Patents

Literature

31results about How to "No residual problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick-shell mussel fat-soluble extract, preparation method and application thereof

InactiveCN101606951APrevent oxidationIncrease contentAntipyreticDigestive systemFreeze-dryingPre treatment

The invention discloses a preparation method of a thick-shell mussel fat-soluble extract, comprising the following steps: (1) thick-shell mussel preprocessing; (2) freeze drying, namely, firstly carrying out freeze drying on the meat scraps of thick-shell mussels and then pulverizing the obtained freeze-drying thick-shell mussel meat in a pulverizer; and (3) supercritical CO2 extraction, namely, carrying out supercritical CO2 extraction on the freeze-drying powder of the thick-shell mussel meat and obtaining the thick-shell mussel fat-soluble extract. The invention also discloses the thick-shell mussel fat-soluble extract prepared according to the method, which is an antiphlogistic active substance containing various unsaturated fatty acids; the thick-shell mussel fat-soluble extract can be used for preparing antiphlogistic enteropathy medicines or health-care foods.

Owner:ZHEJIANG UNIV +1

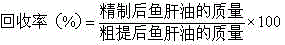

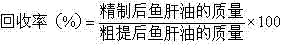

Extracting method of Monkfish liver oil

ActiveCN104651033AImprove qualityHigh extraction rateFatty-oils/fats refiningFatty-oils/fats productionCod liver oilO-Phosphoric Acid

The invention relates to an extracting and refining method of Monkfish liver oil, and belongs to the technical field of aquatic product intensive processing. With Monkfish livers as raw materials, the fish liver oil is extracted from the Monkfish livers by a light alkali hydrolysis and then is refined. The extracting method comprises the following steps of cleaning fresh Monkfish livers, removing impurities, stirring to form a fat paste, degrading protein by a light alkali solution, destroying the combination relation between protein and fat, separating out fat, extracting crude fish liver oil, degumming by phosphoric acid, de-acidifying by sodium hydroxide, de-coloring by activated clay and deodorizing in vacuum, extracting high-quality fish liver oil. The method is simple, the cost is low, the extracting efficiency is high, and the quality of the fish liver oil is good.

Owner:SHANGHAI INST OF TECH

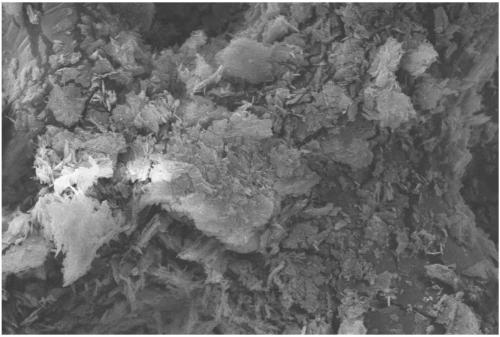

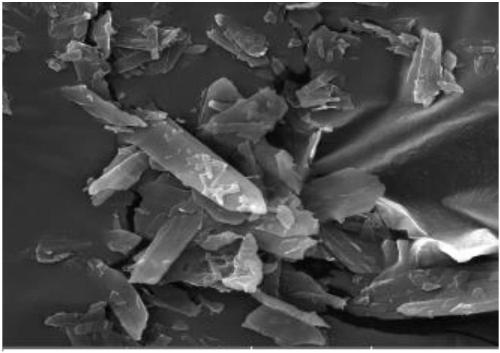

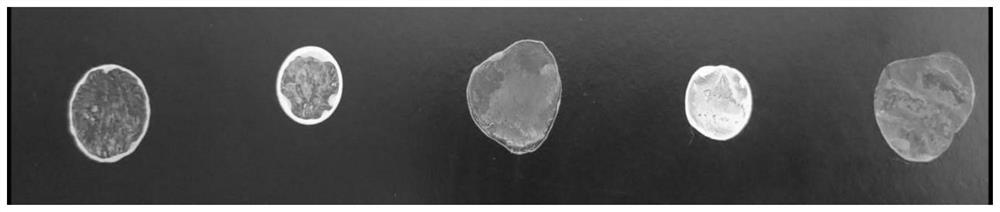

Preparation method of paliperidone palmitate

ActiveCN109400602ASmall particle sizeAvoid damageOrganic chemistryPaliperidone PalmitateCrystallization

The invention belongs to the technical field of medicines and relates to a preparation method of paliperidone palmitate. The method disclosed by the invention comprises the step of precipitating paliperidone palmitate in a mixed solvent of dichloromethane and n-heptane. Paliperidone palmitate particles obtained by the invention are small in particle sizes, flaky, easy to homogenize and grind, andshort in grinding time, have little damage to instruments and equipments, and are short in crystallization time, high in yield and free of solvent residues and particularly suitable for needs of industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD +1

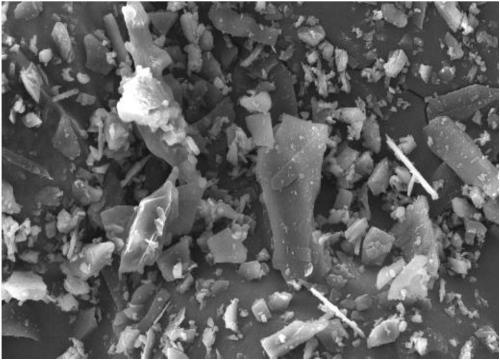

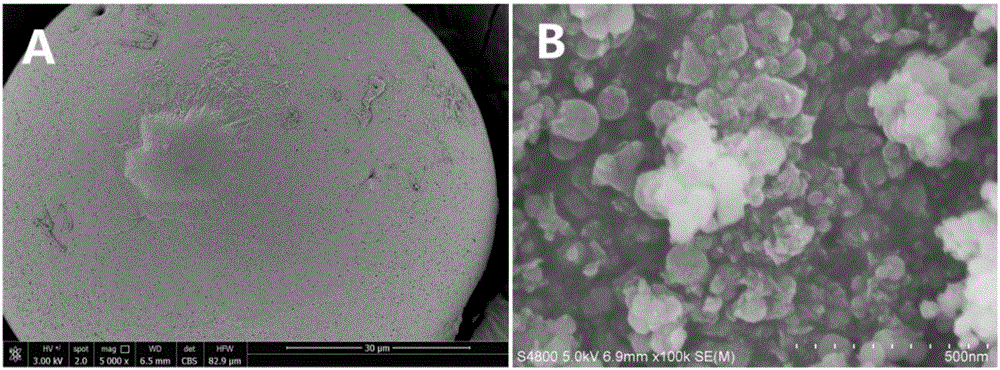

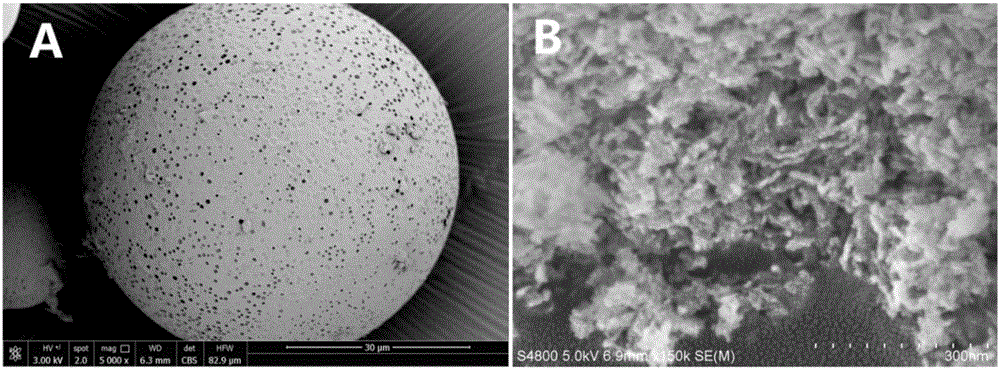

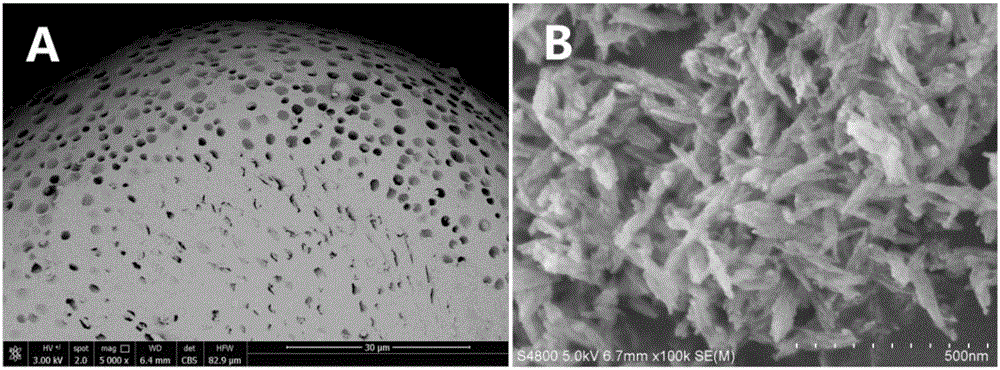

Controlled preparation method of surface porous structure of polylactic acid/HAP (hydroxyapatite) composite microspheres and application

ActiveCN107519536ANo residual problemsSimple preparation processInorganic non-active ingredientsPharmaceutical delivery mechanismSelective laser sinteringEmulsion

The invention discloses a controlled preparation method of the surface porous structure of polylactic acid / HAP (hydroxyapatite) composite microspheres and application. The method is characterized in that HAP and polylactic acid are used as raw materials; the controlled preparation of the surface porous structure of the polylactic acid / HAP composite microspheres is realized by regulating and controlling the size of the HAP on the basis of an emulsion solvent volatilization method. By the method, the additional addition of pore-forming agents is not needed; the self ingredients of the composite microspheres are used for pore formation; the surface hole structure of the prepared microspheres is easy to control. The porous polylactic acid / HAP composite microspheres can be used for additive manufacturing of selective laser sintering and for preparing bone defect repair materials and can also be used as a medicine release carrier for disease treatment.

Owner:WUHAN UNIV OF TECH

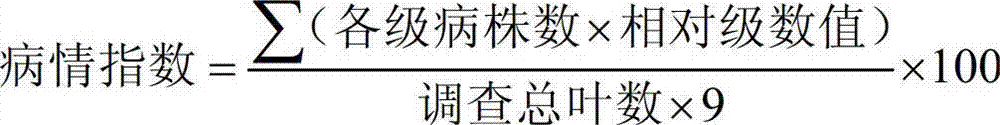

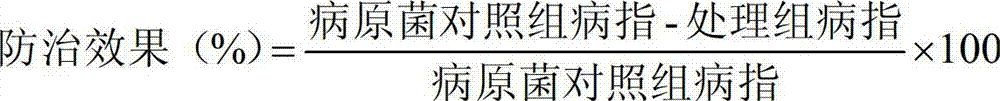

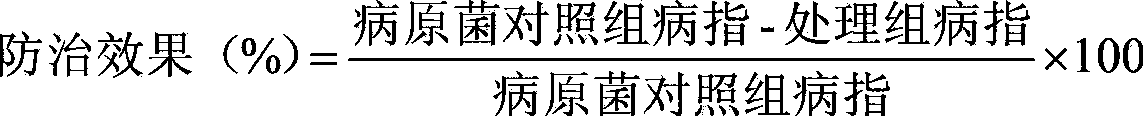

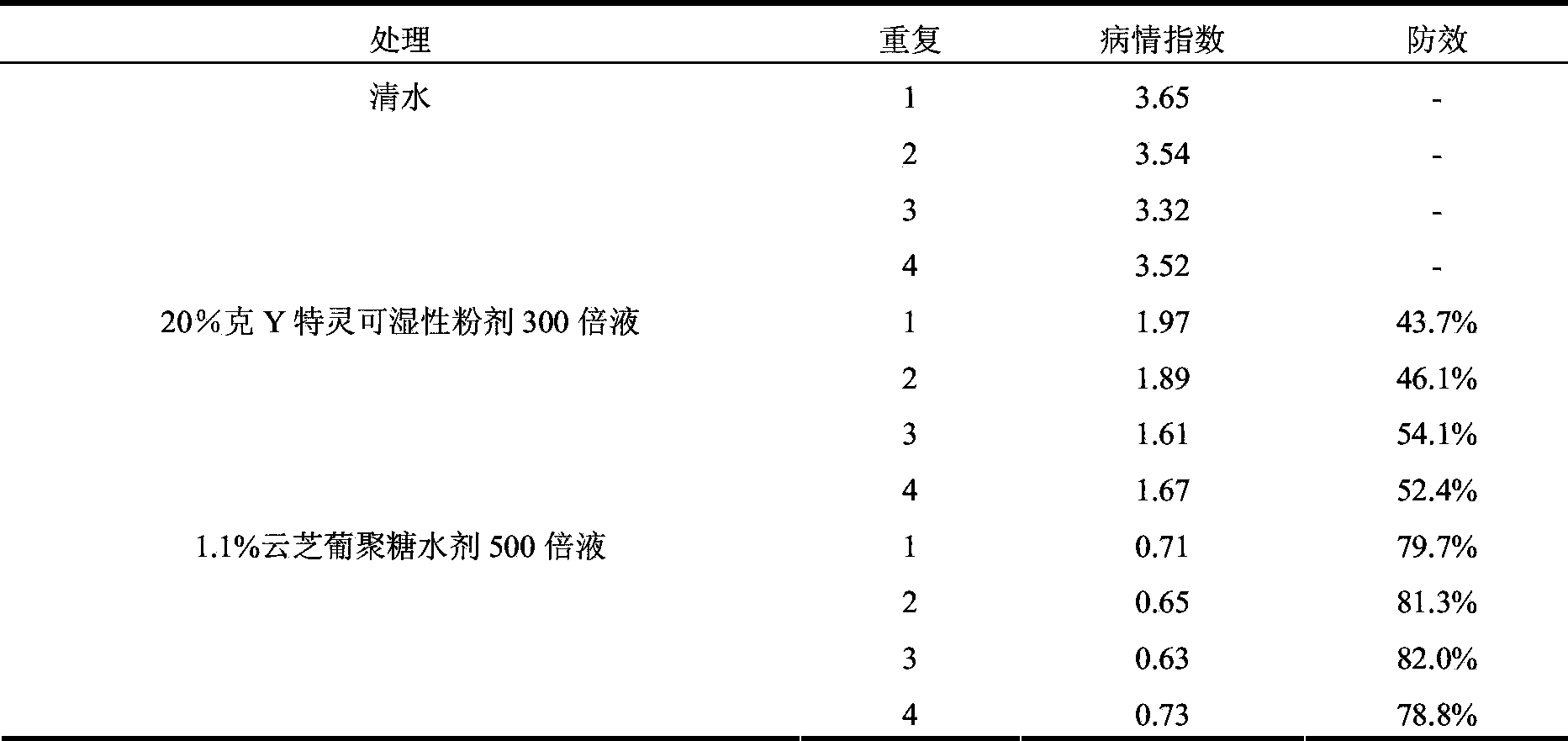

Trametes versicolor glucan water agent and preparation method thereof

ActiveCN103070172ANo residual problemsGood environmental compatibilityBiocideDisinfectantsDecompositionGlycerol

