A kind of atomization preparation device of nickel aluminum powder

A preparation device, nickel-aluminum technology, applied in the field of nickel-aluminum powder atomization preparation device, can solve the problem of uneven particle size distribution of powder materials, and achieve good atomization effect, high line speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

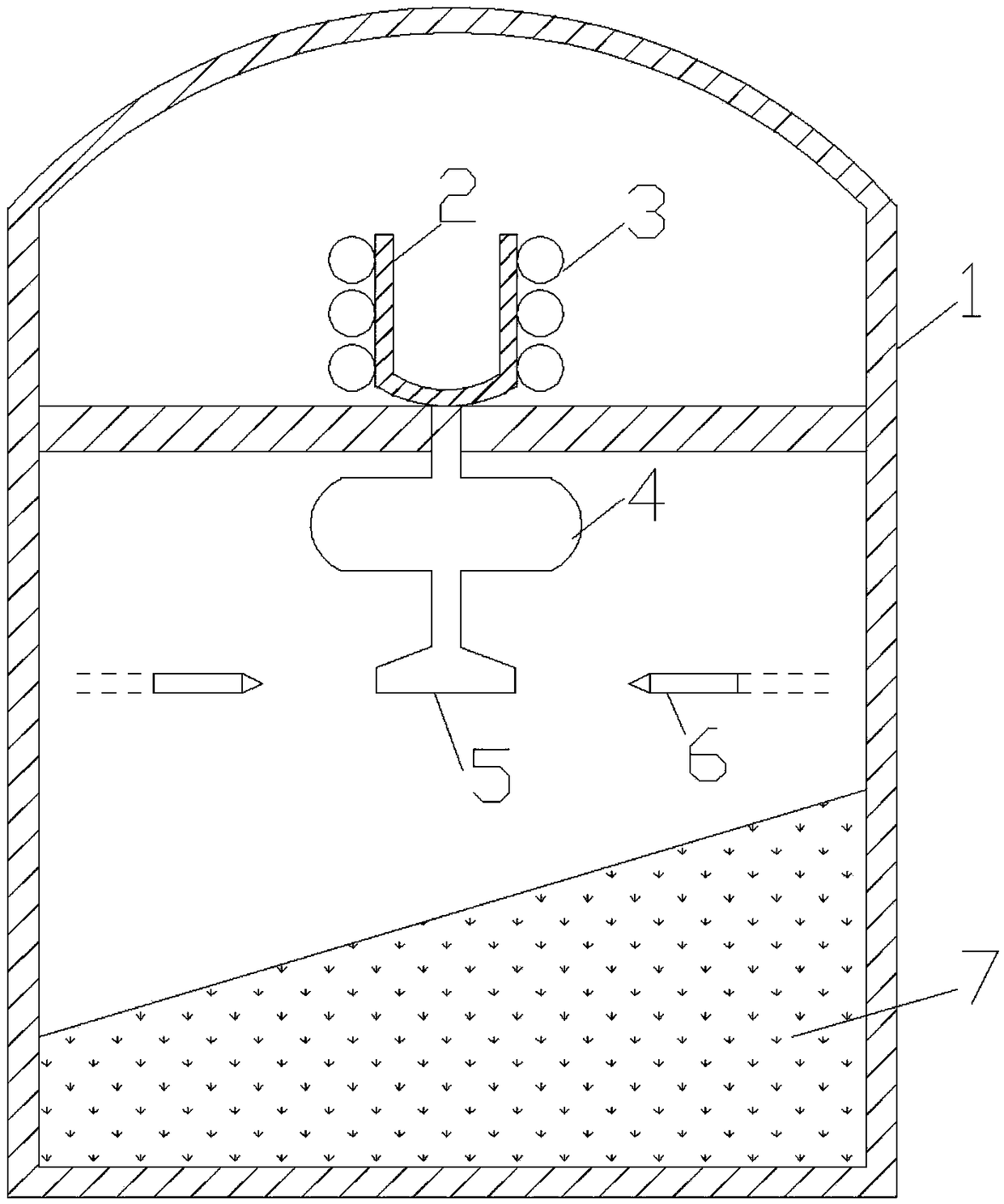

[0013] An atomization preparation device for nickel-aluminum powder, the device includes a furnace body, a smelting chamber, an atomization chamber and a collection chamber.

[0014] The melting chamber is located above the furnace body 1 and includes a crucible 2 with an induction heating body 3 outside the crucible and a furnace cover above the furnace body.

