Soybean milk machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

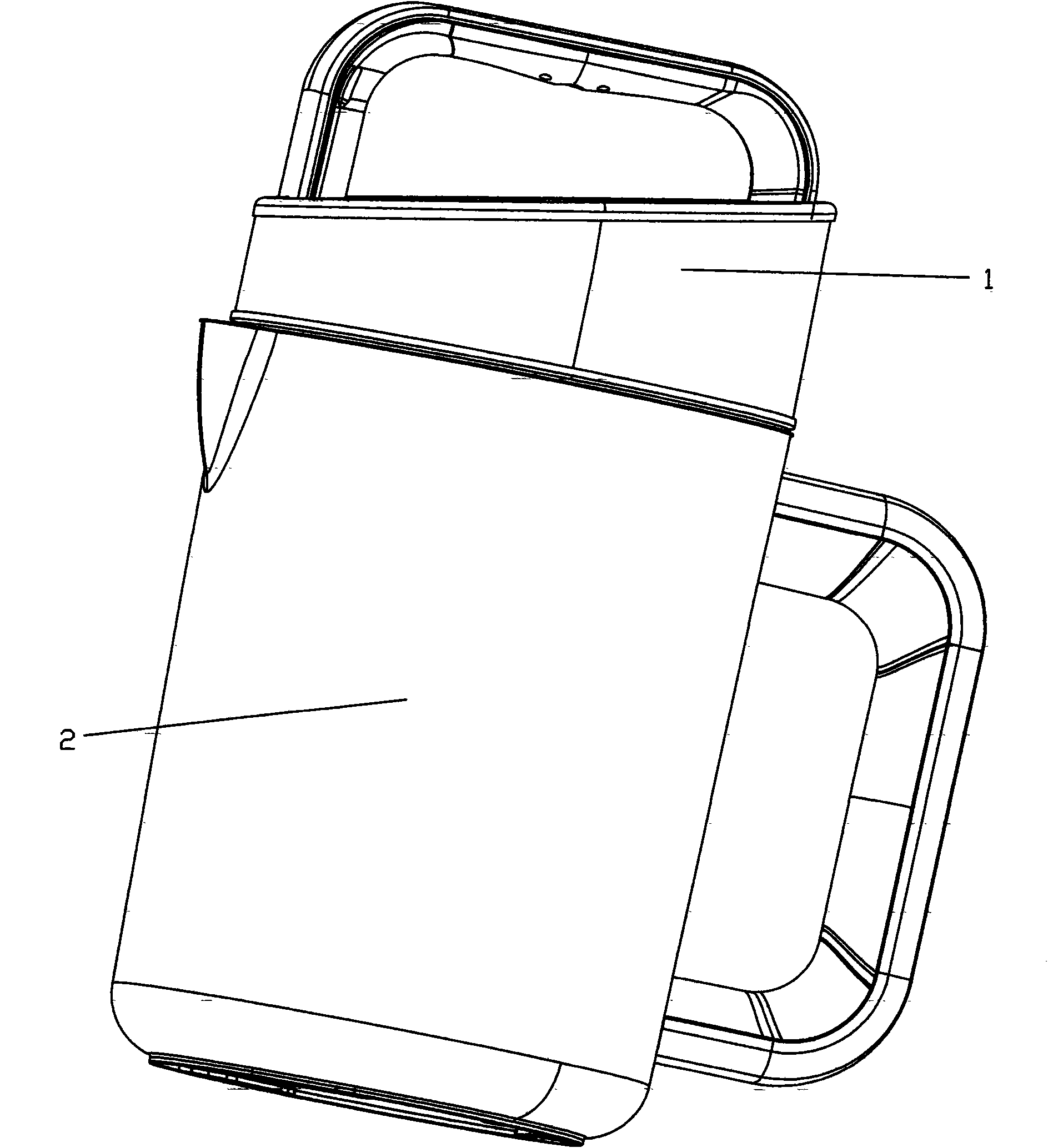

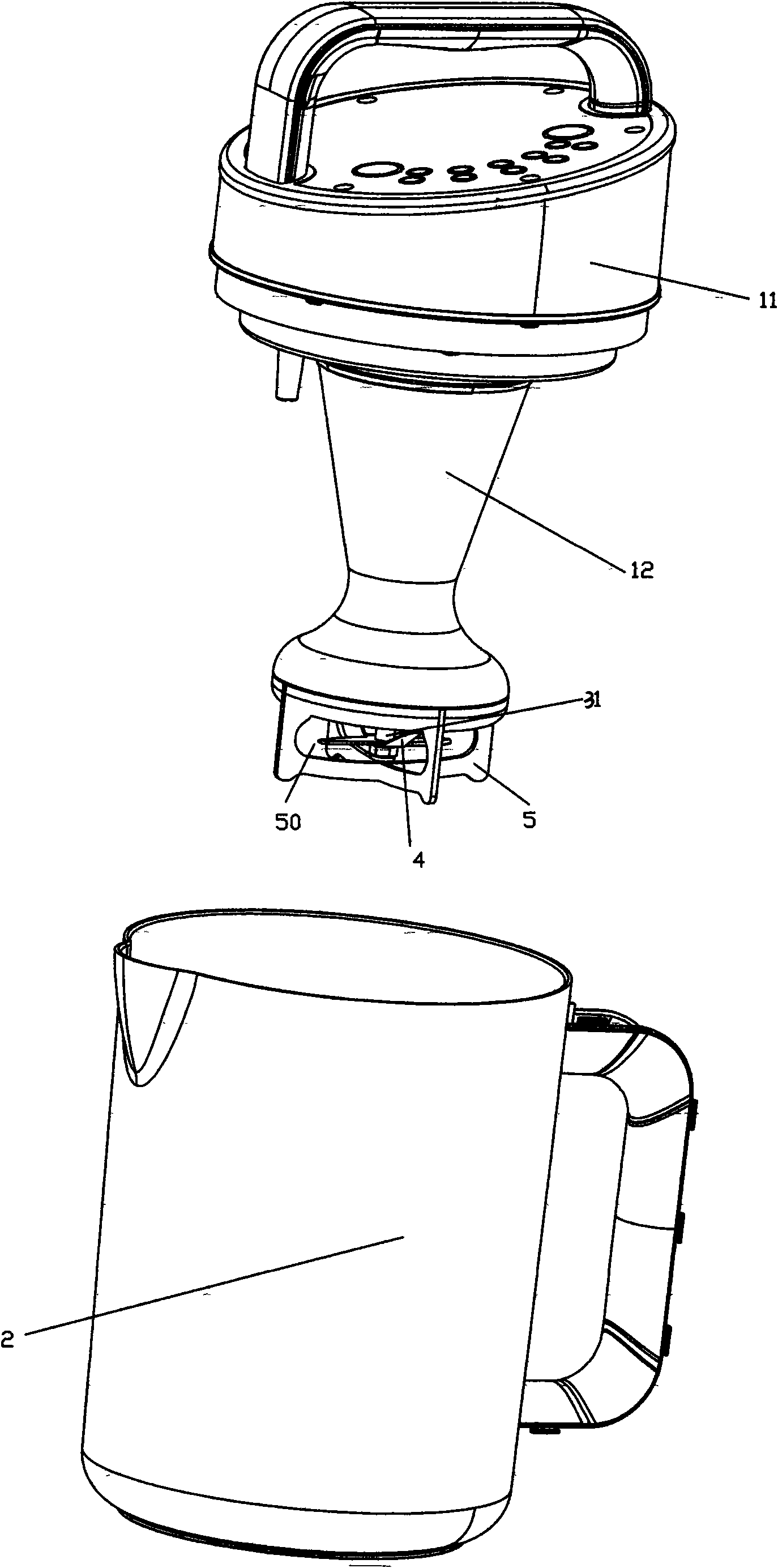

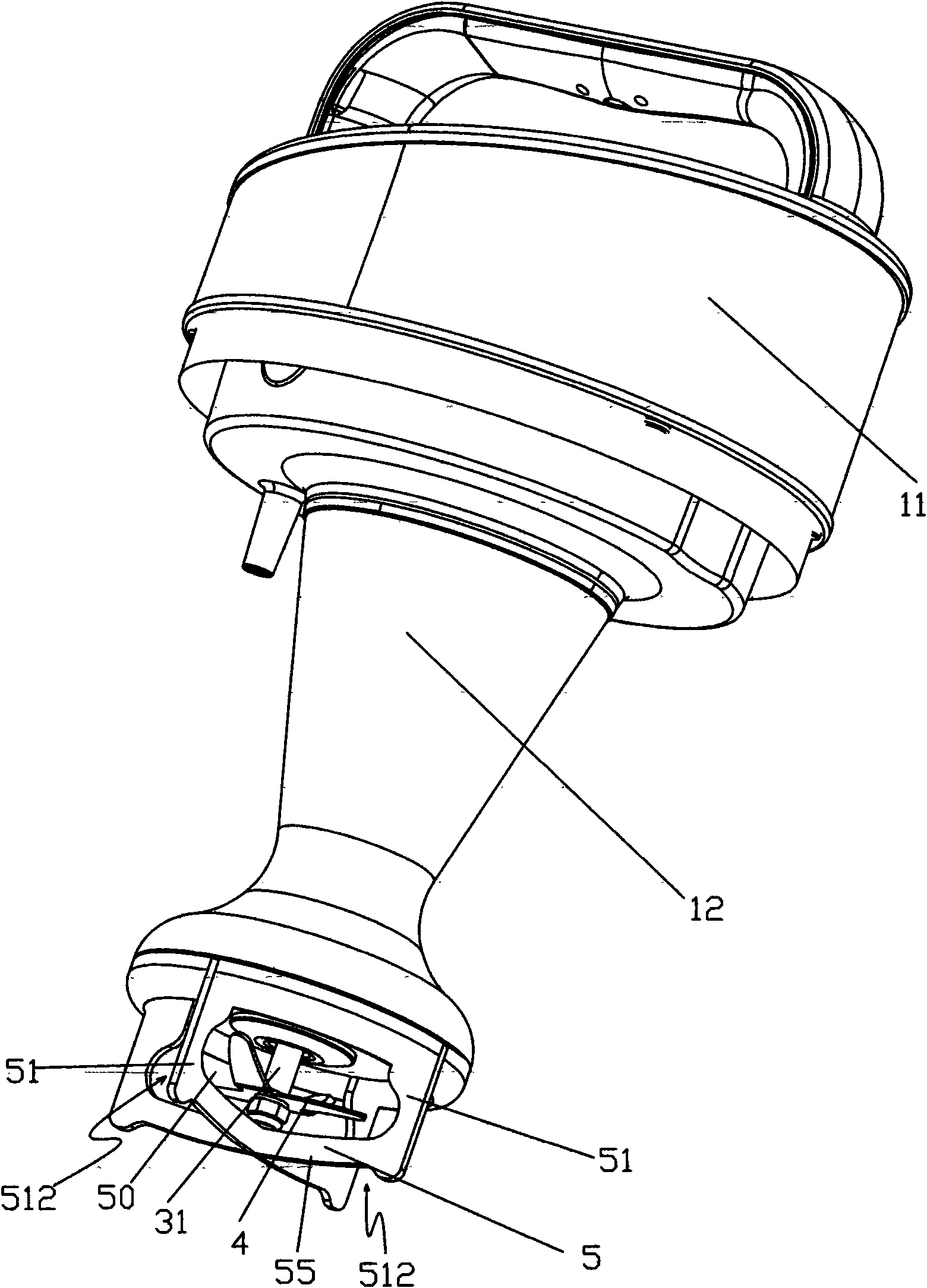

[0026] A kind of soybean milk machine, it comprises machine head 1 and barrel body 2, is provided with control circuit board, motor 3 in machine head 1, machine head 1 comprises machine head upper cover 11 and machine head lower cover 12, the motor of described motor 3 Drive shaft 31 lower end stretches out machine head lower cover 12 and stretches in the staving 2, the lower end of motor drive shaft 31 is provided with crushing cutter 4, is provided between described machine head lower cover 12 and staving 2 inner bottoms. A spoiler 5 is