Eddy kinetic energy gas flow material smashing and material-liquid separation pulping device

A crushing and vortex technology, which is applied in the separation of raw materials, fiber raw materials, fiber raw material processing, etc., can solve the problems of high energy consumption and low efficiency, and achieve the effects of eliminating kinetic energy loss, complete crushing, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

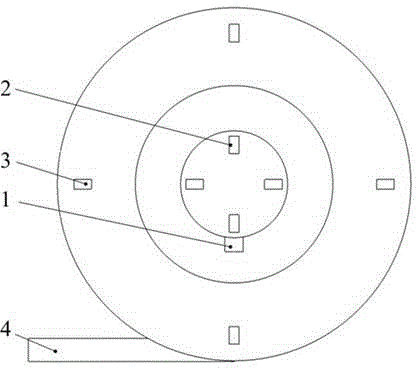

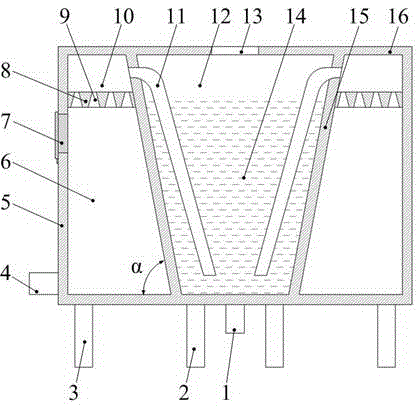

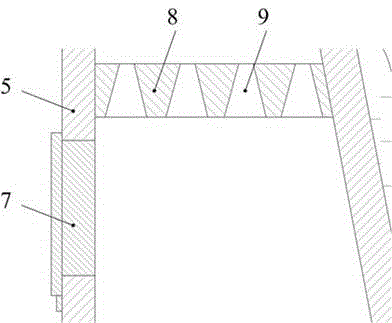

[0021] like figure 1 , figure 2 and image 3 As shown, a kind of pulping equipment with vortex kinetic energy airflow crushing and material-liquid separation of the present invention mainly includes a vortex crushing device and a slurry generating device. The vortex crushing device is mainly composed of an air intake pipe 4, an outer cylinder 5, an inner cylinder 15 and a debris filter device 8. The air intake pipe 4 is installed on the outer edge of the bottom of the outer cylinder 5 and is tangent to the outer edge. This structure can realize The gas enters tangentially and forms a circulation, that is, when the compressed air enters the intake pipe 4, because the intake pipe 4 is tangent to the outer edge of the outer cylinder 5, the gas can be in a state of minimum energy loss under the action of inertia. It rotates along the inner wall of the outer cylinder 5 and forms a vortex in the vortex crushing area 6 to provide sufficient air source for realizing the vortex kine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com