granularity is easy to control, and the crusher is particularly suitable for automatic crush serial production lines.

Owner:ZUNYI TITANIUM

A method for extracting seafood mushroom polysaccharide from seafood mushroom leftovers

The invention relates to a method for extracting seafood mushroom polysaccharides from seafood mushroom leftovers, belonging to the technical field of biochemical separation and purification. The method comprises crushing with a pulverizer, high-pressure homogeneous crushing, high-speed centrifugation, magnetic membrane ultrafiltration and drying. Compared with the prior art, the method has simple extraction process and short extraction time, and can be used in industrialized production. The crushing method adopted in the present invention has high crushing efficiency and short crushing time, so that the extraction rate of active polysaccharides of seafood mushrooms is high (the extraction rate is above 70%), and the functional activity is well preserved, and can be used for large-scale industrial production. The method for extracting active polysaccharides from seafood mushroom leftovers of the present invention has simple extraction process, short extraction time and reduced cost, and can be used in industrialized production. The obtained product can be used for preparing different types of food, health food or medicine.

Owner:福建省神六保健食品有限公司

A kind of solid dispersion method of celecoxib and the preparation method of celecoxib capsule

ActiveCN110604722BEffective dispersionHigh densityPowder deliveryOrganic active ingredientsLACTOSE MONOHYDRATEMechanical milling

The invention provides a solid dispersion method of celecoxib and a preparation method of celecoxib capsules, and the solid dispersion method comprises the following steps: mixing the celecoxib with pharmaceutical adjuvants to obtain raw and auxiliary material mixed powder, and carrying out ultramicro jet milling and / or mechanical milling on the raw and auxiliary material mixed powder, wherein thepharmaceutical adjuvants at least comprise lactose monohydrate and lauryl sodium sulfate. The solid dispersion method disclosed by the invention not only overcomes the characteristic of poor preparation of a celecoxib preparation, but also solves the problem of slow dissolution of the celecoxib, and the preparation is good in stability, so that the preparation is consistent with an original developed preparation (Celebrex) in prescription and dissolution, and the quality consistency and bioequivalence of the celecoxib preparation and the original developed preparation (Celebrex) are ensured.

Owner:SHANDONG CHUANGXIN PHARMA RES & DEV

Multi-cutter bit soybean milk machine

The invention relates to a multi-cutter bit soybean milk machine, which comprises a cup body part and a machine head part, and adopts a way of combining a movable cutter bit and a fixed cutter bit, wherein the rotary speeds of the movable cutter bit and a motor rotary shaft are different during a rotation process, so that different grinding and cutting forces are formed on beans and grains on the upper layer and the lower layer; meanwhile, the rotation speeds on the upper layer and the lower layer of grinding liquid are different, so that the flowability of the grinding liquid along a direction of the upper layer and the lower layer is increased, and a grinding effect is further accelerated; in addition, when an included angle between an upper blade of the fixed cutter bit and the motor rotary shaft is less than 90 degrees, the grinding liquid is driven to flow upwards; when an included angle between the blade of the movable cutter bit and the motor rotary shaft back to a machine head part is less than 90 degrees, the grinding liquid is driven to flow downwards, so that the flowability of the grinding liquid along the direction of the upper layer and the lower layer is further increased, the grinding liquid is accelerated to be ground on the cutter bits with different rotation speeds, the grinding time is short, the beans and the grains can be ground to be finer and smoother, and the taste of a drink is better.

Owner:李耀强

Liquid nitrogen medium/low-temperature crusher for biological sample

InactiveCN102519773BEasily brokenReduce lossesPreparing sample for investigationCircular discCrusher

The invention belongs to the field of biomedical instruments and relates to a liquid nitrogen medium / low-temperature crusher for a biological sample. The liquid nitrogen medium / low-temperature crusher comprises a bottom plate, a limiting fork, a stand column, a lever, a sample cup, sample cup cover, a sample pressure head, a horseshoe-shaped cushion block and a pressurizing slider. A use method of the liquid nitrogen medium / low-temperature crusher comprises the steps of: placing the biological sample at the bottom of the sample cup, pouring liquid nitrogen, covering the sample cup cover, placing the sample pressure head into a hole in the center of the sample cup cover, meanwhile, placing the horseshoe-shaped cushion block so as to erect a circular disc shaped structure on the upper end of the sample pressure head on the horseshoe-shaped cushion block, suspending the sample pressure head in the liquid nitrogen to decrease the temperature of the sample pressure head, removing the horseshoe-shaped cushion block after the temperature of the sample pressure head is decreased, lowering the sample pressure head onto the biological sample, moving the sample cup, the sample cup cover and the sample pressure head to lean against the limiting fork on the bottom plate, and forcibly pressing the lever to transfer the pressure of the lever by the pressurizing slider on the lever to the biological sample in contact with the lower end of the sample pressure head via the sample pressure head, thereby crushing the low-temperature solid-state biological sample in the liquid nitrogen.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

High speed interlayer shearing crusher for nano powder

InactiveCN100357031CSolve the problem of excessive noiseReduce noiseGrain treatmentsNanoparticleElectric machinery

A high-speed interlayer-shearing pulverizator for preparing nanoparticles is composed of high-speed motor, supporting frame, movable and fixed sealing plates, gas or liquid circulating pump, main cylinder, multi-hole static plates, multi-hole moving plates, oil sealing, feeding tank, discharging valve, etc.

