Controlled preparation method of surface porous structure of polylactic acid/HAP (hydroxyapatite) composite microspheres and application

A technology of hydroxyapatite and composite microspheres, which is applied in medical preparations of non-active ingredients, pharmaceutical formulas, medical science, etc., can solve the problems of many variables to be controlled, difficulties in process amplification, and residues of pore-forming agents, etc., to achieve Easy regulation, simple preparation process and high dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

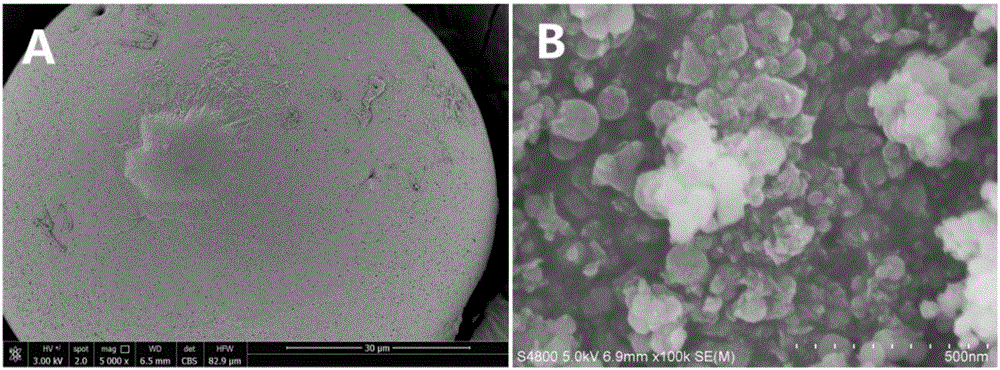

Embodiment 1

[0025] First, the precipitation method was used to prepare nano-HAP at 37 °C, and the Ca 2+ Calcium nitrate aqueous solution and PO with a concentration of 0.0334mol / L 4 3- Diammonium hydrogen phosphate aqueous solution with a concentration of 0.02mol / L, and then according to the Ca / P molar ratio of 1.67 stoichiometric ratio, heat and stir the prepared solution on a constant temperature magnetic stirrer at 37°C, and rapidly diammonium hydrogen phosphate aqueous solution Pour into the calcium nitrate aqueous solution, stir vigorously and mix evenly, after mixing evenly, add concentrated ammonia water dropwise to the solution, control the pH of the solution in the range of 10-11, react at 37°C for 1 hour, centrifuge the milky white turbid liquid, and deionized water Rinse three times to obtain a white precipitate, which is stored in a refrigerator for freezing. After the white precipitate is frozen, it is dried in a freeze dryer and taken out for later use. After testing, the ...

Embodiment 2

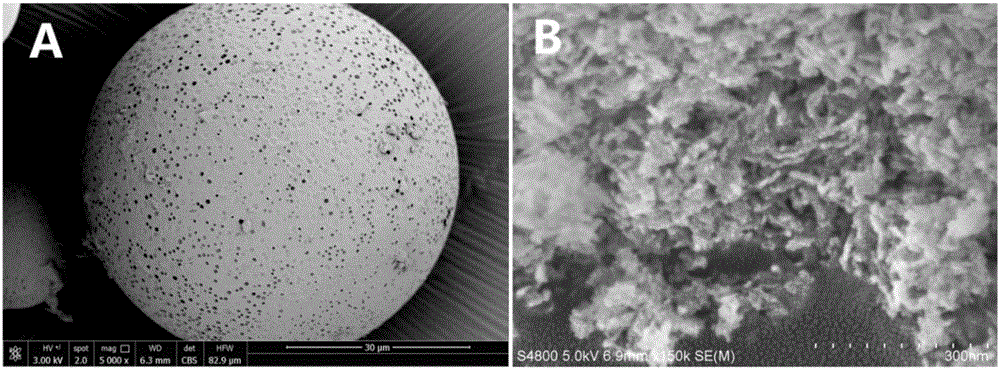

[0029] First, nano-HAP was prepared at 60 °C by precipitation method. Separately prepare Ca 2+ Calcium nitrate aqueous solution and PO with a concentration of 0.0334mol / L 4 3-Diammonium hydrogen phosphate aqueous solution with a concentration of 0.02mol / L, and then according to the Ca / P molar ratio of 1.67 stoichiometric ratio, heat and stir the prepared solution on a constant temperature magnetic stirrer at 60°C, and rapidly diammonium hydrogen phosphate aqueous solution Pour into calcium nitrate aqueous solution, stir vigorously and mix evenly, add concentrated ammonia water dropwise to the solution after mixing evenly, control the pH of the solution in the range of 10-11, react at 60°C for 1 hour, centrifuge the milky white turbid liquid, and deionized water Rinse three times to obtain a white precipitate, which is stored in a refrigerator for freezing. After the white precipitate is frozen, it is dried in a freeze dryer and taken out for later use. After testing, the av...

Embodiment 3

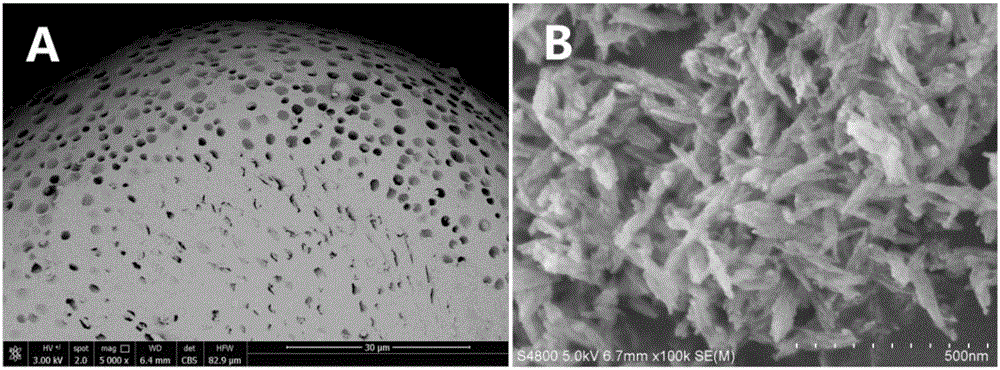

[0033] First, nano-HAP was prepared by precipitation method at 80 °C. Separately prepare Ca 2+ Calcium nitrate aqueous solution and PO with a concentration of 0.0334mol / L 4 3- Diammonium hydrogen phosphate aqueous solution with a concentration of 0.02mol / L, and then according to the Ca / P molar ratio of 1.67 stoichiometric ratio, heat and stir the prepared solution on a constant temperature magnetic stirrer at 80°C, and rapidly diammonium hydrogen phosphate aqueous solution Pour into calcium nitrate aqueous solution, stir vigorously and mix evenly, add concentrated ammonia water dropwise to the solution after mixing evenly, control the pH of the solution in the range of 10-11, react at 80°C for 1 hour, centrifuge the milky white turbid solution, and deionized water Rinse three times to obtain a white precipitate, which is stored in a refrigerator for freezing. After the white precipitate is frozen, it is dried in a freeze dryer and taken out for later use. After testing, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com