Reuse method for plastic handset sheathing material

A mobile phone shell and plastic technology, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problems that the product is difficult to control accurately, the pressure, temperature and additives are not easy to control, and it is not easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

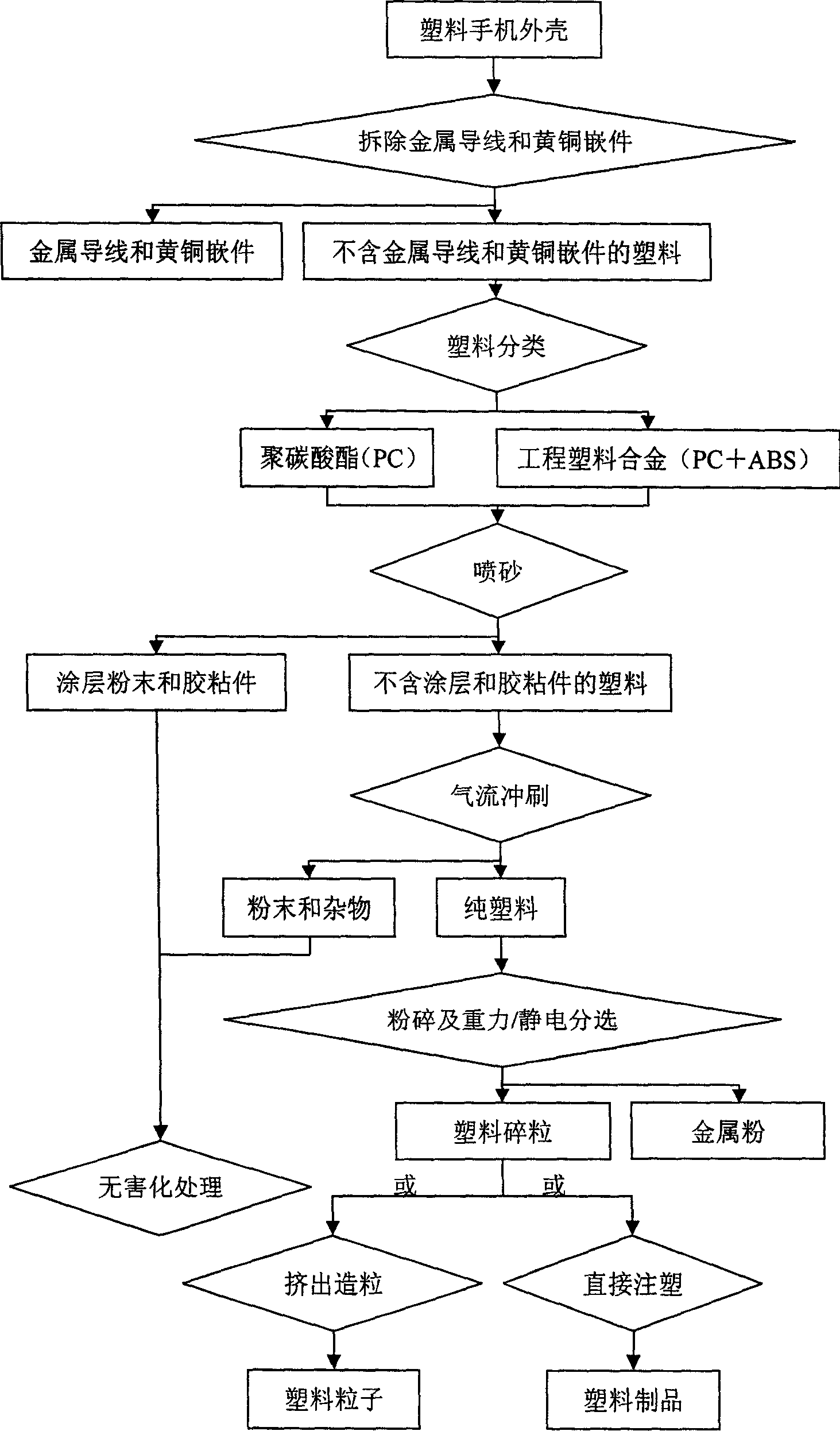

[0027] Select 1kg of engineering alloy plastic marked with "PC+ABS" on the inside of the plastic case, manually remove the metal leads and embedded brass screw holes, put the mobile phone case into the sandblasting box for surface sandblasting, the air pressure is 0.5MPa, and the sand grains The diameter is 5mm, and the time is 30min. The surface pigment coating and adhesive parts are all peeled off and mixed into the sand particles. After being collected by winnowing (wind speed 10m / s), they are incinerated at 1300°C; the plastics without surface coating are taken out and cleaned with compressed air. (Air flow pressure 0.5MPa) After blowing off the surface debris, enter the pulverizer for crushing, select a screen with a diameter of 5mm, and separate the metal in the shell through wind selection (wind speed 30m / s), the metal is mainly stainless steel, non- The metal is an engineering plastic alloy (PC+ABS). Put the plastic granules into the extrusion granulator to granulate, ...

Embodiment 2

[0030] Select 1kg of polycarbonate plastic marked with "PC" on the inside of the shell, mechanically cut and remove the metal leads and embedded brass screw holes, put the mobile phone shell into the sandblasting box for surface sandblasting, select the airflow pressure 1.0MPa, and the sand grains The diameter is 3mm, and the time is 30min. The surface pigment coating and adhesive parts are all peeled off and mixed into the sand particles. They are collected by the water spinning method (the centrifugal speed of the particles is 100rpm, and the resting time is 20s after stopping the centrifugal rotation). They are incinerated in an incinerator at 1300°C. No environmental pollution; take out the plastic without surface coating, and use compressed air (air flow pressure 1.0MPa) to blow off the surface impurities, then enter the pulverizer for crushing, select the screen diameter of 2mm, and use the electrostatic method to remove the metal in the shell Separation, the air temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com