Double-impeller wind-feeling-free sunflower seed huller

A windless, double impeller technology, applied in the fields of shelling, pod removal, food science, etc., to achieve the same effect of shell opening, avoid air pollution, and improve the efficiency of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

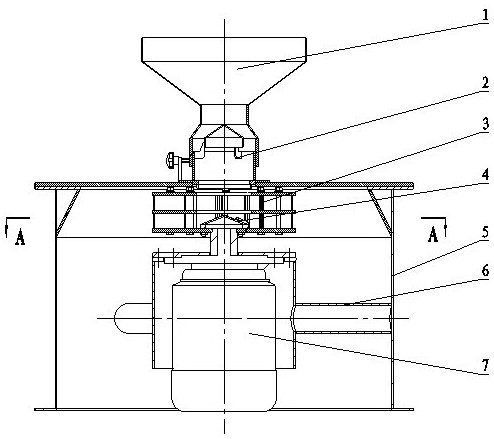

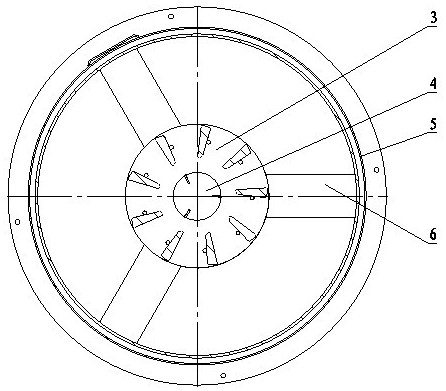

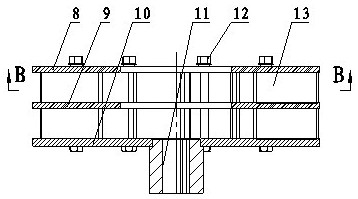

[0026] as attached figure 1 ~ attached Figure 11 As shown, the present invention includes housing 5, feeding hopper 1, motor 7, impeller 3 and motor fixing frame 6, feeding hopper 1 is installed on the top of housing 5, and motor 7 is installed in housing 5 by motor fixing bracket 6, The impeller 3 is installed on the output shaft of the motor 7; the impeller 3 is a double impeller, and it is composed of an upper disc 8 of the impeller, a middle disc 9 of the impeller, a lower disc 10 of the impeller and 13 ceramic blades, and the ceramic blade 13 is arranged on the impeller Between the disc 8, the impeller middle disc 9 and the impeller lower disc 10, each layer is provided with 9 pieces, the actual number is not limited, and can be increased or decreased according to the needs. 10 and the ceramic blade 13 are fixed together with fastening bolts 12 to form a whole. There are three installation holes 14 on the impeller lower plate 10, and there is also a motor shaft sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com