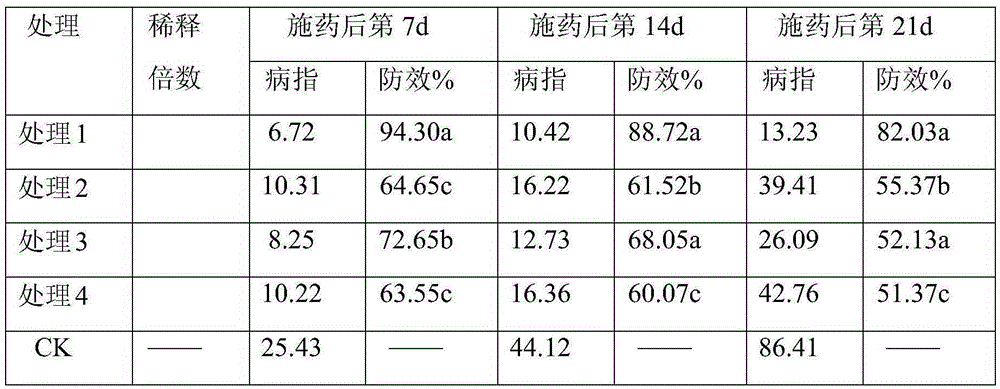

The invention relates to a trametes versicolor glucan water agent and a preparation method thereof, in particular to a trametes versicolor glucan water agent for potato Y virus. The water agent comprises the following components in percentage by weight: 1.0 to 2.0 percent of trametes versicolor glucan crude product, 5.0 to 8.0 percent of surfactant alkyl glucoside, 3.0 to 5.0 percent of decomposition-preventing agent 1,2-butanediol, 4.0 to 10.0 percent of antifreezing agent glycerol and the balance of double distilled water. The trametes versicolor glucan crude product is prepared by fermenting the trametes versicolor strain with the collection number of CGMCC No.6760 and extracting the glucan. The average control effect of 500-fold solution of the trametes versicolor glucan water agent on the potato Y virus is more than 78 percent, in particular, the average control effect of 1.1 percent trametes versicolor glucan water agent on the potato Y virus is up to 80.4 percent and is more excellent than 30-fold solution of 20 percent gram Y Tring wettable powder.

Owner:西安恒田生物科技有限公司

Crop gray mold prevention and treatment agent and preparation method thereof

ActiveCN103349021APlay a preventive roleGood treatment effectBiocideFungicidesCure ratePesticide residue

The invention relates to a crop gray mold prevention and treatment agent, which takes an extract of a leaf of cattail as a raw material. The extract comprises a preservative. According to the agent, the leaf of the cattail is taken as the raw material; the extract can be obtained by decocting or juicing, then is sprayed onto crops after diluted with water, and can exert a prevention function when the crops are not attacked, and exert a good treatment function when the crops are attacked; a cure rate reaches 100% according to a field test; the agent not only can prevent and treat gray mold, but also has an obvious preventive effect on other fungus diseases; and in addition, the leaf of the cattail is a wild vegetable, and can be eaten, so that the problem of pesticide residue cannot occur in actual use.

Owner:天津市蓟县绿普生蔬菜种植有限公司

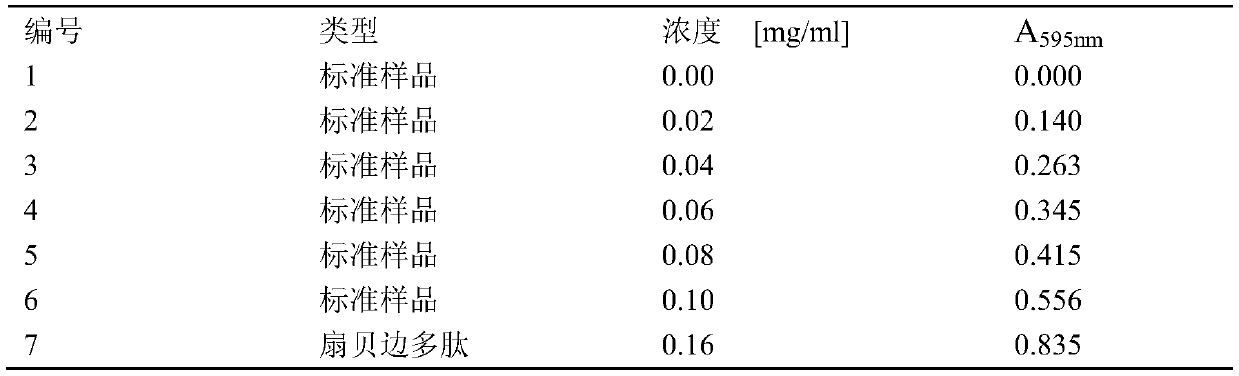

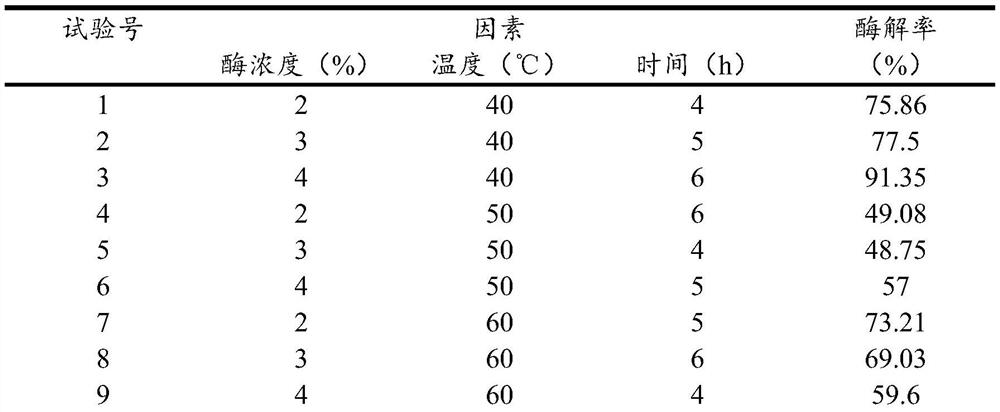

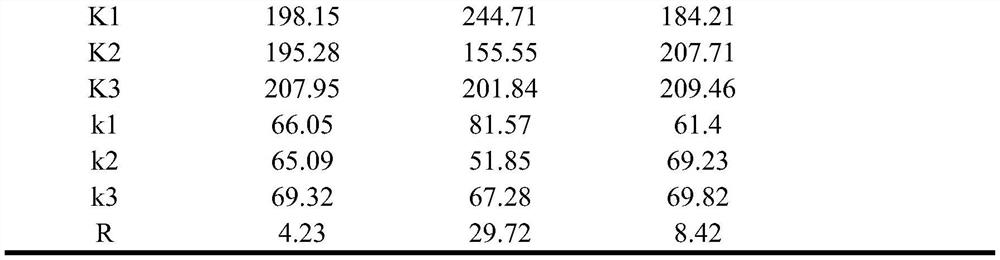

Preparation method and application of scallop edge whitening peptide

ActiveCN107523601BEasy to prepareEasy to operateCosmetic preparationsToilet preparationsTyrosineTyrosinase

The invention discloses a preparation method and application of a scallop edge whitening peptide. The preparation method of the whitening peptide includes: (1) scallop edge pretreatment: take the scallop edge, cut it into pieces, add water with a set multiple of the scallop edge mass to carry out Homogenize to get scallop edge homogenate; (2) Enzymolysis: Add pepsin and trypsin to the scallop edge homogenate in step (1) successively for enzymolysis to obtain enzymolysis; (3) Adjustment step (2) The pH of the enzymolysis solution is 6.8-7.2, centrifuged to take the supernatant to concentrate, add a set proportion of absolute ethanol, stir alcohol precipitation, the supernatant after centrifugation is the crude extract of scallop edge polypeptide; after purification, the scallop Edge Whitening Peptides. The invention only needs simple double enzymatic hydrolysis and alcohol precipitation process to obtain the scallop edge whitening peptide which can significantly inhibit the activity of tyrosinase, has the application potential as an active ingredient of whitening cosmetics, and has high activity, good biocompatibility, and safety Advantages such as non-toxic and side effects.

Owner:SHANDONG UNIV

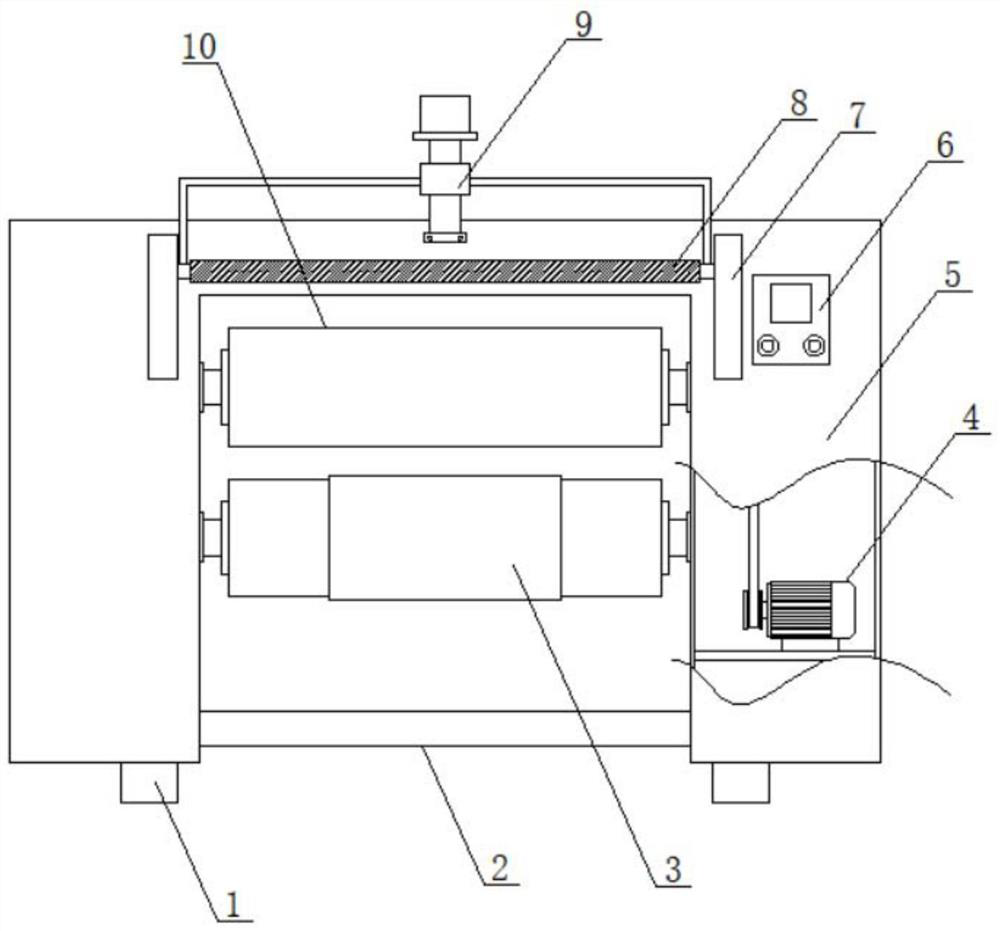

Printed matter die cutting device

PendingCN113771134AAvoid incomplete cleaningEasy to adjustMetal working apparatusElectric machineryEngineering

The invention discloses a printed matter die cutting device which comprises a machine box and foot pads, wherein one foot pad is arranged on each of the left side and the right side of the lower end of the machine box, the machine box is fixedly connected with the foot pads through bolts, a controller is arranged on the right side of the front end of the machine box and electrically connected with a power source, and a transmission mechanism is arranged at the right end in the machine box. For the printed matter die cutting device disclosed by the invention, by changing a traditional manual adjustment mode into an existing mode of connection transmission through a lead screw and a sleeve, in this way, adjustment can be more convenient and faster, and different heights of the two sides cannot occur during adjustment. When the printed matter die cutting device is used for cleaning, at this time, a second motor rotates to drive the lead screw to rotate and can rotate forwards and backwards, so that the sleeve can move up and down, a bracket can be driven to move, a cleaning roller can move, the left end and the right end of the cleaning roller are the same in elevation, cleaning can be more thorough, and residues are avoided.

