Patents

Literature

45results about How to "Adjust feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

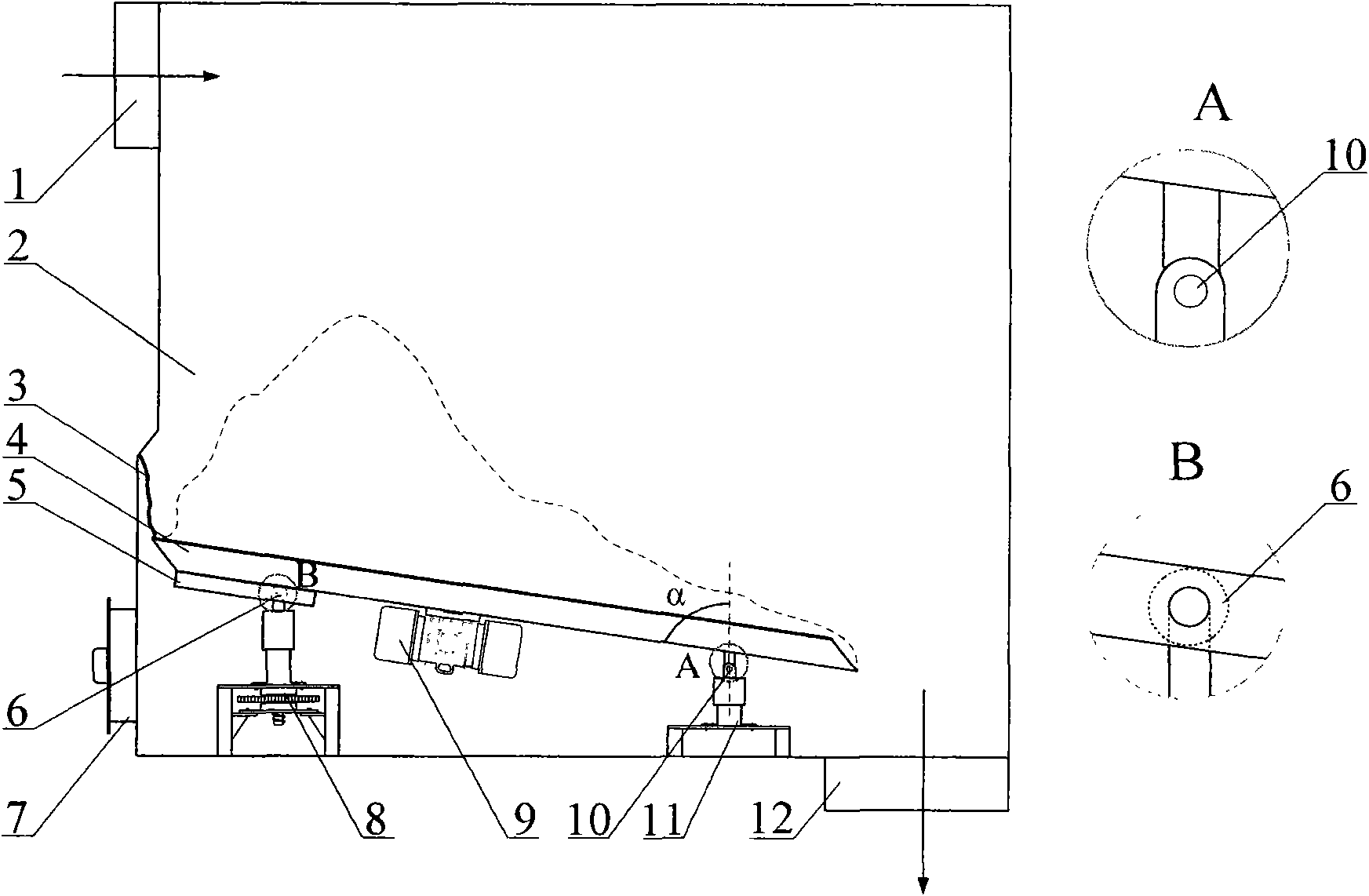

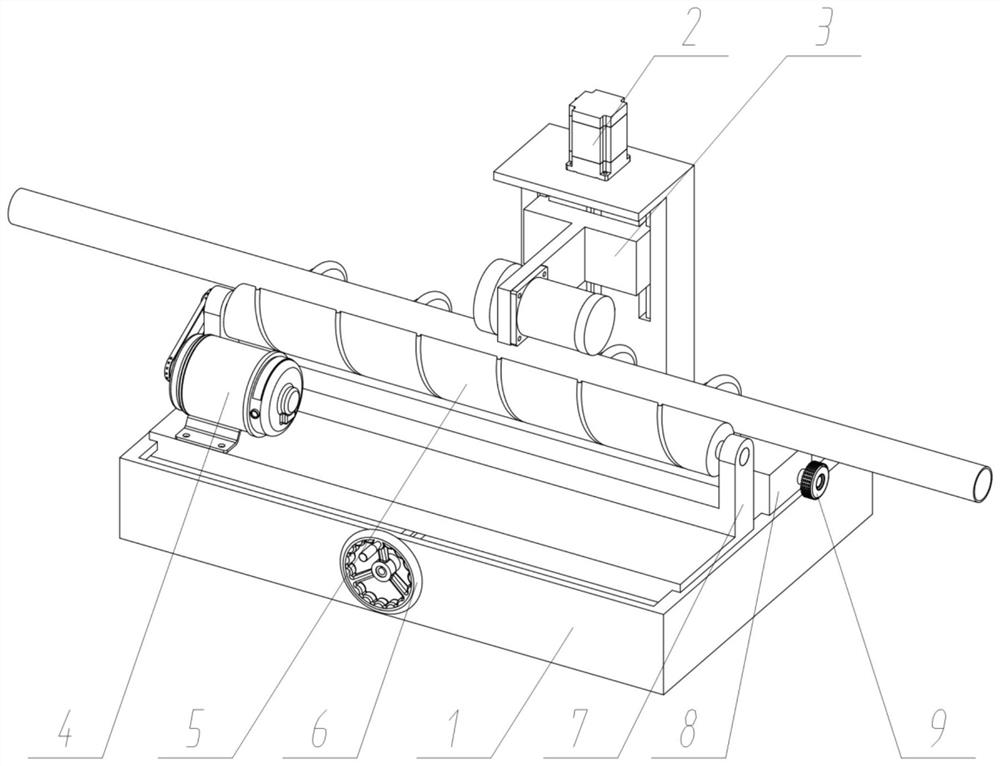

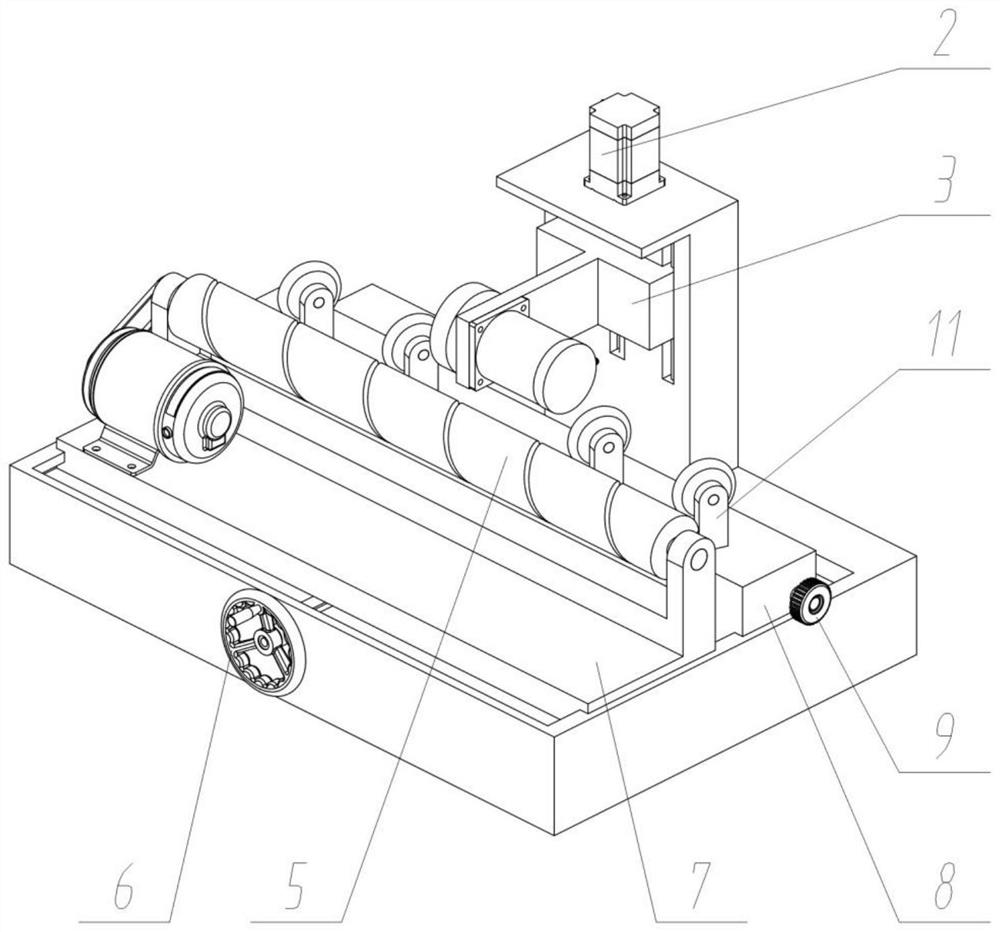

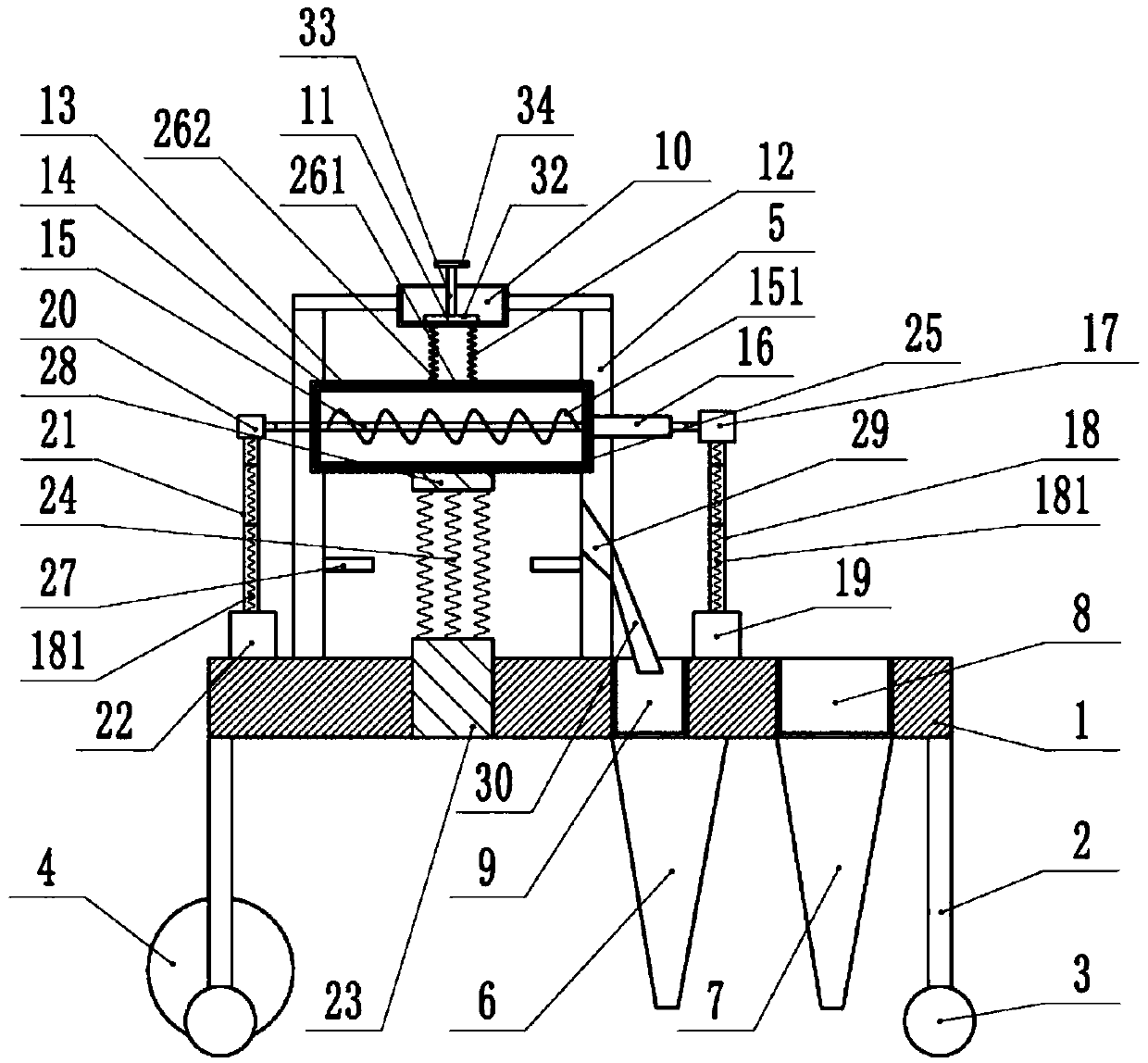

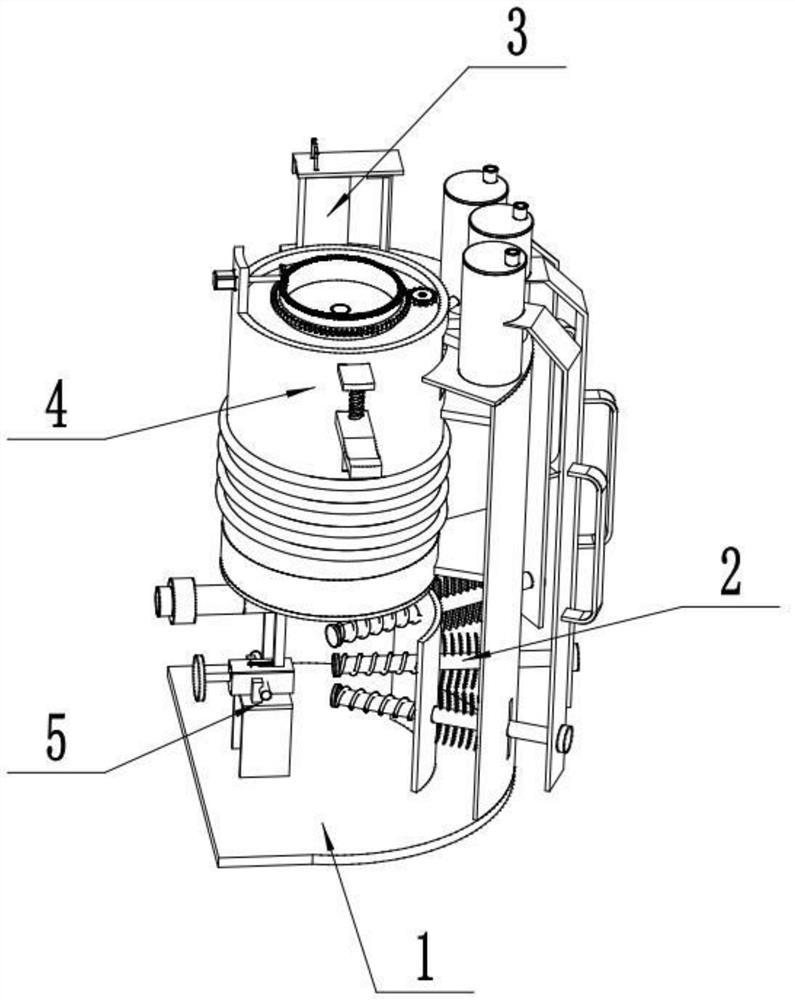

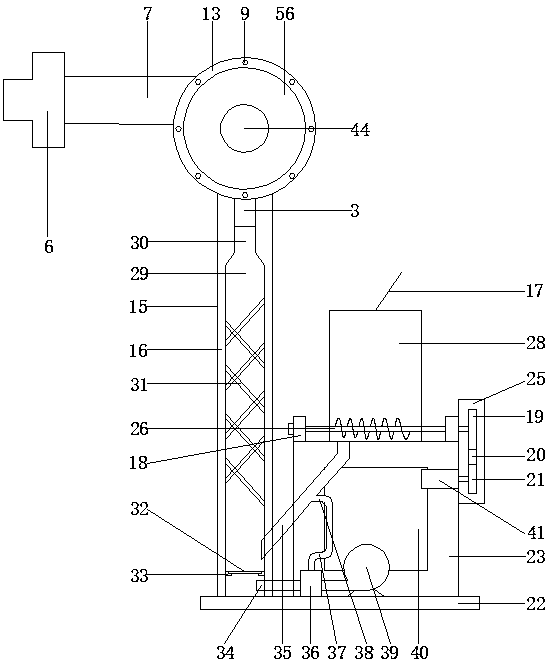

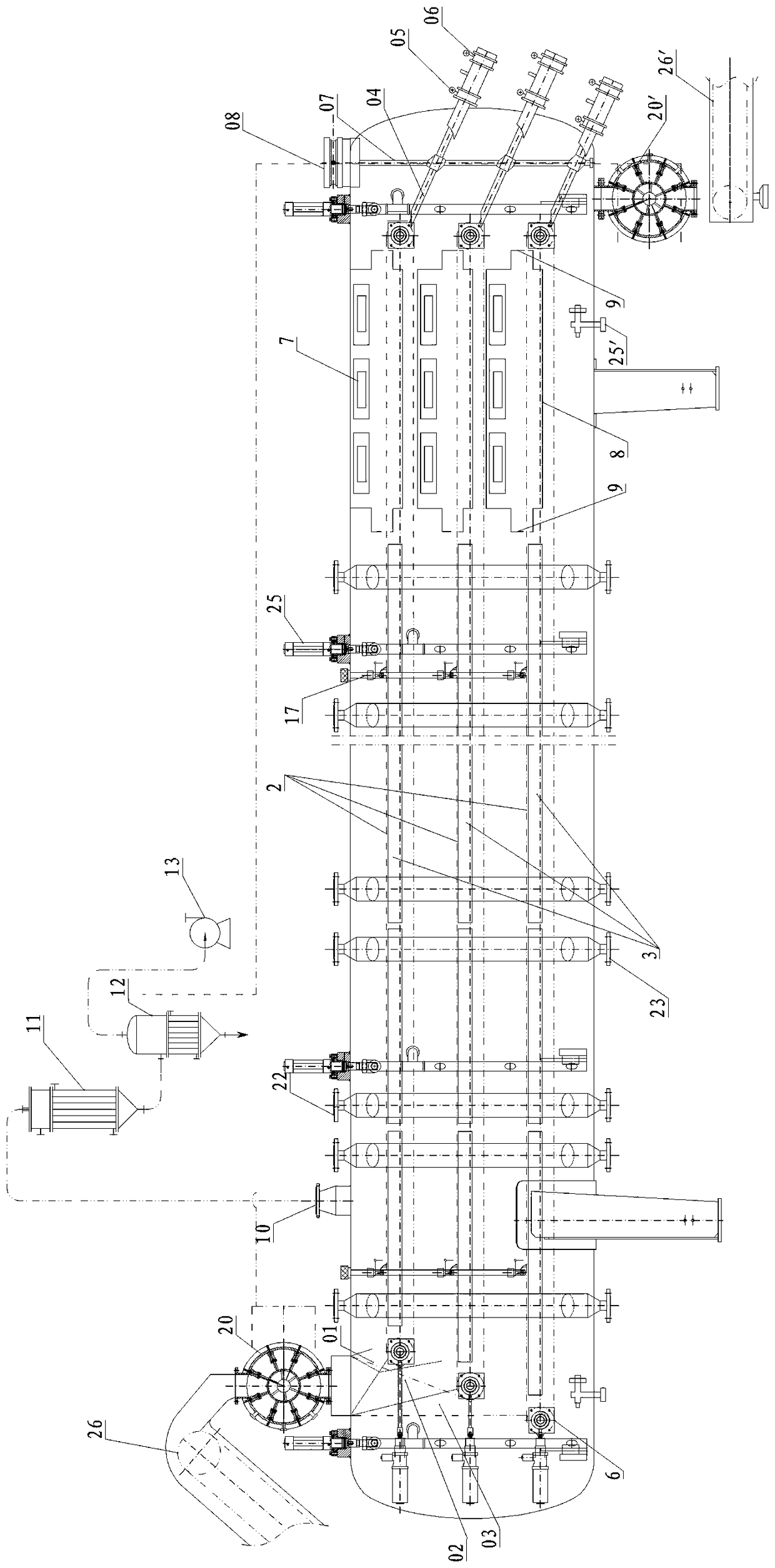

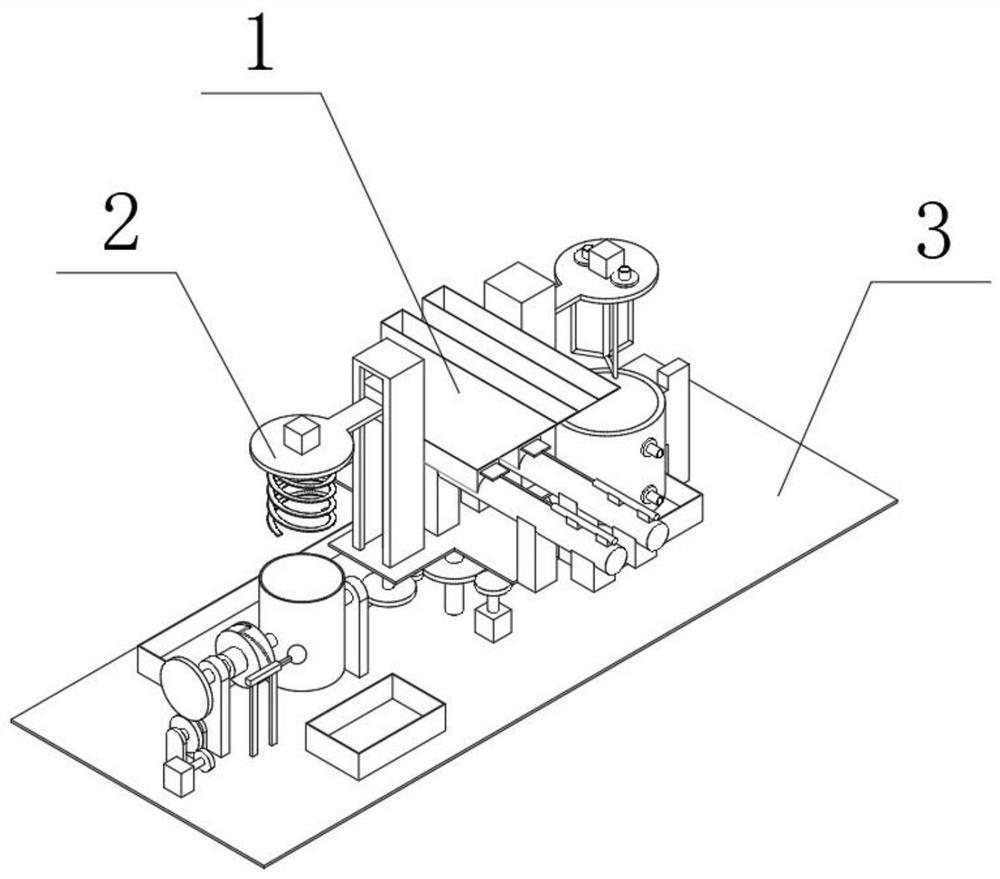

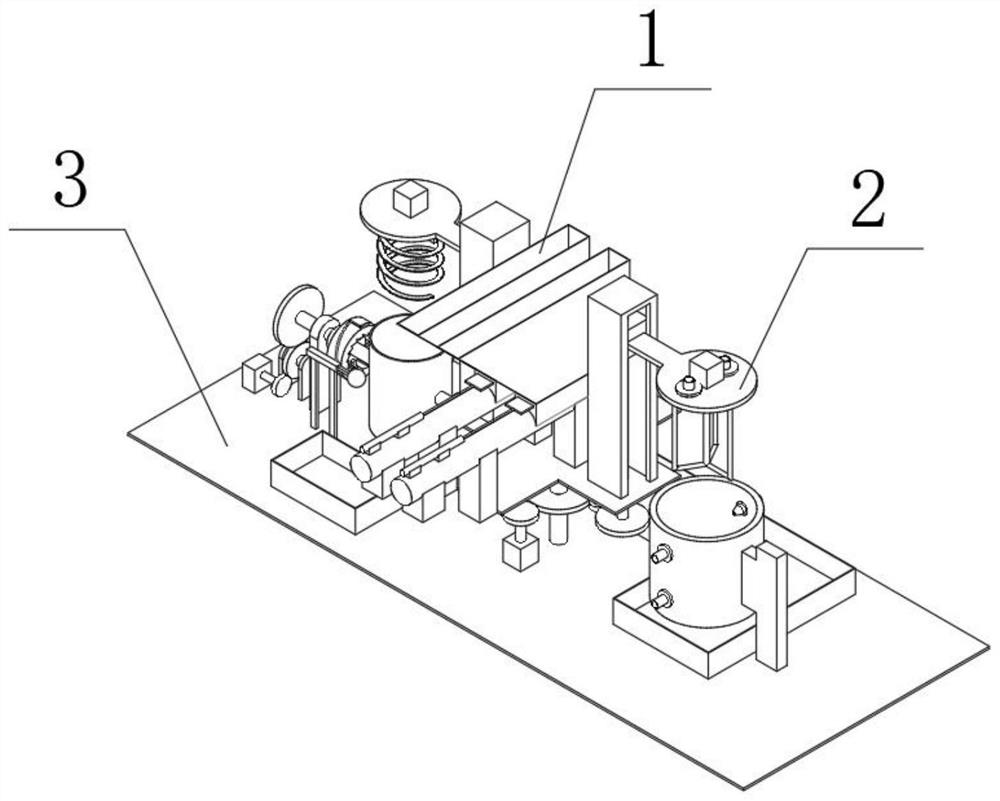

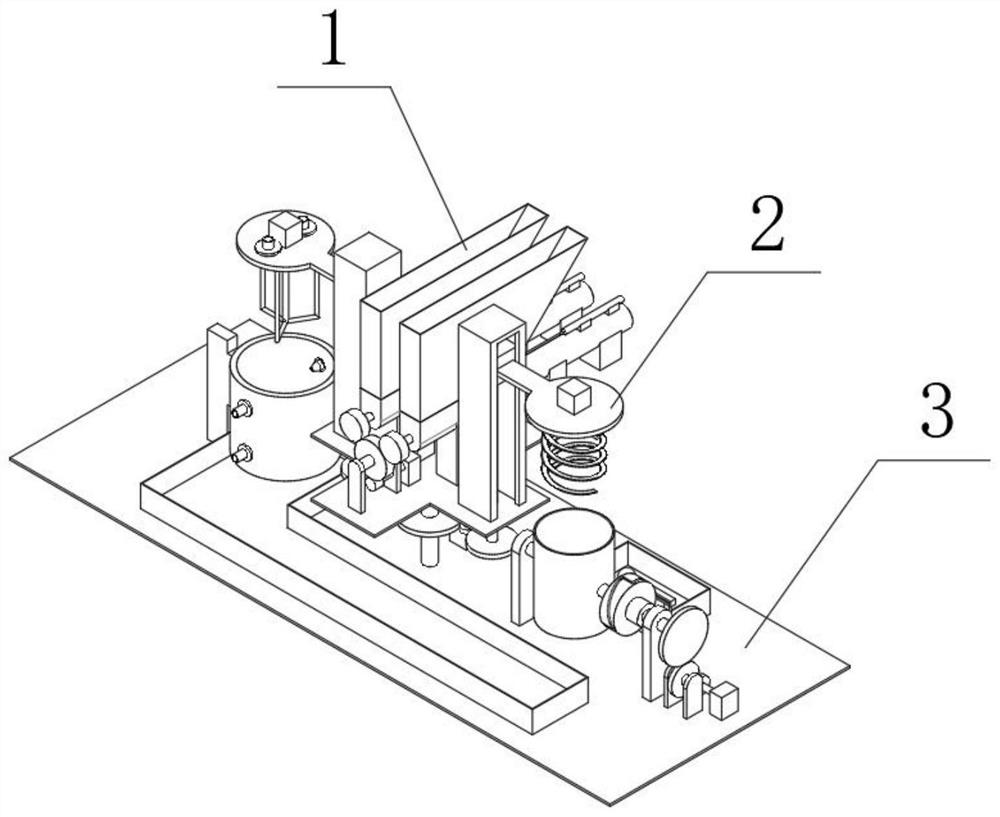

Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

ActiveCN101613039AContinuous, stable and even distribution of materialsAchieve free rotationLarge containersLoading/unloadingMultiple formsMaterial distribution

