Nut shelling equipment for food processing

A technology for food processing and nuts, which is applied in the field of shelling equipment, can solve the problems of consuming a lot of time and energy, low efficiency, unfavorable cost saving and human resources, etc., and achieve the effect of reducing workload and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

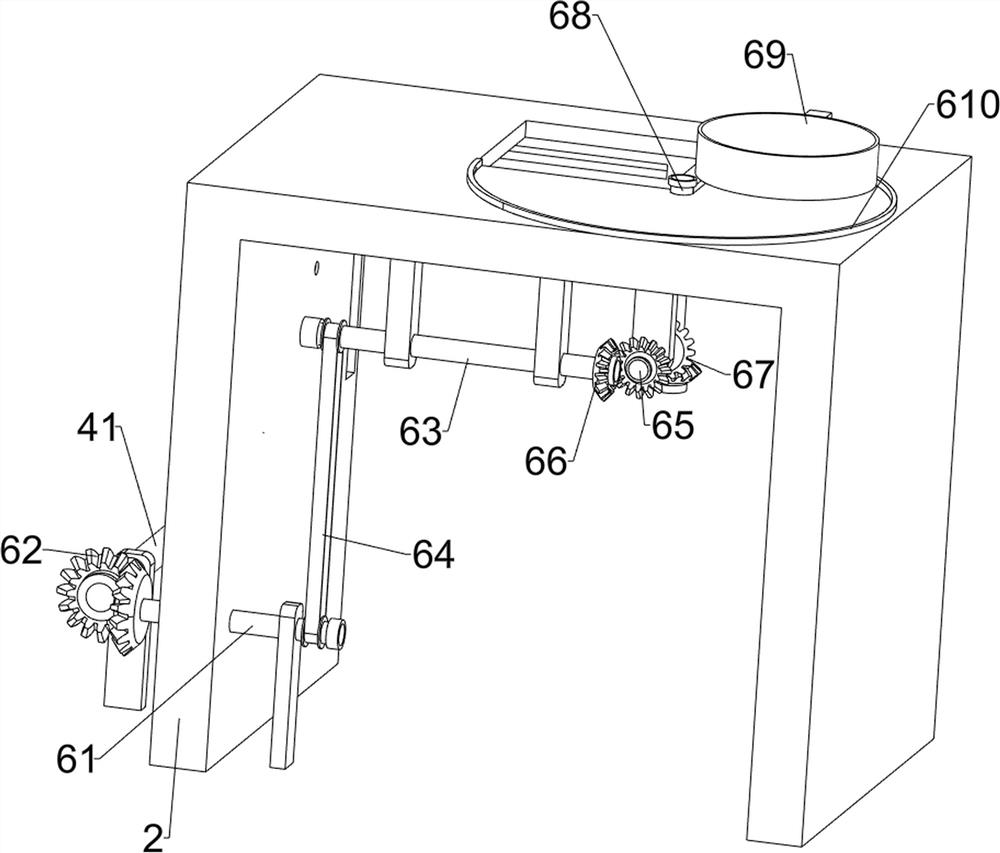

[0081] A kind of nut shelling equipment for food processing, such as figure 1 As shown, it includes a base 1, a workbench 2, a servo motor 3, a beating mechanism 4 and a feeding mechanism 5, a workbench 2 is arranged on the left side of the top of the base 1, a servo motor 3 is installed on the right front side of the base 1, and the servo A beating mechanism 4 is provided on the output shaft of the motor 3 and the workbench 2, and a blanking mechanism 5 is provided on the base 1, the beating mechanism 4 and the workbench 2.

[0082] When nuts need to be shelled, people first pour a certain amount of nuts into the beating mechanism 4, and then start the servo motor 3, the output shaft of the servo motor 3 rotates to drive the beating mechanism 4 to operate, and the beating mechanism 4 moves downward to perform the beating operation on the nuts After the nuts are patted, the beating mechanism 4 moves upwards to reset, and at the same time drives the unloading mechanism 5 to mov...

Embodiment 2

[0084] On the basis of Example 1, such as figure 2 and image 3 As shown, the beating mechanism 4 includes a first rotating shaft 41, a missing gear 42, a first rack 43, a special-shaped rod 44, a first spring 45, a first guide frame 46, a second rack 47, a bearing seat 48, a second Rotating shaft 49, the first straight gear 410, pressing plate 411 and baffle plate 412, the first rotating shaft 41 is provided on the servomotor 3 output shafts, the first rotating shaft 41 front portion is provided with missing gear 42, and the sliding type setting of the lower part of the workbench 2 right sides There is a first rack 43, the first rack 43 meshes with the missing gear 42, and the front and rear sides of the upper part of the first rack 43 are provided with special-shaped rods 44, between the top of the first rack 43 and the inner upper wall of the right part of the workbench 2 Connected with a first spring 45, a first guide frame 46 is provided on the right side of the top of ...