Owner:无锡市春阳印刷包装有限公司

Treatment method for mites of pleurotus geesteranus

The invention discloses a treatment method for mites of pleurotus geesteranus and relates to the technical field of edible mushroom pest control. The method includes the following steps that compost is subjected to heaping fermentation, when the temperature of the heaping position 25-30 cm deep is 65-70 DEG C, fermentation is carried out for 32-36 hours, and then heaps are turned over; when the temperature of the heaping position 25-30 cm position is 65-70 DEG C again, fermentation is carried out for 6-8 hours, the heaps are cooled to 25 DEG C, and the heaps are bagged for inoculation; fungus bags are moved into a culture chamber, a yellow plate with the surface coated with mineral oil is hung in the culture chamber every 12-15 square meters, and yellow plates are replaced every 7-10 days; after hyphae are full of the bags, the bags are moved into a mushroom house for bag arrangement, a vessel is put on a mushroom bed of the mushroom house every 8-10 square meters, mixed liquor formed by starch, cane sugar, plant ash and water is put in the vessels, and the mixed liquor in the vessels is replaced every 10-15 days. The problem that medicine residues exist in existing pleurotus geesteranus mite treatment, so that human health is affected is solved.

Owner:LIUCHENG XINTIANDI ECOLOGICAL AGRI DEV

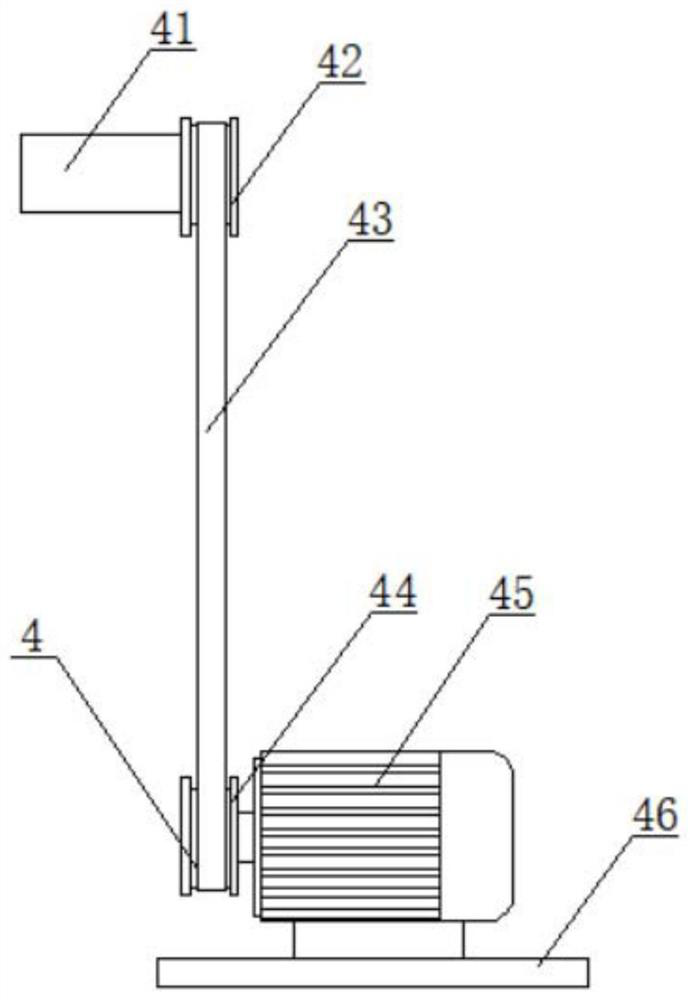

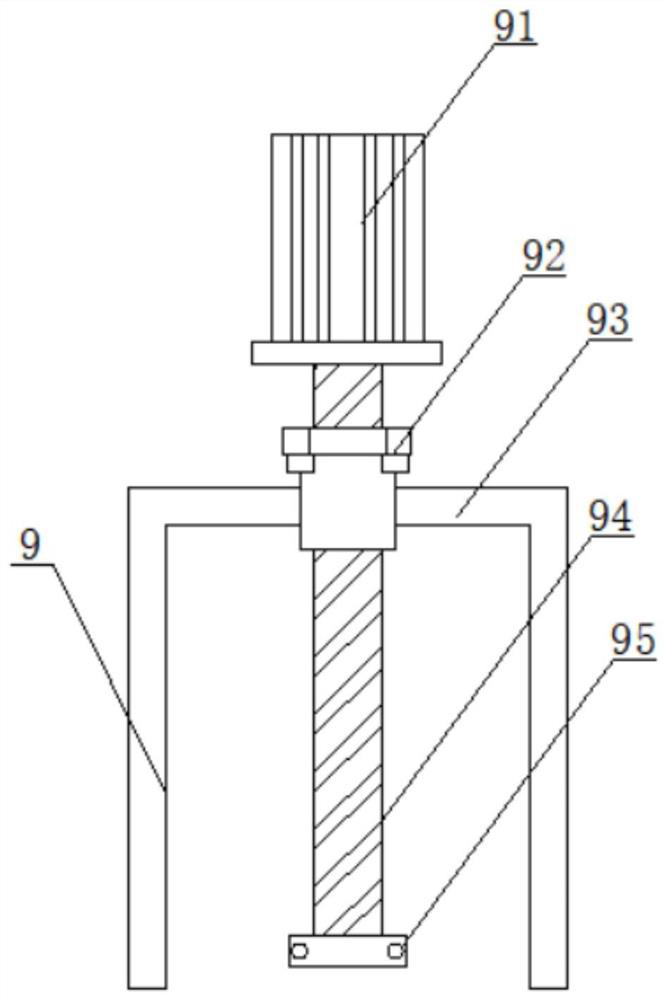

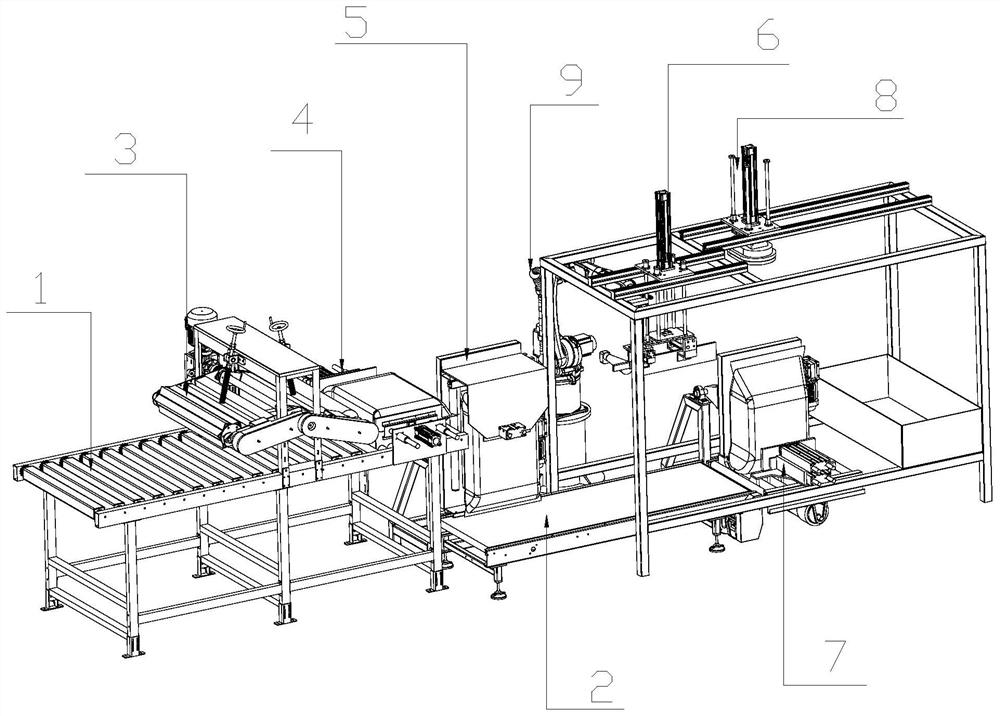

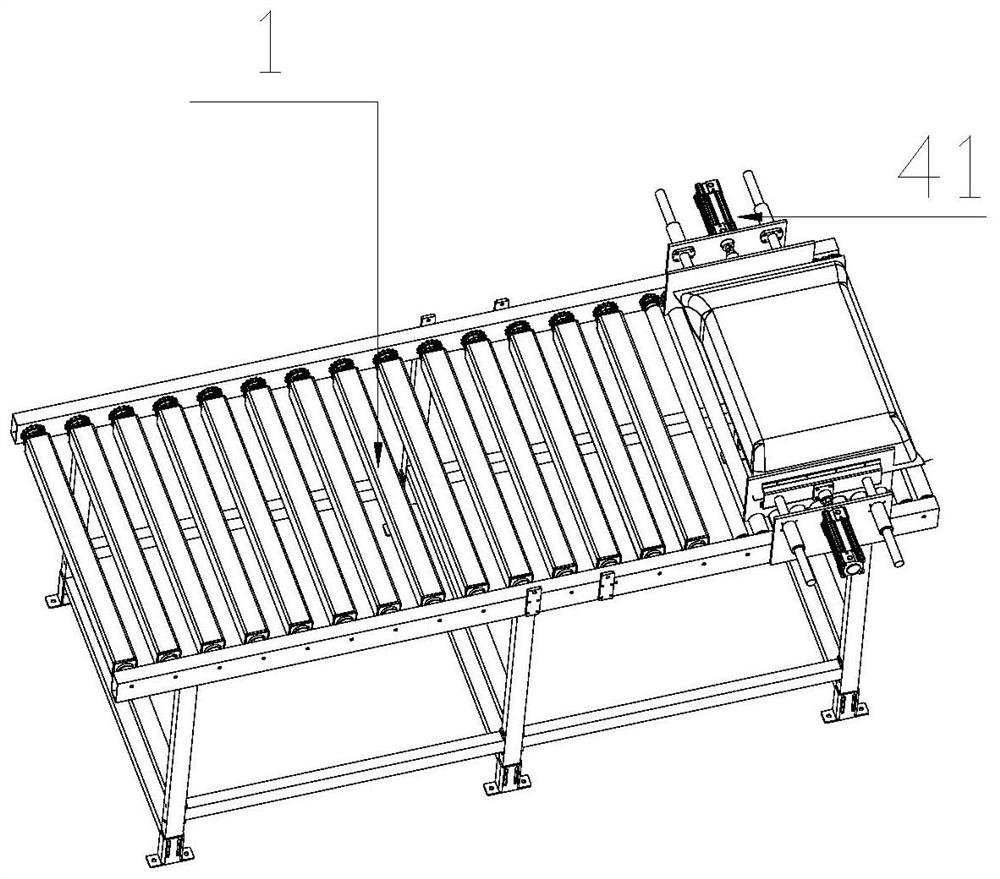

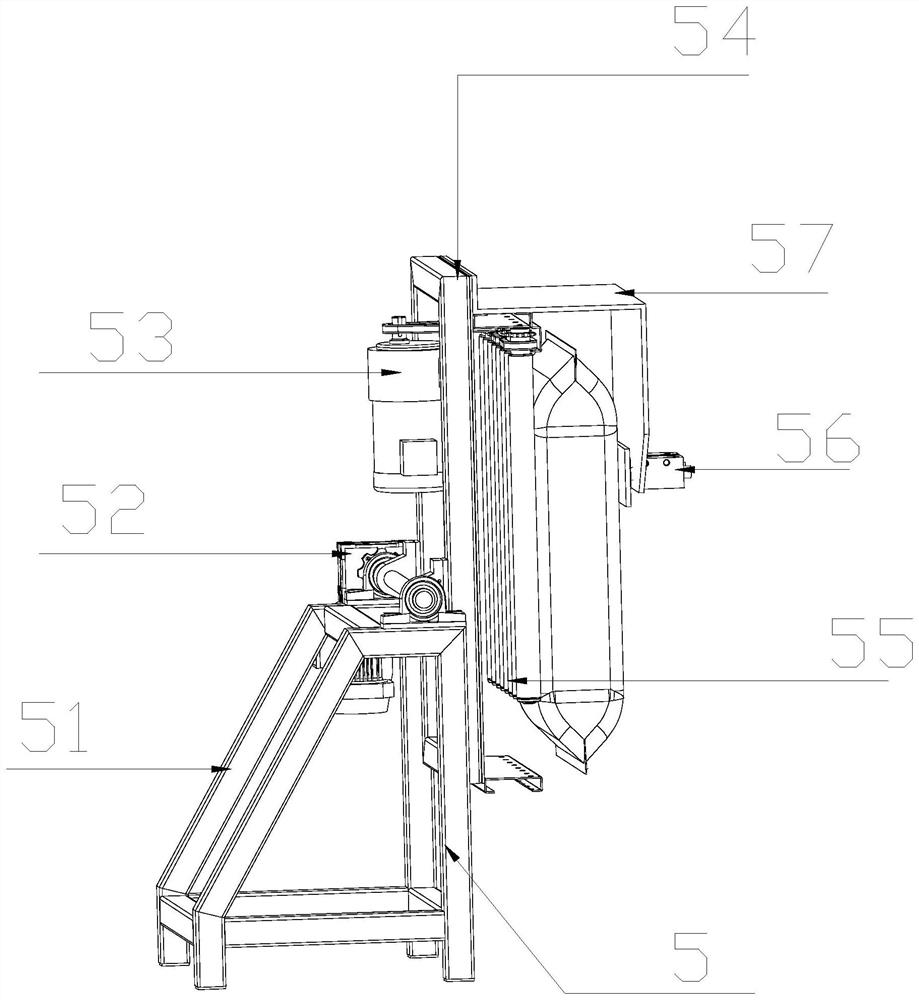

Bag opening system for bag with sealing rope

ActiveCN113173305ARealize automatic recyclingNo residual problemsPlastic recyclingUnpacking by cuttingStructural engineeringMechanical engineering

The invention provides a bag opening system for a bag with a sealing rope. The bag opening system comprises a conveying mechanism, a leveling mechanism, a bag overturning and standing mechanism, a bag positioning mechanism and a discharging mechanism, wherein the leveling mechanism, the bag overturning and standing mechanism, the bag positioning mechanism and the discharging mechanism are arranged on the conveying mechanism in sequence; a bag opening robot is arranged on one side of the bag positioning mechanism; and a bag recycling mechanism is arranged above the discharging mechanism. According to the bag opening system for the bag with the sealing rope, the robot can automatically open the sealing rope and automatically pour materials, and the bag and the rope can be automatically recycled; in the process, the materials cannot be polluted by sundries, and the problem of material residues cannot occur; and the working efficiency is improved, the working quality is controllable, and the labor intensity of workers is reduced.

