Preparation method of gypsum board coagulant and gypsum board coagulant prepared by preparation method

A coagulant and gypsum board technology, applied in the field of gypsum board coagulant, can solve the problems of disturbing the production stability of gypsum board, reducing the compressive strength of gypsum board, affecting the pulverization effect of ball mill, etc., and achieve small bulk density and particle size distribution , the time required for coagulation is short, and the effect of promoting coagulation is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

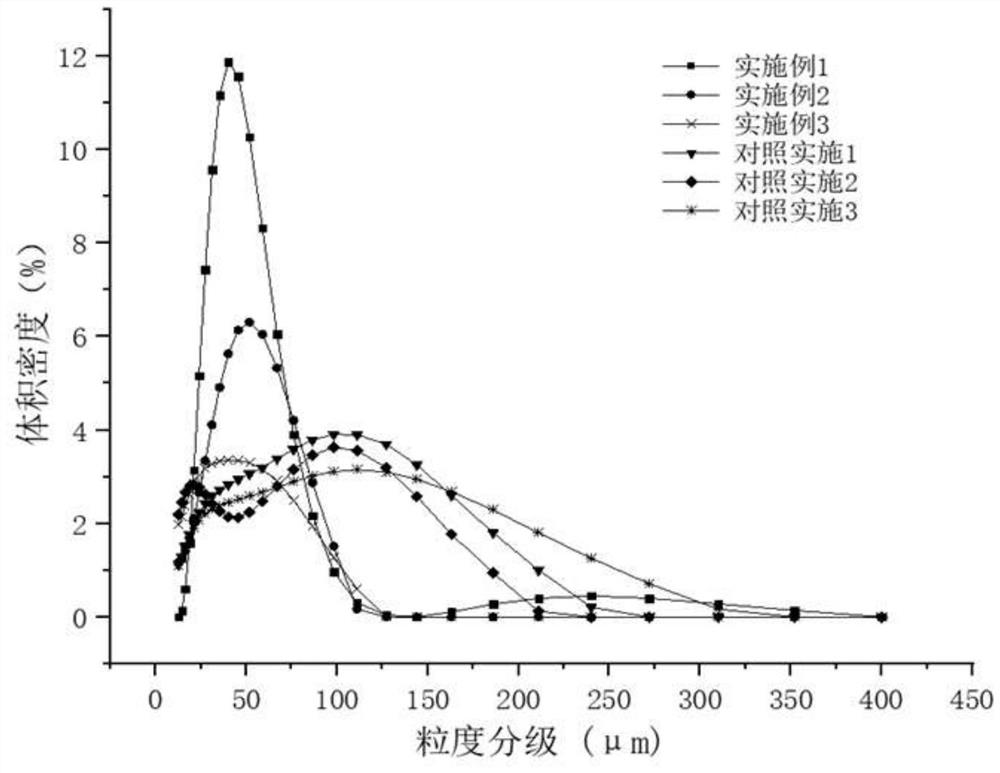

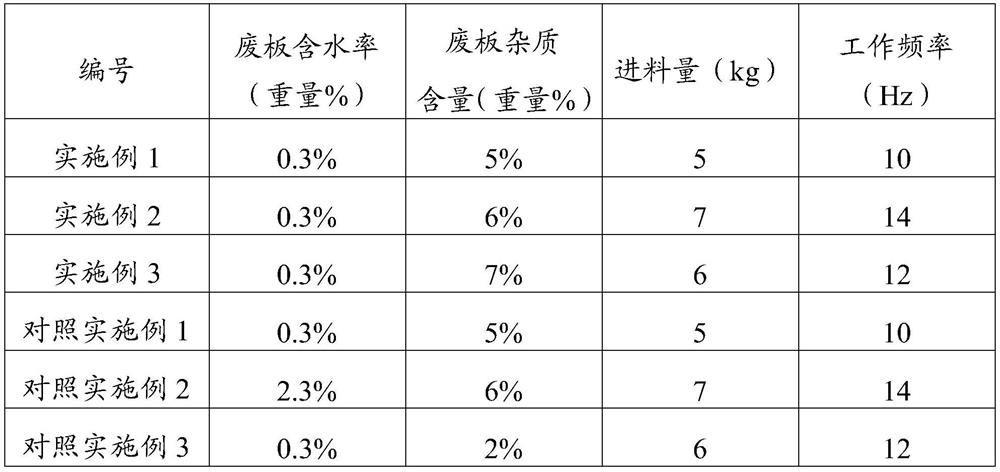

[0024] According to the waste board with a certain water content and impurity content provided in Table 1 as raw material, and according to the equipment feed rate and operating frequency set in Table 1, the gypsum board coagulant is prepared, wherein Examples 1-3 and Comparative Examples The equipment used in 2-3 is the vertical impact mill of the model CSM410-V manufactured by Alpine Company, and the equipment used in Comparative Example 1 is the planetary ball mill of the model QXQM-2.

[0025] Table 1

[0026]

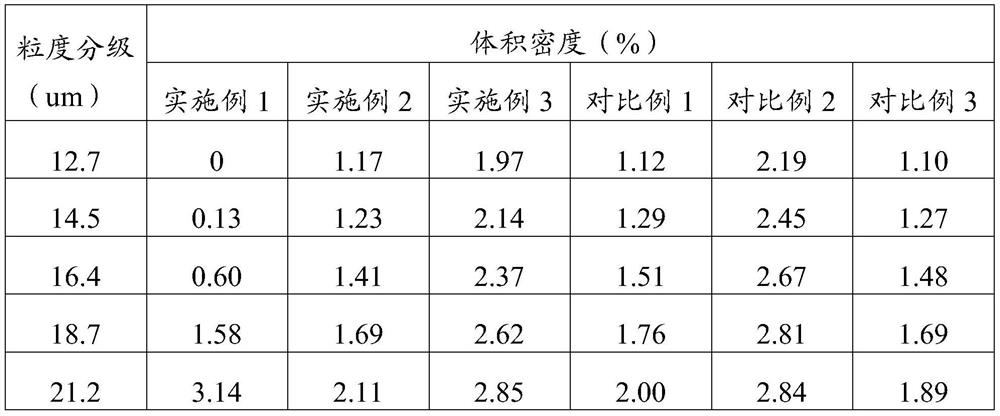

[0027] Performance Testing

[0028] 1. Use the gypsum board coagulant prepared by above-mentioned embodiment and comparative example to carry out the test of bulk density and its specific surface area respectively, the specific surface area of coagulant is measured by Blaine specific surface area measuring instrument to it, and the measuring method of bulk density is as follows :

[0029] Bulk density test method: the gypsum board coagulant in the embodiment...

Embodiment 2

[0043] Example 2 Compared with Comparative Example 2, the impact mill is also used to prepare the coagulation accelerator for gypsum board. The lower the moisture content of the waste board, the shorter the time required for the coagulation of the gypsum board, and the better coagulation-accelerating effect of the coagulation accelerator. And the strength of gypsum board has also been improved to a certain extent. Embodiment 3 Compared with comparative example 3, the coagulation accelerator for gypsum board is also prepared by using impact mill, the higher the impurity content of the waste board, the shorter the time required for gypsum board coagulation, and the coagulation accelerator effect of the coagulation accelerator is better, The strength of gypsum board has also been improved to a certain extent.

[0044] In summary, compared with the gypsum board coagulant prepared by ball mill, the coagulant for gypsum board prepared by impact mill has smaller bulk density, larger ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com