Battery electrode polar column glass sealing-in structure and method

A battery electrode and junction structure technology, which is applied to small-sized batteries/battery packs, structural parts, battery pack parts, etc., can solve the problem that the thermal shock resistance and mechanical shock resistance of sealing glass cannot meet expectations well , Did not consider the mechanical firmness of the electrode pole glass seal assembly, did not explain the thermal expansion coefficient of the components, etc., to achieve the effects of reducing the risk of thermal shock, good weather resistance, and improving electrical insulation and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

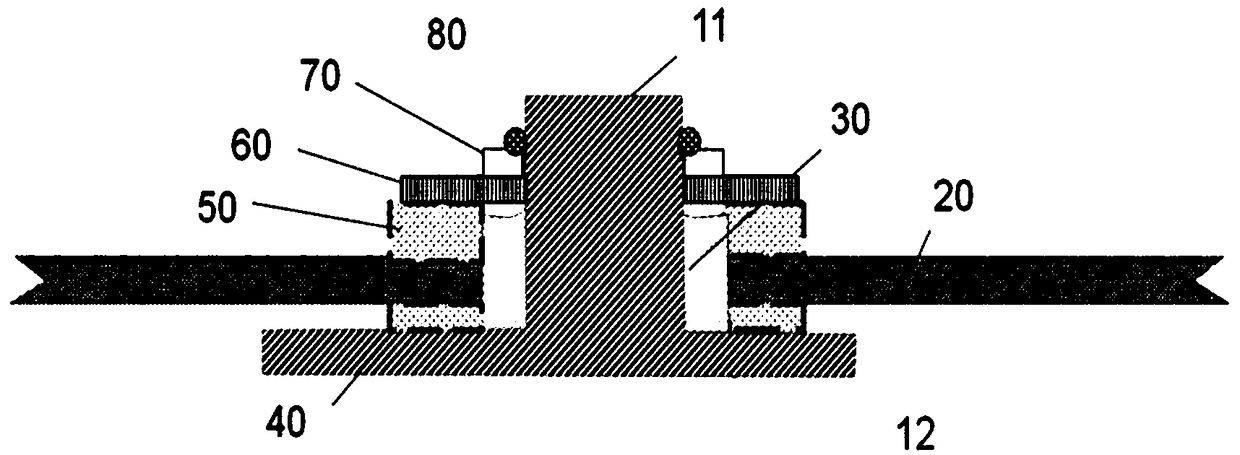

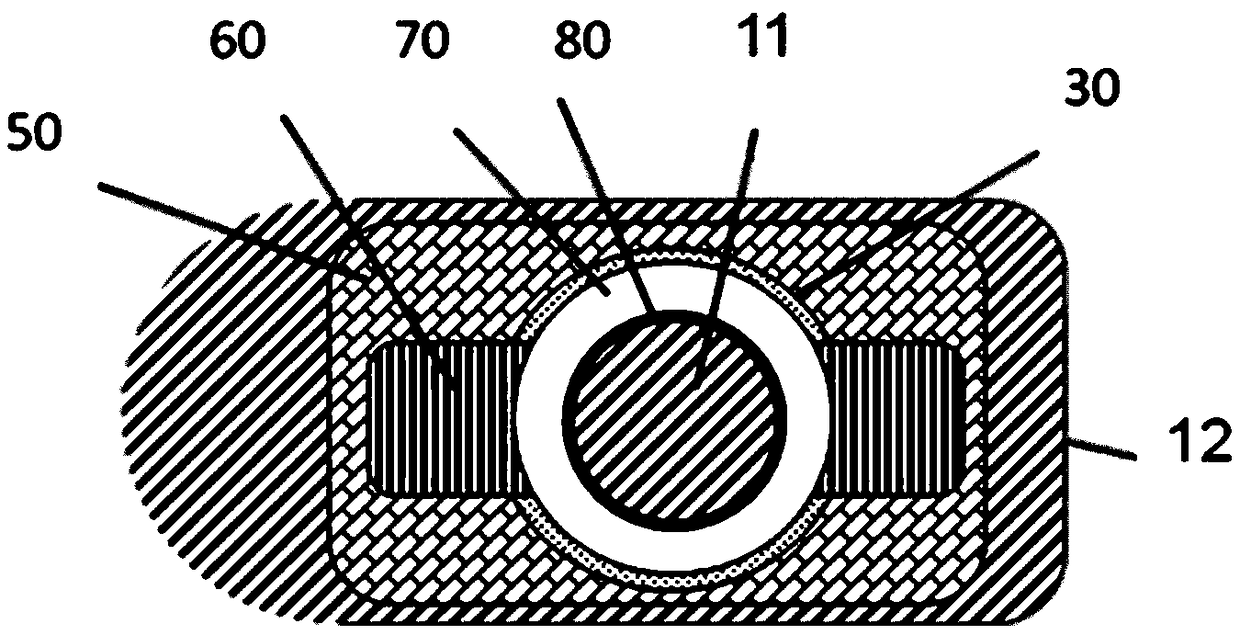

[0042] Please refer to Fig. 1(a) and Fig. 1(b), a kind of battery electrode pole glass sealing structure, it includes electrode base and electrode aluminum stem 11, above the electrode base, electrode aluminum stem 11 The lower glass gasket 40, the battery cover plate 20, the upper glass gasket 50, the gasket fixing piece 60, the fixing ring 70 and the solder ring 80 are set sequentially from bottom to top; wherein, the glass lower gasket 40, the battery cover plate 20 and the There is an annular gap with the same diameter between the glass upper gasket 50 and the electrode aluminum stem 11; the annular gap is filled with aluminum sealing glass 30 