Owner:天津日博工业技术有限公司

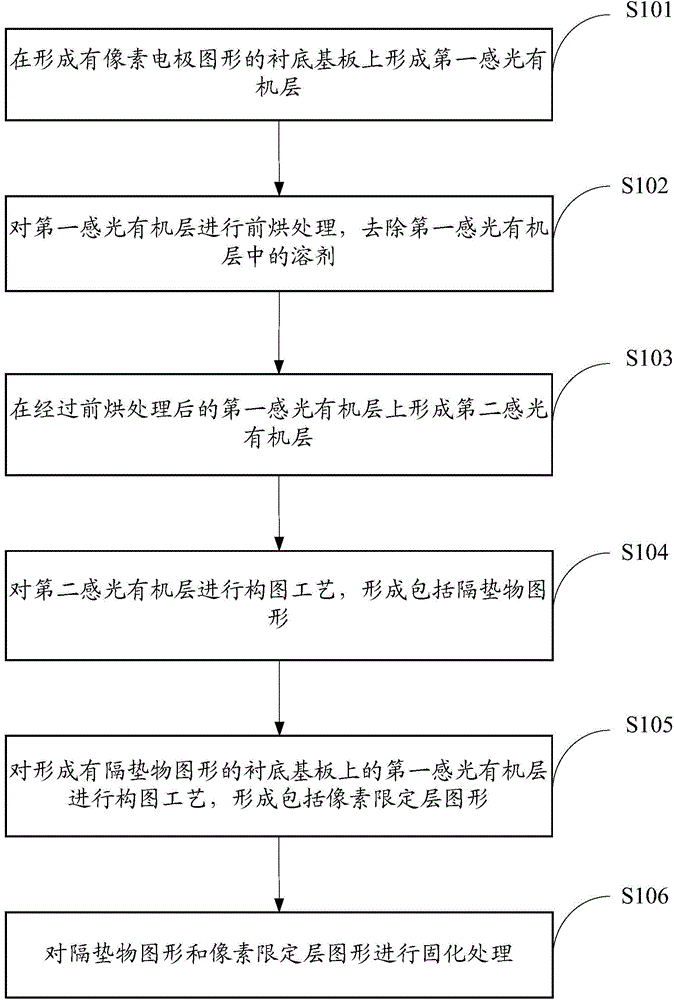

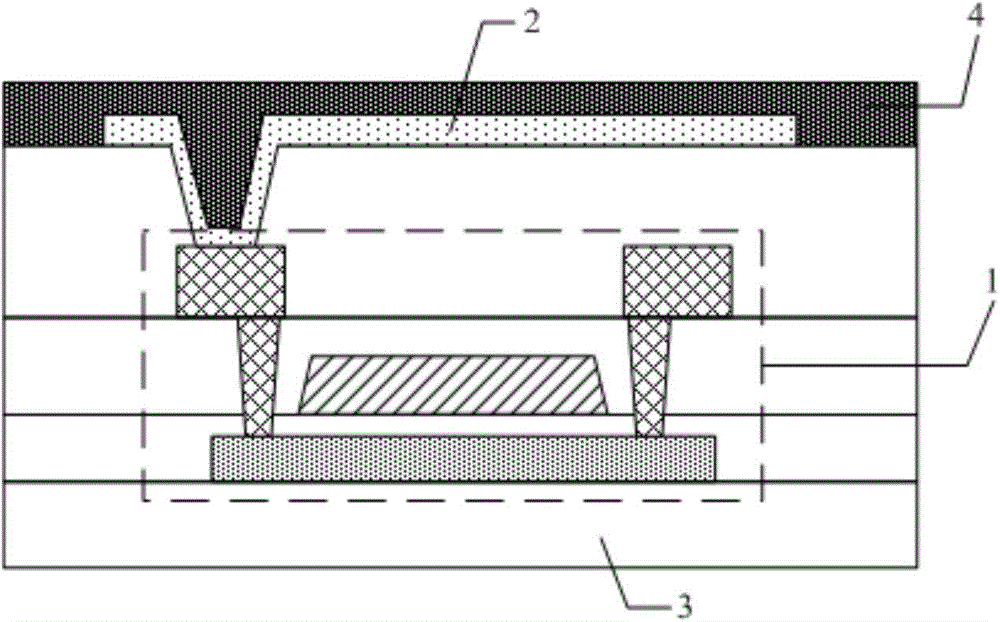

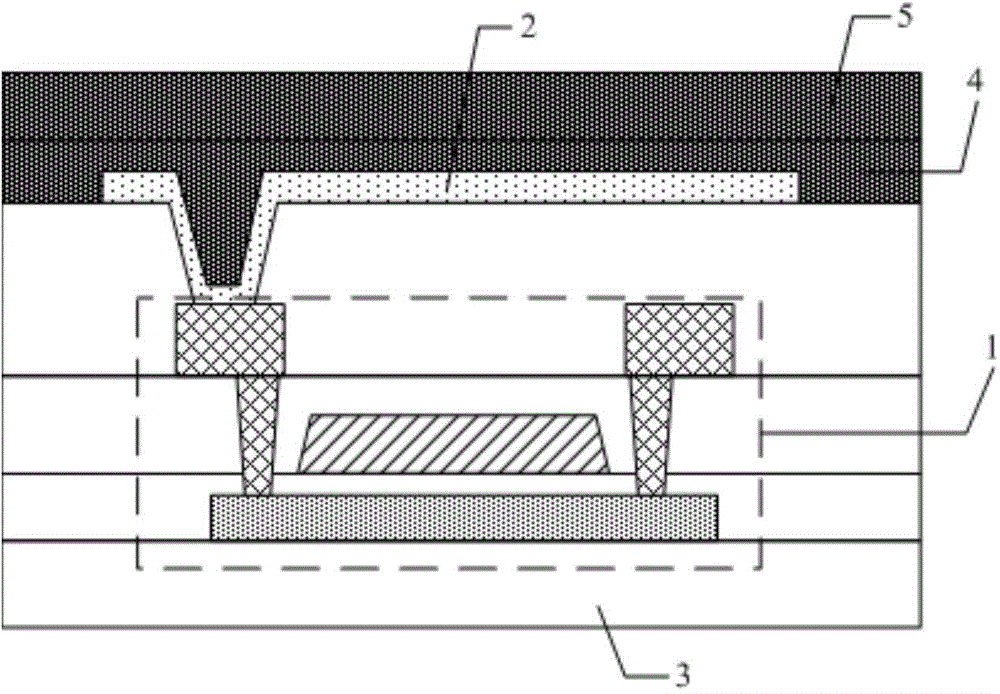

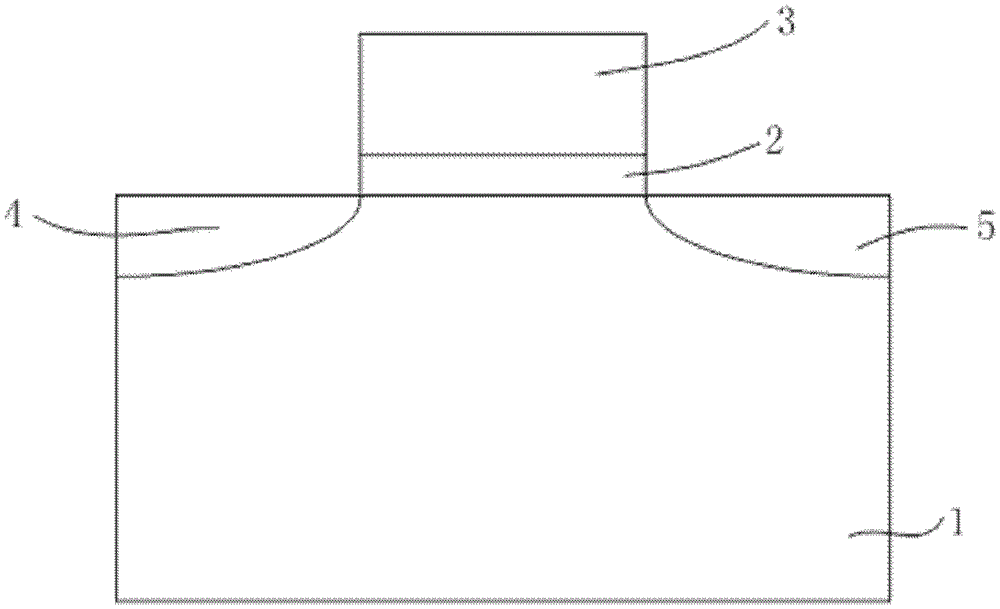

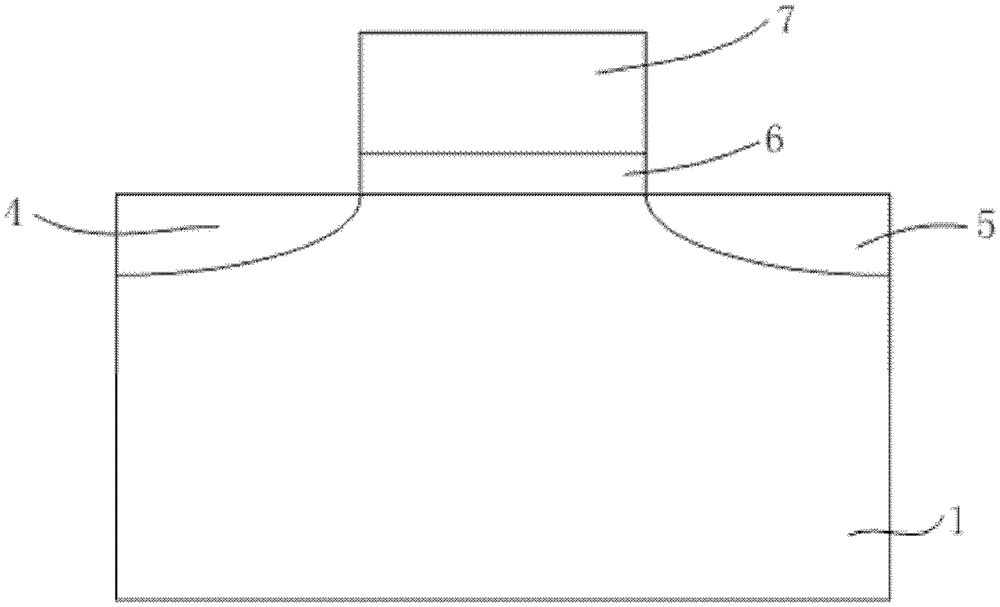

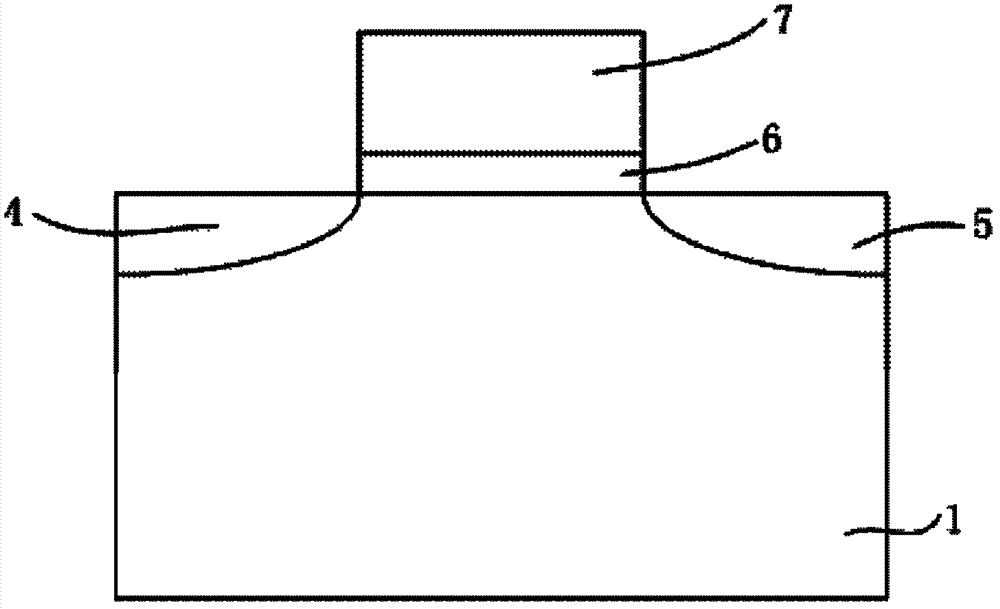

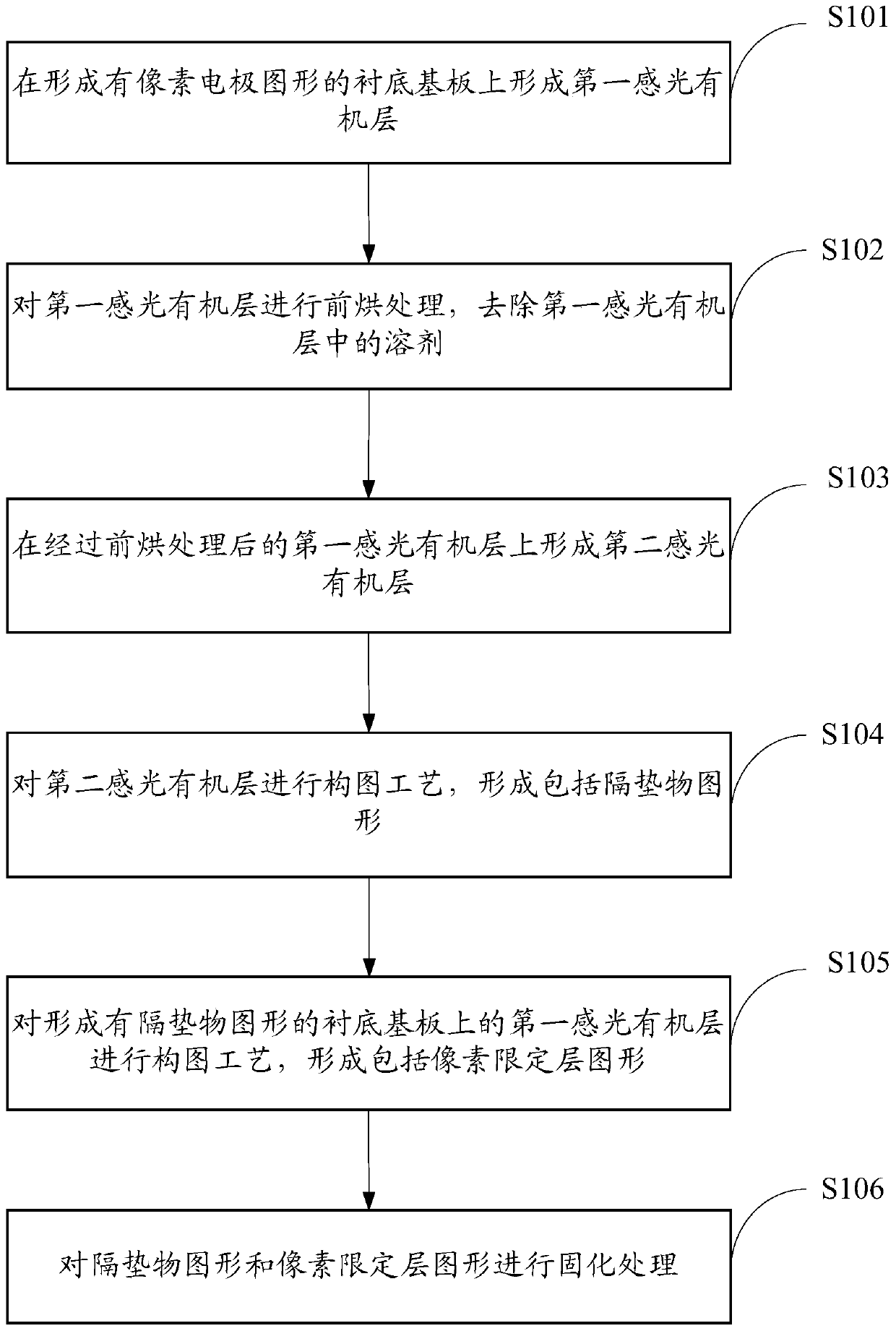

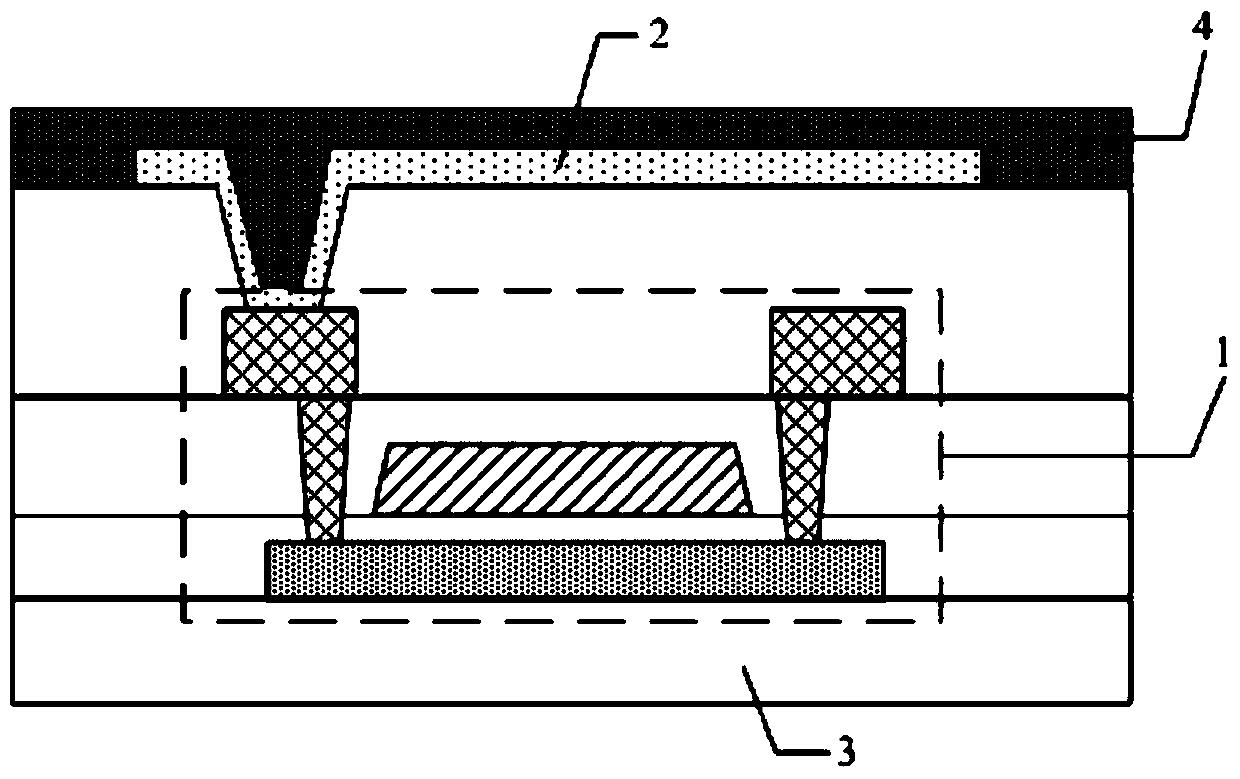

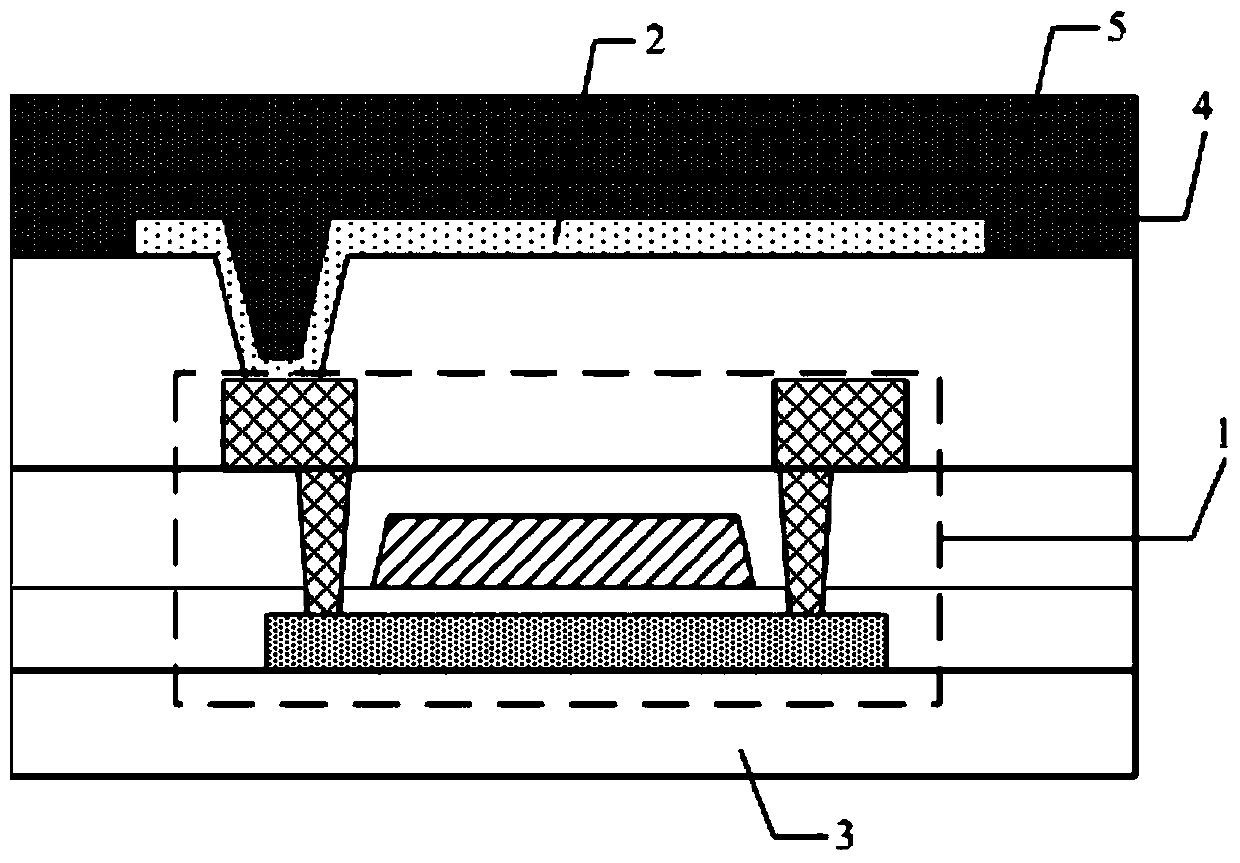

Array substrate of organic electroluminescent display panel, manufacturing method and display device

ActiveCN104576528AReduce photosensitivityImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyOrganic layer

The invention discloses an array substrate, a manufacturing method and a display device of an organic electroluminescent display panel. According to the manufacturing method of the array substrate, after a first photosensitive organic layer is formed, prebaking treatment is carried out on the first photosensitive organic layer, a solvent in the first photosensitive organic layer is removed, and therefore adhesion between the first photosensitive organic layer and a film layer