Embodiment 3

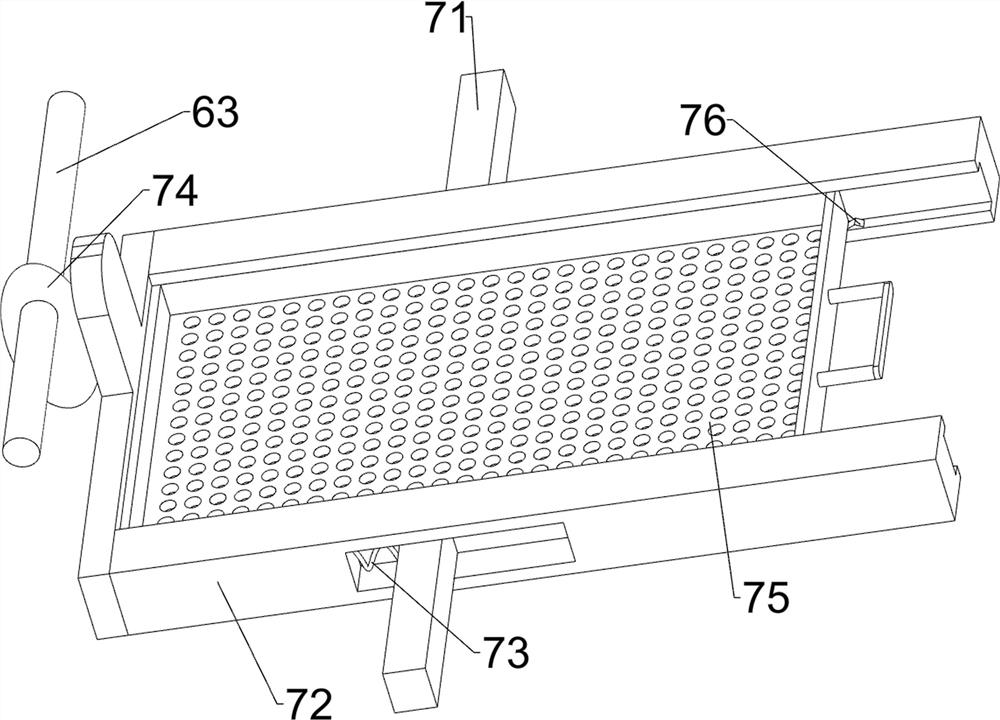

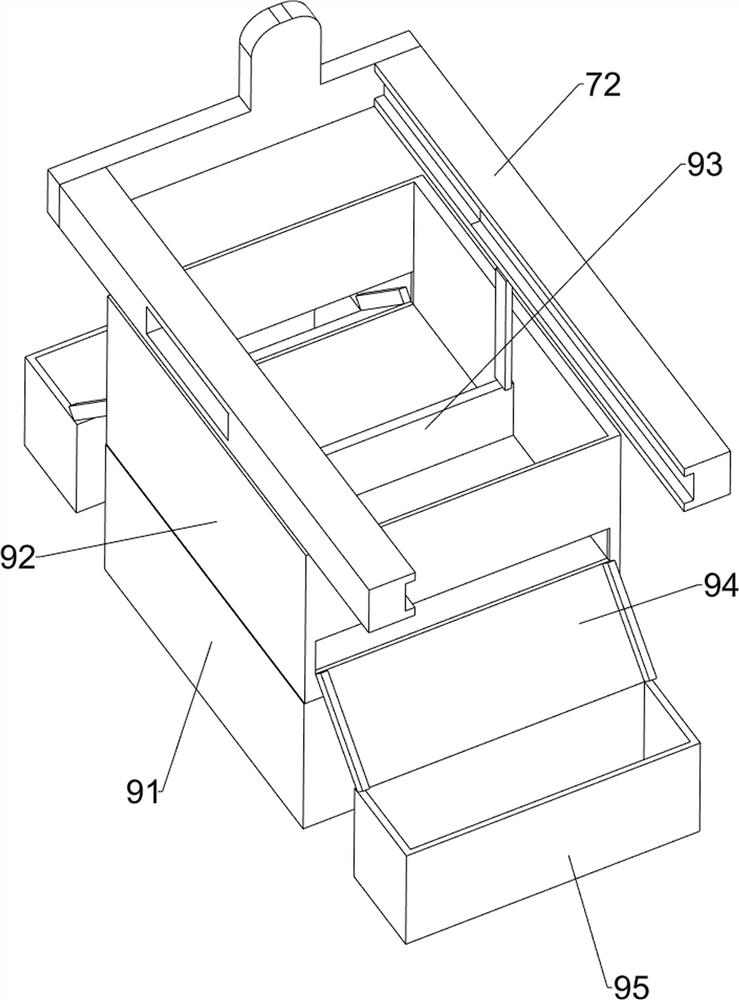

[0089] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a material shifting mechanism 6, a material shaking mechanism 7, a chip blowing mechanism 8 and a waste collection mechanism 9. The workbench 2 and the first rotating shaft 41 are provided with a material shifting mechanism 6, and the workbench 2 and the material shifting mechanism 6 A shaker mechanism 7 is provided on the top, a chip blower mechanism 8 is provided on the special-shaped rod 44 on the front side and the workbench 2, and a waste material collection mechanism 9 is provided on the base 1 and the shaker mechanism 7 .

[0090] When in use, people can pour nuts into the feeding mechanism 6. After the servo motor 3 is started, the first rotating shaft 41 rotates to drive the feeding mechanism 6 to operate. At the same time, the pressing plate 411 rotates downward to beat, and then the pressing plate 411 rotates upward to reset. When the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com