A kind of method of industrialized preparation white kidney bean α-amylase inhibitor

An amylase inhibitor, the technology of white kidney bean, which is applied in the directions of pharmaceutical formulations, the function of food ingredients, and medical preparations containing active ingredients, etc. Sexuality, unfavorable environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

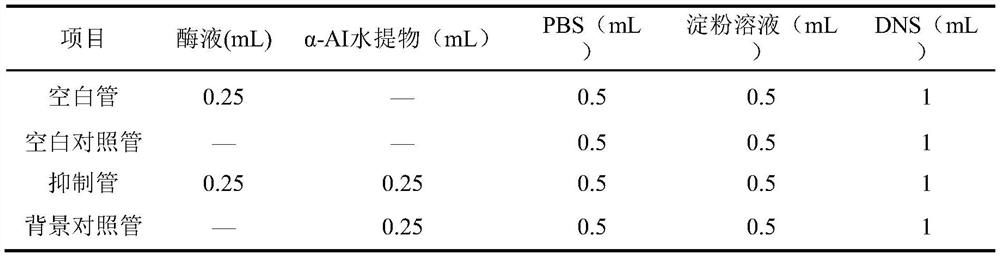

Method used

Image

Examples

Embodiment 1

[0059] Get 1kg of white kidney beans and peel them with a dry peeling machine;

[0060] Pulverize the dehulled white kidney beans with a dry grinder and pass through a 40-mesh sieve to obtain white kidney bean powder;

[0061] Extract the white kidney bean powder and water for 1 hour at a stirring speed of 60 r / min at a material-to-liquid ratio of 1:3 (w / w);

[0062] Use a decanter centrifuge to centrifuge the material at a speed of 3000r / min and a differential speed of 10r / min to collect the slurry;

[0063] After heating the slurry to 50°C with a tubular heater, add β-amylase at a ratio of 2.0 U / g dry weight of white kidney bean bean powder, and fully enzymatically hydrolyze for 2 hours to obtain an enzymolyzed solution;

[0064] Filter the enzymatic solution with a ceramic membrane with a pore size of 0.6 μm, and collect the filtrate;

[0065] The filtrate is ultrafiltered with a 150kDa ultrafiltration membrane, and the permeate is collected;

[0066] The permeate is ult...

Embodiment 2

[0070] Get 1kg of white kidney beans and peel them with a dry peeling machine;

[0071] Grinding the dehulled white kidney beans with a dry grinder, and passing through a 50-mesh sieve to obtain white kidney bean powder;

[0072] Extract white kidney bean powder and water for 2 hours at a stirring speed of 100 r / min at a material-to-liquid ratio of 1:4 (w / w);

[0073] Use a decanter centrifuge to centrifuge the material at the parameters of a rotating speed of 2500r / min and a differential speed of 15r / min to collect the slurry;

[0074] After heating the slurry to 60°C with a tubular heater, add β-amylase at a ratio of 4.0 U / g dry weight of white kidney bean bean powder, and fully enzymolyze for 2 hours to obtain an enzymolyzed solution;

[0075] Filter the enzymatic solution with a ceramic membrane with a pore size of 0.8 μm, and collect the filtrate;

[0076] The filtrate is ultrafiltered with a 120kDa ultrafiltration membrane, and the permeate is collected;

[0077] The ...

Embodiment 3

[0081] Get 1kg of white kidney beans and peel them with a dry peeling machine;

[0082] Pulverize the dehulled white kidney beans with a dry grinder, and pass through a 60-mesh sieve to obtain white kidney bean powder;

[0083] Extract white kidney bean powder and water for 2 hours at a stirring speed of 120 r / min at a material-to-liquid ratio of 1:5 (w / w);

[0084] Use a decanter centrifuge to centrifuge the material at the parameters of a rotating speed of 3300r / min and a differential speed of 12r / min to collect the slurry;

[0085] After heating the slurry to 55°C with a tubular heater, add β-amylase at a ratio of 6.0 U / g dry weight of white kidney bean bean powder, and fully enzymolyze for 1 hour to obtain an enzymolyzed solution;

[0086] Filter the enzymatic solution with a ceramic membrane with a pore size of 1.0 μm, and collect the filtrate;

[0087] The filtrate is ultrafiltered with an 80kDa ultrafiltration membrane, and the permeate is collected;

[0088] The per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com