Airtight pulverizer and application thereof

A pulverizer and airtight technology, which is applied in the field of airtight pulverizers, can solve the problems that the mechanical seal cannot meet the airtightness, the quality and diameter of the incoming material are limited, and the power of the closed pulverization is insufficient, so as to improve the accuracy of the experiment. , improve the crushing efficiency, and the effect of good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

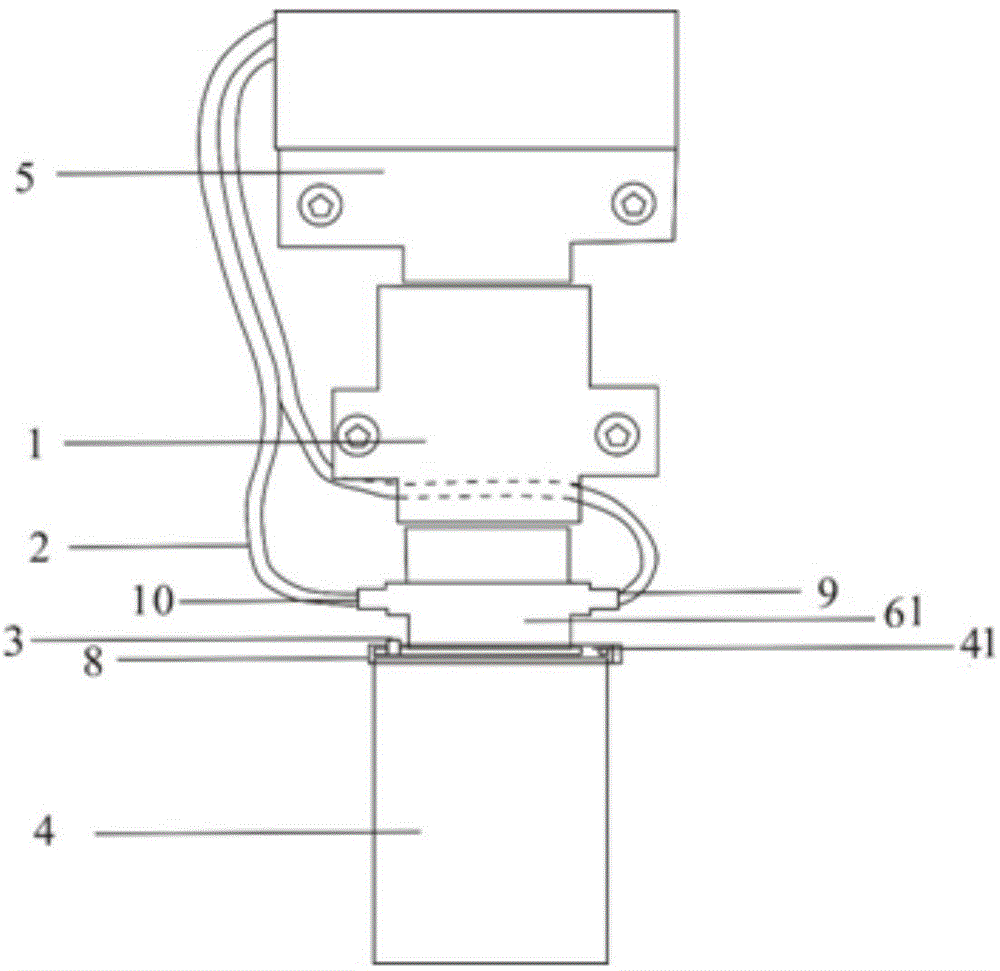

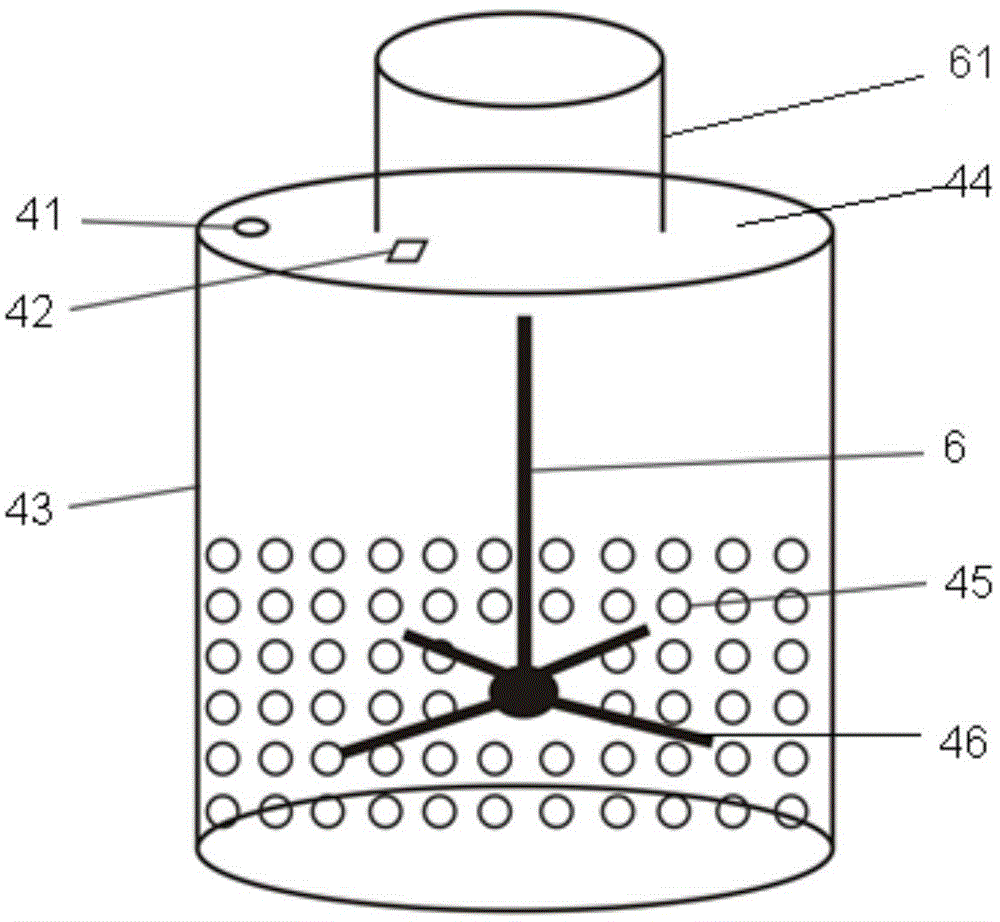

[0035] The invention provides an airtight pulverizer, which includes a sample pulverization tank and a non-contact torque transmission system. As the power source of the pulverizer, the non-contact torque transmission system adopts the principle of