where a pixel electrode is located is enhanced, and photonasty of the first photosensitive organic layer is reduced; then, a second photosensitive organic layer is formed on the first photosensitive organic layer, and the composition technology is carried out on the second photosensitive organic layer to form a spacer graph, and the first photosensitive organic layer cannot be affected; the composition technology is carried out on the first photosensitive organic layer to form a pixel limit layer graph, and primary curing treatment is carried out on the spacer graph and the pixel limit layer graph. Therefore primary curing treatment can be omitted, so that the manufacturing technology of a spacer and the pixel limit layer is simplified. The problem that organic material residues cannot exist is solved.

Owner:BOE TECH GRP CO LTD

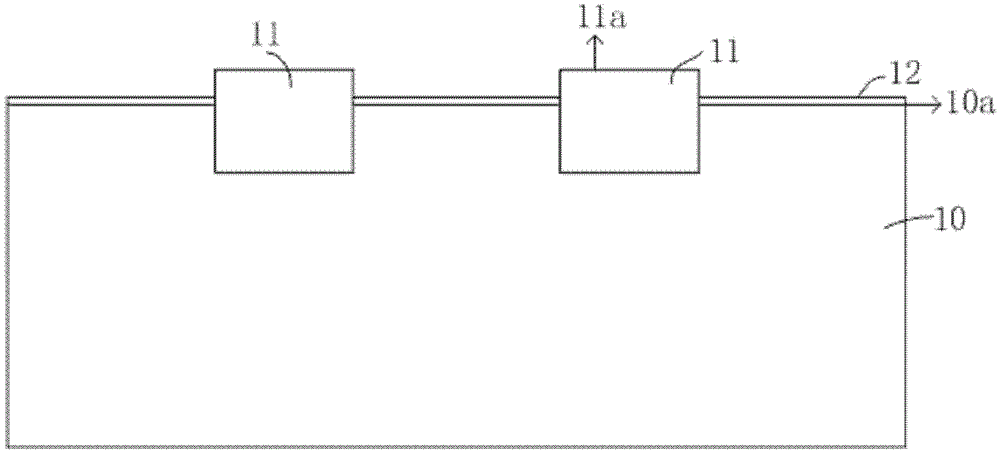

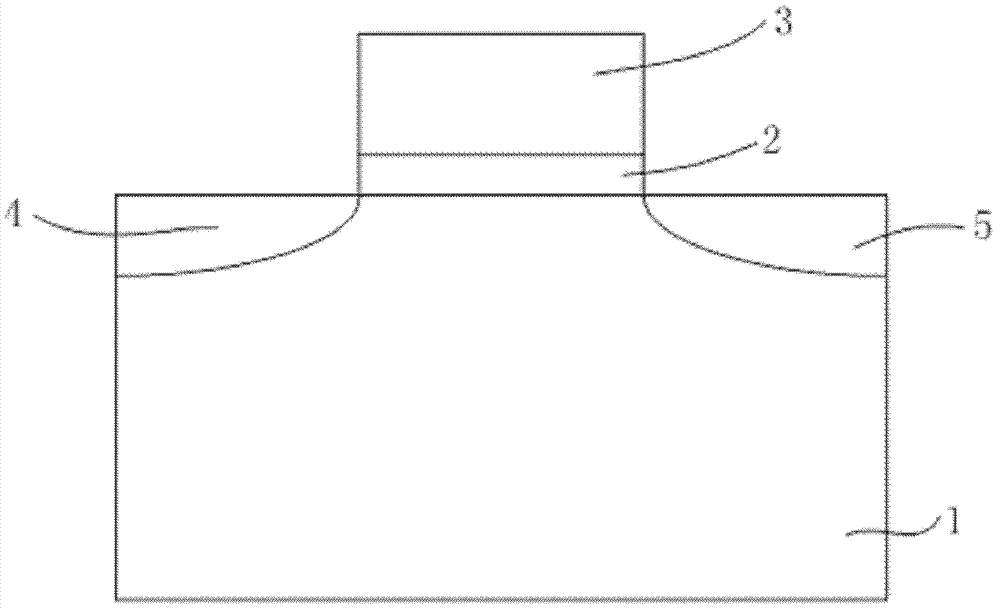

Method for fabricating semiconductor device with metal gate stack

ActiveCN103117214BReduce aspect ratioNo residual problemsSemiconductor devicesEngineeringSemiconductor