Owner:UNIV OF SCI & TECH BEIJING

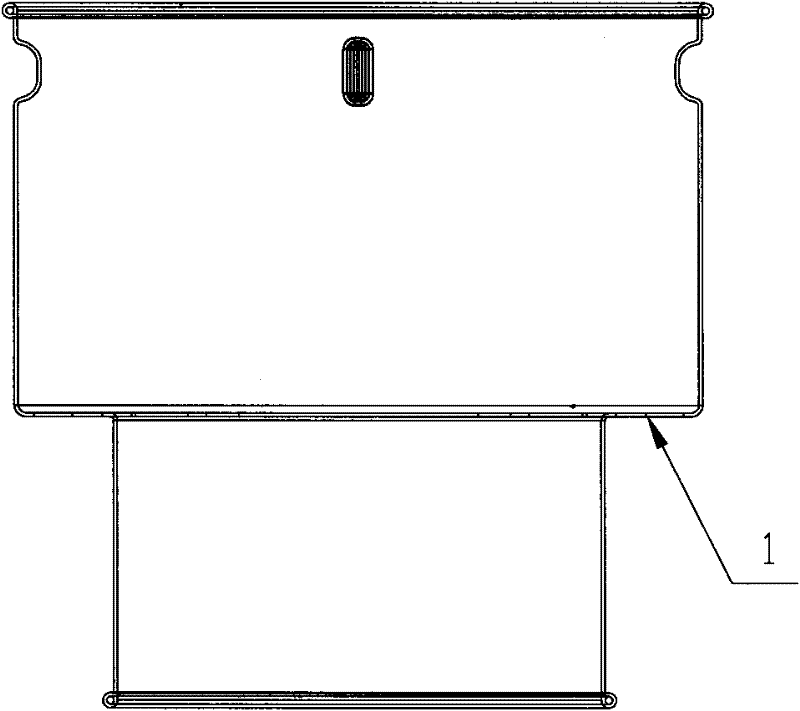

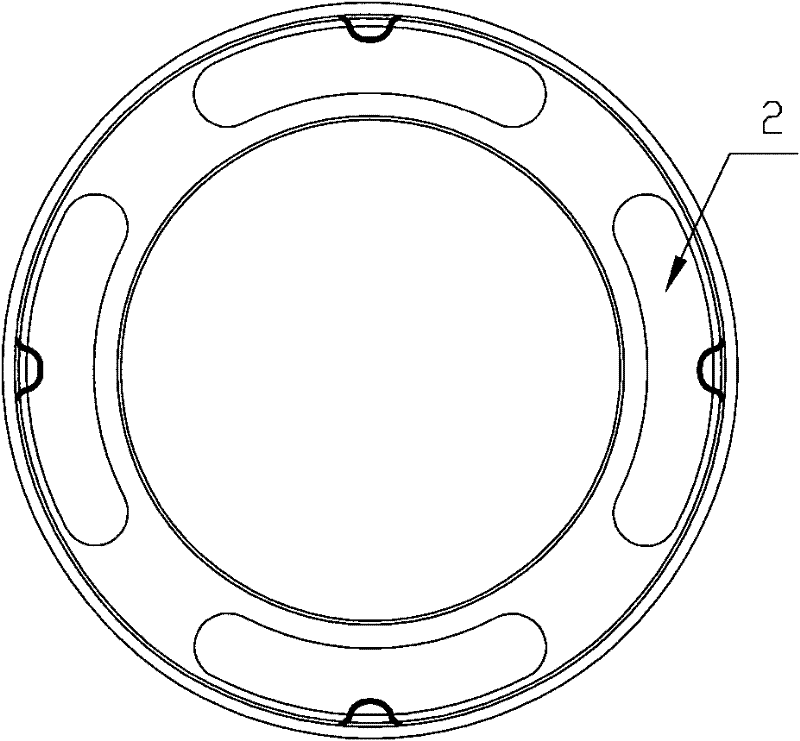

Structurally improved polyflow cup for soybean milk machine

InactiveCN102283580AShorten return pathShort crushing timeBeverage vesselsMilk substitutesEngineeringJoint surface

The invention discloses a flow-concentrating cup for a soybean milk machine with improved structure. Based on the direction of use, the cup body is a T-shaped hollow cylinder with a diameter at the upper end greater than that at the lower end. On the surface, at least one through hole is provided on the annular joint surface. The present invention adopts a double-ring structure. The through hole on the annular joint surface and the lower end of the cup form a soymilk circulation channel, which greatly shortens the soymilk return path, so that the unit time The number of internal grinding and cutting is greatly increased, which makes the fine grinding efficiency of the soymilk machine high, the crushing time of the soymilk machine is short, and the pulp yield is high.

Owner:KUSN GOLDBERRY ELECTRONICS

A technology for preparing nanometer Chinese medicinal materials by liquid phase shear dispersion

ActiveCN103623012BReduce agglomerationAlleviate functional factor degenerationUnknown materialsFood preparationNanoparticleNanometre

The invention discloses a technology of preparing a nanometer traditional Chinese medicine material by liquid-phase shear dispersion. According to the technology, a traditional Chinese medicine material is used as a raw material, and the nanometer traditional Chinese medicine material having a particle diameter of 50-300 nm is rapidly prepared by utilization of a high-shear dispersion smashing technology. The traditional Chinese medicine material can be prepared into solid nanoparticles and also can be prepared into nanometer traditional Chinese medicine suspension.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com