non-contact torque transmission to transmit the torque power outside the sample pulverization tank to the sample pulverization tank in a non-drilling direct contact manner, thus providing full gas A solid basis for implementation.

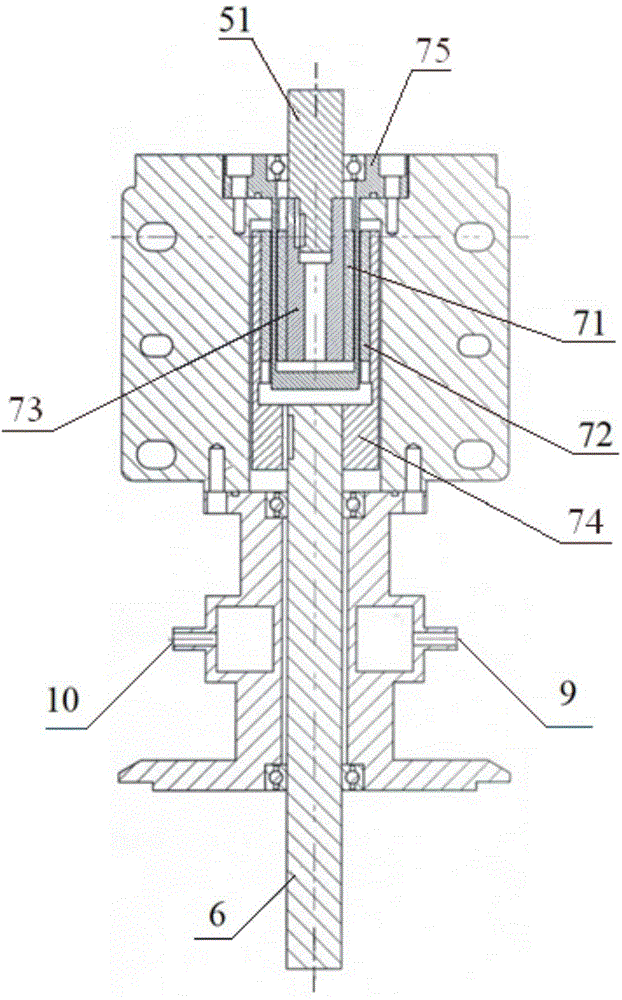

[0036] see figure 2 As shown, the non-contact torque transmission system includes a motor 5 , a magnetic shaft 6 and a magnetic transmission coupling 1 , the motor 5 is connected through the magnetic transmission coupling 1 and drives the magnetic shaft 6 to rotate. Among them, the magnetic transmission coupling 1 is used as a transmission component of the non-contact torque transmission system, and adopts the principle of magnetic coupling to realize the transmission of torque and motion between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com