Hydraulic crushing bucket

A technology of hydraulic crushing and hydraulic motor, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problems of high price of large-scale crushing equipment, inability to perform crushing work, and difficulty in fixing the installation position, so as to achieve convenient, fast and convenient installation. The effect of replacing and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will be described in detail in conjunction with the technical solutions in the embodiments of the present invention:

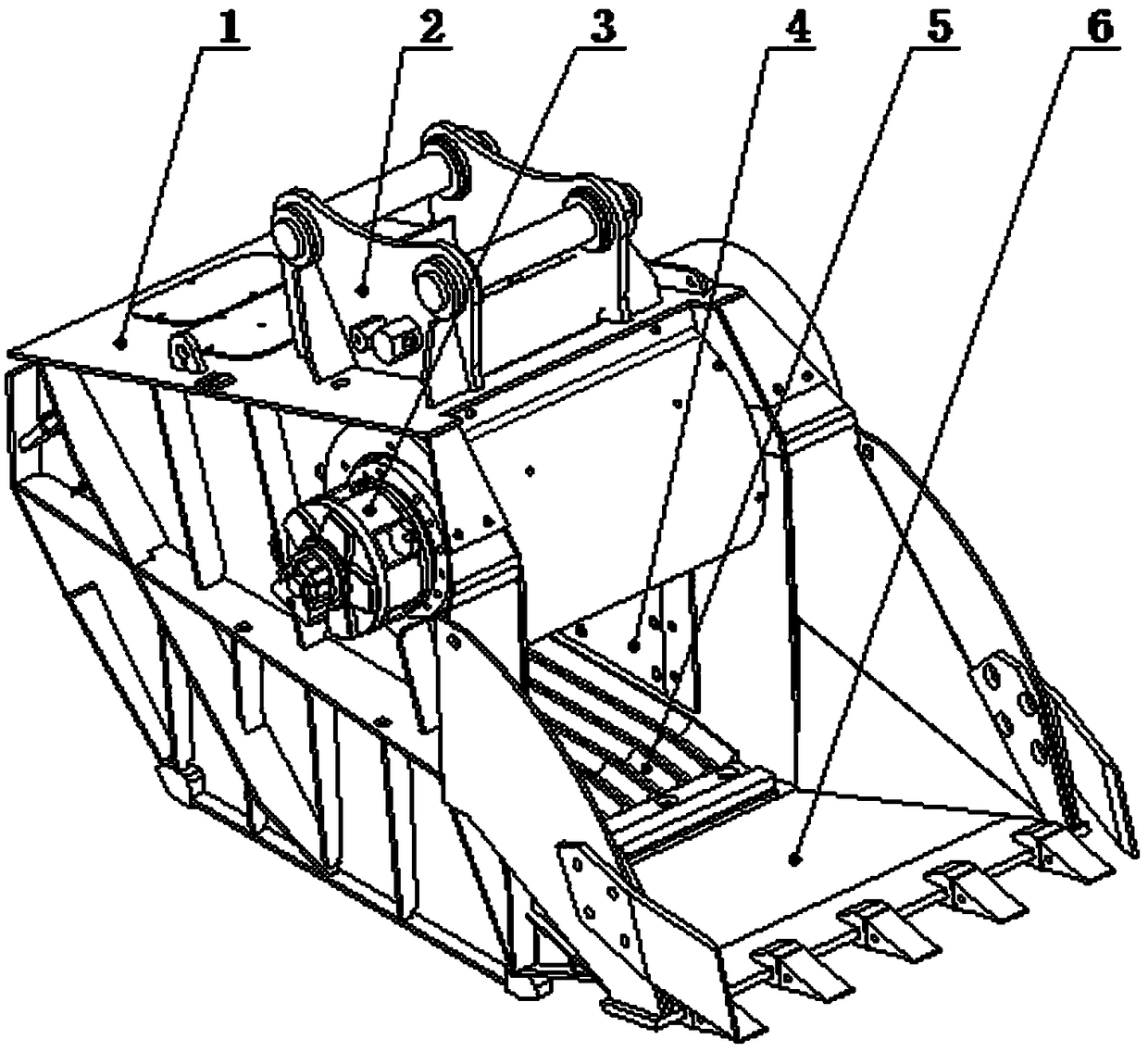

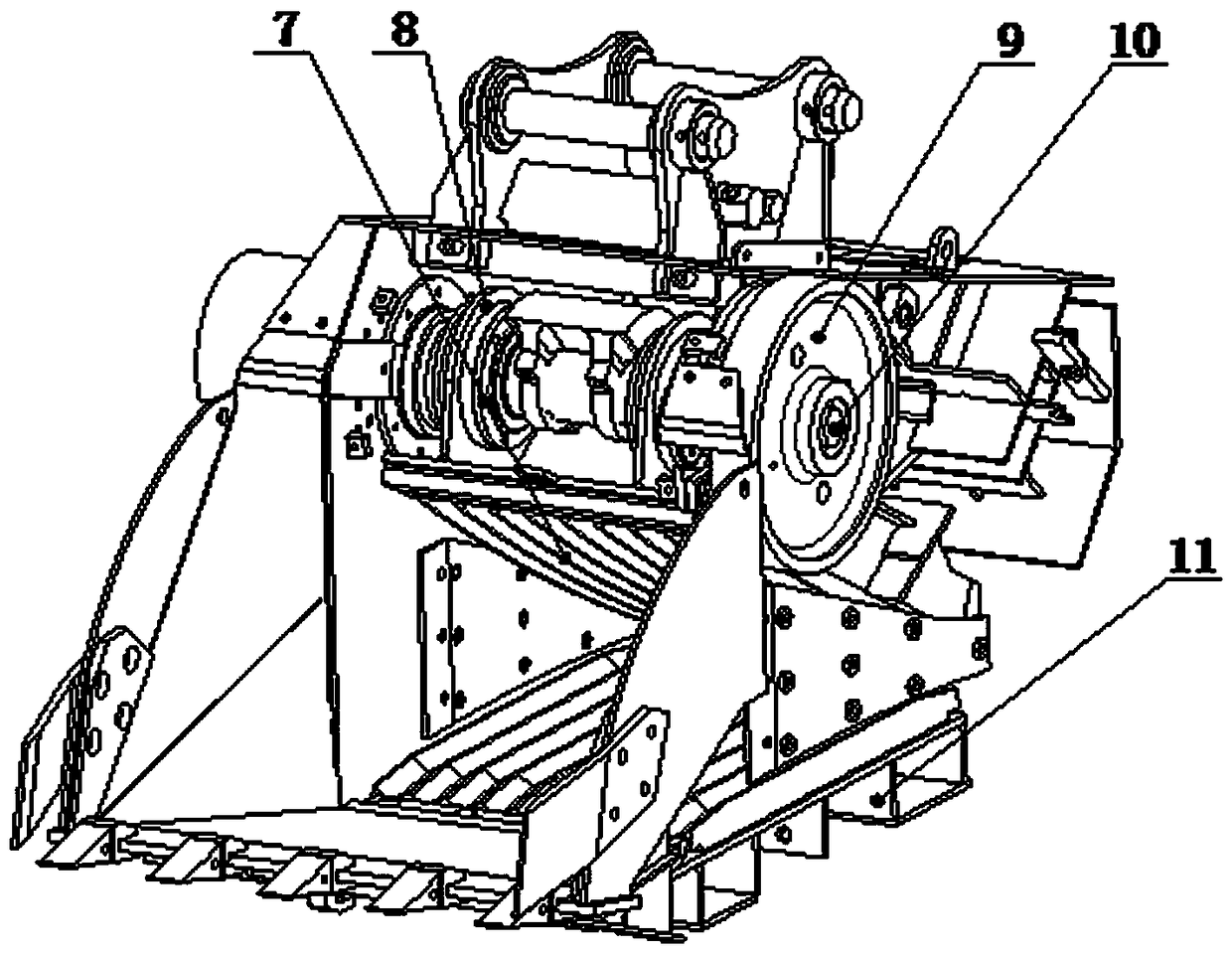

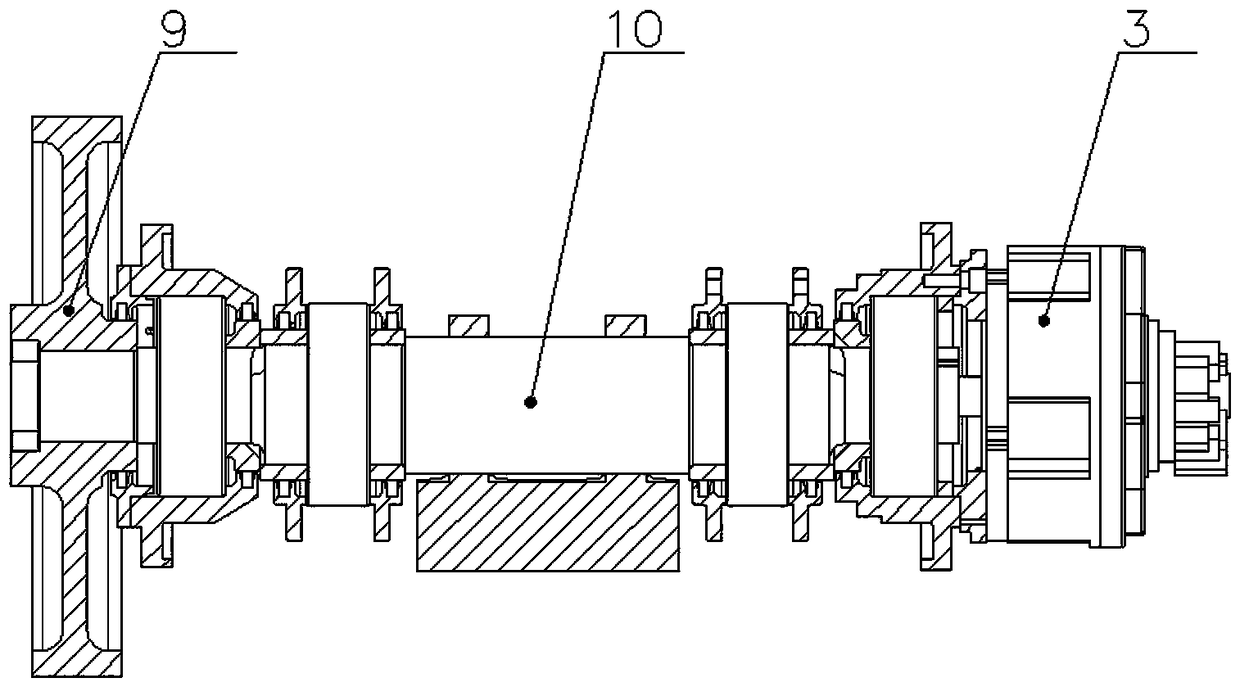

[0014] see figure 1 , figure 2 , image 3 As shown, a hydraulic crushing bucket proposed by the present invention includes a main body (1), a connector (2), a crushing mechanism, and a transmission mechanism. Each side of the main body (1) is equipped with a piece made of high-strength wear-resistant material. The baffle (4), the connector (2) is welded on the main body (1), so that the hydraulic breaker can be installed on a loader or an excavator. The crushing mechanism includes a fixed jaw (5) and a movable jaw (7), the fixed jaw (5) is fixedly connected to the inner side of the chassis (11) of the main body (1), and the movable jaw (7) is arranged on the fixed jaw (5) The opposite side and the fixed jaw plate (5) form a crushing space with a large upper end and a smaller lower end. The transmission mechanism includes a hydraulic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com