Movable cone of inertial cone crusher

A cone crusher and moving cone technology, applied in grain processing, etc., can solve the problems of reduced economic benefits and high cost of crushers, and achieve the effects of strong integrity, low failure rate, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

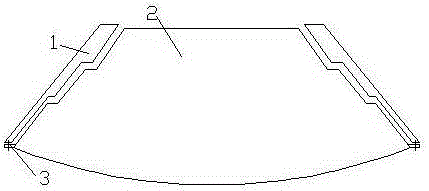

[0022] Such as figure 1 Shown is a moving cone of an inertia cone crusher, the moving cone of the inertia cone crusher: a cone cover 1, a cone body 2, and a convex ring 3, the moving cone includes a cone cover 1 and a cone body 2, the Cone cover 1 is the cone body that the interior is evacuated, and the inner cone wall surface of described cone cover 1 is provided with inverted steps, and the step surface of described inverted steps is set as level, and the outer cone wall surface of described cone body 2 is provided with positive steps, so The positive step that the outer cone wall surface is provided with matches the inverted step that the inner cone wall surface of the cone cover 1 is provided with, and the diameter of the inner cone wall surface circle of the cone cover 1 at the same horizontal position is greater than the outer cone wall surface circle of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com