Preparation method of paliperidone palmitate

A technology of paliperidone and palmitic acid, applied in the field of medicine, can solve problems such as large particle size, and achieve the effects of small particle size, high yield and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

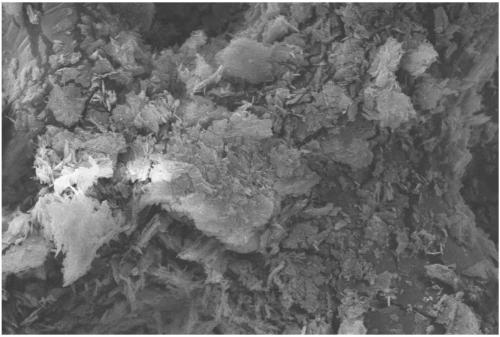

[0042] 15g of paliperidone palmitate was dissolved in 150mL of dichloromethane at room temperature to obtain a dichloromethane solution of paliperidone palmitate, which was added dropwise to 2.25L of n-heptane, and the temperature was controlled at 3°C. Acceleration 2mL / min, stirring speed 250 rpm / min. After the dropwise addition was completed, keep stirring for 30 min to crystallize, filter, rinse the filter cake with 160 mL of n-heptane, and dry under reduced pressure at 50° C. for more than 6 h to constant weight to obtain 14 g of paliperidone palmitate (yield 93%). SEM topography ( figure 1 ) shows flaky crystals with particle size distribution d 10 : 1.00, d 50 : 3.59, d 90 : 11.24. The average particle size of FBRM is 9.16 μm. Dichloromethane and n-heptane solvent residues were not detected.

[0043]Examples 2-4 refer to the operation process of Example 1, and the conditions in Table 1 are used for the corresponding replacement to prepare paliperidone palmitate cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com