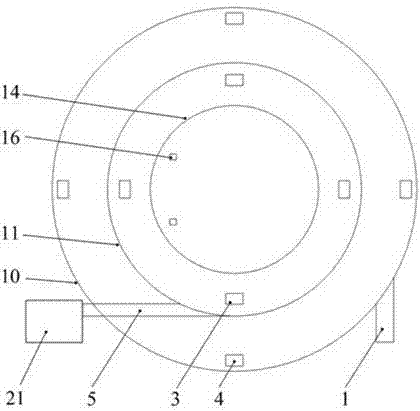

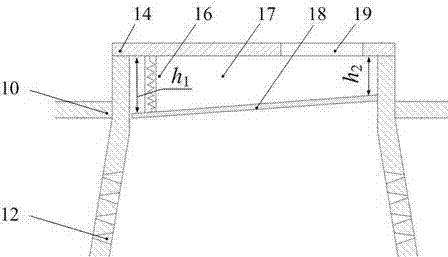

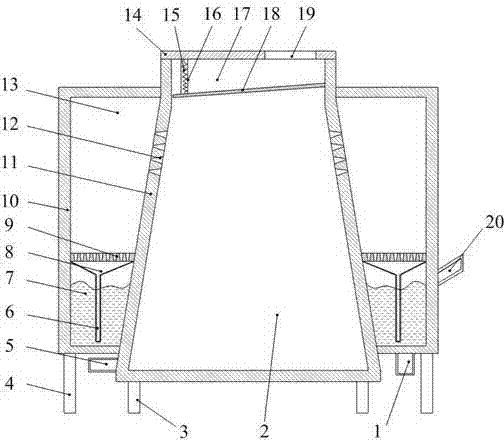

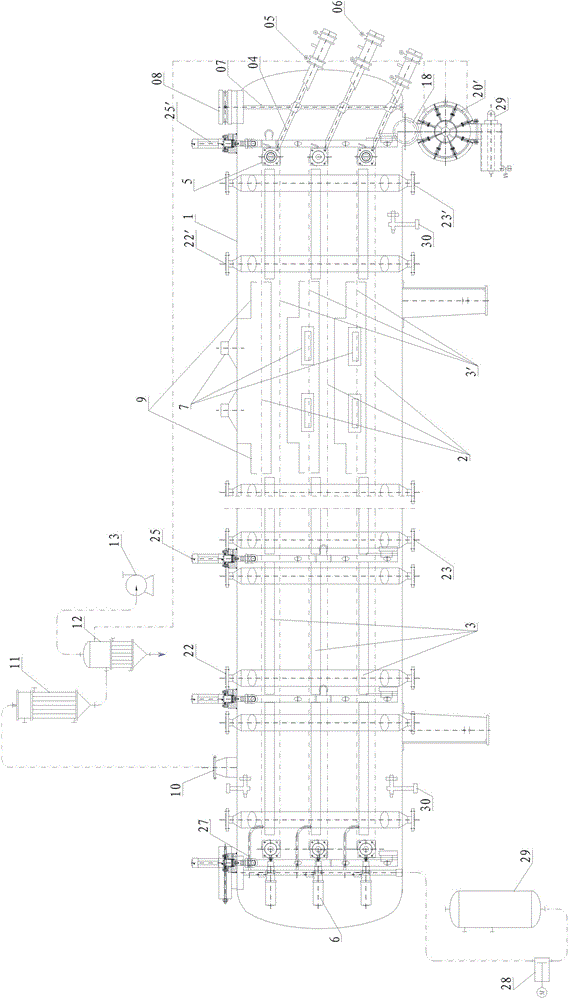

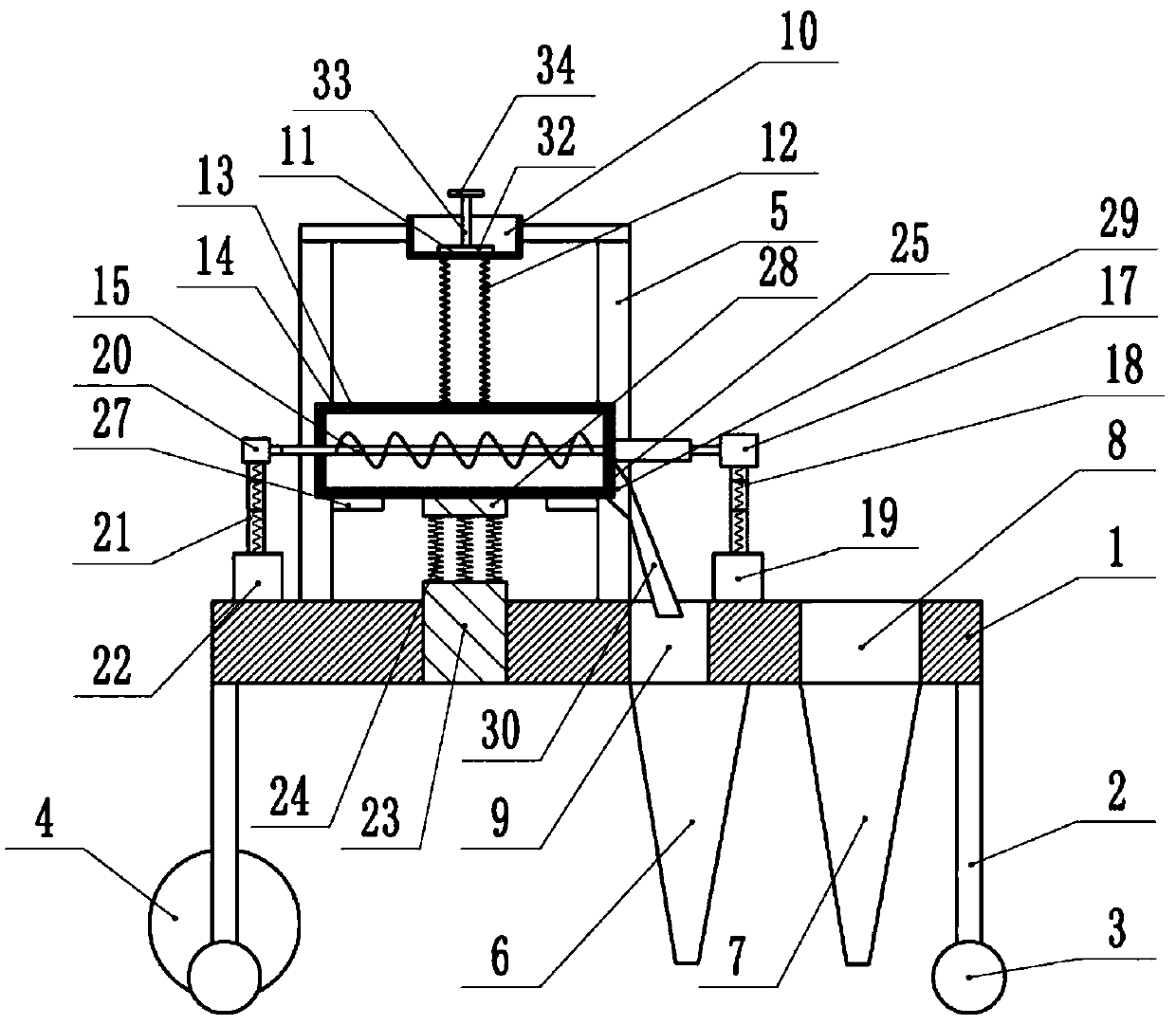

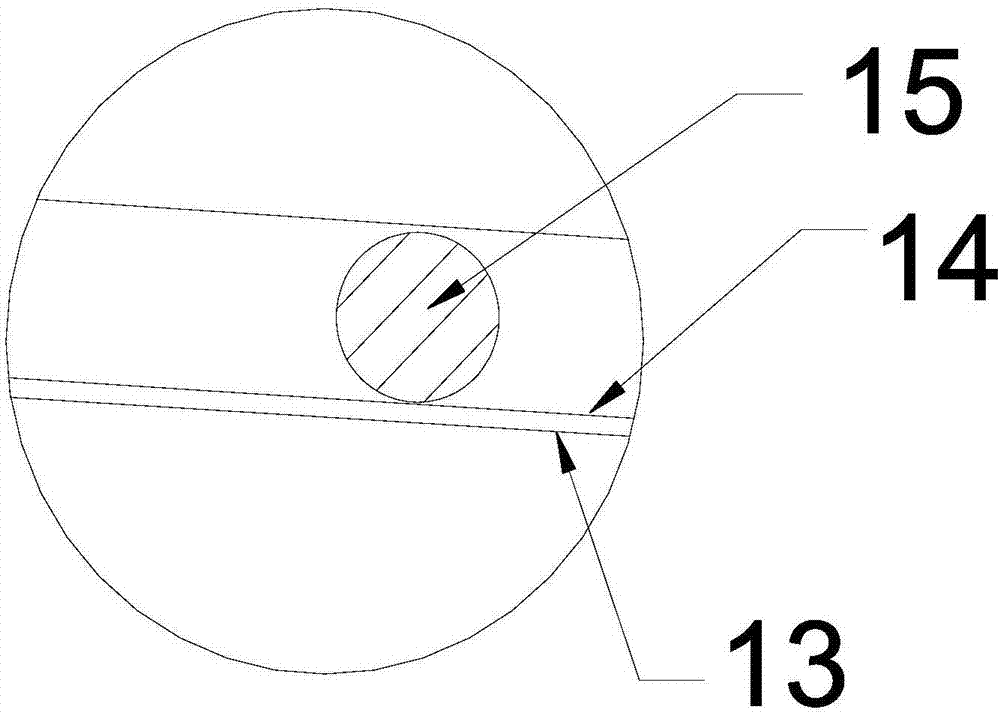

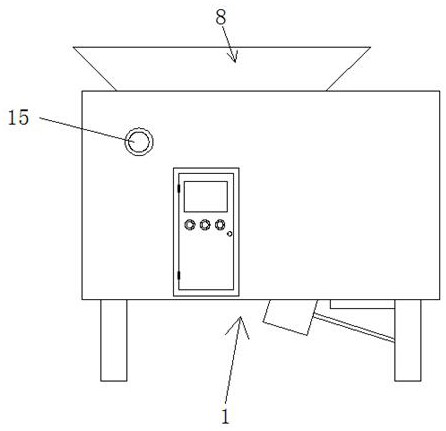

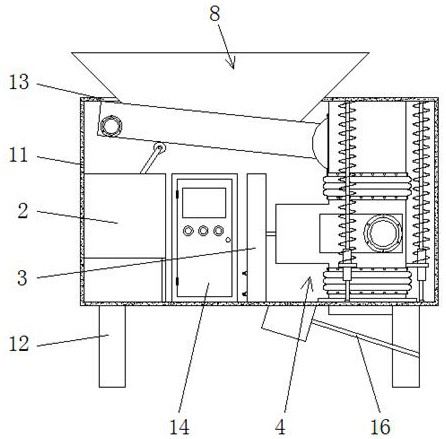

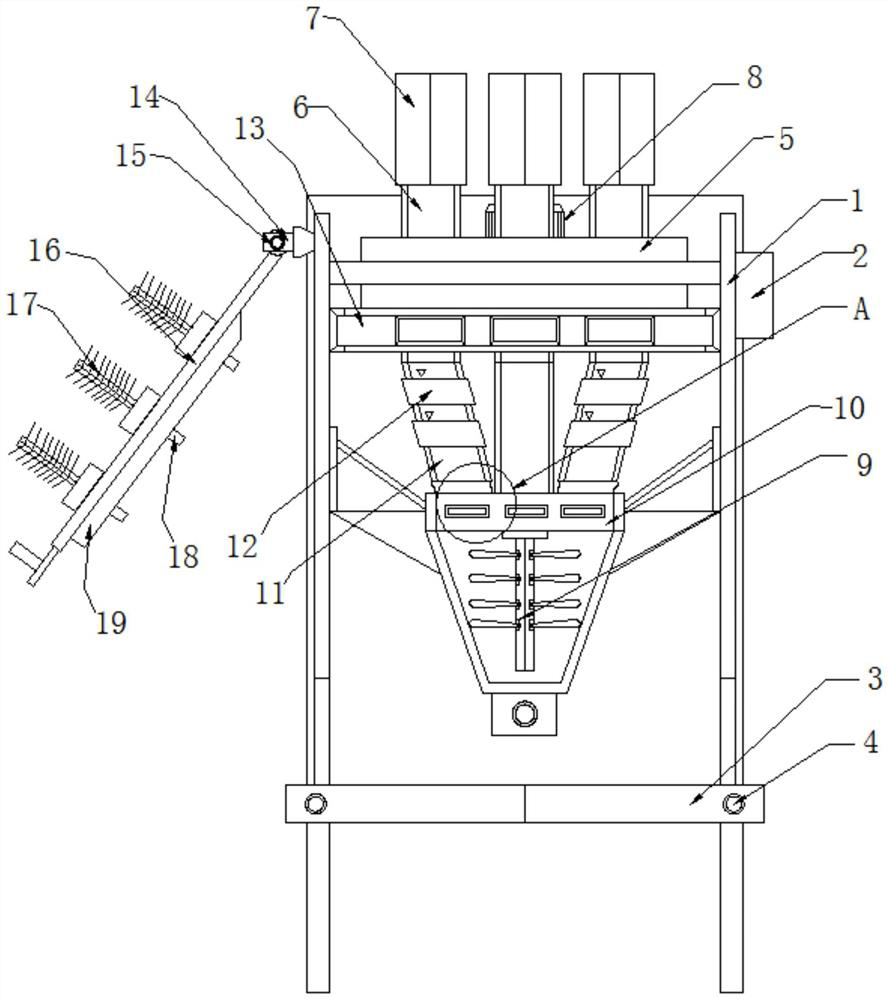

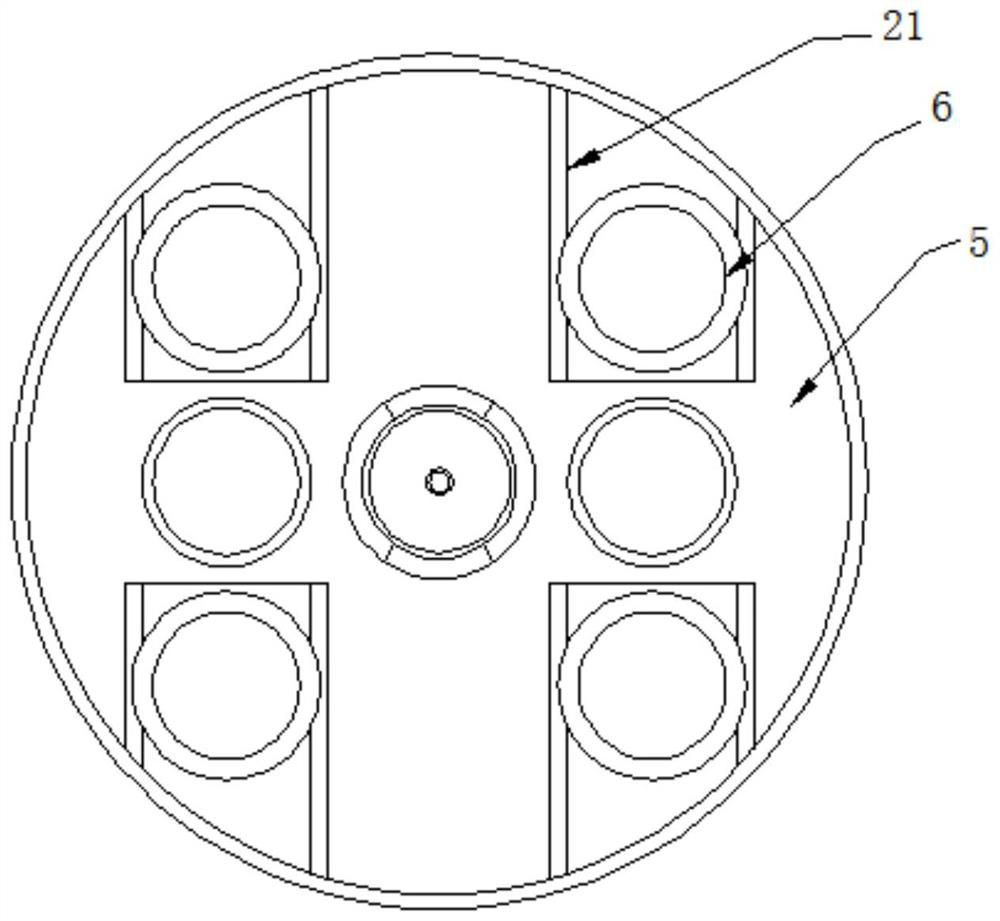

The invention relates to a biomass feed divider with changeable trough obliquity and vibration frequency and amplitude, which realizes continuous, stable and safe feed division by adopting two regulating measures of changing obliquity of a trough and changing vibration frequency and amplitude and by exciting force generated by a vibrating motor (9). The device is formed by arranging one or a plurality of independent distributors in parallel, wherein each distributor mainly comprises a trough body (4), a vibrating motor (9), an elevating (8), a spring supporting mechanism (11) and an auxiliary mechanism; the trough body (4) is supported by the spring supporting mechanism (11) at the front part and the elevating (8) at the rear part, the vibrating motor (9) is arranged in the middle of the bottom of the