Crushing machine

A technology of crushers and crushing chambers, which is applied in the direction of grain processing, etc., and can solve problems such as material retention, blockage, and influence on the uniform advancement of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

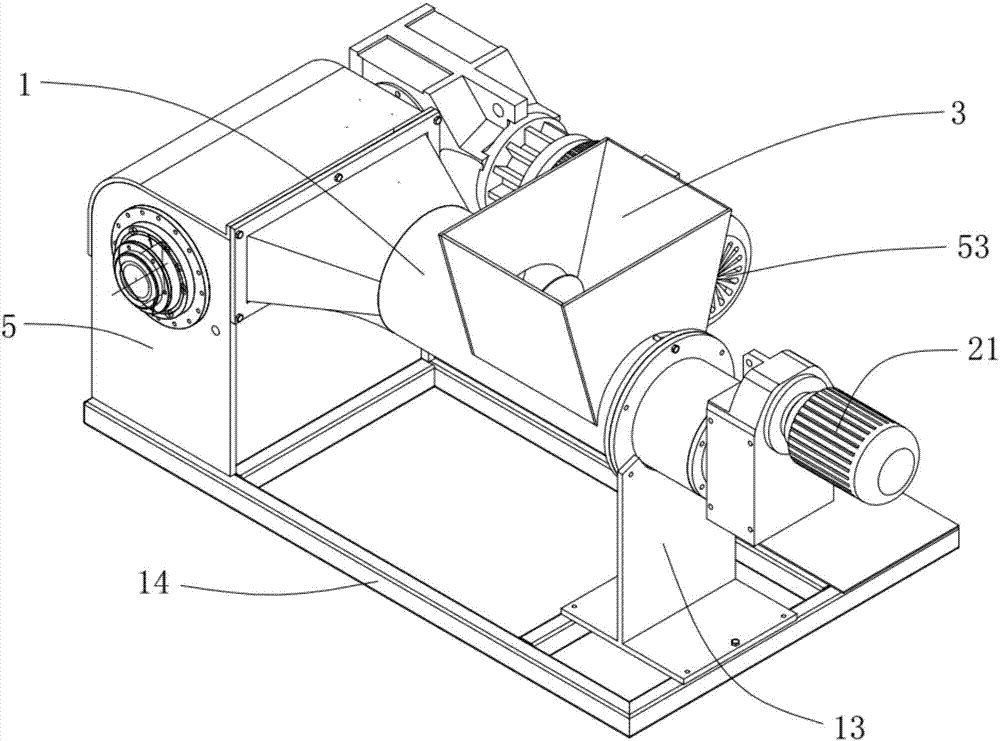

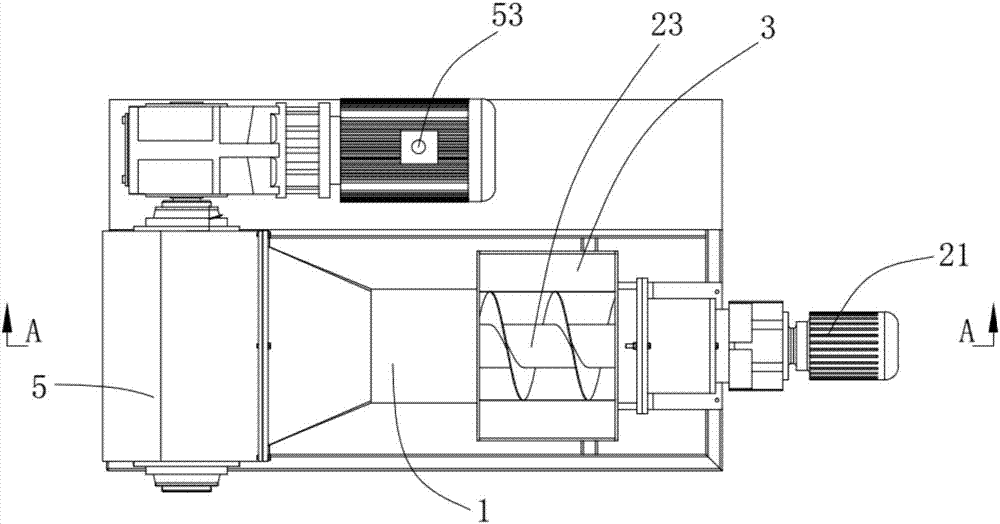

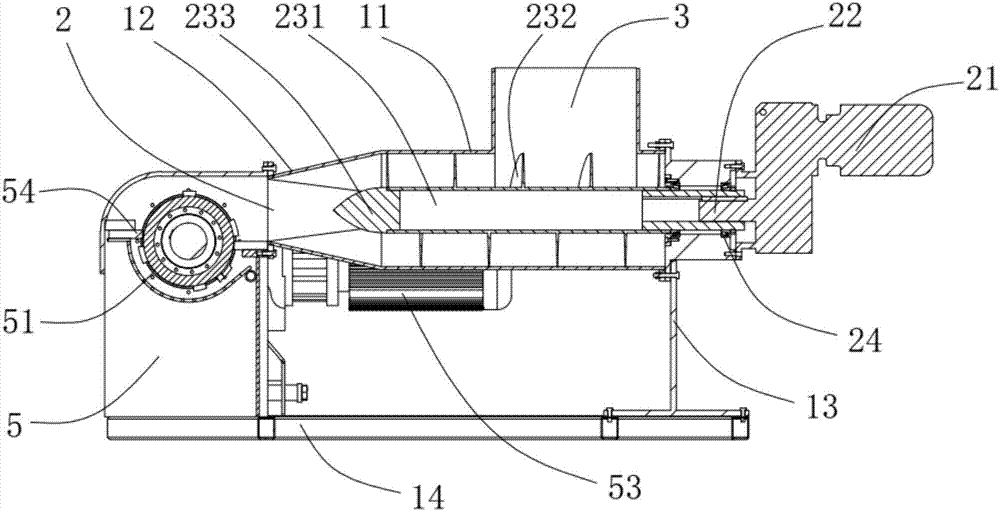

[0032] Such as Figure 1-3 As shown, the crusher according to the present invention includes a screw feeding device rotating barrel 1, the front end of the rotating barrel 1 is provided with a discharge port 2, and the upper part of the rotating barrel 1 is provided with a feeding port 3 , the rear end of the rotary barrel 1 is provided with a geared motor 21, and the geared motor shaft 22 of the geared motor 21 passes through the rotary barrel 1 and is fixedly connected with the screw conveying shaft 23 arranged inside the rotary barrel 1, The screw conveying shaft 23 is connected with the rotating barrel 1 through a bearing 24 . The bearing 24 is a tapered roller bearing.

[0033] The discharge port 2 is connected with a crushing device 5. The crushing device 5 includes a crushing cavity and a crushing knife 51 arranged in the crushing cavity. The crushing knife 51 passes through the crushing moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com