Preparation method of spirulina protein powder

A technology of spirulina powder and spirulina, which is applied to peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of long process route, low production efficiency, high energy consumption, etc., and achieve simple process, low cost, The effect of high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

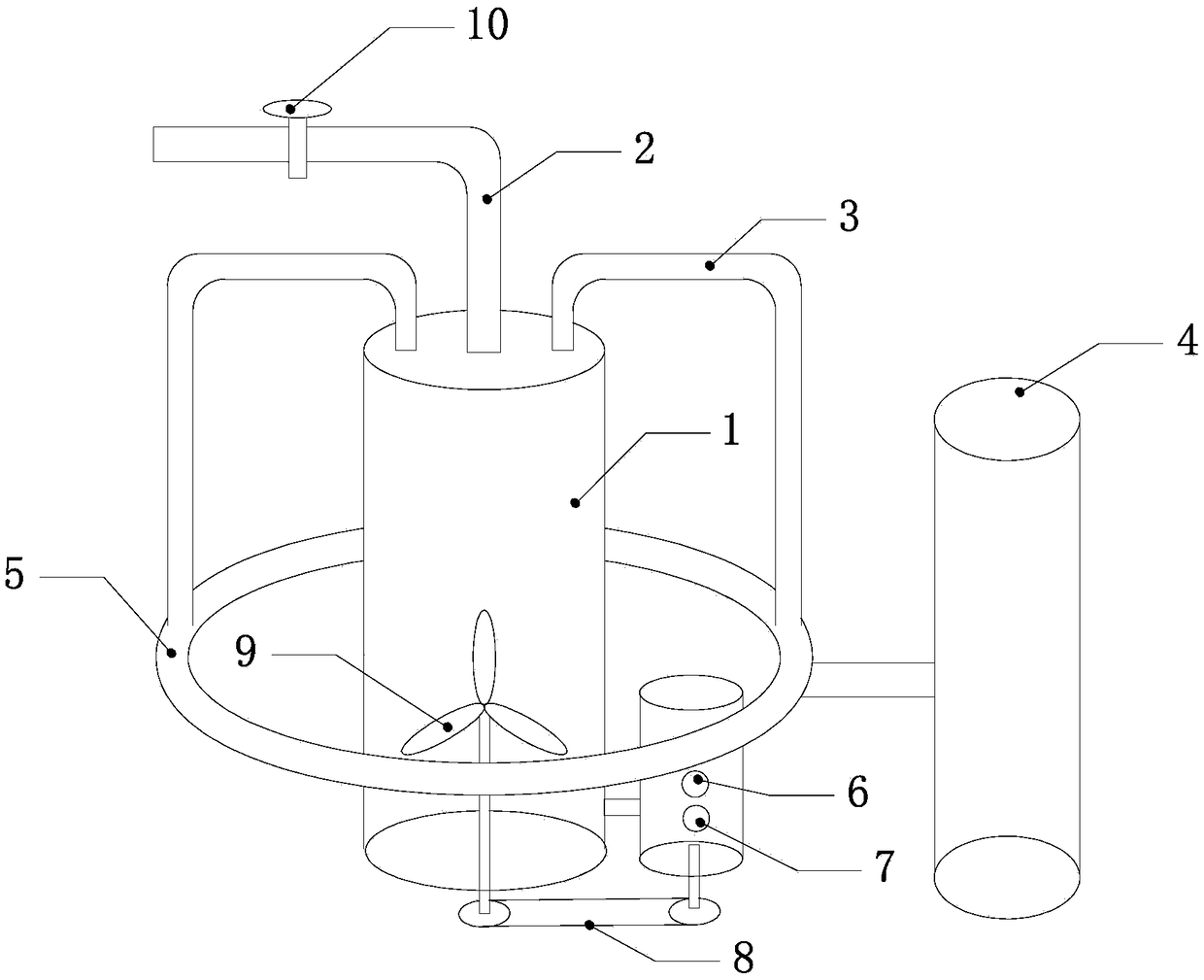

Image

Examples

Embodiment 1

[0030] A preparation method of spirulina protein powder, comprising the following steps:

[0031] A, 125kg of spirulina is pulverized by a pulverizer to obtain spirulina powder with a mesh number of 1200-1500, wherein the pulverizer speed is 5000-1000r / min, and the pulverization time is 10-15min;

[0032] B. Add 1000kg of water to the pulverized spirulina powder and stir evenly, the stirring temperature is controlled at 20°C, and the stirring time is 8h. The spirulina powder fluid after the uniform stirring is placed in a high-pressure homogenizer for homogenization. Make the spirulina powder swell, burst, and release the broken spirulina protein, wherein the temperature of the spirulina powder treated by the high-pressure homogenizer is controlled below 12°C to prevent the denaturation of the protein in the spirulina powder due to excessive temperature;

[0033] C. Add 3% calcium chloride to the broken spirulina protein, and automatically squeeze out the protein liquid in the...

Embodiment 2

[0038] The difference between Example 2 and Example 1 is that in step B, the stirring temperature is 15° C., and the stirring time is 10 h.

[0039] The purity of the spirulina protein powder prepared in Example 1 is 70%, and the concentration is 12g / L; the purity of the spirulina protein powder prepared in Example 2 is 75%, and the concentration is 13g / L, prepared by the preparation method of the spirulina protein powder of the present invention The purity and concentration of the spirulina protein powder have been greatly improved, and the entire production and purification process adopts a physical method based on an air flotation separation and purification device. The air flotation separation and purification device combines the extraction of the spirulina protein powder with the The separation of light impurities is combined into one, which simplifies the process flow and improves the use efficiency and separation quality of products. At the same time, the spirulina prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com