trough body (4), and the rear part of the trough body (4) is connected with bulkhead by canvas (3). The device integrates material storage and material distribution, is not only suitable for hard biomass but also is suitable for soft biomass, and has lateral expansibility, thereby being convenient to be used together with material equipment of various types.

Owner:SOUTHEAST UNIV

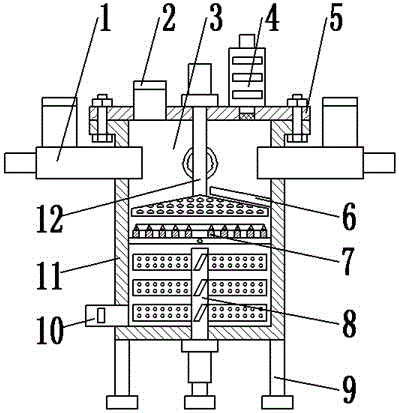

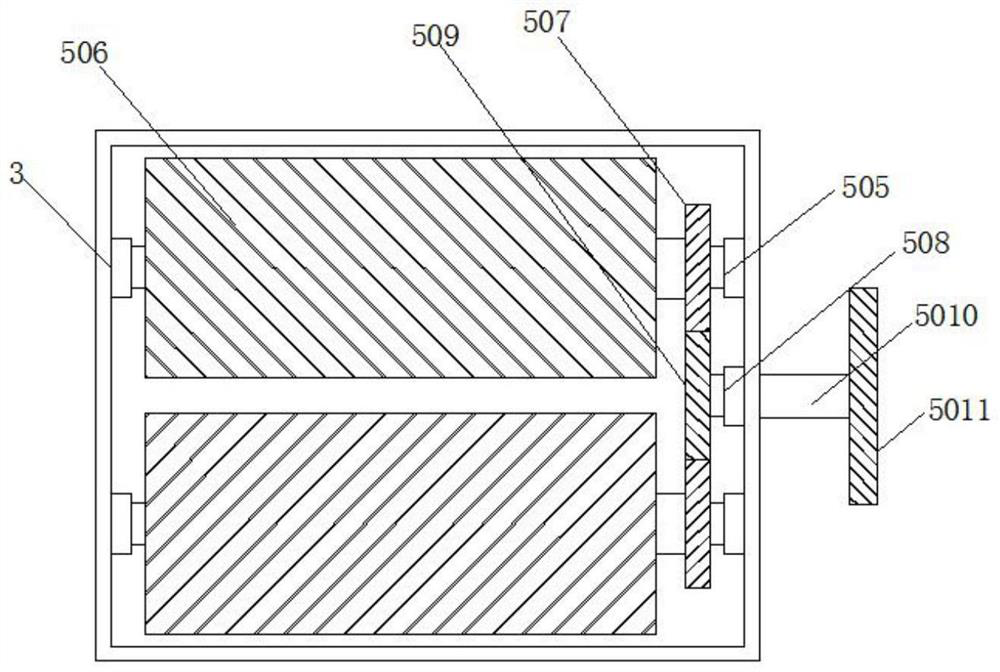

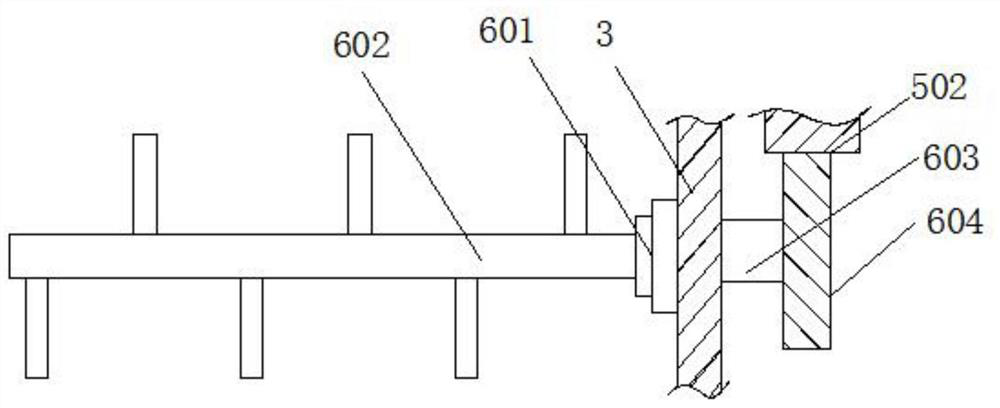

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

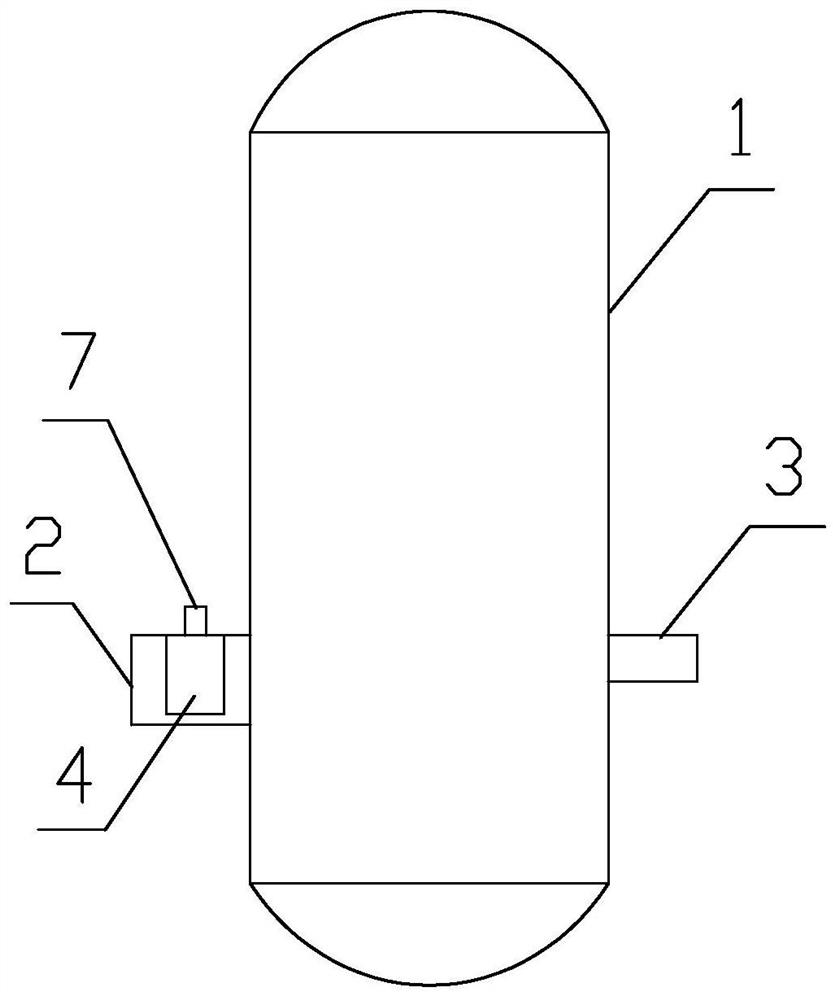

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

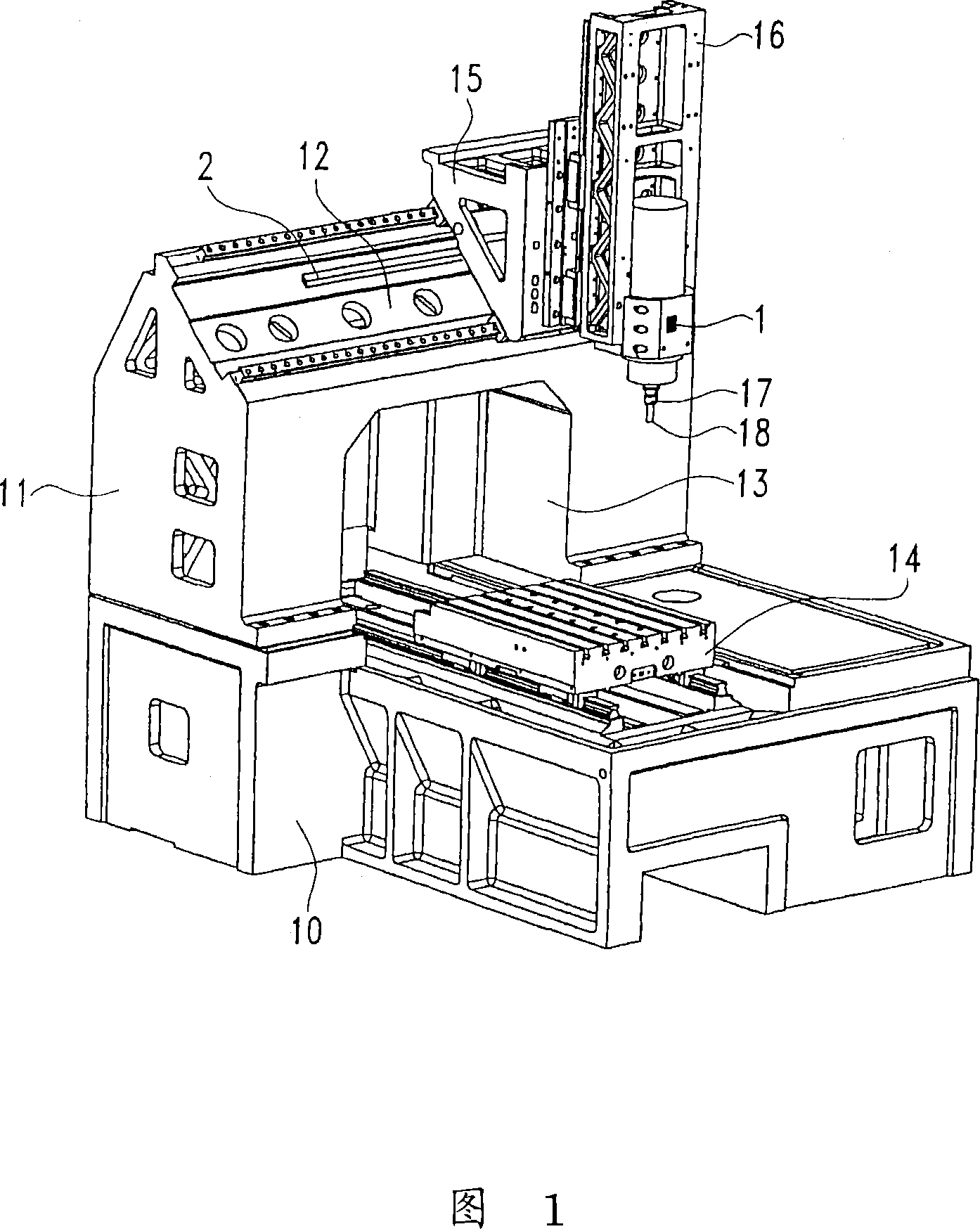

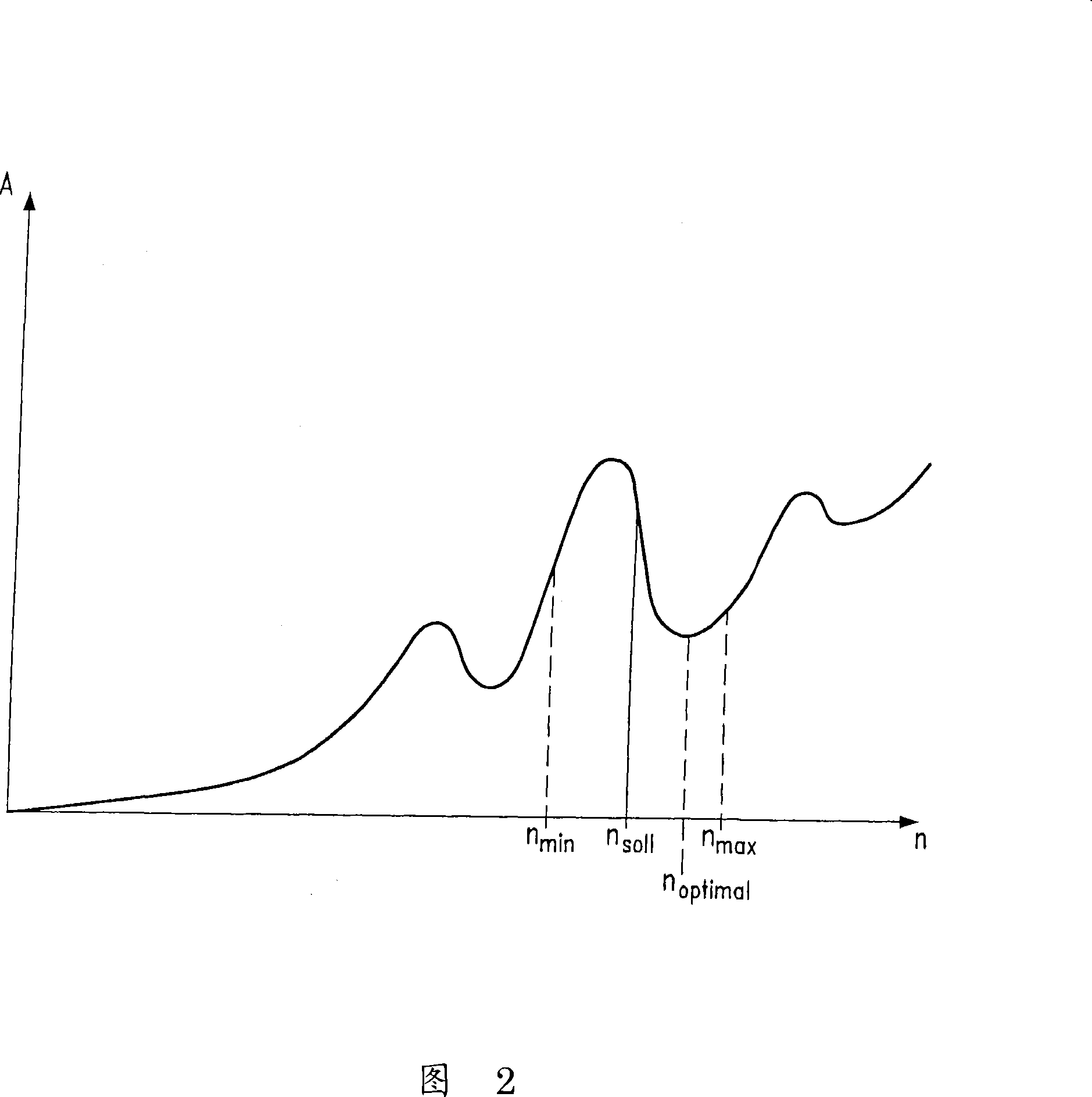

Method for vibration-optimizing a machine tool

InactiveCN101180157AAvoid resonanceSuppress resonanceAutomatic control devicesFeeding apparatusDrive shaftControl theory

The invention relates to a method for vibration-optimizing a machine tool. The inventive method is characterized by setting a driven shaft (17) rotating, and then covering a speed range. The vibrations produced in the speed range are measured and an optimum speed having a minimum vibration is determined and adjusted.

