Special-shaped ore grinding medium

A technology of grinding media and special shape, which is applied in the field of grinding media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

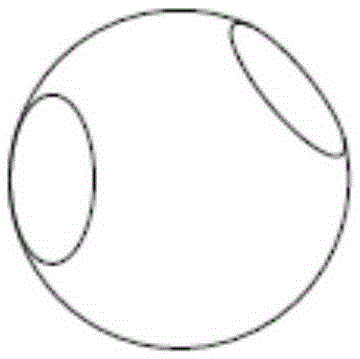

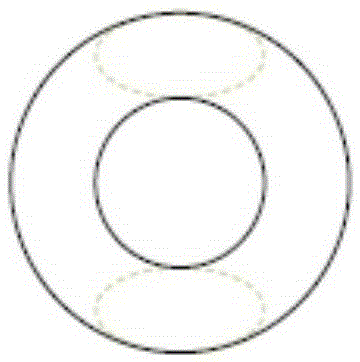

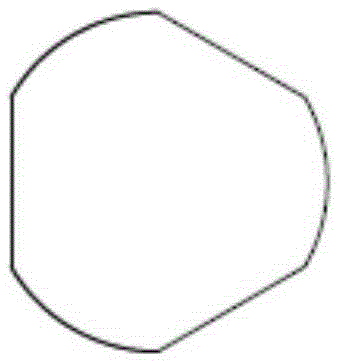

Image

Examples

Embodiment 1

[0019] Test conditions: The ore used in the test is a high-magnesium phosphate ore, which has been crushed to -1mm. The mill used for the test was Type mill, the filling rate is 40%, the addition amount of the two grinding media is 14Kg, the concentration of the grinding slurry is 65%, the grinding amount is 1Kg each time, and the grinding time is 11 minutes. Sieve analysis uses 0.074mm and 0.025mm sieves. The specifications and specific test results of the two grinding media are as follows:

[0020] New grinding medium: specification R=30mm, section circle diameter D=15mm;

[0021] Steel ball: specification R=30mm.

[0022] Table 1 Comparison test of two kinds of grinding media on the grinding effect of high-magnesium phosphate ore raw ore / %

[0023]

[0024] It can be seen from the test results in Table 1 that the grinding medium of the present invention has certain advantages over steel balls in the grinding effect of high-magnesium phosphate ore raw ore. Under the...

Embodiment 2

[0026] Test conditions: The ore used in the test is high-magnesium phosphate rock, which is taken from the sand settling of the cyclone. The mill used for the test was Type mill, the filling rate is 40%, the addition amount of the two grinding media is 14Kg, the concentration of the grinding slurry is 65%, the grinding amount is 1Kg each time, and the time is 11 minutes. Sieve analysis uses 0.074mm and 0.025mm sieves. The specifications and specific test results of the two grinding media are as follows:

[0027] New grinding medium: specification R=30mm, section circle diameter D=15mm;

[0028] Steel ball: specification R=30mm.

[0029] Table 2 Comparison test of two kinds of grinding media on the grinding effect of high magnesium phosphate rock cyclone sand settling / %

[0030]

[0031] As can be seen from the test results in Table 2, the ore grinding medium of the present invention has a better grinding effect on high-magnesium phosphate rock cyclone sand settling tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com