The invention provides a manufacture method of a semiconductor device provided with a metal grid lamination. The manufacture method of the semiconductor device provided with the metal grid lamination comprises the steps: forming shallow groove isolation structures on a semiconductor substrate, wherein the tops of the shallow groove isolation structures are higher than the surface of the semiconductor substrate; forming a filling layer on the semiconductor substrate and removing the filling layer which exceeds the tops of the shallow groove isolation structures, enabling the filling layer surface and the tops of the shallow groove isolation structures to be located on the same height through controlling the technology precision when the filling layer is removed, and enabling the tops of polycrystalline silicon virtual grids on the shallow groove isolation structures and the top of a polycrystalline silicon virtual grid between two adjacent shallow groove isolation structures to be located on the same height in the subsequent manufacture process. Therefore, a series of problems which are caused due to the fact that the tops of the polycrystalline silicon virtual grids are not located on the same height in an existing manufacturing method are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

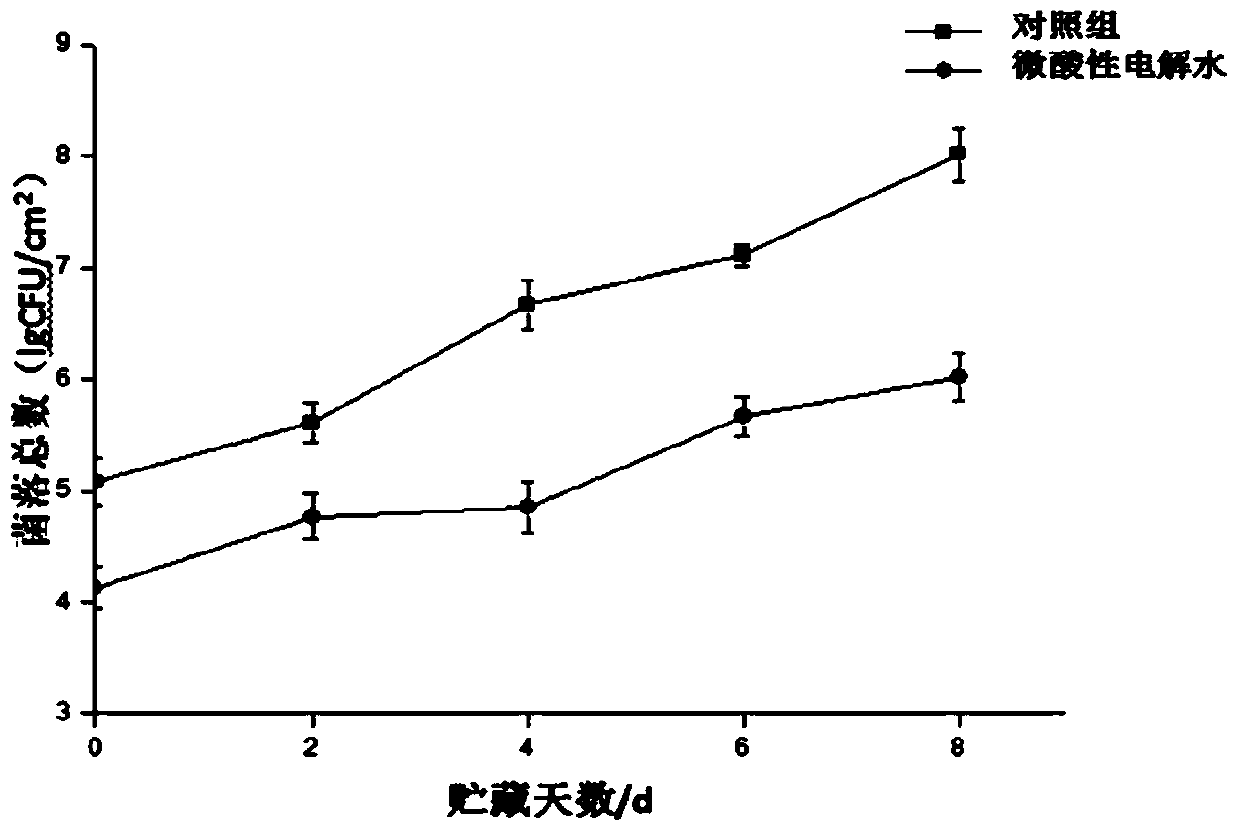

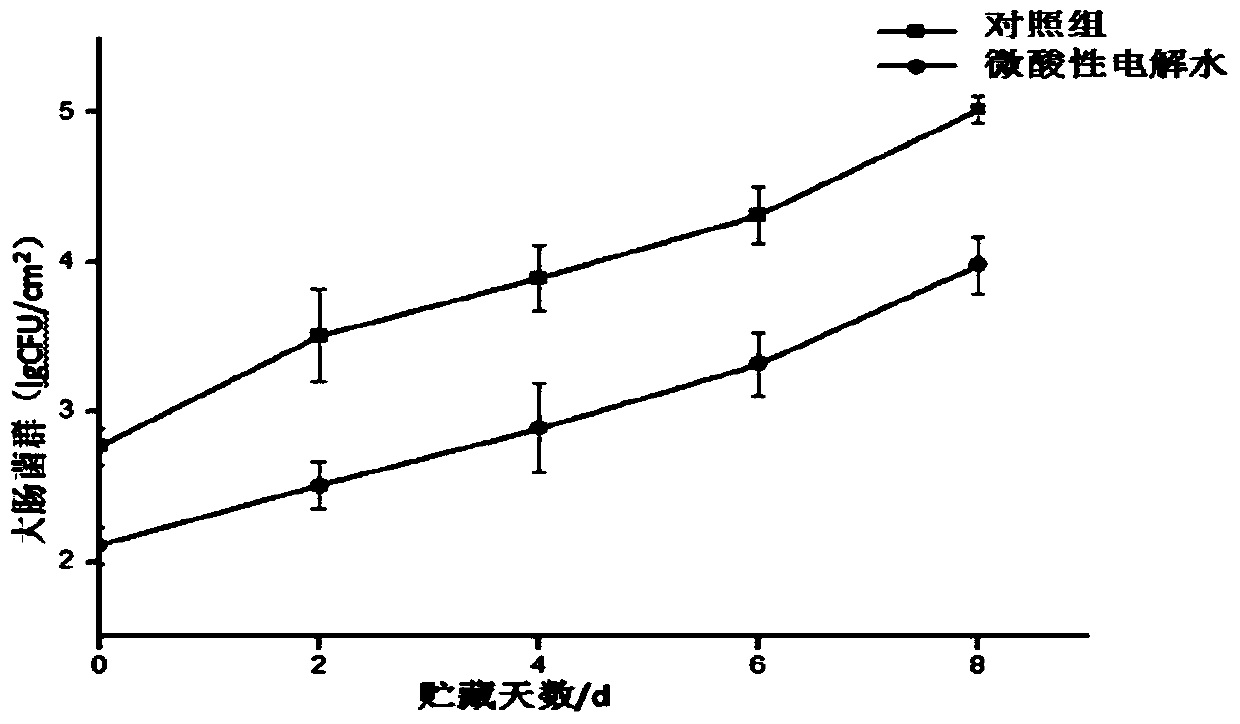

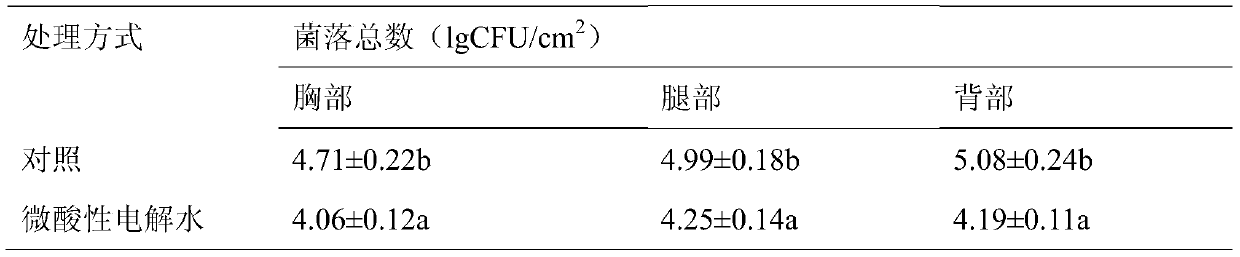

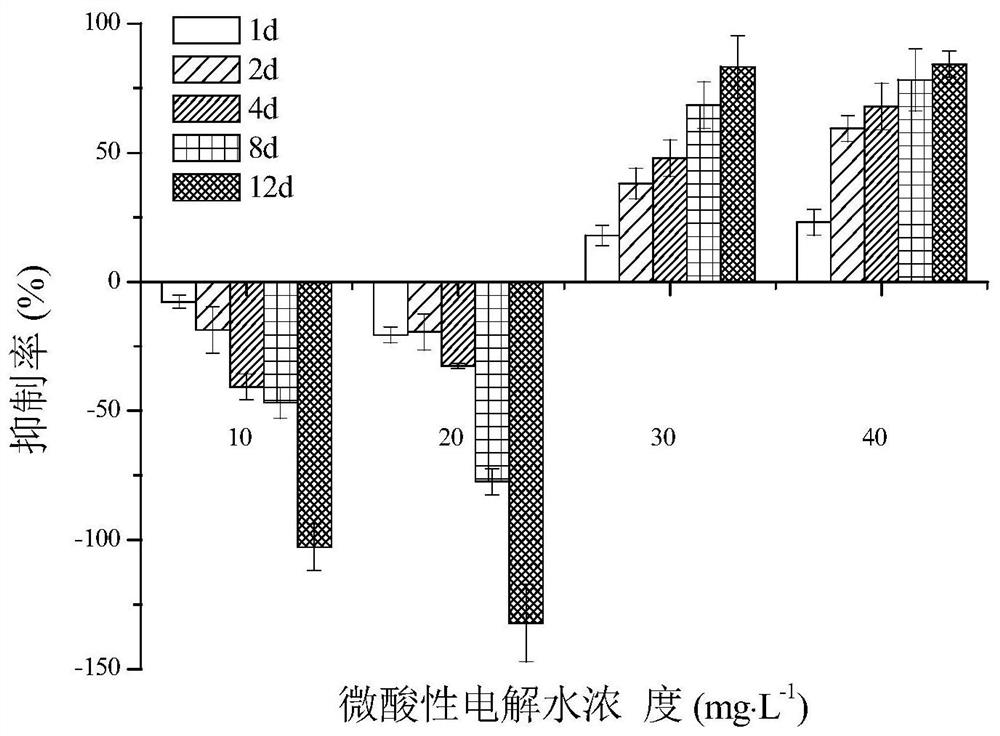

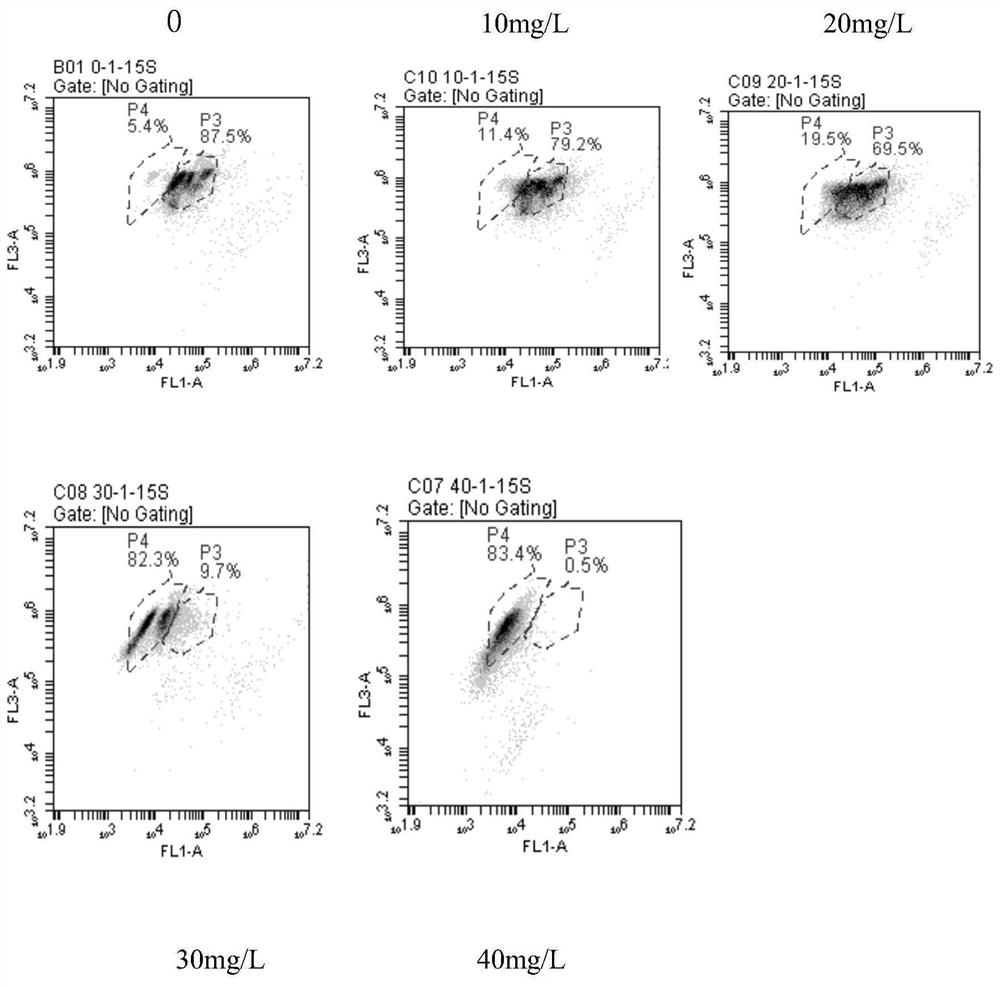

Bacteria reduction treatment method for broiler carcasses after pre-cooling based on slightly acidic electrolyzed water

ActiveCN105851197BReduce pollutionReduce negative impactMeat/fish preservation using liquidsMeat/fish preservation by freezing/coolingProduction lineElectrolysis

The invention provides a method for carrying out bacteria-reducing treatment on precooled chicken carcasses based on slightly acidic electrolyzed water. According to the method, the slightly acidic electrolyzed water is used for acting on the precooled chicken carcasses in a pressure spraying way, and then bacteria-reducing treatment is carried out. After the method is adopted, the initial bacteria carrying amounts of all parts of the surfaces of the chicken carcasses are effectively reduced, the shelf lives of the chicken carcasses are prolonged, and the colors of the surfaces of the chicken carcasses are not influenced. After the carcasses are precooled, a spray washing action way is adopted, so that the disadvantage of a poor bacteria-reducing effect caused by cross contamination and organic matter accumulation in a precooling process of the traditional chicken slaughtering processing production line is made up. The slightly acidic electrolyzed water has the advantages of being efficient, economical, environment-friendly, free from residue and recyclable, thus not influencing the sensory quality of the chicken carcasses, protecting human health and environment, saving water and lowering the costs of related slaughtering production enterprises while playing a good role in bacteria reduction.

