Preparation method and application of wet-responsive color-changing fiber

A color-changing fiber and background color technology, which is applied in the field of preparation of wet-response color-changing fibers, can solve various problems such as difficulty in color change, easy residue of toxic intermediates or heavy metal ions, etc., and achieves wide application range, wide response conditions, strong practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a wet-responsive color-changing fiber, comprising the following steps:

[0033] S1, Preparation of nano-microspheres

[0034] S2, preparation of spinning precursor solution: dissolving polyvinyl alcohol and carbon tubes in water to obtain a spinning precursor solution with a concentration of 10%-30%;

[0035] S3, coagulation bath preparation: adding silica nano-microspheres into the salt solution and alcohol solution to form a coagulation bath uniformly dispersed with nano-microspheres; wherein, the mass fraction of silica nano-microspheres is 30-70%;

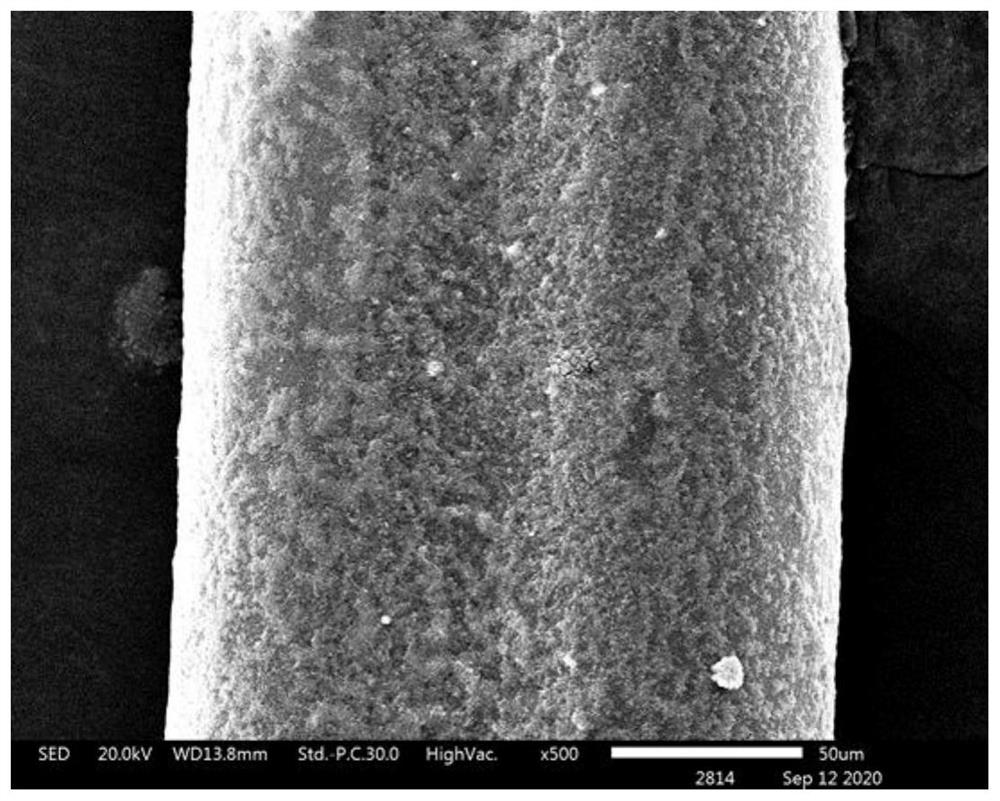

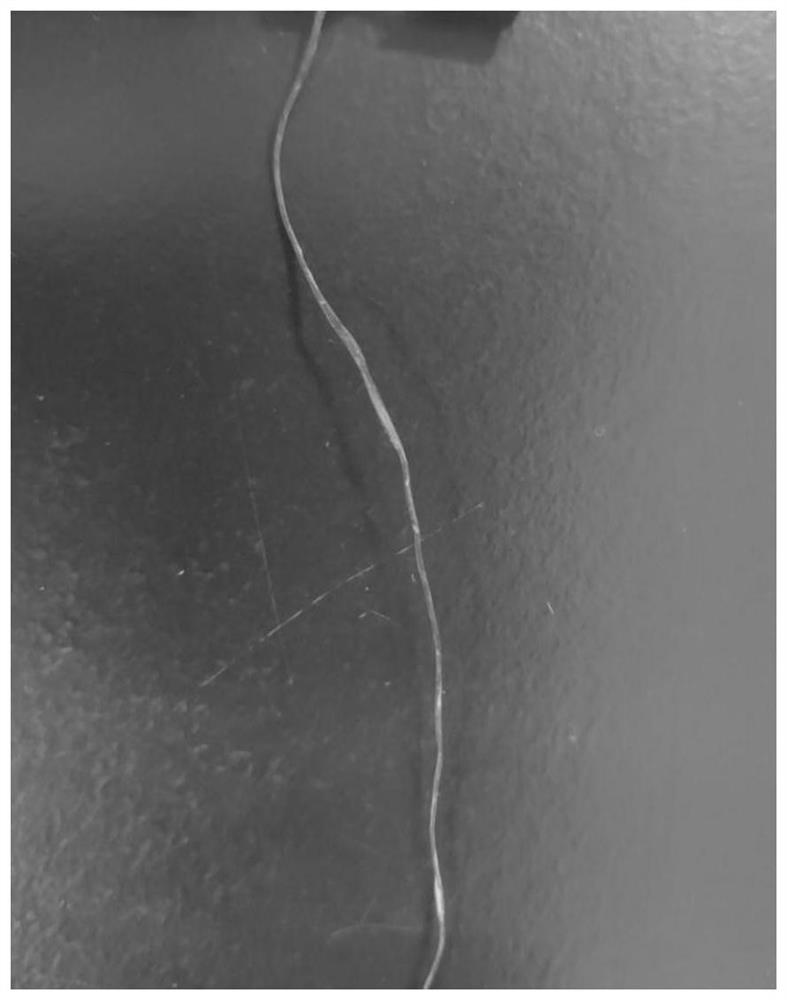

[0036] S4, wet-spinning to prepare wet-responsive color-changing fibers: the spinning precursor solution prepared in step S2 is extruded through the spinneret of the spinning machine at an extrusion speed of 80 m / min to form a fine stream of the original solution, which is then fed into the coagulation bath to make Silica nano-microspheres were attached to the surface and i...

Embodiment 1

[0039] Embodiment 1 provides a preparation method of wet-responsive color-changing fiber, which comprises the following steps:

[0040] S1, the preparation of silica microspheres:

[0041] Mix 25ml of deionized water, 60ml of ethanol and 2ml of ammonia with magnetic stirring, and mix well. 2 ml of tetraethyl orthosilicate was added to the mixed solution, and after the reaction was stirred at a constant temperature for 2 hours, centrifuged, washed, and dried to prepare silica microspheres with a particle size of 250 nm.

[0042] S2, preparation of spinning precursor solution: dissolving polyvinyl alcohol and carbon tubes in water to obtain a spinning precursor solution with a concentration of 15%;

[0043] S3, coagulation bath preparation: adding silica nano-microspheres into a salt solution (sodium sulfate) and an alcohol solution (ethanol) to form a coagulation bath uniformly dispersed with nano-microspheres; wherein, the mass of the silica nano-microspheres The score is 70...

Embodiment 2-5

[0049] Embodiments 2-5 respectively provide a method for preparing a wet-responsive color-changing fiber. Compared with Embodiment 1, the difference is that the parameters in step S1 are changed to obtain nano-microspheres with different particle sizes. All other operations remain unchanged. The specific parameters of step S1 of embodiment 2-5 are as follows:

[0050] Table 1 Specific parameters of step S1 of embodiment 2-5

[0051]

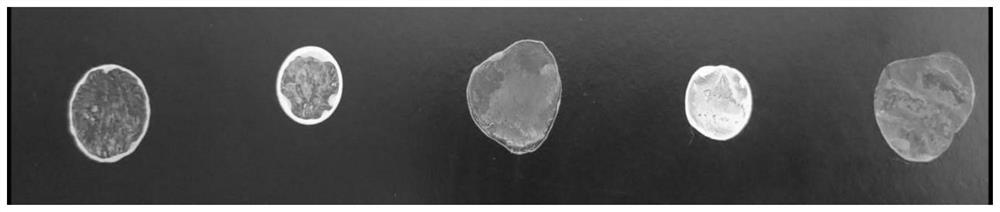

[0052] The particle size and color of the nano-microspheres prepared in Example 2-5 are shown in Table 2, specifically as shown in Table 2. image 3 shown.

[0053] The particle size and color of the nano-microspheres prepared in Table 2 Example 2-5

[0054] SiO 2 Particle size (nm)

[0055] Experiments found that fibers with blue, green, pink and purple colors were prepared through Examples 2-5, respectively. When these different colors of moisture-responsive fibers meet water, due to the expansion of the fibers due to water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com