Technology of preparing nanometer traditional Chinese medicine material by liquid-phase shear dispersion

A technology of nanometer Chinese herbal medicines and Chinese herbal medicines, applied in the direction of food preparation, medical preparations containing active ingredients, pharmaceutical formulas, etc., to achieve the effects of improving bioavailability, simple operation, and conducive to industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

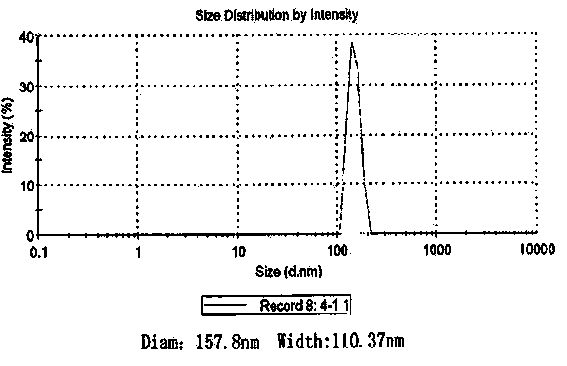

[0028] Weigh 200 g of Radix Astragali, dry at 45° C., pulverize with a pulverizer, and pass through a 100-mesh sieve to obtain 150 g of medicinal material particles larger than 100 mesh. Put the medicinal material granules in a shear tank filled with deionized water, the mass ratio of medicinal material granules to deionized water is 1:10, disperse evenly, and soak for 1 hour. Cooling water is passed into the jacket of the shear tank to control the working temperature at room temperature. Then carry out continuous shearing and crushing, the shearing speed is 16000 r min -1 , the shearing time is 40min. Under the condition of a temperature of 45 DEG C, the astragalus suspension is dried by vacuum drying, the nano astragalus particles are gathered into a thin film, and then dispersed to obtain the nano astragalus particles.

Embodiment 2

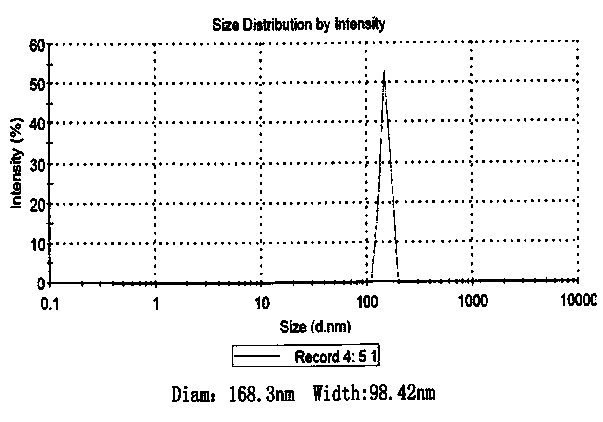

[0030] Weigh 500 g of lily medicinal material, dry at 30° C., pulverize with a pulverizer, and pass through a 100-mesh sieve to obtain 470 g of medicinal material particles larger than 100 mesh. The medicinal material granules were placed in a shear tank filled with physiological saline, the mass ratio of the medicinal material granules to the physiological saline was 1:20, after they were evenly dispersed, soaked for 0.5h. Cooling water is passed into the jacket of the shear tank to control the working temperature at room temperature. Then carry out continuous shearing and crushing, the shearing speed is 18000 r min -1 , the shearing time is 30min. Under the condition of a temperature of 30° C., the lily suspension is dried by vacuum microwave drying, and the nano-lily particles are aggregated into a thin film, which is then dispersed to obtain the nano-sized lily particles.

Embodiment 3

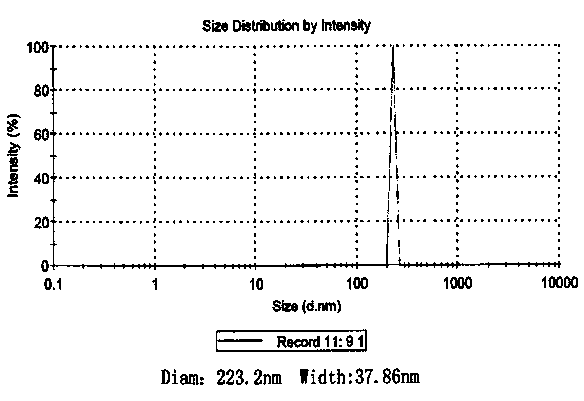

[0032] Weigh 100 g of pilose antler medicinal material, dry it at 25° C., pulverize it with a pulverizer, and pass through a 100-mesh sieve to obtain 80 g of medicinal material particles larger than 100 mesh. Put the medicinal material granules in a shear tank filled with olive oil, the mass ratio of the medicinal material granules to olive oil is 1:5, after they are evenly dispersed, soak for 2 hours. Cooling water is passed into the jacket of the shear tank to control the working temperature at room temperature. Then carry out continuous shearing and crushing, the shearing speed is 20000 r min -1 , the shearing time is 20min. The suspension of nano velvet antler is obtained, and then it is directly used in the preparation of nano velvet velvet soft capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com