Owner:P&L合资有限公司

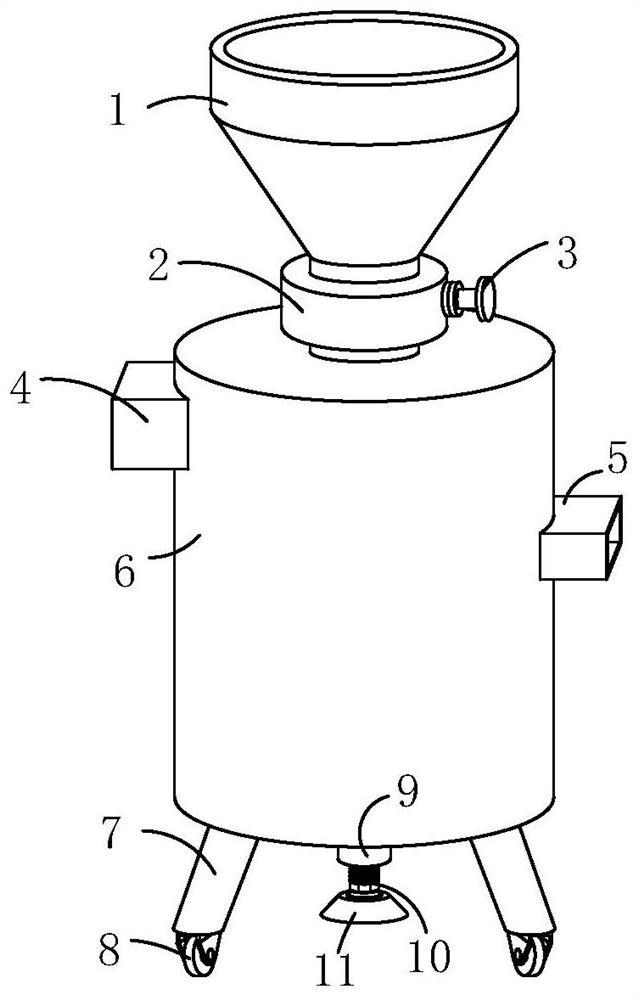

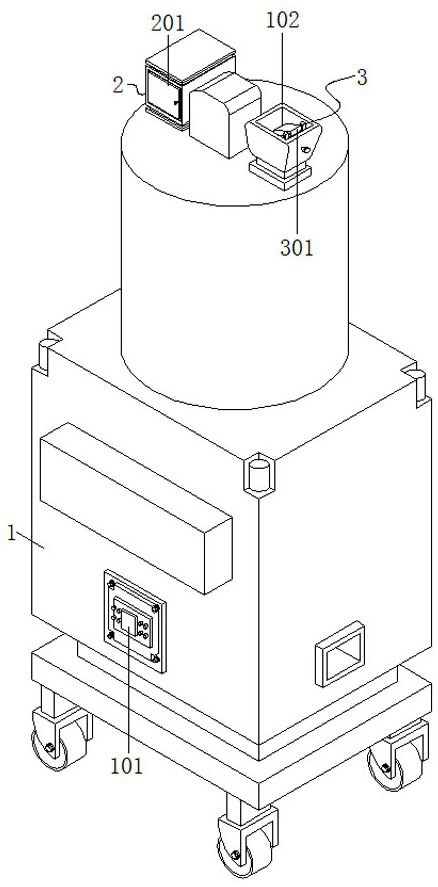

Pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown

InactiveCN104727173AGuaranteed stabilityEliminate shakingRaw material divisionLiquid stateLiquid water

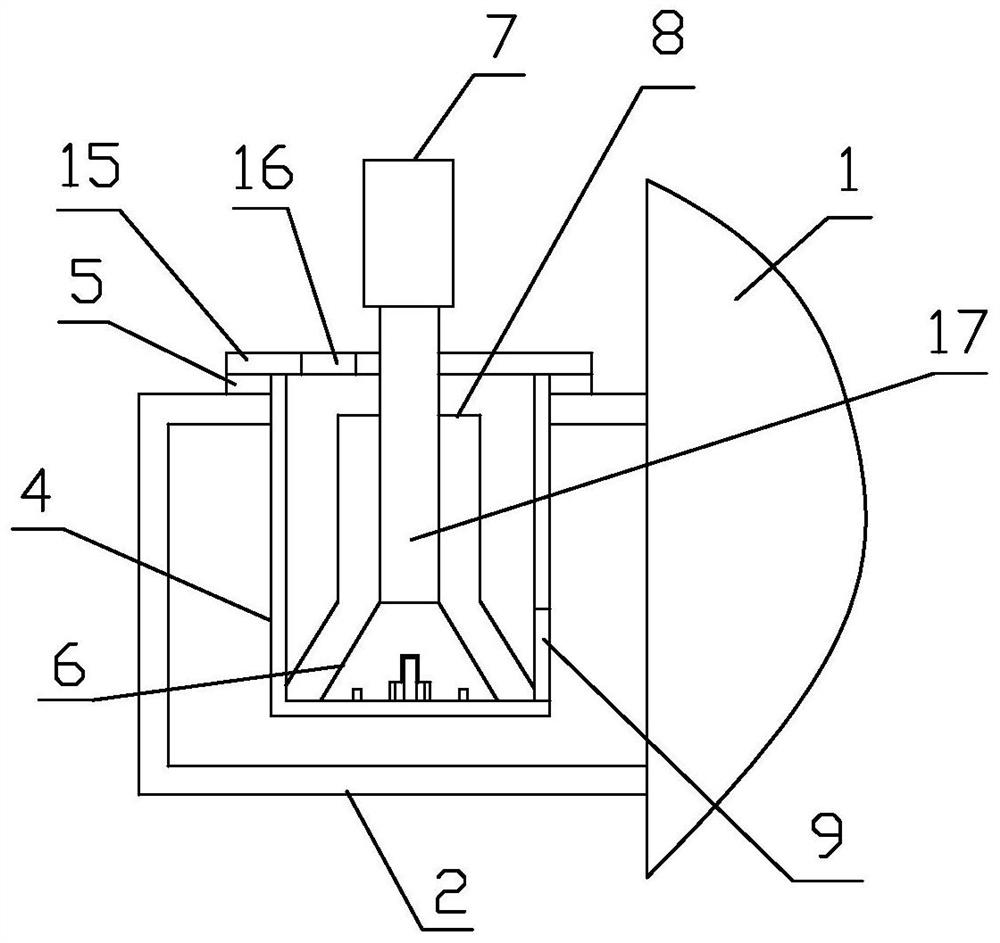

The invention provides a pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown. The pulping device mainly comprises a feeding device, a vortex breakdown device and a liquid pulp generating device and is characterized in that solid and liquid are separated, air vortex breakdown is conducted firstly, and then broken materials are mixed with liquid water to form pulp. According to the pulping device, feeding amount control and sealing are achieved through a buffering and sealing plate and a spring, tangential feeding of air is achieved and loop current is formed through an air inlet tangent to the outer edge of the bottom of an inner conical cylinder, rotational flow is accelerated twice through a tapered primary vortex breakdown area and an oblique secondary vortex breakdown area, the broken materials are screened twice and blockage prevention is achieved through circular truncated cone-shaped holes in a primary filtering device and a secondary filtering device, and mixing and stirring of solid and liquid are achieved through a broken material delivery pipe.

Owner:UNIV OF JINAN

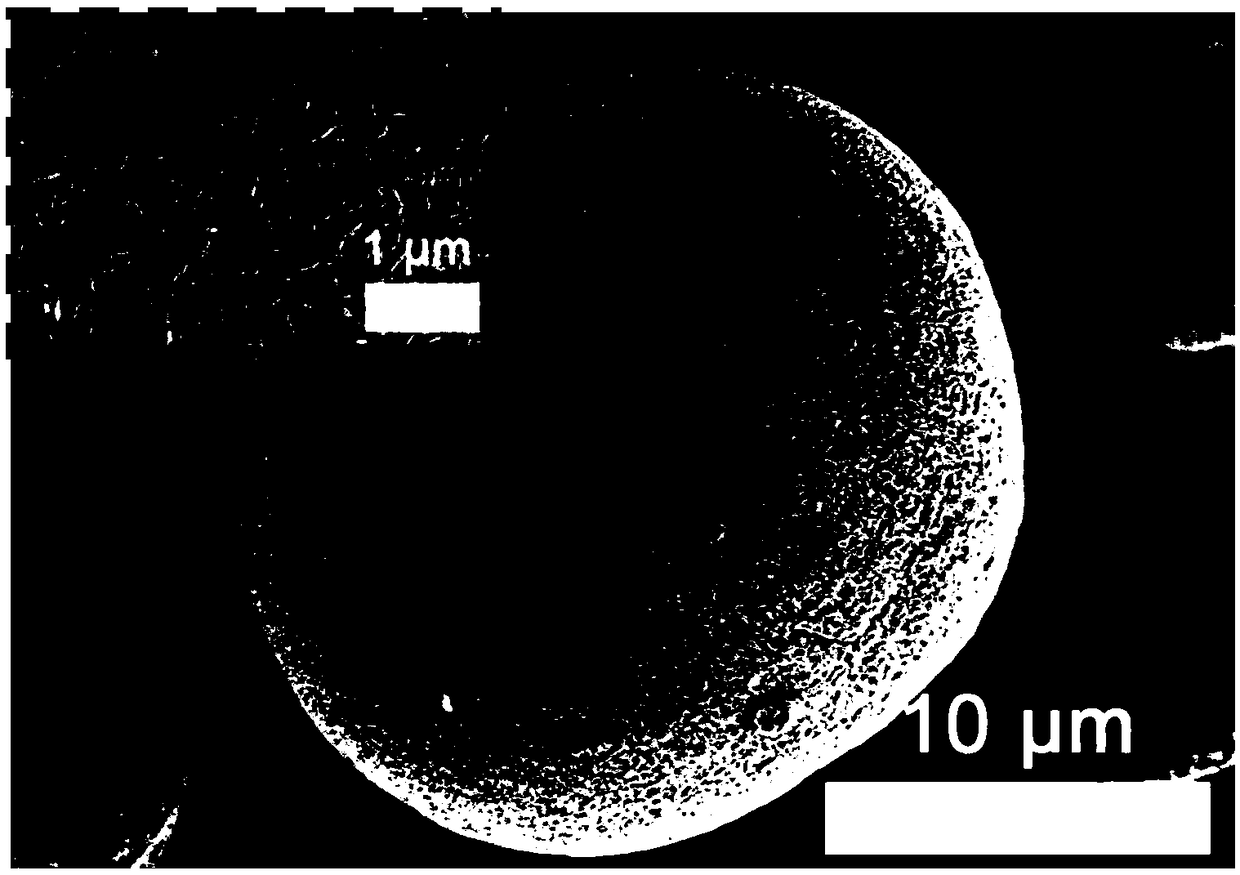

A NCM ternary cathode material with hierarchical structure

ActiveCN109244454AIncrease compaction densityImprove cycle stabilityCell electrodesSecondary cellsElectrical batteryManganese

The invention relates to an NCM ternary cathode material with a special hierarchical structure, and belongs to the field of chemical energy storage batteries. A ternary cathode material precursor of nickel, cobalt and manganese is added to the deionized water with stirring, the pH value is controlled, and then a mixed metal salt solution and a mixed alkali solution are added dropwise under a protective gas atmosphere, so that the pH value is stabilized at 10-12, and control that feeding time and the reaction temperature to obtain the modify nickel-cobalt-manganese ternary cathode material precursor; Then the modified Ni-Co-Mn ternary cathode precursor and lithium salt were mixed and calcined evenly to obtain a NCM ternary cathode material with hierarchical structure. The compaction density, cyclic stability and magnification performance of the material are greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

