Full-automatic meat shredding machine

A shredder, fully automatic technology, applied in grain processing and other directions, can solve the problems of increasing processes, wasting manpower and energy, and achieving the effects of improving efficiency, complete crushing, and short crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

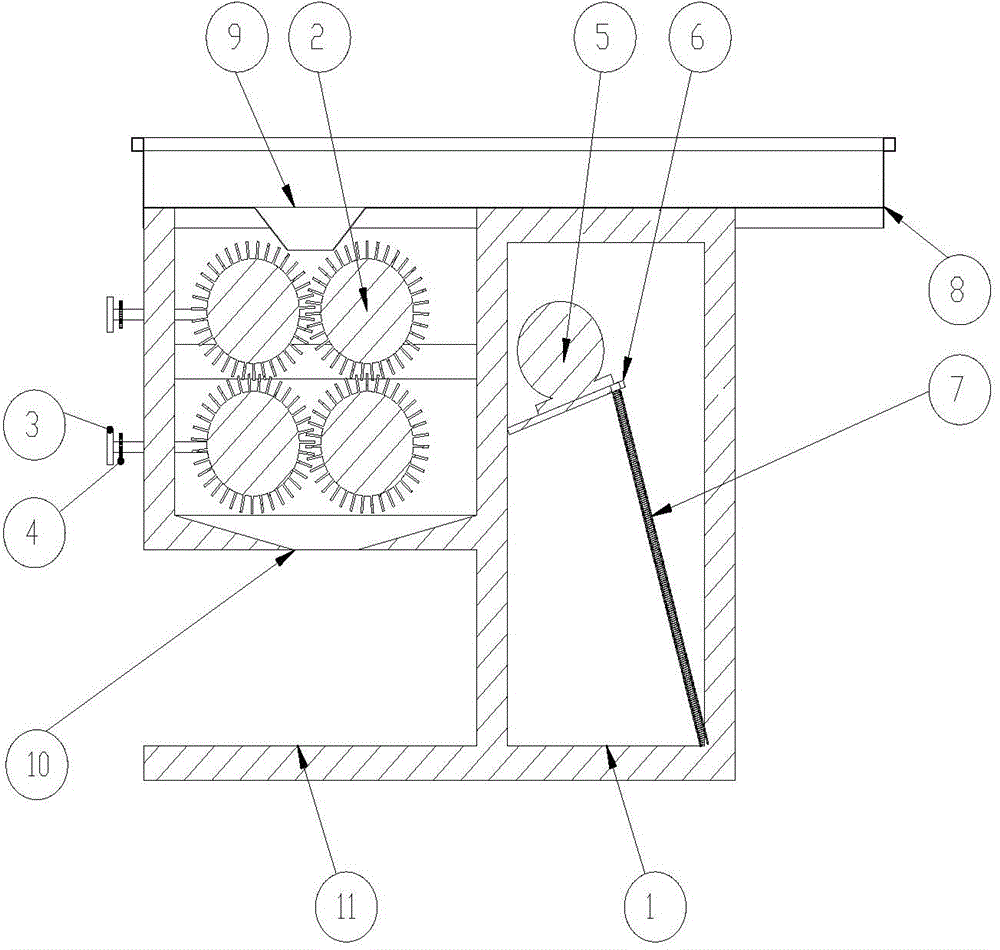

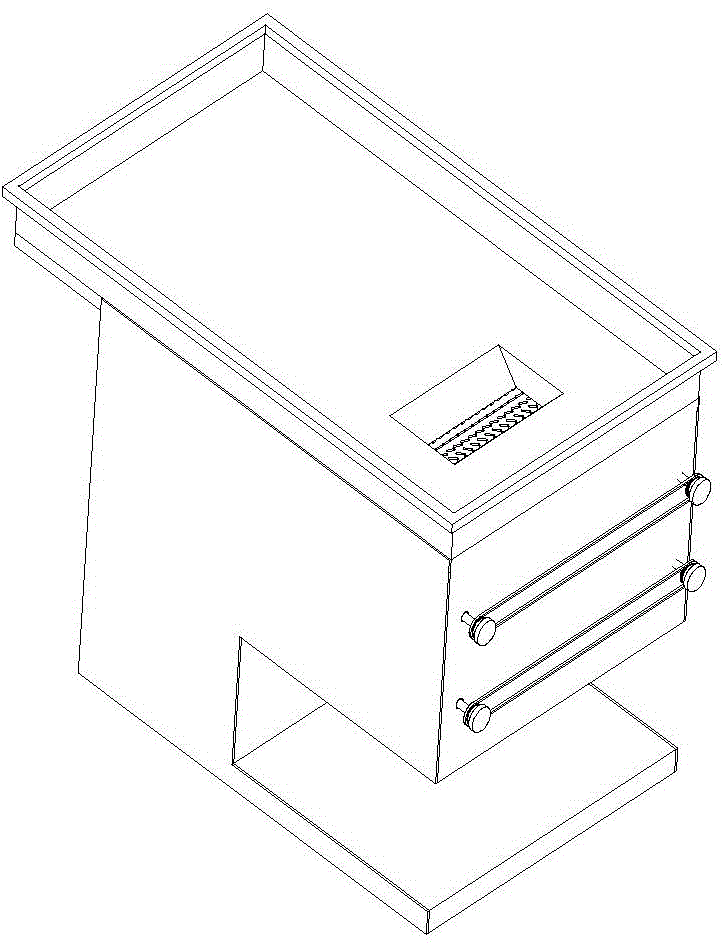

[0010] A full-automatic meat shredding machine, including an electrical room housing 1, a pin tooth roller 2, a wheel handle 3, a rack 4, a motor 5, a support table 6, a support frame 7, a feeding table 8, a feeding port 9, Discharge port 10, discharge platform 11; needle-toothed rollers 2 are 4 in total, two layers up and down, two in each layer; motor 5 is arranged on support table 6, drives needle-toothed roller 2 to mesh and rotate; feeding port 9, outlet The feed ports 10 are respectively set at the corresponding positions in the middle of the upper and lower pin tooth rollers 2; the bearings at both ends of the roller shafts of the upper and lower outer pin tooth rollers 2 can move laterally, and the bearings at both ends of the roller shaft are vertical to the direction of the roller shaft and pass through the screw rods respectively. A wheel handle 3 is connected, and a gear is arranged inside the wheel handle, and the two gears in the horizontal direction are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com