Owner:NANJING AGRICULTURAL UNIVERSITY

A controllable preparation method and application of polylactic acid/hydroxyapatite composite microsphere surface porous structure

ActiveCN107519536BNo residual problemsSimple preparation processInorganic non-active ingredientsPharmaceutical delivery mechanismSelective laser sinteringEmulsion

The invention discloses a controlled preparation method of the surface porous structure of polylactic acid / HAP (hydroxyapatite) composite microspheres and application. The method is characterized in that HAP and polylactic acid are used as raw materials; the controlled preparation of the surface porous structure of the polylactic acid / HAP composite microspheres is realized by regulating and controlling the size of the HAP on the basis of an emulsion solvent volatilization method. By the method, the additional addition of pore-forming agents is not needed; the self ingredients of the composite microspheres are used for pore formation; the surface hole structure of the prepared microspheres is easy to control. The porous polylactic acid / HAP composite microspheres can be used for additive manufacturing of selective laser sintering and for preparing bone defect repair materials and can also be used as a medicine release carrier for disease treatment.

Owner:WUHAN UNIV OF TECH

Trametes versicolor glucan water agent and preparation method thereof

ActiveCN103070172BNo residual problemsGood environmental compatibilityBiocideDisinfectantsDecompositionGlycerol

The invention relates to a trametes versicolor glucan water agent and a preparation method thereof, in particular to a trametes versicolor glucan water agent for potato Y virus. The water agent comprises the following components in percentage by weight: 1.0 to 2.0 percent of trametes versicolor glucan crude product, 5.0 to 8.0 percent of surfactant alkyl glucoside, 3.0 to 5.0 percent of decomposition-preventing agent 1,2-butanediol, 4.0 to 10.0 percent of antifreezing agent glycerol and the balance of double distilled water. The trametes versicolor glucan crude product is prepared by fermenting the trametes versicolor strain with the collection number of CGMCC No.6760 and extracting the glucan. The average control effect of 500-fold solution of the trametes versicolor glucan water agent on the potato Y virus is more than 78 percent, in particular, the average control effect of 1.1 percent trametes versicolor glucan water agent on the potato Y virus is up to 80.4 percent and is more excellent than 30-fold solution of 20 percent gram Y Tring wettable powder.

Owner:西安恒田生物科技有限公司

A kind of extraction method of Ankang cod liver oil

ActiveCN104651033BImprove qualityHigh extraction rateFatty-oils/fats refiningFatty-oils/fats productionCod liver oilPhosphoric acid

The invention relates to an extracting and refining method of Monkfish liver oil, and belongs to the technical field of aquatic product intensive processing. With Monkfish livers as raw materials, the fish liver oil is extracted from the Monkfish livers by a light alkali hydrolysis and then is refined. The extracting method comprises the following steps of cleaning fresh Monkfish livers, removing impurities, stirring to form a fat paste, degrading protein by a light alkali solution, destroying the combination relation between protein and fat, separating out fat, extracting crude fish liver oil, degumming by phosphoric acid, de-acidifying by sodium hydroxide, de-coloring by activated clay and deodorizing in vacuum, extracting high-quality fish liver oil. The method is simple, the cost is low, the extracting efficiency is high, and the quality of the fish liver oil is good.

Owner:SHANGHAI INST OF TECH

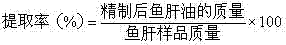

Method for preventing and treating kadsura coccinea leaf blight disease

The invention belongs to the technical field of prevention and treatment of plant diseases and pests, and particularly relates to a method for preventing and treating the kadsura coccinea leaf blightdisease. The method specifically comprises the following step: spraying traditional Chinese medicinal liquid at the early onset once a day, wherein the spraying amount for each plant is 50 to 100 ml.The traditional Chinese medicinal liquid is prepared from the following raw materials in parts by weight: 20 to 50 parts of fructus cnidii, 10 to 40 parts of calamine, 5 to 20 parts of pericarpium granati, 3 to 16 parts of oldenlandia diffusa and 1 to 6 parts of folium ilicis purpurea. By the use of the method disclosed by the invention, during prevention and treatment of the leaf blight disease,and the problem of remaining of harmful substances is solved; furthermore, the method is efficient, green, environmentally friendly and pollution-free.

Owner:桂林斯泰硕农农业科技有限公司

Sea cucumber fat-soluble extract, lip balm containing the extract and preparation method

ActiveCN105832646BEasy to prepareEasy to operateCosmetic preparationsToilet preparationsBiotechnologyHydrolysate

The invention discloses a fat-soluble extract of a sea cucumber, a lipstick containing the extract and preparation methods of the fat-soluble extract and the lipstick containing the extract. The preparation method of the extract comprises the following steps of (1), preprocessing the sea cucumber, so as to obtain a homogenate of the sea cucumber; (2), enzymolysis: carrying out enzymolysis on the homogenate of the sea cucumber in the step (1) through pepsase and trypsase in sequence, so as to obtain an enzymatic hydrolysate; (3), regulating the pH (potential of Hydrogen) of the enzymatic hydrolysate to be 6.8 to 7.2, taking a supernatant fluid to carry out concentration, then adding sesame oil in a set proportion into the supernatant fluid, agitating and extracting an obtained mixture for several times, carrying out centrifugation after extraction, and merging supernatant fluids to obtain the fat-soluble extract of the sea cucumber. The lipstick containing the extract, which is provided by the invention, has a better rehabilitation effect, and the phenomenon that a lip becomes dry and chapped can be removed within a short time through rehabilitation.

Owner:YANTAI HUAKANG SEAFOOD

Thick-shell mussel fat-soluble extract, preparation method and application thereof

InactiveCN101606951BPrevent oxidationIncrease contentAntipyreticDigestive systemFreeze-dryingFreeze dry

The invention discloses a preparation method of a thick-shell mussel fat-soluble extract, comprising the following steps: (1) thick-shell mussel preprocessing; (2) freeze drying, namely, firstly carrying out freeze drying on the meat scraps of thick-shell mussels and then pulverizing the obtained freeze-drying thick-shell mussel meat in a pulverizer; and (3) supercritical CO2 extraction, namely, carrying out supercritical CO2 extraction on the freeze-drying powder of the thick-shell mussel meat and obtaining the thick-shell mussel fat-soluble extract. The invention also discloses the thick-shell mussel fat-soluble extract prepared according to the method, which is an antiphlogistic active substance containing various unsaturated fatty acids; the thick-shell mussel fat-soluble extract can be used for preparing antiphlogistic enteropathy medicines or health-care foods.

Owner:ZHEJIANG UNIV +1

A kind of method of industrialized preparation white kidney bean α-amylase inhibitor

ActiveCN108703989BIncrease vitalitySafe and reliableMetabolism disorderNatural extract food ingredientsPlant LectinsAmylase inhibitors

The invention discloses a method for industrially preparing a white kidney bean α-amylase inhibitor, which belongs to the field of preparation of plant active ingredients. In the method of the present invention, white kidney beans are dry-peeled, dry-crushed, and sieved to make soybean powder, then the soybean powder is extracted with water, centrifuged, and the slurry is collected, and the slurry is fully enzymolyzed with β-amylase to obtain the enzyme The enzymolysis liquid is filtered with a ceramic membrane, the obtained filtrate is ultrafiltered with an 80-150kDa ultrafiltration membrane, the permeate is ultrafiltered with a 15-30kDa ultrafiltration membrane, and the retentate is spray-dried to obtain white Kidney bean alpha-amylase inhibitor. The white kidney bean α-amylase inhibitor product prepared by the present invention not only has high α-amylase inhibitor activity, does not contain starch, does not have plant lectin and trypsin inhibitor activity, has reliable physiological efficacy and safety, and is prepared The process is green and environmentally friendly, adapts to the requirements of modern industrial production, and has significant economic and social benefits.

Owner:新产业大健康科技(珠海)有限公司

Preparation method and application of wet-responsive color-changing fiber

ActiveCN112962164BWet Response Color Change RealizationRealize visual monitoringAlginate artificial filamentsMonocomponent synthetic polymer artificial filamentFiberVisual monitoring

The invention provides a preparation method and application of a moisture-responsive color-changing fiber. The preparation method of the moisture-responsive color-changing fiber includes the following steps: passing the spinning dope into a coagulation bath containing nano-microspheres, so that the microspheres are attached to the fiber with hygroscopic expansion to form structural color to obtain the moisture-responsive color-changing fiber. When the color-changing fiber encounters water, the fiber absorbs water and expands, which changes the arrangement of nano-microspheres, and the structural color disappears. After the water evaporates, the fiber returns to its original color. The wet-responsive color-changing fiber is prepared by a wet spinning method, which has a simple process and can be industrially produced; the wet-responsive color-changing fiber prepared by this method has firm adhesion of nano-microspheres and strong practicability; the fiber can develop color when it encounters water, and has a fast response , and the response conditions are wide (cold water vapor can make it change color), which can be applied to the fabric to realize the visual monitoring of the environmental humidity.

Owner:WUHAN TEXTILE UNIV

Manufacture method of semiconductor device provided with metal grid lamination

ActiveCN103117214AReduce aspect ratioNo residual problemsSemiconductor devicesEngineeringSemiconductor

The invention provides a manufacture method of a semiconductor device provided with a metal grid lamination. The manufacture method of the semiconductor device provided with the metal grid lamination comprises the steps: forming shallow groove isolation structures on a semiconductor substrate, wherein the tops of the shallow groove isolation structures are higher than the surface of the semiconductor substrate; forming a filling layer on the semiconductor substrate and removing the filling layer which exceeds the tops of the shallow groove isolation structures, enabling the filling layer surface and the tops of the shallow groove isolation structures to be located on the same height through controlling the technology precision when the filling layer is removed, and enabling the tops of polycrystalline silicon virtual grids on the shallow groove isolation structures and the top of a polycrystalline silicon virtual grid between two adjacent shallow groove isolation structures to be located on the same height in the subsequent manufacture process. Therefore, a series of problems which are caused due to the fact that the tops of the polycrystalline silicon virtual grids are not located on the same height in an existing manufacturing method are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Acid etching surface treating method of tetragonal polycrystal zirconia ceramic implant tooth

The invention records an acid etching surface treating method of a tetragonal polycrystal zirconia ceramic implanting tooth. A ceramic implant tooth is soaked into acid etching solution which contains hydrofluoric acid 55-65 vol.%, phosphoric acid 20-45 vol.%, treatment is conducted at a temperature of 15-35 DEG C for 12-36h. Using acid etching at normal temperature can reach the aim of increasing degree that zirconium oxide ceramic surface is uniformly roughened. According to the acid etching surface treating method of the tetragonal polycrystal zirconia ceramic implanting tooth, compared with commonly adopted surface sand blasting treatment which causes the problem that residues extruded into a coarse surface may cause the risk of tissue inflammation at a surgery patient's periphery of an implanted body, acid solution is adopted instead of sand blasting treatment, which is simple to remove, so residue problem doesn't happen.

Owner:四川北极光口腔医疗器械有限公司

Array substrate of organic electroluminescence display panel, manufacturing method and display device

ActiveCN104576528BReduce photosensitivityImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingGraphicsDisplay device

The invention discloses an array substrate of an organic electroluminescence display panel, a manufacturing method and a display device. In the manufacturing method of the array substrate, after the first photosensitive organic layer is formed, the first photosensitive organic layer is pre-baked , remove the solvent in the first photosensitive organic layer, to enhance the adhesion between the first photosensitive organic layer and the film layer where the pixel electrode is located, and reduce the photosensitivity of the first photosensitive organic layer; after that, in the first photosensitive organic layer Form a second photosensitive organic layer on top, and perform a patterning process on the second photosensitive organic layer to form a spacer pattern, which will not affect the first photosensitive organic layer; after that, perform a patterning process on the first photosensitive organic layer to form a pixel definition layer Graphics, and one curing treatment for spacer graphics and pixel definition layer graphics; in this way, one curing treatment can be reduced, thereby simplifying the manufacturing process of spacer and pixel definition layers, and there will be no problem of organic material residue .