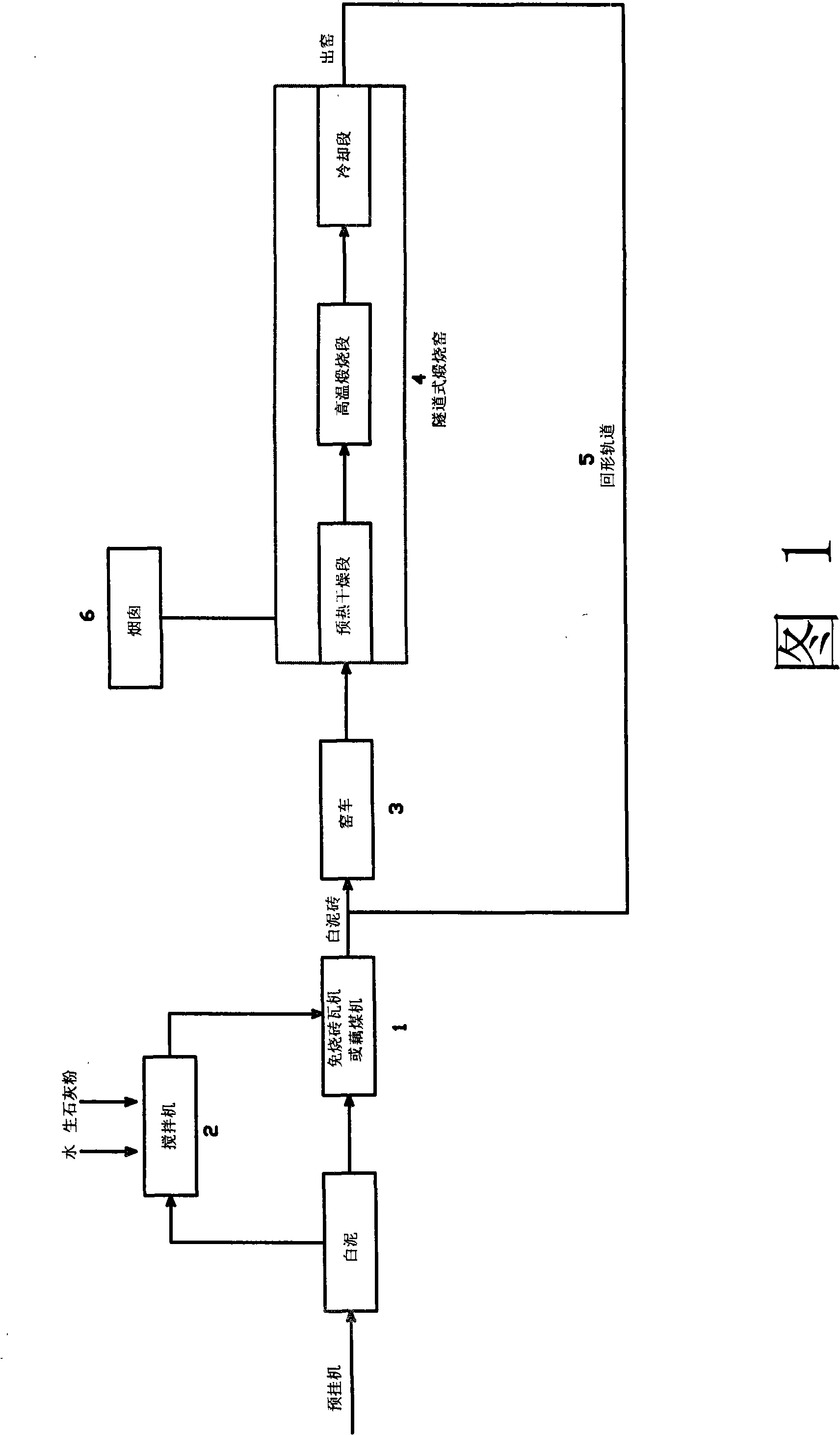

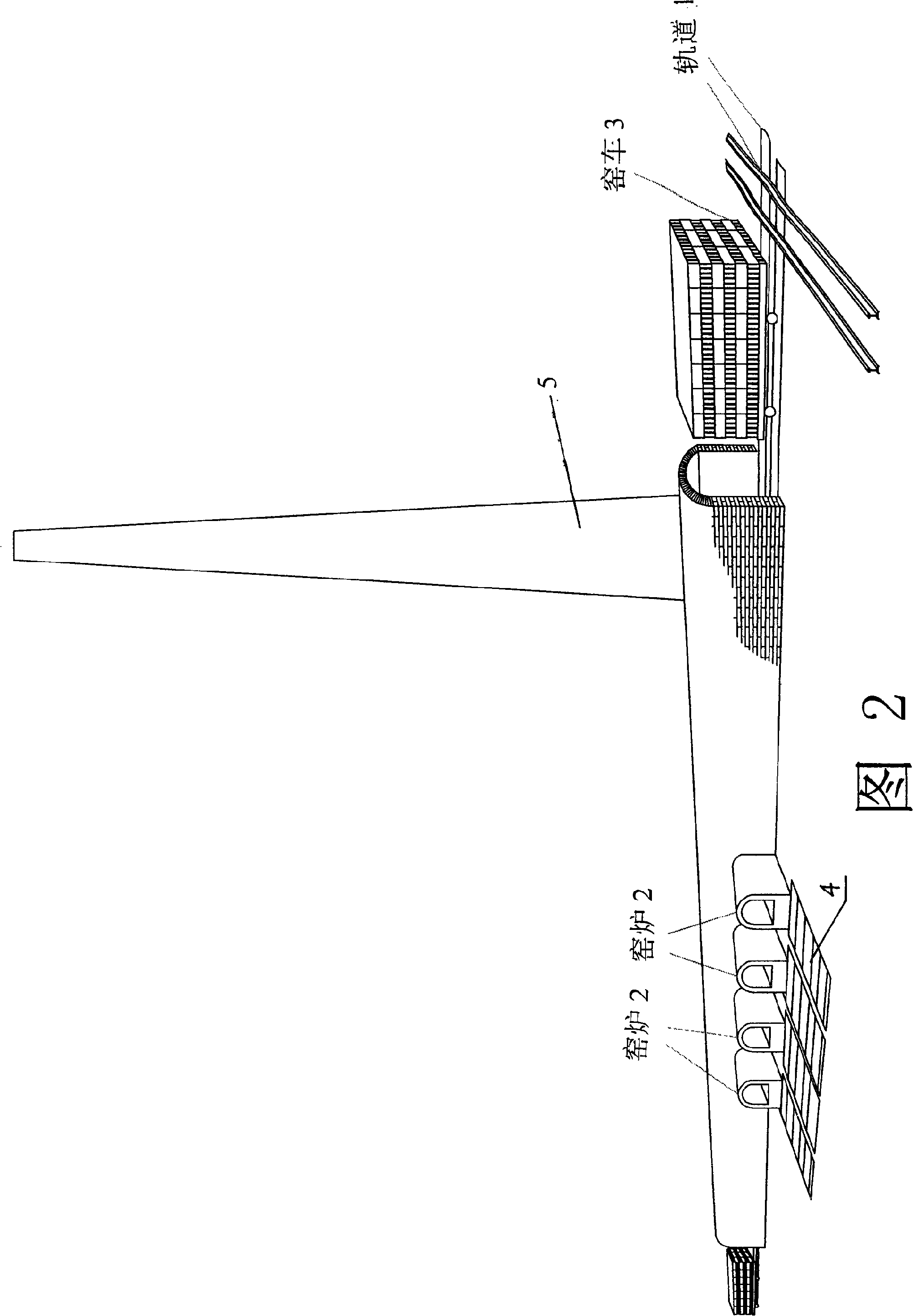

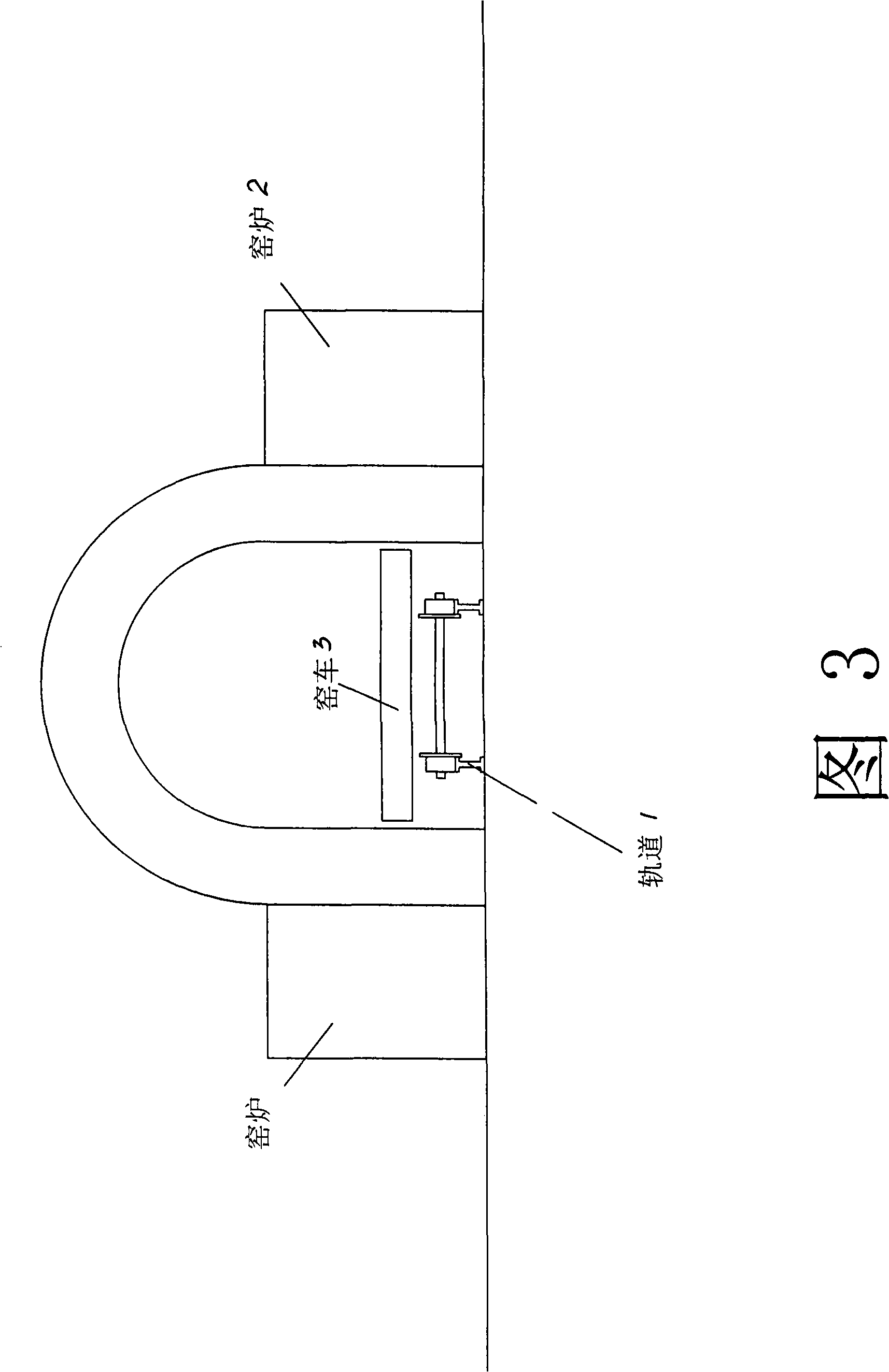

Process for recovering white slime and tunnel type calcining kiln for the method

InactiveCN101318780ALower quality requirementsNo need to dryFurnace typesCeramic materials productionBrickFiltration

The invention discloses a method for recovering white mud and a tunnel type calcinating kiln using the same. The method is to recover white mud by subjecting a great deal of white mud generated as a by-product in the production of pulp and paper enterprises to water filtration, mud regulation, brick making, car loading, calcination and kiln discharge and other processes and to calcine the white mud in the tunnel type calcinating kiln at a temperature of between 1, 050 and 1, 250 DEG C, which solves the problem of difficult recovery of white mud. The method has the advantages of simple process, energy conservation, high recovery and low cost.

Owner:怀化市德兴环保科技有限公司

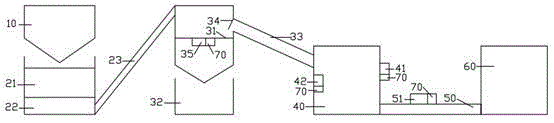

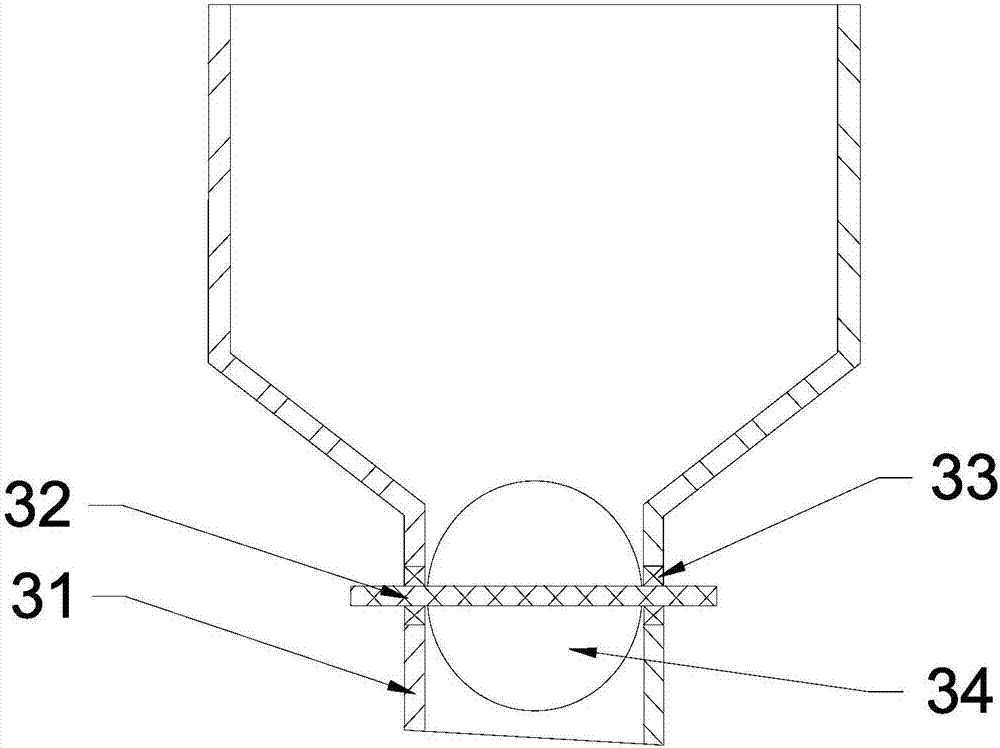

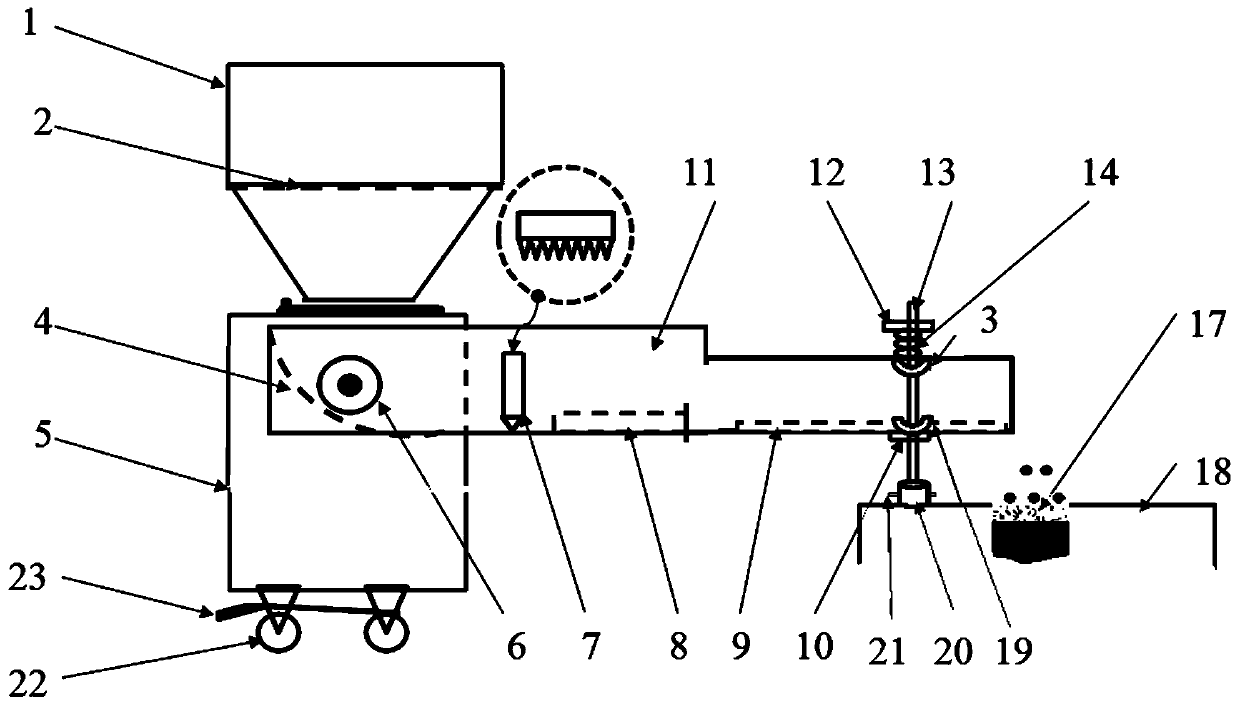

Biomass pyrolytic carbonization system feeding device

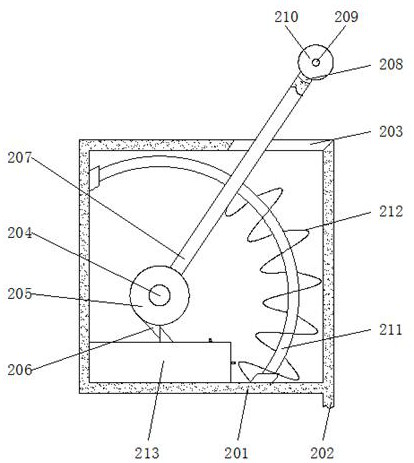

InactiveCN105713628AHigh purityImprove carbonization efficiencyBiofuelsSpecial form destructive distillationBiomassEngineering

The invention discloses a biomass pyrolytic carbonization system feeding device. The device comprises a raw material storage bin, a crushing device, an impurity removal device, a drying device and a PLC control system; the crushing device is arranged below the raw material storage bin; the impurity removal device is connected with the crushing device through a conveyor belt; the drying device is arranged below the impurity removal device; the crushing device comprises a crusher and a storage device; the storage device is arranged below the crusher; a collecting device is arranged below a vibration screen; the side of the vibration screen is provided with a conveying channel connected with the drying device; the drying device is connected with a carbonization machine through a transmission device; and the PLC control system is connected with the impurity removal device, the drying device and the transmission device. The feeding device provided by the invention is capable of improving product purity, reducing production time and improving production efficiency.