and the glass lower gasket 40 and the glass upper gasket 50 are thermally connected to the aluminum sealing glass 30; Both the fixing piece 60 and the fixing ring 70 are in close contact with the electrode aluminum stem 11 ; the solder ring 80 welds the fixing ring 70 and the electrode aluminum stem 11 . Wherein, the electrode base i...

Embodiment 2

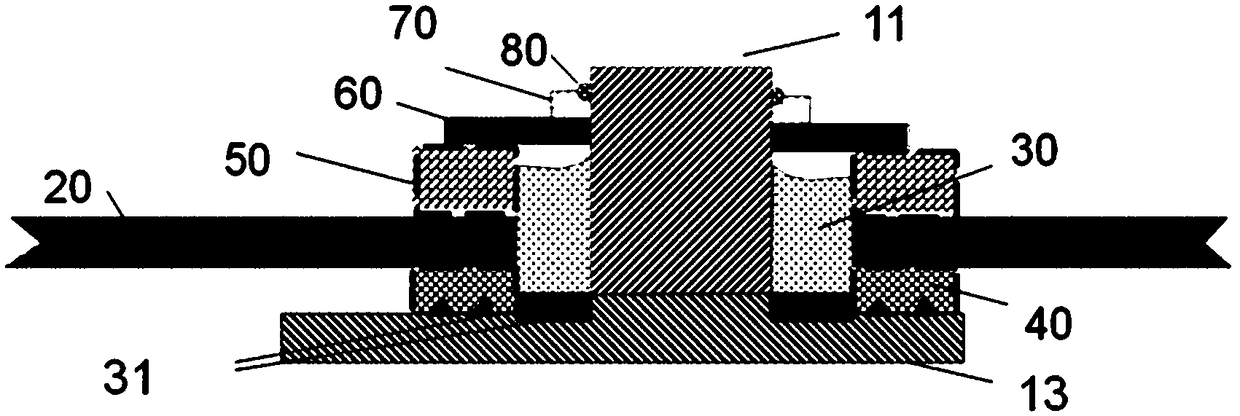

[0064] This embodiment is similar to the embodiment with minor differences, please refer to Fig. 2 (a) and Fig. 2 (b), in the present embodiment, electrode copper coin quality base 10-3 is replaced by composite process such as friction welding that battery negative electrode needs Copper plate, its coefficient of thermal expansion is about 17.6x10 -6 / ℃, much smaller than the thermal expansion coefficient of aluminum or aluminum alloy. In order to better reduce the interface thermal stress, it is best to use newly adjusted low-temperature copper sealing glass 30-1, such as phosphate glass copper sealing glass 30-1 resistant to electrolyte corrosion, whose thermal expansion coefficient is between that of copper and that of the lower gasket 40, while the thermal expansion coefficient of the lower gasket 40 is slightly lower than that of the aluminum cover plate. The problem is how to introduce the copper-sealed glass 30-1 into the lower gasket 40. If it is too thin (2mm), the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com