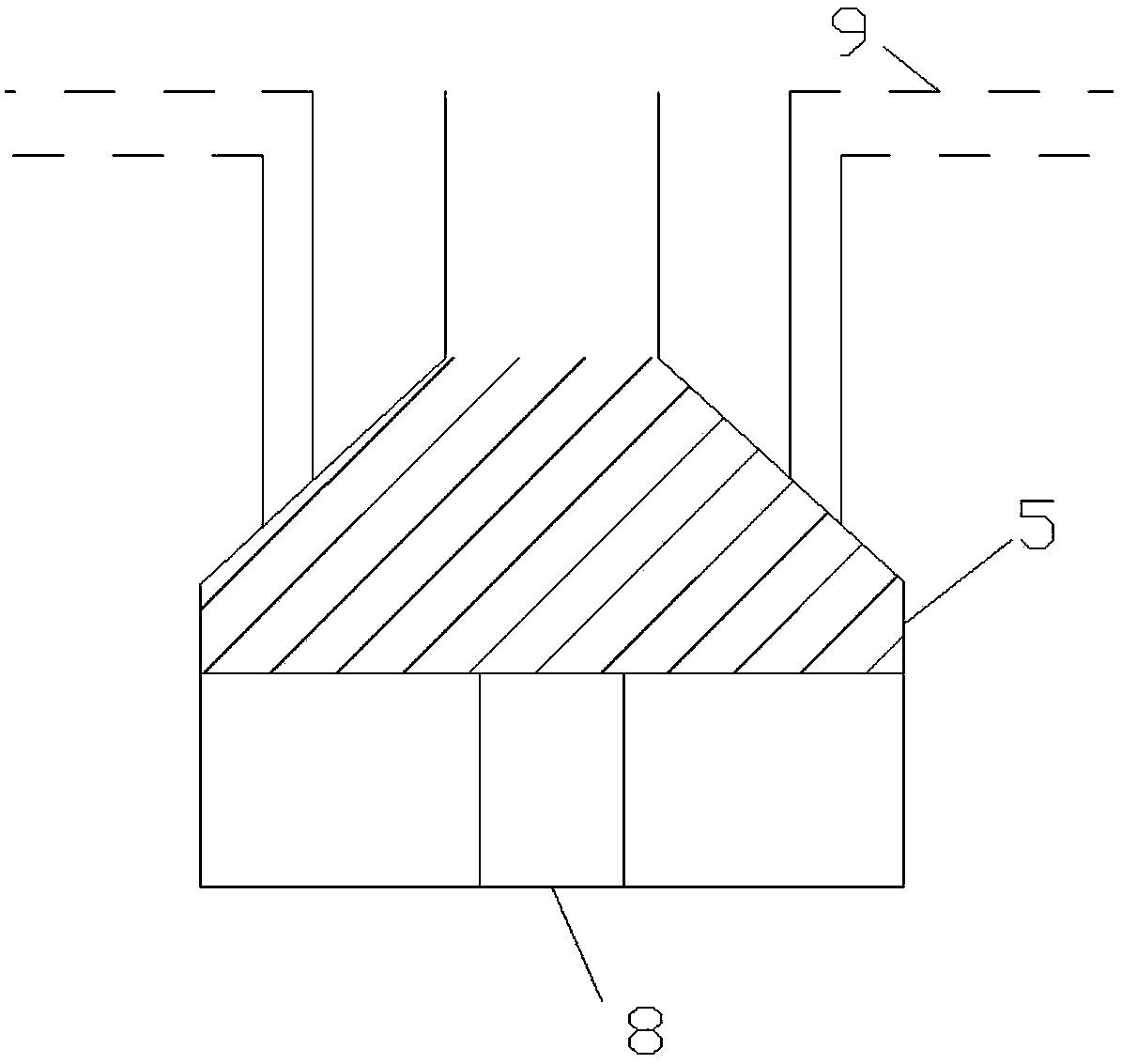

[0015] A partition is provided between the smelting chamber and the atomizing chamber, and the atomizing chamber is provided with a liquid storage bag 4 made of refractory material, the diameter of the liquid storage bag is 20 cm, the height is 50 cm, and the liquid storage bag is wrapped There is insulation cotton, and the bottom of the induction melting crucible is connected to the liquid storage bag through a diversion tube. The diversion tube is provided with an opening / closing mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com