Owner:泰州瑞沣环保科技有限公司

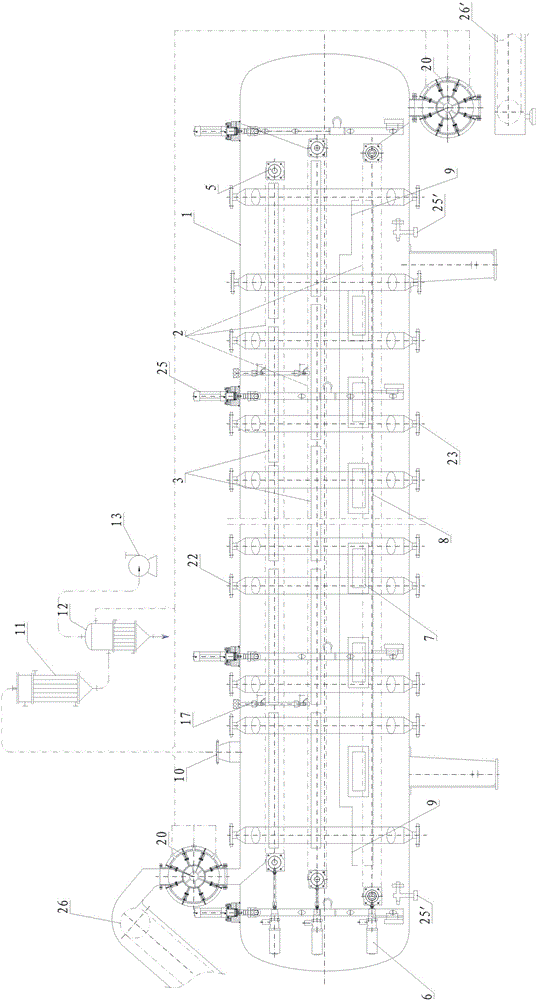

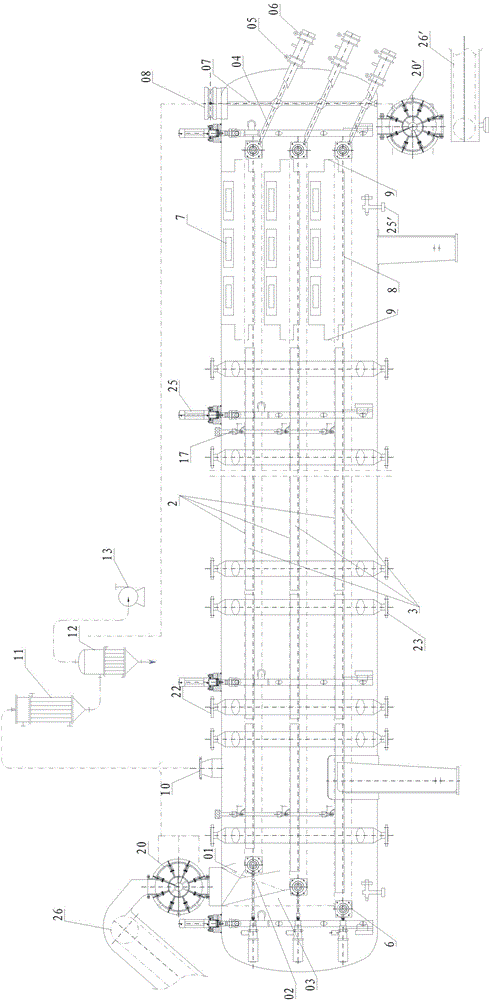

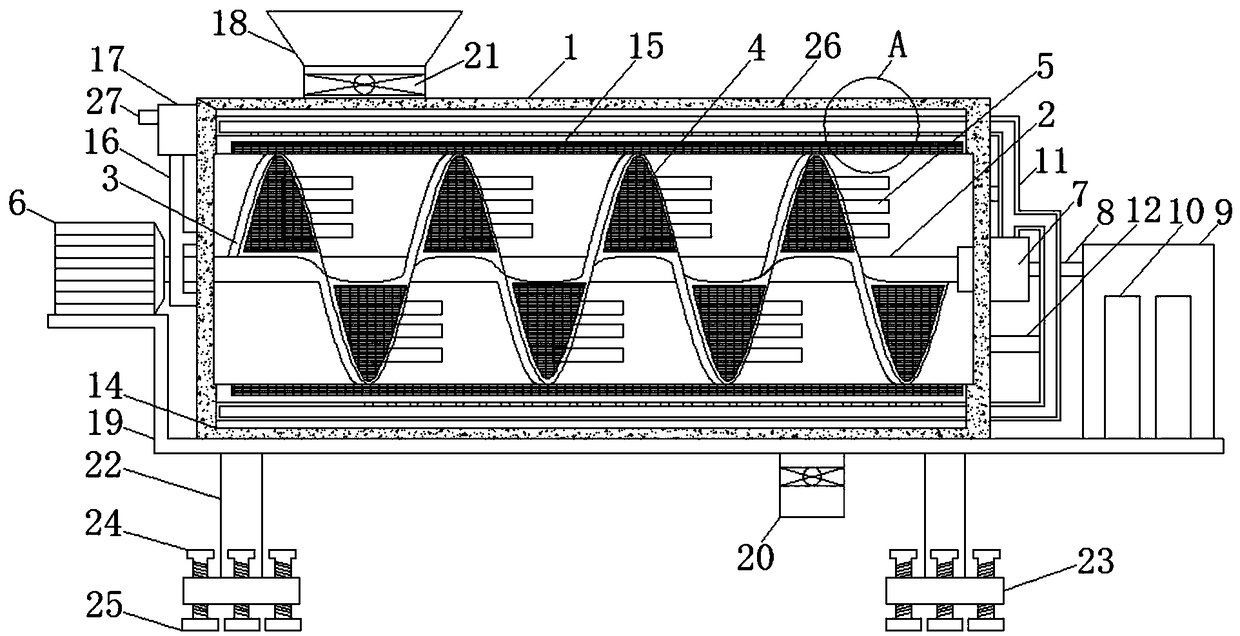

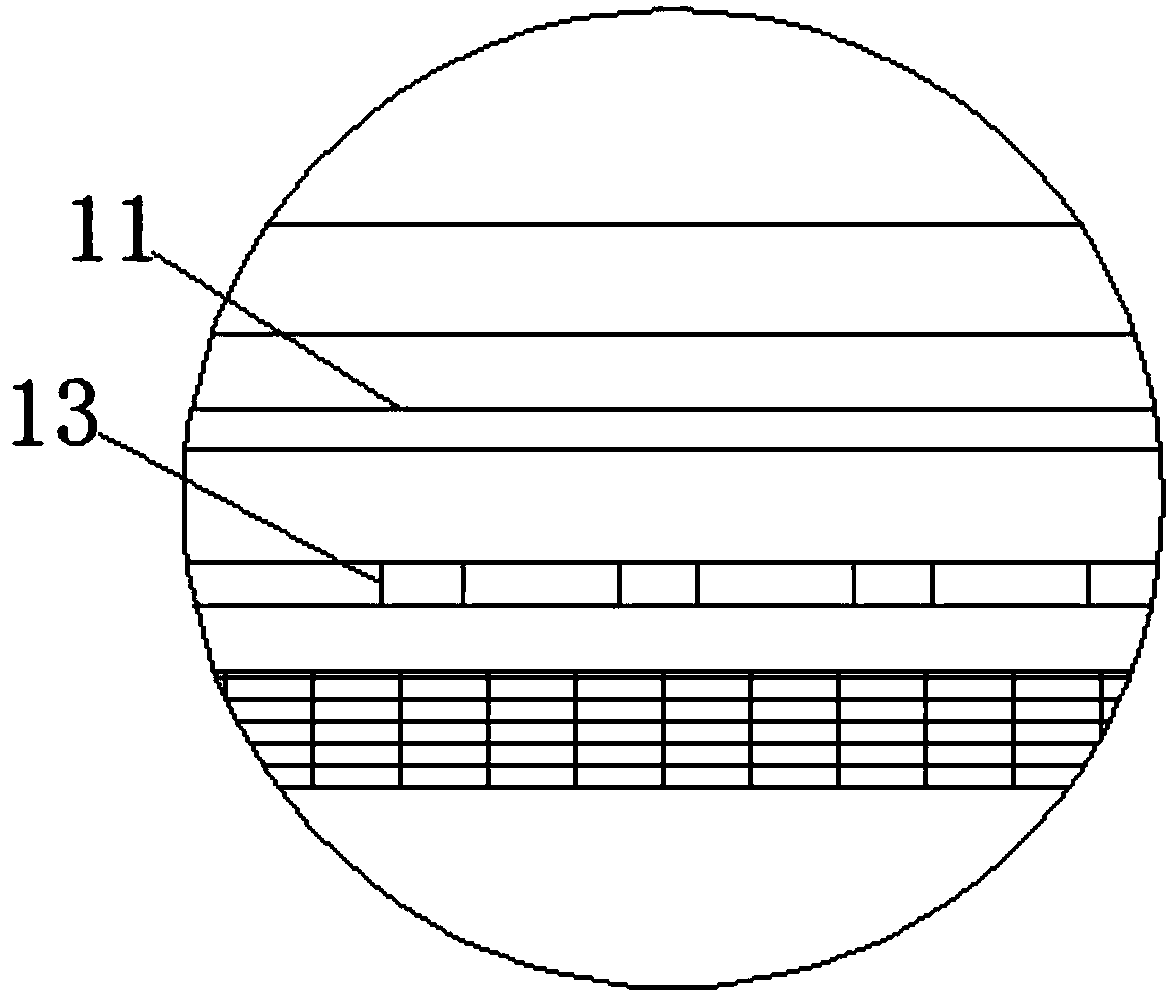

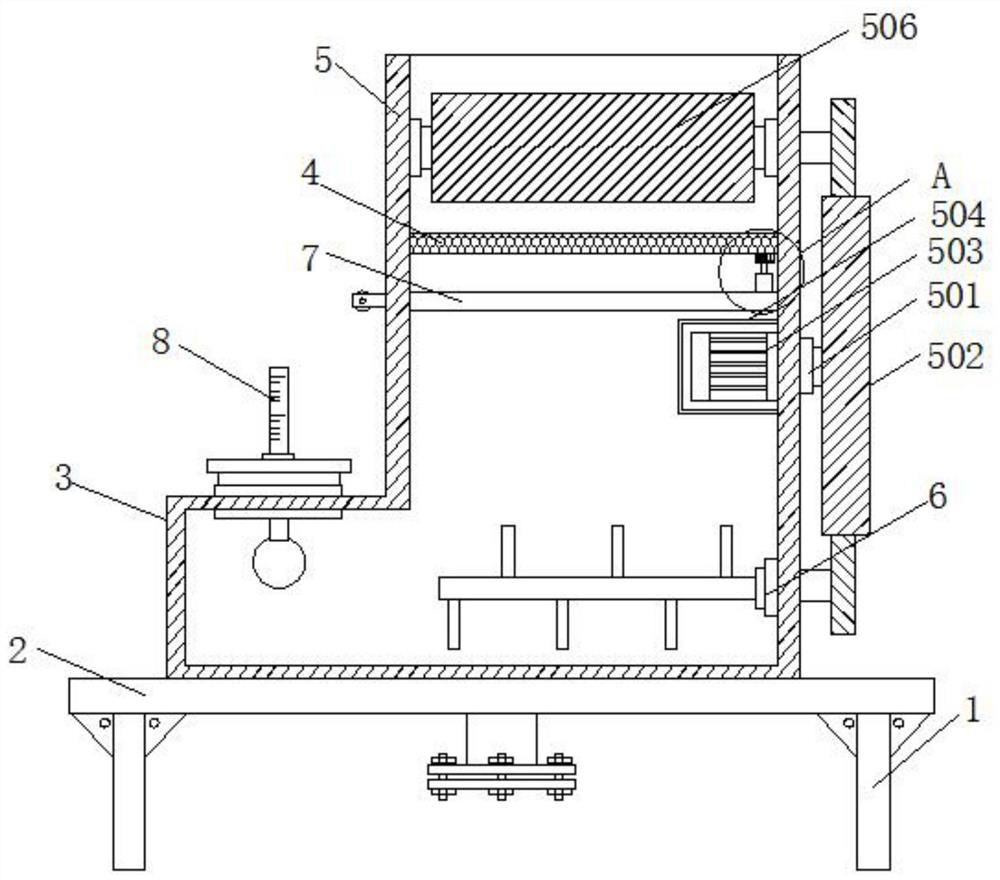

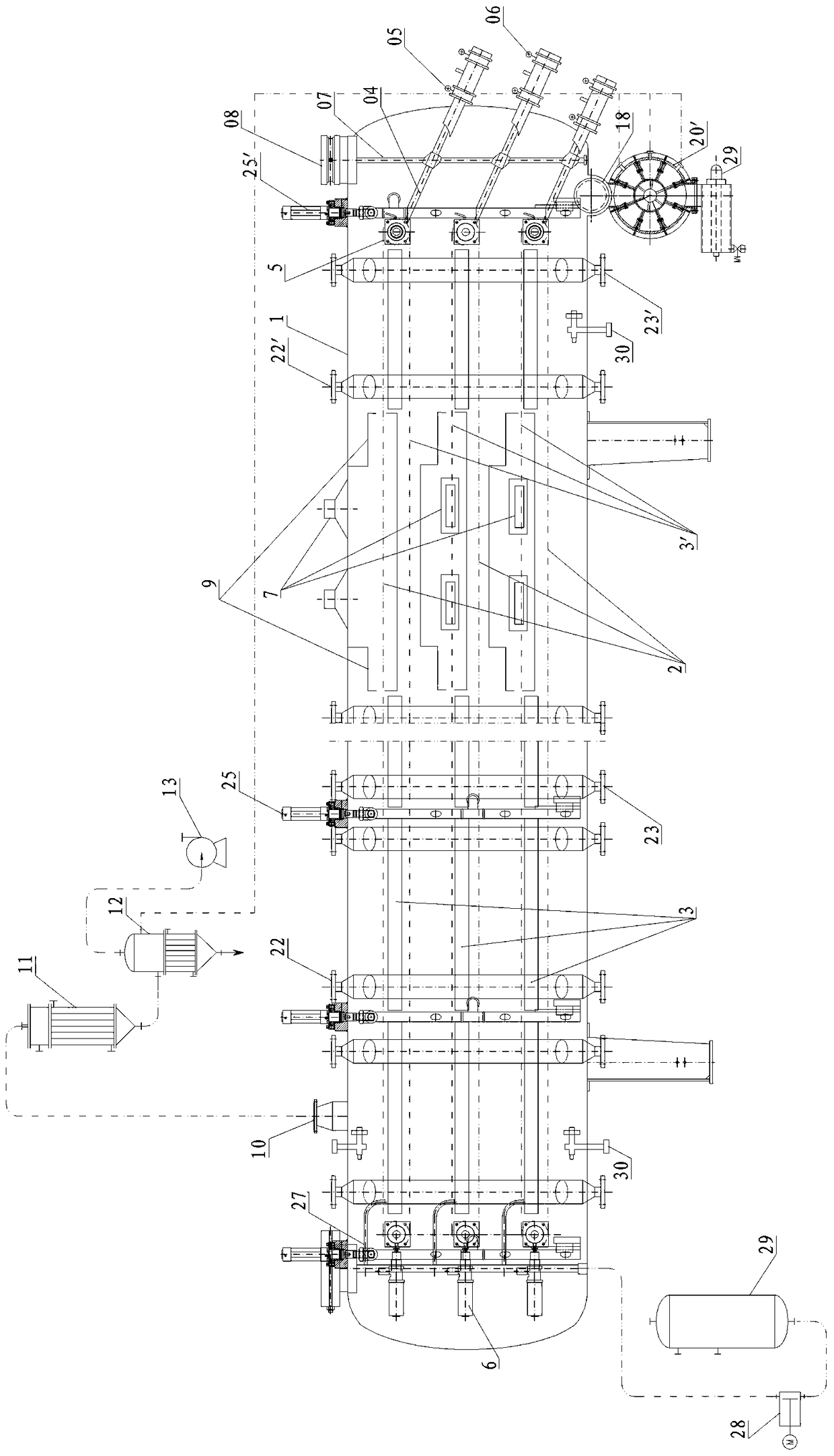

Efficient continuous vacuum microwave drying machine

ActiveCN105258480AFeed amount can be set freelyAdjustable drying temperatureEngine sealsPharmaceutical product form changeProcess engineeringSolid-state

Owner:陈长清

Ultrafine grinder with residue filtering function for building coating production

InactiveCN110801924AScientific and reasonable structureEasy to useDispersed particle filtrationDirt cleaningElectric machineryStructural engineering

The invention discloses an ultrafine grinder with a residue filtering function for building coating production. The ultrafine grinder comprises a grinding box body, wherein a control switch is embedded into one end of the grinding box body; a feeding hopper is connected to the top end of the grinding box body; and a guide plate is connected to the inner wall of the feeding hopper. The ultrafine grinder disclosed by the invention is scientific and reasonable in structure and safe and convenient to use; by arranging a grinding bin, a grinding motor, a grinding rod, a filter screen and an auger delivery pipe, raw materials can be ground, and the overlarge raw materials can be secondarily ground through the auger delivery pipe, so that the overlarge raw materials are prevented from being discharged, the grinding effect is good, and the condition that the subsequent processing is influenced due to the overlarge raw materials is avoided; and by arranging a fixed pressing block, a feeding rotating plate, a fixed groove and a feeding baffle, the position of the feeding baffle can be adjusted, and the fixed pressing block is plugged into the fixed groove to fix the position of the feeding baffle, so that the feeding rate is rapidly adjusted, and meanwhile, the raw material grinding rate can be adjusted.

Owner:湖州互融新材料科技有限公司

Air-blowing drier for production of attapulgite zearalenone adsorbing agent

InactiveCN108955170APull away quicklyEasy to pass throughDrying gas arrangementsDrying machines with non-progressive movementsSorbentSpiral blade

The invention discloses an air-blowing drier for production of an attapulgite zearalenone adsorbing agent. A spiral blade is fixedly connected to the outer side of a rotary roller, a first screen plate is connected with the middle of the spiral blade in a penetrating mode, a stirring plate is fixedly connected with the right side of the first screen plate, an air pump is fixedly connected with themiddle of the right side of a machine body, a first air inlet pipe communicates with the top of the air pump, the upper portion and the lower portion of the face, close to the right side of the machine body, of the first air inlet pipe communicate with second air inlet pipes, the opposite sides of two groove inner cavities are connected with a second screen plate in a penetrating mode, one end ofan air outlet pipe communicates with an exhaust fan, a feeding groove communicates with the left side of the top of the machine body, and a discharge groove is connected with the right side of the bottom of a supporting plate in a penetrating mode. By arranging the air pump, the first air inlet pipe, air inlet holes, the first screen plate, the exhaust fan, the spiral fan, the feeding groove, thedischarge groove, a valve, a bottom plate, a bolt and a gasket, the air-blowing drier for production of the attapulgite zearalenone adsorbing agent is high in practicability.

Owner:江苏伊居科技有限公司

Rapid dirt and rust removing mechanism for outer walls of steel pipes

PendingCN112757131AGood sandingNeutral goodGrinding carriagesGrinding machinesMining engineeringPipe

The invention discloses a rapid dirt and rust removing mechanism for outer walls of steel pipes, and relates to the technical field of steel pipe machining. The problems that an existing dirt and rust removing device for steel pipes only cleans pipelines within a certain diameter range during use, parts with large diameters are prone to falling off during cleaning, meanwhile, the feeding speed adjusting difficulty is large in the pipeline cleaning process, and adjusting operation is inconvenient are solved. The rapid dirt and rust removing mechanism comprises a mounting base. The top of the mounting base is fixedly connected with a set of lifting driving piece. The left side and the right side of the top of a guide wheel bearing piece are each rotationally connected with a set of guide assembly. A rust removing cleaning device is mounted at the front part of a lifting seat. The rapid dirt and rust removing mechanism has good feeding and conveying capacity, meanwhile can be adjusted according to needs and can carry out rust removing on pipelines with different diameters, the situation that steel pipes fall off due to too large diameters of the steel pipes is effectively avoided, meanwhile, the feeding speed can be adjusted so as to guarantee the rust removing effect, cleanliness of the surfaces of the pipelines is guaranteed, and the rapid dirt and rust removing mechanism is simple to use and convenient to operate.

Owner:丁月红

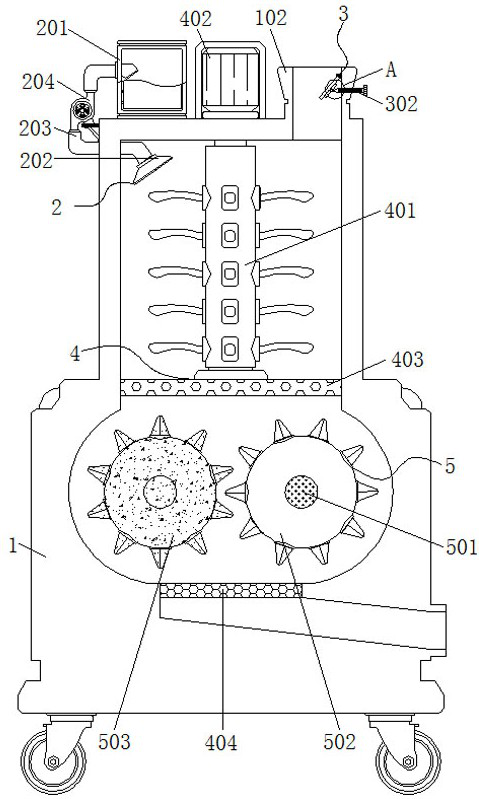

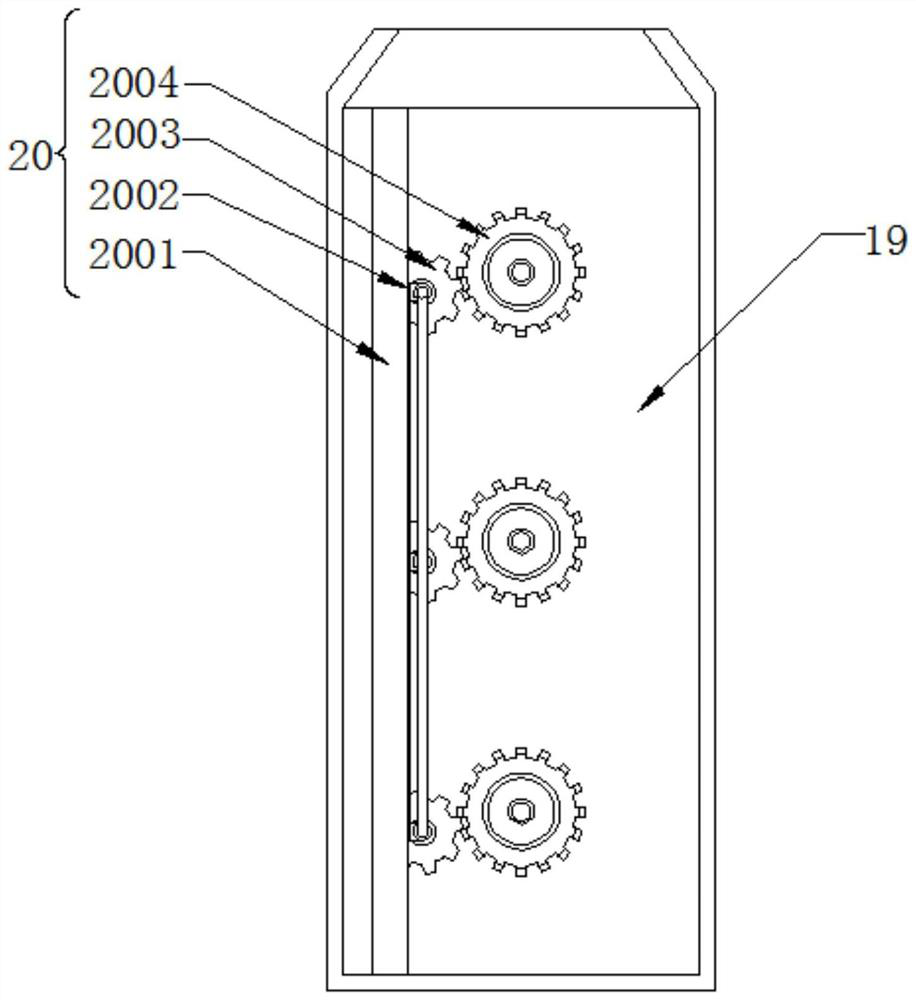

Corn crusher capable of controlling feeding speed

InactiveCN107684966AAdjust feed rateChange feed rateGrain treatmentsAgricultural engineeringPre compression

The invention discloses a corn pulverizer for controlling feeding speed, which comprises a pulverizer body, a support frame is installed at the bottom of the pulverizer body, a rotating rod is connected to the inner bottom of the pulverizer body, and the pulverizer body is connected with the The joint of the rotating rod is provided with a support bearing, and the outer side of the end of the rotating rod away from the supporting bearing is evenly provided with a pulverizing knife, and the side of the pulverizing knife close to the supporting bearing is provided with a screen installed on the pulverizer body, and the screen There are two sets of rolling wheels on one side of the pulverizer body, a feeding port is provided at the end of the pulverizer body close to the rolling wheels, and a feeding regulating device is provided at the feeding port, and the feeding regulating device includes a feeding Frames, adjusting plates, slides, push blocks and threaded rotary rods. The device of the invention is simple in structure and novel in design, can quickly adjust the feeding speed of corn kernels, and can pre-extrude the corn with combined rolling wheels, which can reduce the wear of the crushing knife and has strong practicability.

Owner:弘毅天承知识产权股份有限公司

Synthesis method of N, N-dimethylacetamide

InactiveCN103524369ASame operationLiquid level is stableOrganic compound preparationCarboxylic acid amide separation/purificationAcetic acidPtru catalyst

The invention relates to a synthesis method of N, N-dimethylacetamide. The method adopts a catalytic reaction distillation technology to improve an acetic acid catalyzed condensation method, and includes: adding well metered glacial acetic acid and a catalyst in order into a four-neck flask equipped with a vent pipe, a thermometer, an external cooling bath and a rectification column, then introducing a dimethylamine gas into a reaction bottle through a flowmeter and a buffering bottle to undergo a neutralization reaction, then adding the neutralization solution into the rectification column bottom connected with cooling water, two-stage cooling, the thermometer and the vent pipe to undergo catalytic reaction-rectification, and then employing intermittent method and continuous method to carry out secondary rectification on a DMAC crude product collected from the reaction rectification. The method provided by the invention makes use of reaction heat, and the reaction process has low energy consumption. The reaction and product separation can be accomplished in a tower, the technological process is simplified, the reaction yield and selectivity are improved, and the product purity can reach 99.7%-99.9%. Also, fewer wastes are discharged in the preparation process, and the product entrainment loss is small.