arranged, and the spoiler 5 includes two or more spoilers 51 and spoiler ribs 55 connected to the lower ends of the spoilers 51 . The spoiler 5 is provided with a spoiler space 50 , and the crushing cutter 4 extends into the spoiler space 50 . When the motor drives the motor transmission shaft 31 to rotate, it also drives the crushing cutter 4 to rotate at the same time. The crushing cutter 4 drives the beans and water placed on the bucket bo...

Embodiment 2

[0036] The spoiler 5 includes a mouth-shaped plate 53 , the center of the mouth-shaped plate 53 forms a flow-disturbing space 50 , and the crushing cutter 4 extends into the flow-disturbing space 50 .

[0037] The fixed connection mode of the mouth plate 53 can be: the mouth plate 53 is movably connected on the motor drive shaft 31 . When the motor drives the motor transmission shaft 31 to rotate, it also drives the crushing cutter 4 to rotate, and the crushing cutter 4 drives the beans and water placed on the barrel body 2 to form a vortex while crushing the beans, so that the mouth plate 53 moves along with the vortex. Rotate on the motor transmission shaft 31 and slide up and down. like Figure 5 As shown, the mouth plate 53 can also be directly fixed on the motor drive shaft 31 .

[0038] The fixed connection mode of mouth plate 53 can also be: as Image 6 As shown, the mouth plate 53 is fixedly connected to the bottom of the lower cover 12 of the machine head. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com