Owner:BOE TECH GRP CO LTD

A kind of versicolor versicolor glucan water-dispersible granule and its preparation method and application

ActiveCN104472485BGood environmental compatibilityNo residual problemsBiocideDisinfectantsWater dispersibleAdhesive

Owner:陕西恒田生物农业有限公司

Pest control method for plantation of crops

The invention provides a pest control method for plantation of crops. A liquid medicine which is used concretely comprises the following raw materials in parts by weight: 10-20 parts of chilli powder, and 1-10 parts of lemonade whose mass concentration is 30%; the control method comprises the following steps: (1) the liquid medicine is prepared into a spraying agent; (2) during prevention, the liquid medicine is sprayed one time a day, and 7 days of continuous spraying is regarded as a period; (3) during treatment, spraying is carried out 2-3 times a day, and 7-10 days of continuous spraying is regarded as a period. The method has the following beneficial effects: crops are sprayed, the method can play a prevention effect before crops are invaded, and the method can play a good treatment effect after crops are invaded; during on-site tests, the cure rate of diseases due to aphids reaches 95%; except control of aphids, the method has obvious preventing, expelling and treating effects for piercing-sucking insect pests, such as Tetranychus cinnbarinus, leaf eating insects, fleas, and mosquitoes without drug residue problems in actual use.

Owner:天津市宝坤农业科技有限公司

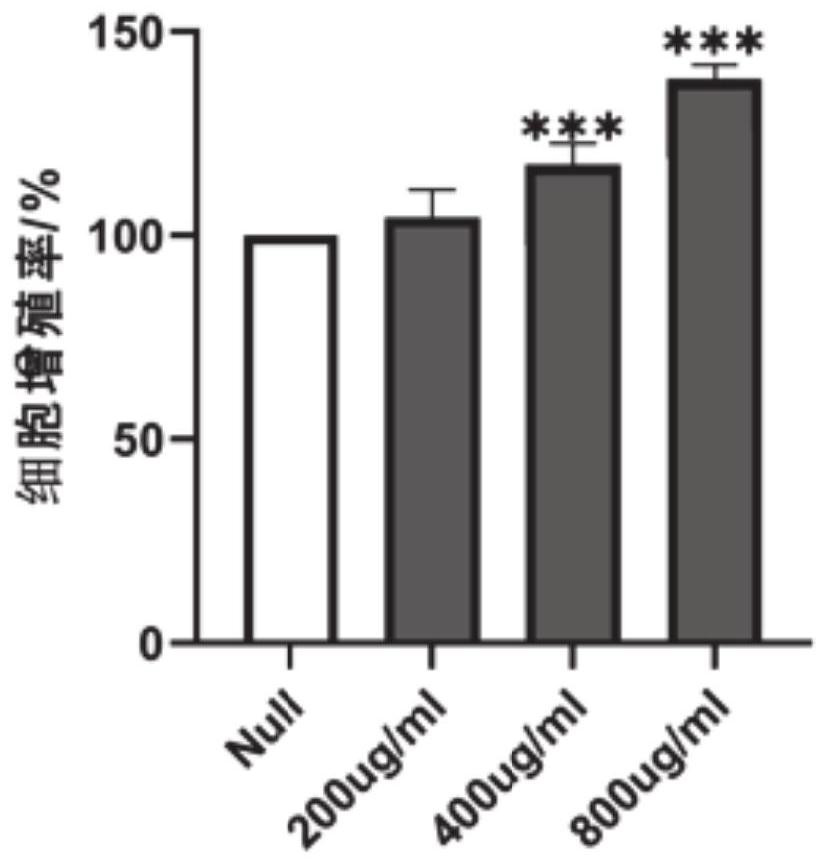

A kind of sea sausage glue and its preparation method and application

ActiveCN113122604BEasy to prepareEasy to operateConnective tissue peptidesPeptide/protein ingredientsMacrophage proliferationEngineering

The invention relates to the field of food processing and application, in particular to a sea sausage glue and a preparation method and application thereof. Collagen from sea sausage was extracted by enzymatic method, and the concentrated gel product was further prepared. The activity of the product was evaluated by measuring its proliferative activity on macrophages, and it was found that it could significantly promote the proliferation of macrophages. This not only prolongs the preservation period of sea sausage, but also is more conducive to further development of sea sausage products, increases resource utilization, and provides a basis for future research and resource development of sea sausage.

Owner:威海银河生物技术股份有限公司

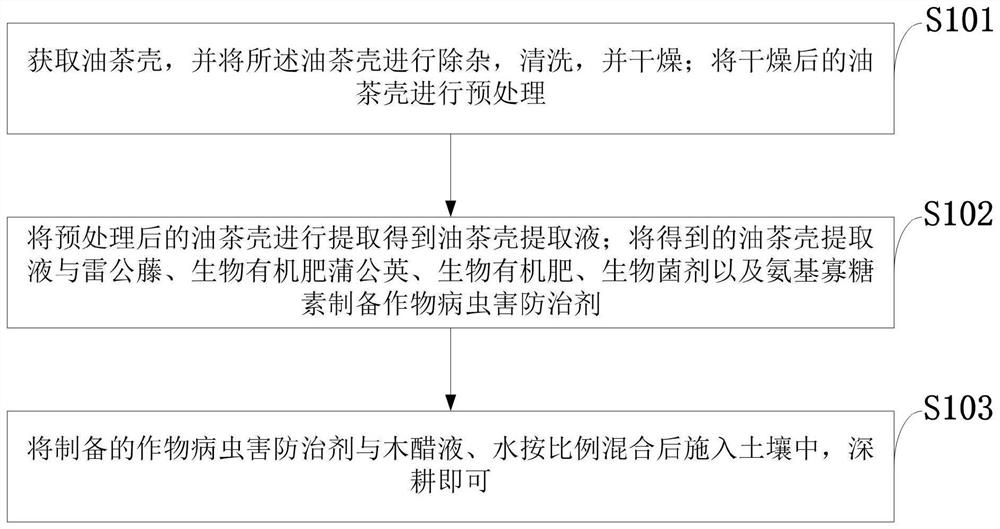

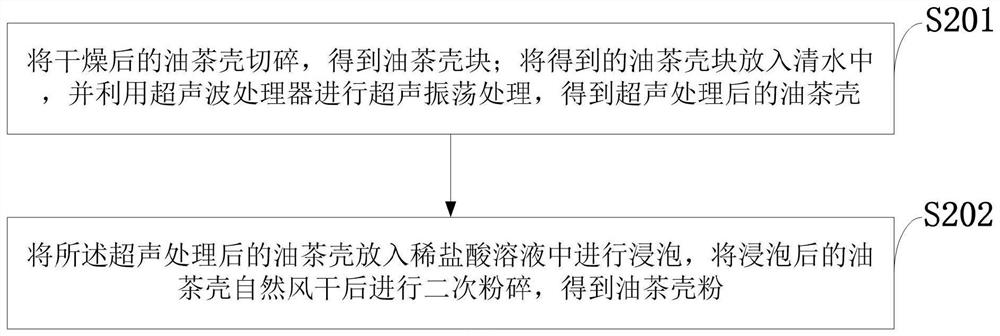

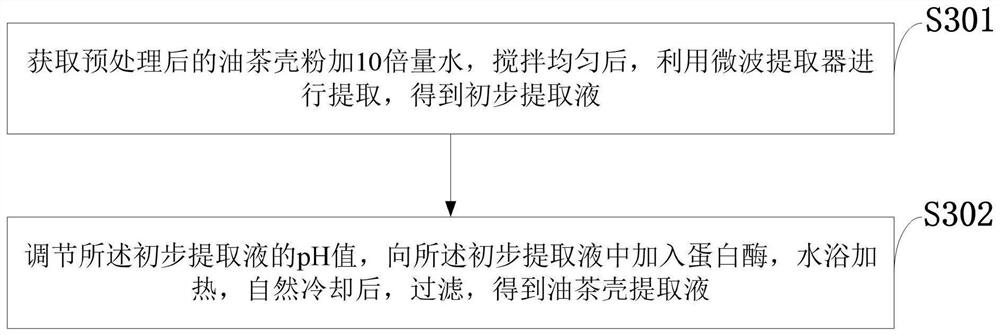

Method for preventing and treating insect pests of crops by utilizing camellia oleifera shells

The invention belongs to the technical field of pest control, and discloses a method for controlling crop pests by using camellia oleifera shells, which comprises the following steps: obtaining camellia oleifera shells, removing impurities from the camellia oleifera shells, and drying; the dried camellia oleifera shells are pretreated; extracting the pretreated camellia oleifera shells to obtain a camellia oleifera shell extracting solution; preparing a crop pest control agent from the obtained camellia oleifera shell extracting solution, tripterygium wilfordii, dandelion, a biological organic fertilizer, a biological agent and amino-oligosaccharin; the prepared crop pest control agent is mixed with wood vinegar and water in proportion and then applied to soil, and deep ploughing is carried out. Natural plants or Chinese herbal medicines such as camellia oleifera shells and tripterygium wilfordii are used for preparing the crop pest control agent, pest control can be effectively carried out, and the control effect is good; meanwhile, the problem of pesticide residues is avoided, and the drug resistance of diseases and pests is not enhanced.

Owner:袁昌选

Method for preventing and treating dying of straw mushroom

InactiveCN107750826AReduce dead mushroomsQuality improvementCultivating equipmentsMushroom cultivationSaccharumSucrose

The invention discloses a method for preventing and treating dying of straw mushroom. The method comprises the following steps: stacking a culturing material and carrying out fermentation, adding 3% of tea seed meal into the obtained stacking material, carrying out uniform mixing under stirring, adding gypsum contained water and carrying out wetting, carrying out fermentation at 45 to 50 DEG C for15 to 20 days, and turning the stacking material once every 2 to 3 days; after the stacking material is turned, tedding the stacking material, carrying out cooling to 25 DEG C, and carrying out bagging; after completion of bagging, carrying out sterilization at atmospheric pressure to 100 DEG C, and maintaining the temperature for 8 to 10 hours; after completion of sterilization, transferring sterilized strain bags into a culture room, hanging one ozone generator every 12 to 15 square meters into the culture room, carrying out incubation for 30 minutes, opening the ozone generator, closing the ozone generator after 60 minutes, and starting inoculating when ozone is decomposed into oxygen in 30 minutes; and when the strain bags are full of mycelia, transferring the strain bags into a mushroom room, permutating the strain bags, placing one vessel every 8 to 10 square meters on a mushroom bed, putting a mixed solution formed by starch, sucrose, plant ash and water into the vessel, and replacing the mixed solution once every 10 and 15 days.

Owner:太湖县金江源农业发展有限公司

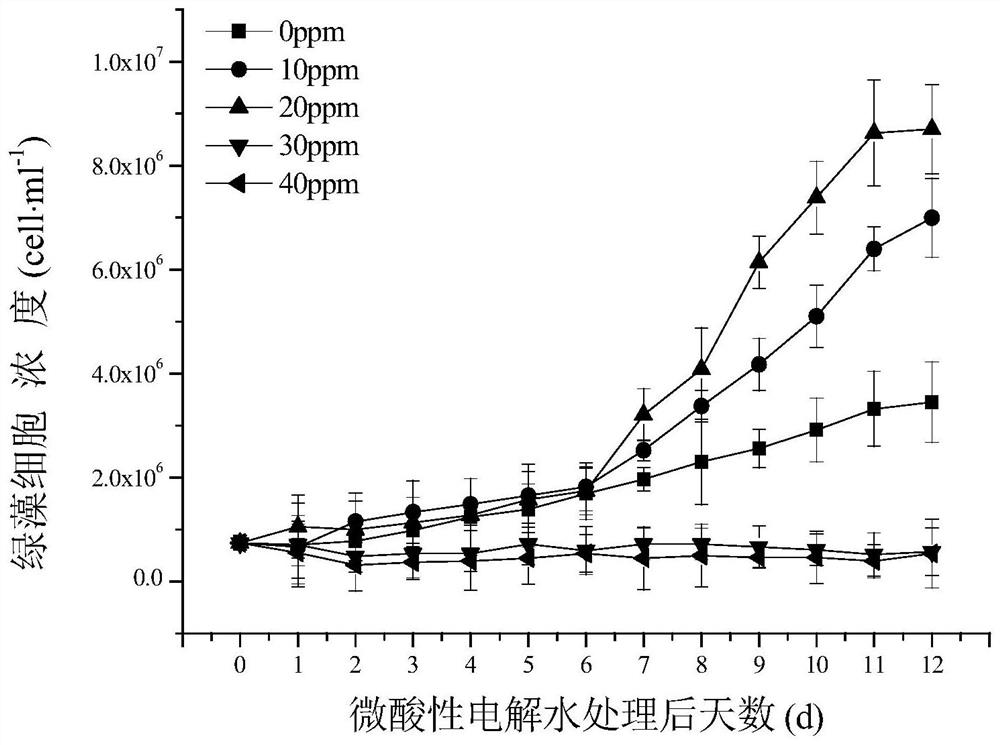

A kind of green algae treatment method based on slightly acidic electrolyzed water

ActiveCN111533241BStrong redox potencyLittle chemical propertiesSpecific water treatment objectivesWater/sewage treatment by reductionMicroorganismElectrolysed water

The invention provides a method for treating green algae based on slightly acidic electrolyzed water. The method of the present invention selects to use slightly acidic electrolyzed water as the treatment agent, which has strong redox effect, and at the same time, it will be reduced to water after interacting with the tested organism, and will dissipate quickly without causing the problem of disinfectant residue. Compared with traditional treatment agents, slightly acidic electrolyzed water is more efficient and safe, friendly to the human body and the environment, and will not cause secondary pollution; it is also conducive to the maintenance of factory production equipment and the environment. Relevant studies have shown that slightly acidic electrolyzed water will not carry microorganisms after sterilization, and its chemical properties will not change much, and it still has a good sterilization effect. It can be recycled within a certain period of time.

Owner:JIANGSU ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com