Owner:连云港阳方催化科技有限公司

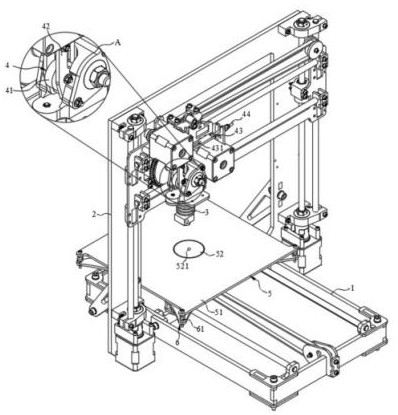

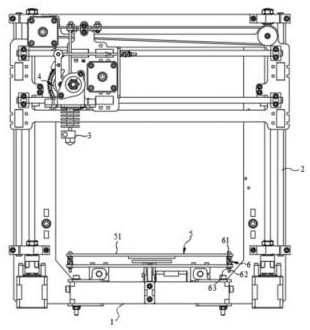

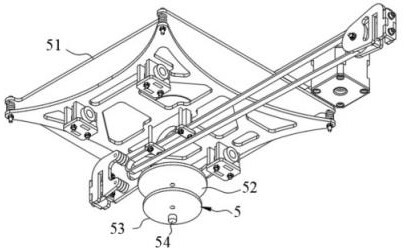

3D printing equipment with precise leveling function

InactiveCN113561475AAdjust feed rateAdjust the fitManufacturing platforms/substrates3D object support structuresIndustrial engineeringSupport plane

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Waste PET material recycling device and waste PET material remanufacturing method

ActiveCN112339162AImprove construction efficiencyQuality improvementPlastic recyclingGear wheelRemanufacturing

The invention relates to a waste PET material recycling device. The waste PET material recycling device comprises a supporting column, a supporting plate is fixedly connected to the top end of the supporting column, a box body is fixedly connected to the top end of the supporting plate, a filter screen is fixedly connected to the upper end of the inner wall of the box body, a crushing mechanism isinstalled at the upper end of the filter screen, a first bearing connected with one side of the box body in an embedded mode is arranged in the crushing mechanism, a first gear is rotatably connectedto the surface of the first bearing, a motor is connected to one side of the inner wall of the box body in an embedded mode, and the surface of the motor is movably connected with a protection box ina sleeved mode. According to the waste PET material recycling device, under the action of a material crushing mechanism, two crushing rollers can be driven by the motor to relatively rotate, recycledPET materials are rapidly extruded to be in a particle shape with the size smaller than 1.5 cm, later dissolving and processing operation is facilitated, the construction efficiency of material recycling and remanufacturing is improved, impurities in a solution can be filtered through a filter, the quality of a reproduced product is improved, and the motor can drive a stirring paddle to rotate atthe same time.

Owner:东莞市鼎杰新材料有限公司

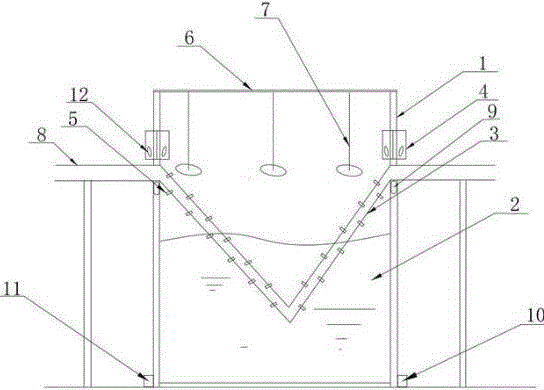

Photographic film cooling device

The invention discloses a photographic film cooling device. The photographic film cooling device comprises a rack and a cooling pond arranged below the rack. The photographic film cooling device is characterized in that the photographic film cooling device further comprises a guide rail and a cooling box; one end of the guide rail is connected with the rack, and the other end of the guide rail is also connected with the rack; the middle portion of the guide rail is arranged in the cooling pond; the middle portion, in the cooling pond, of the guide rail is in the shape of V; besides, the two edges of the guide rail are provided with fixing clamps capable of freely moving; the cooling box is arranged at the position of the joint of the guide rail and the rack; and a beam is arranged on the portion, above the cooling pond, of the rack and provided with a vertically-downward spray head. The photographic film cooling device is basic in structure and easy to operate; by means of the arrangement of the guide rail and the fixing clamps, a photographic film normally enters the cooling pond and is completely immersed in the cooling liquid, regular cooling is achieved, and the cooling efficiency is improved through the cooling box; and a speed controller controls the speed of the guide rail, finally, the feeding speed of a rubber sheet in winding is adjusted, and the winding effect is better.

Owner:SICHUAN YUANXING RUBBER

Compaction device for road repairing

ActiveCN109610284AGuaranteed liquidityPrevent from hardening and solidificationRoads maintainenceEngineeringMechanical engineering

The invention relates to the technical field of municipal engineering road maintenance and particularly discloses a compaction device for road repairing. The compaction device comprises rolling wheels, a discharging table and uprights, wherein a rubble groove and a mixing groove are formed in the discharging table; a mixing barrel is arranged above the discharging table and comprises an inner barrel and an outer barrel; feeding ports are formed in side walls of the inner barrel and the outer barrel; the inner barrel is internally provided with a stirring rod; a rack and elastic pieces are alsoarranged on a table top of the discharging table; the outer barrel is vertically and slidingly connected with the rack; the inner barrel rotates along an inner side wall of the outer barrel; the bottom of the outer barrel is connected with the elastic pieces; discharge ports are formed in the ends, slidingly connected with the rack, of the outer barrel and the inner barrel; a through port is formed in a side wall of the rack; limiting plates are arranged below the through ports; when the outer barrel slides to the limiting plates, the discharge port of the outer barrel is communicated with the through port; a feeding mechanism is arranged above the outer barrel and communicated with the feeding port of the outer barrel; and compaction wheels are mounted on the uprights. The compaction device is used for road repairing, improves stirring uniformity of raw materials, and avoids solidification and agglomeration of the raw materials.

Owner:ZUNYI NORMAL COLLEGE

A method and equipment for treating organic silicon slag by chlorination

ActiveCN108529683BWide variety of sourcesLow priceIron oxides/hydroxidesFluidised-bed furnacesFerric hydroxideIron powder

The invention discloses a method for treating organic silicon slag by the aid of chlorination processes. The method includes steps of 1, adding reducing agents into the organic silicon slag to obtainmixtures after aging treatment is carried out on the organic silicon slag, continuously adding the mixtures into a boiling chlorination furnace, carrying out chlorination roasting and selectively chlorinating copper and iron in the organic silicon slag; 2, adding slag chlorinated at the step 1 into water, and washing and dissolving copper chloride and iron chloride in the slag to obtain chloride mixed solution; 3, adding iron powder into the chloride mixed solution, replacing copper in the chloride mixed solution and carrying out filtering to obtain copper powder and iron-containing solution;4, adding quicklime into the iron-containing solution, regulating the pH (potential of hydrogen) value of solution, filling the solution with air, oxidizing the solution, and carrying out filter separation to obtain iron hydroxide precipitates and iron-precipitated solution; 5, drying the iron hydroxide precipitates to obtain finished products. The method has the advantages that environmental protection problems due to waste organic silicon slag can be solved by the aid of the method, valuable metal copper, iron, silicon and the like in the organic silicon slag can be recycled by the aid of the method, and accordingly the method is economical and environmentally friendly.

Owner:CHENGDU SILICON TECH CO LTD

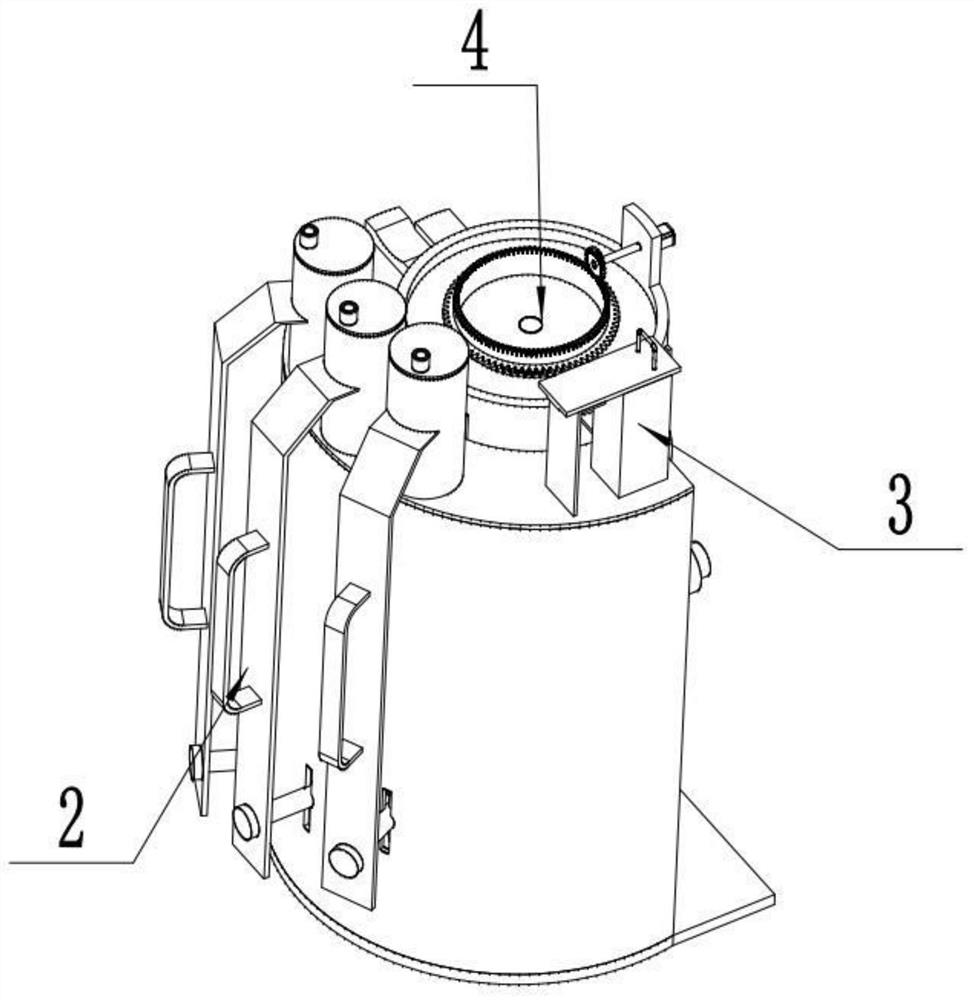

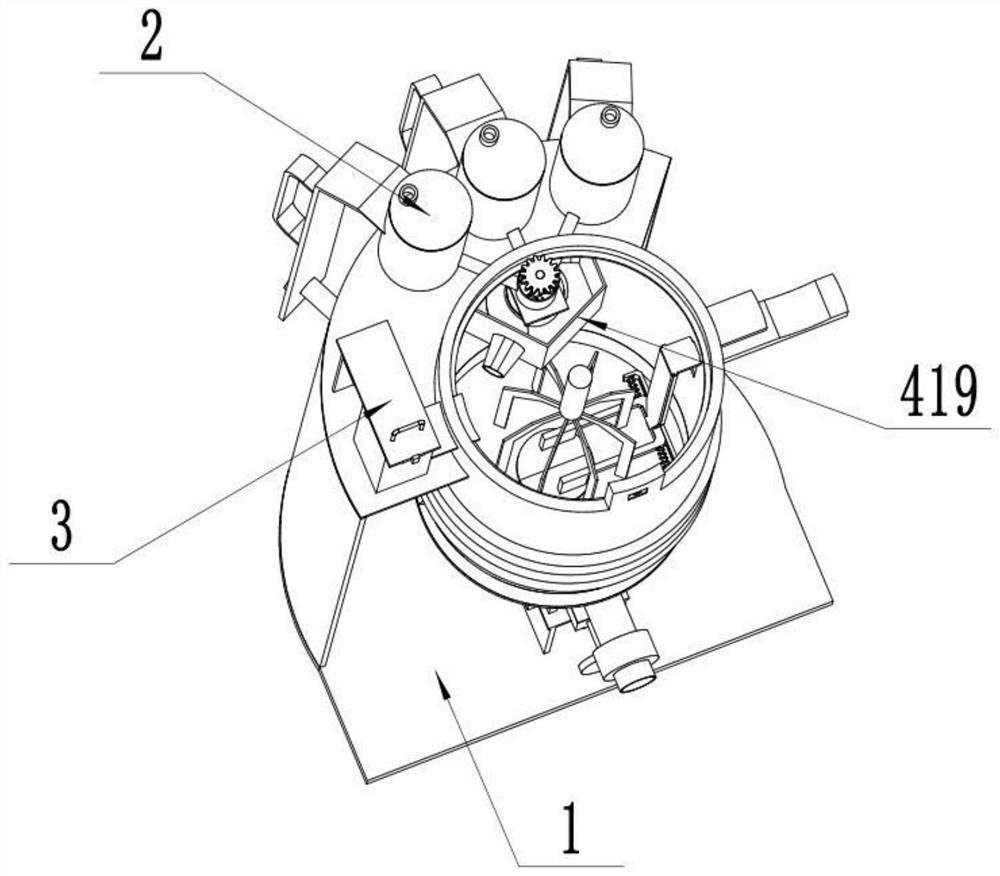

Mixing and compounding kettle for antistatic agent production

ActiveCN113750945AEnergy savingStir wellResistance/reactance/impedenceChemical/physical/physico-chemical stationary reactorsElectric machineryChemistry

The invention discloses a mixing and compounding kettle for antistatic agent production, and relates to the technical field of antistatic agent production reaction kettles.The mixing and compounding kettle comprises a base, a first feeding assembly used for adding raw materials and a detection assembly used for detecting the resistance value of an antistatic agent are arranged on the base, and a reaction assembly used for generating the antistatic agent is arranged on the first feeding assembly; and the detection assembly is arranged below reaction assembly, and one side of the reaction assembly is provided with a second feeding assembly for adding an initiator; according to the reaction assembly, mixing, compounding and stirring of various raw materials and the initiator are driven by one motor, energy is saved, stirring is more sufficient, the reaction rate is increased, meanwhile, during reaction, the temperature of a reaction cylinder is automatically controlled, so that the reaction is more stable, the detection assembly can timely extract a sample for inspection after the antistatic agent is generated, and the inspection efficiency is improved.

Owner:杭州永盛塑料抗静电材料厂

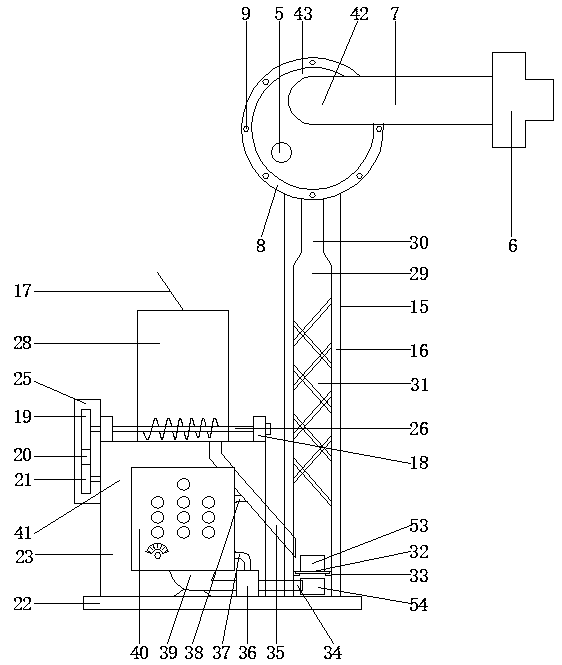

Processing method of bean product

InactiveCN111670958AAdjust feed rateImprove stabilityCheese manufactureAgricultural engineeringWrench

The invention relates to the field of bean product processing, in particular to a processing method of a bean product. A feeding hopper, a connecting disc, a round rod, a movable cavity, a residue outlet, a pulp outlet, a pulping equipment body, supporting columns, rollers, a connecting column, a threaded groove, a threaded column, a hexagonal groove, a suction cup, a baffle, a first rotating shaft, a second rotating shaft, bearings, a first connecting plate, a limiting hole, a second connecting plate, a limiting column, a reset spring, a connector, a first through hole and a second through hole are included. The first connecting plate and the second connecting plate can be separated by pulling the round rod, at the moment, the reset spring can be in a compressed state, and meanwhile, theround rod is rotated to enable the baffle in the connecting disc to rotate so as to adjust the position of the baffle, and under the action of the reset spring, the limiting column can be clamped in the limiting hole again to fix the baffle; and the hexagonal groove is clamped through a monkey wrench, the threaded column and the connecting column can rotate relatively while the monkey wrench is rotated, and therefore the suction cup and a containing table are attracted.

Owner:安徽派农生态农业有限公司

Gravel screening machine with adjustable feeding speed

InactiveCN107952668AIncrease the number ofTo achieve the purpose of multi-stage screeningSievingScreeningAgricultural engineeringSieve

A sand and gravel screening machine with adjustable feeding speed, which relates to the field of sand and gravel processing, includes a screening cylinder placed laterally inclined, a fixing mechanism for fixing the screen, and the screening cylinder includes a The feeding mechanism, the screening net inside the cylinder and a plurality of material outlets, the screening net includes a first screening net and a second screening net, and the first screening net and the second screening net will screen the cylinder The interior is divided into three independent cavities, and each cavity is connected to a material outlet. The pores of the first sieve are larger than the pores of the second sieve; the first sieve and the second sieve The dredging device is respectively provided under the bottom of the casing; the feeding mechanism includes a casing, and a rotating shaft passing through the casing is arranged under the inside of the casing, and symmetrically arranged baffles are connected to the rotating shaft. The invention solves the problems of low efficiency of the existing screening machine, easy blockage of the screening net and inability to adjust the feeding speed of the feed port.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Waste treatment device for civil engineering construction

ActiveCN113368951AReduce labor intensityImprove practicalityGrain treatmentsConstruction engineeringWaste treatment

The invention discloses a waste treatment device for civil engineering construction. The waste treatment device comprises a containing device, and a feeding device is arranged at the top of the containing device. Through cooperation of a crushing device, a driving device and a retracting device, the distance between a right crushing roller and a left crushing roller can be automatically increased when the waste treatment device for civil engineering construction encounters objects which cannot be crushed, so that the objects which cannot be crushed leak out, time delay caused by the fact that the waste treatment device for civil engineering construction is jammed by the objects which cannot be crushed is avoided, further improvement of treatment efficiency is facilitated, meanwhile, crushing teeth on the right crushing roller and the left crushing roller are prevented from being damaged, and the service life of the right crushing roller and the left crushing roller is prolonged; through cooperation of the containing device and the crushing device, raised dust generated in the crushing process is isolated, the raised dust is prevented from polluting the environment, and the practicability of the waste treatment device for civil engineering construction is improved.

Owner:岳远刚

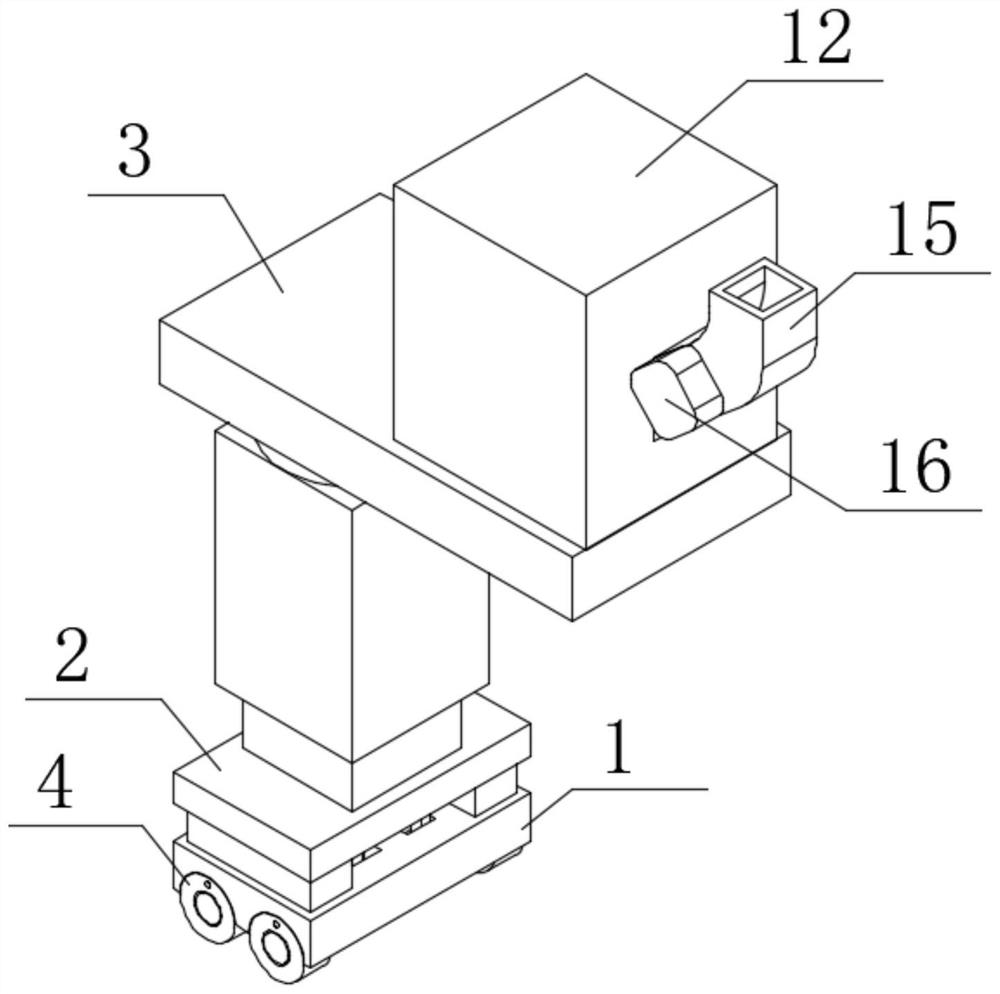

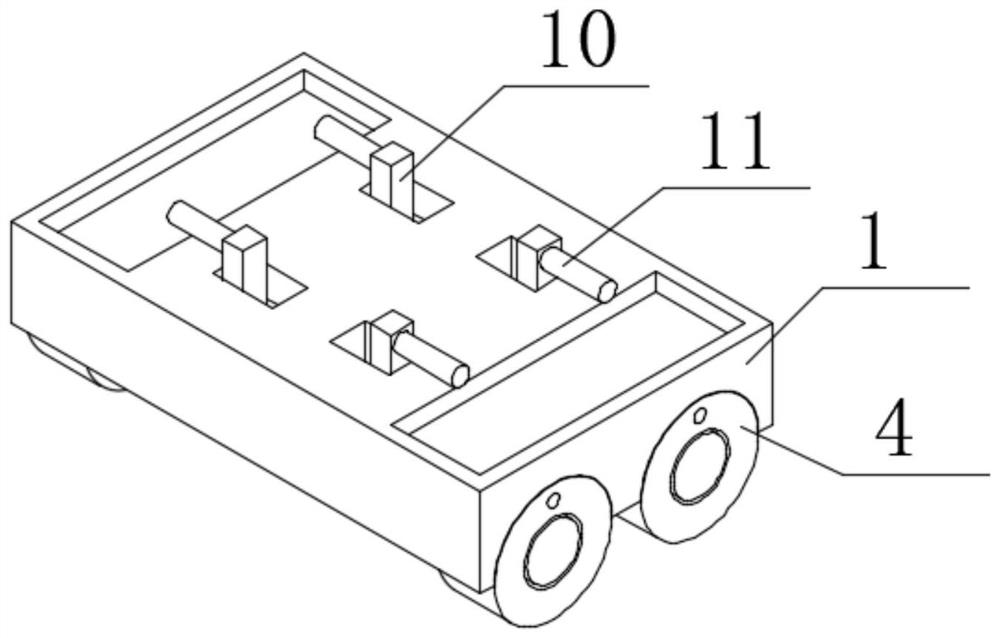

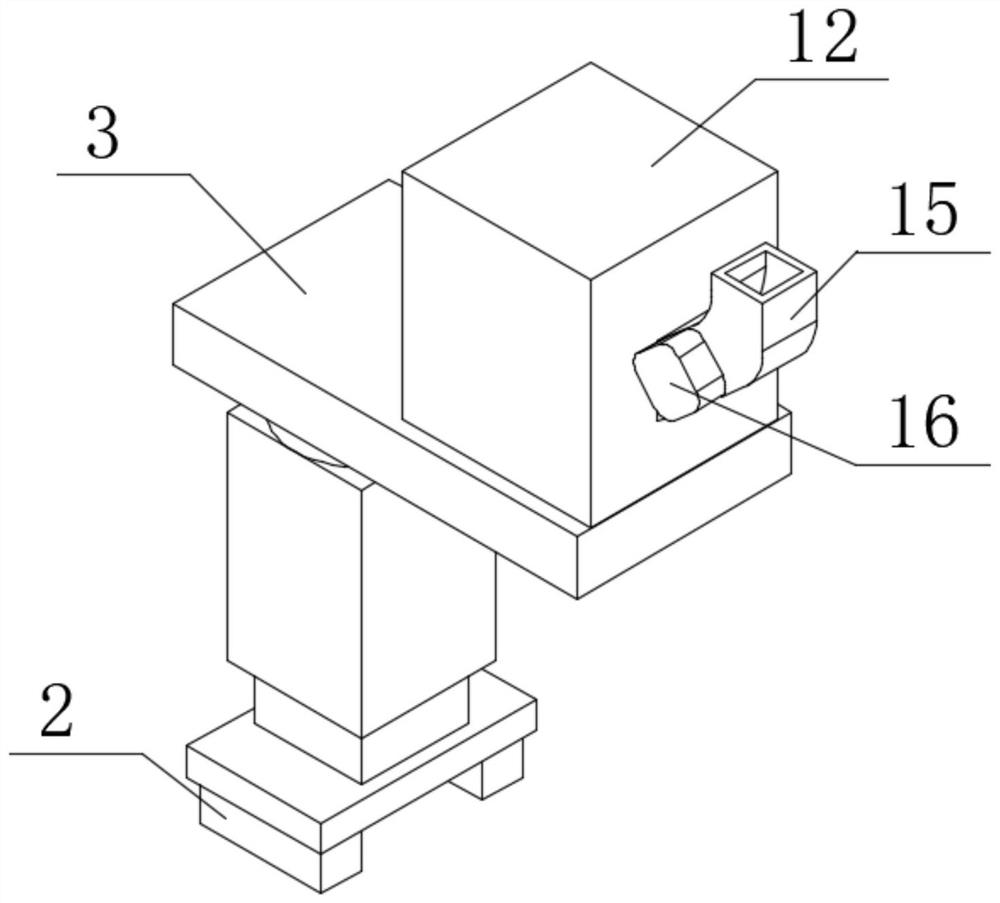

Self-sealing type hydraulic feeding machine

InactiveCN111891778AImprove convenienceFlexible moving processLoading/unloadingLap jointMachine design

The invention discloses a self-sealing type hydraulic feeding machine, and belongs to the technical field of feeding machine design. The self-sealing type hydraulic feeding machine comprises a supporting base; advancing wheels are rotatably connected with four corners of the supporting base; limiting springs are fixedly connected with the inside of the supporting base; limiting discs are connectedwith one sides of the limiting springs in a lap joint mode; limiting rods are connected with one ends of the limiting discs in a threaded mode; fixed rods are fixedly connected with the other ends ofthe limiting discs; the limiting springs are connected with the surfaces of the fixed rods in a sleeving mode; and push blocks are connected with one ends of the fixed rods in a threaded mode. According to the self-sealing type hydraulic feeding machine, electric extensible rods are controlled to retract, the limiting rods are inserted into limiting holes in the advancing wheels to lock the advancing wheels, so the advancing wheels cannot rotate and the feeding machine cannot roll; and the feeding machine can be effectively fixed, the moving mode of the feeding machine can be flexibly switched, the conflict between moving and fixing of the feeding machine is avoided, and the use convenience of the feeding machine is improved.

Owner:佛山市晨耀机械科技有限公司

Biomass particle temperature-increasing and freeze-proofing system for heliogreenhouse

PendingCN108684396ARealize the collectionDiffuse fullyClimate change adaptationSolid fuel combustionGreenhouseProcess engineering

The invention discloses a biomass particle temperature-increasing and freeze-proofing system for a heliogreenhouse. The system comprises a fuel feeding machine, a combustion machine and a heat exchange device, and the fuel feeding machine, the combustion machine and the heat exchange device are integrally formed. According to the system, feeding, air blowing and air inducing equipment can be adjusted, and heat can be sufficiently collected and diffused under the condition of low energy consumption; hot air collection and circulation with small-load combustion, large-area heat exchange, multi-point-location collection and full-coverage circulation is achieved so that heat dissipated by combustion, exchange and circulation devices can all be collected into a circulating system and quickly diffused to all directions of the heliogreenhouse; the utilization rate of the heat is effectively increased, the loss amount of the heat is reduced, a new way for standardized and routinized application of biomass particle fuel in temperature-increasing and freeze-proofing procedures of the heliogreenhouse is put forward, organic combination of ecology, environmental protection and circulation of modern facility agriculture is achieved, and the advancement level takes the lead in China.

Owner:酒泉中天新能源科技有限公司

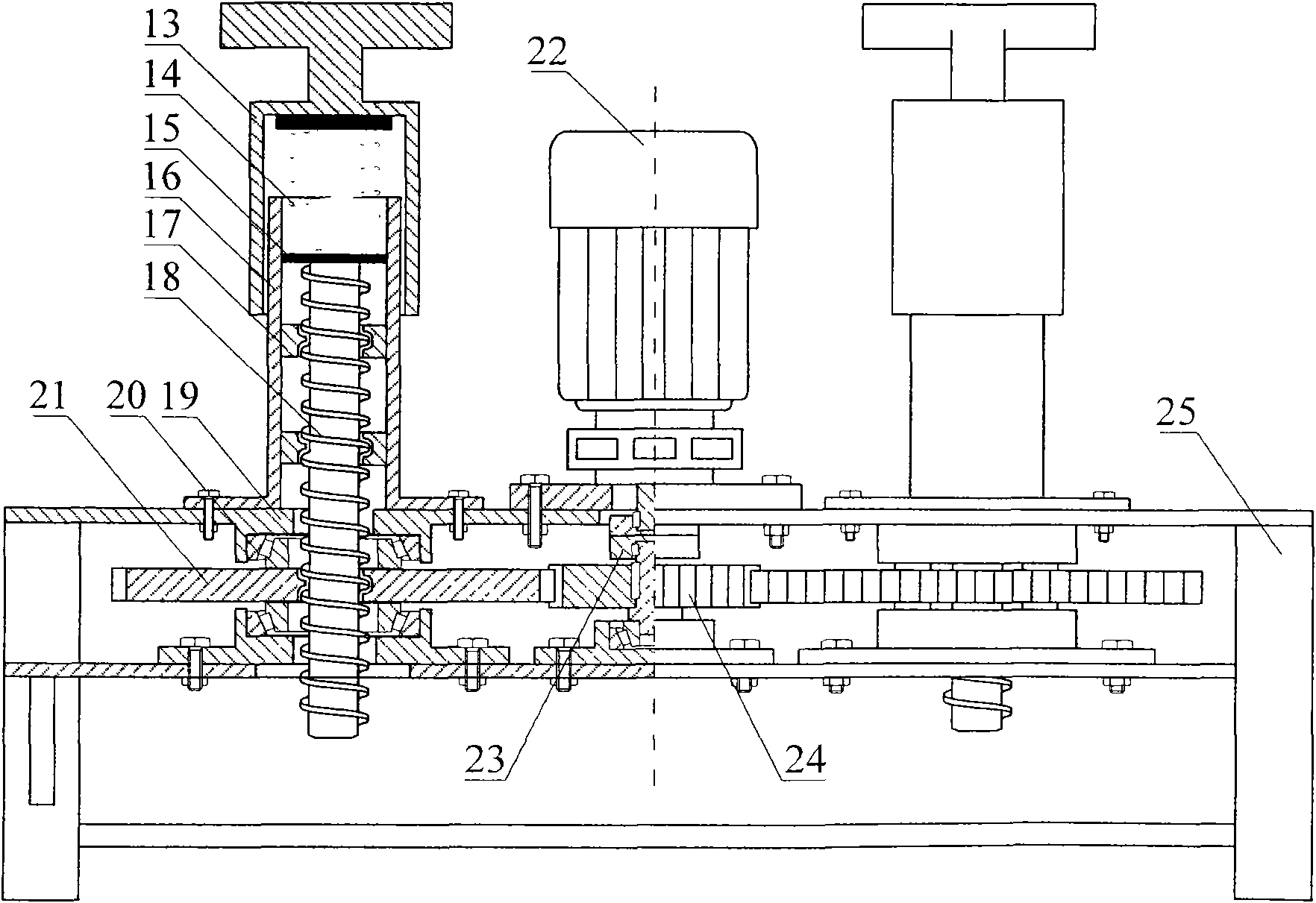

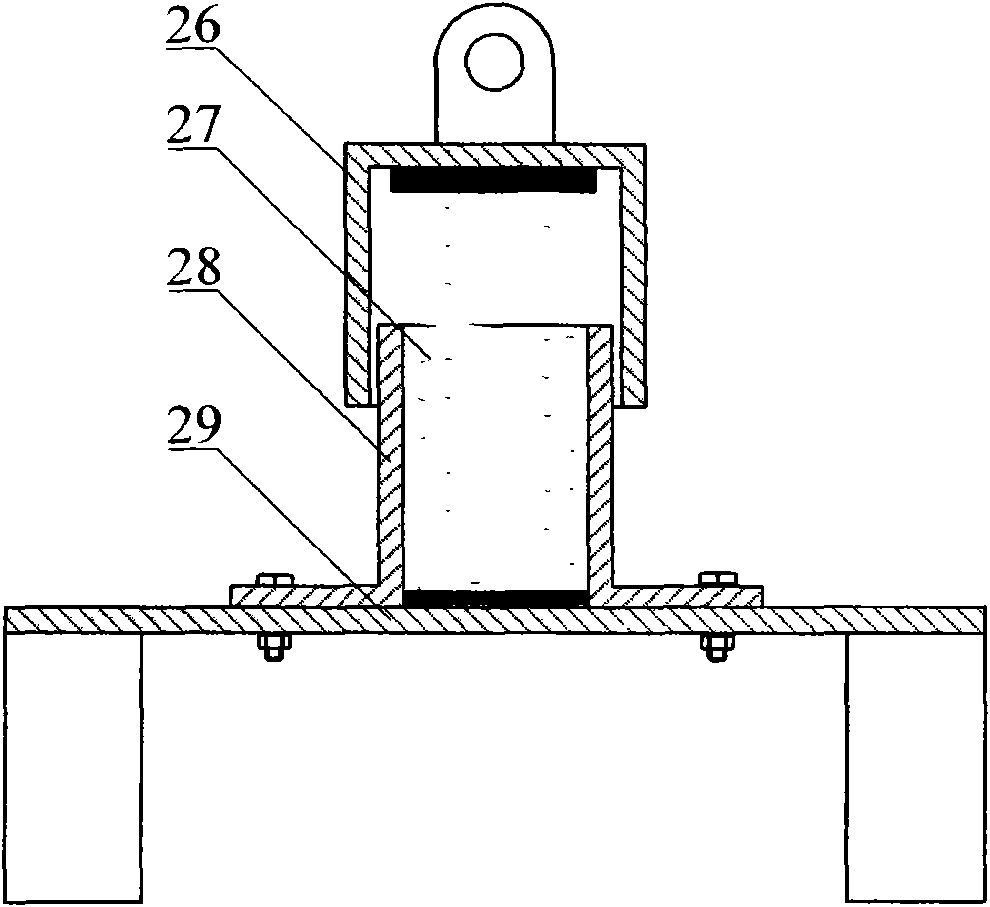

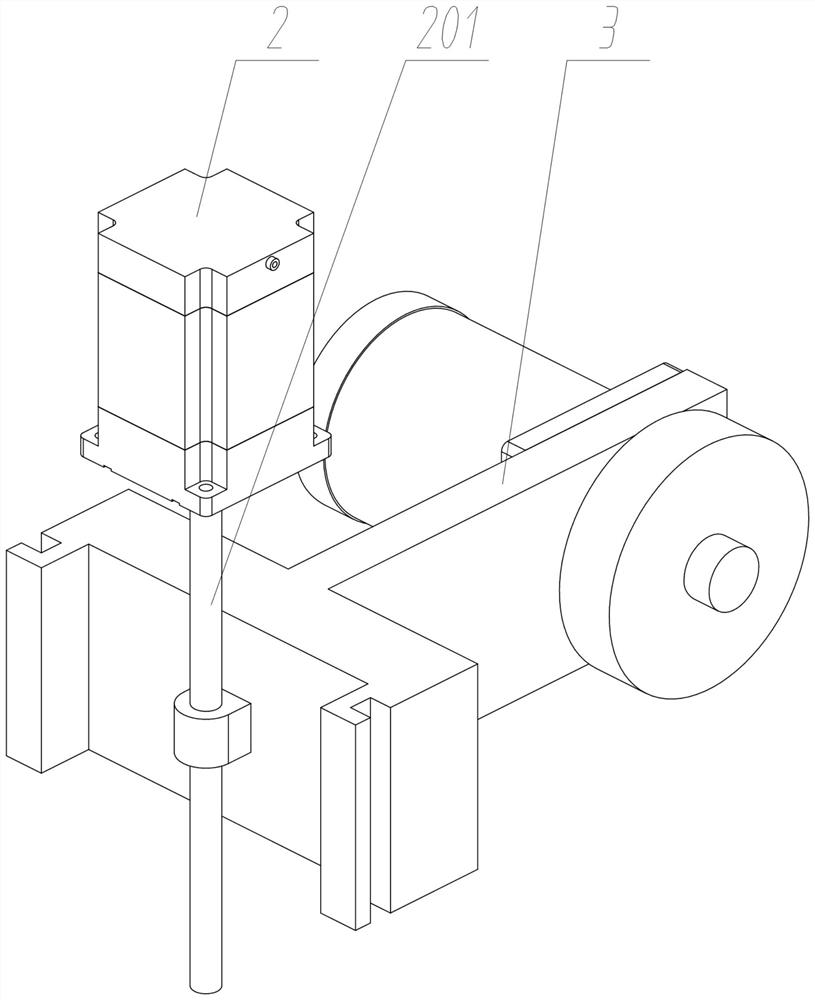

Casting powder adding device

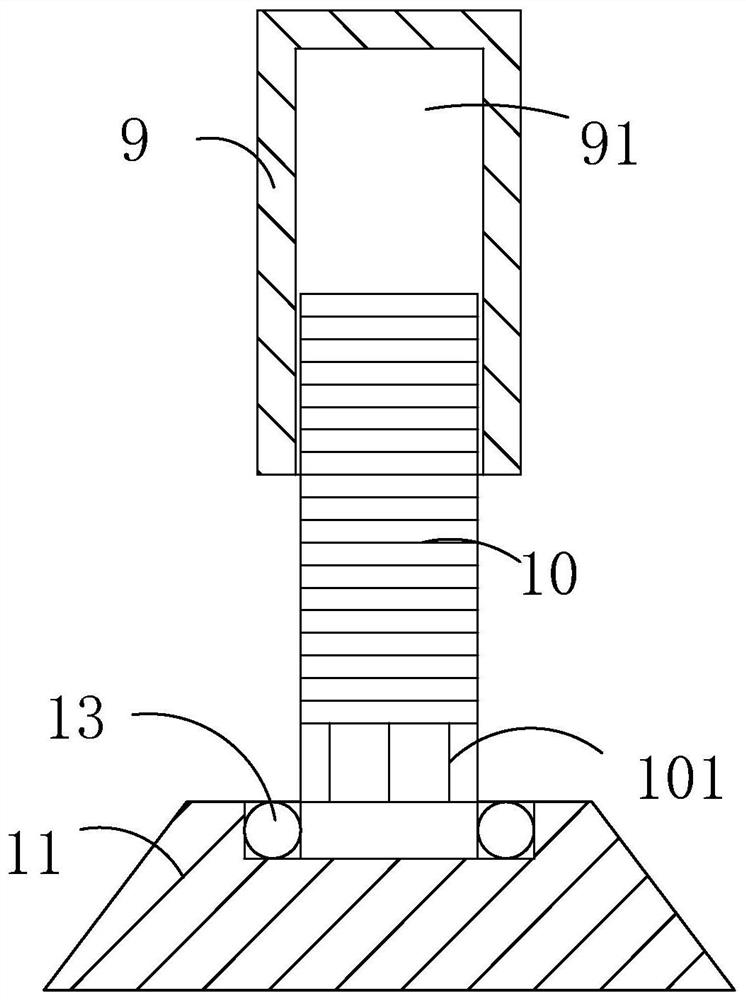

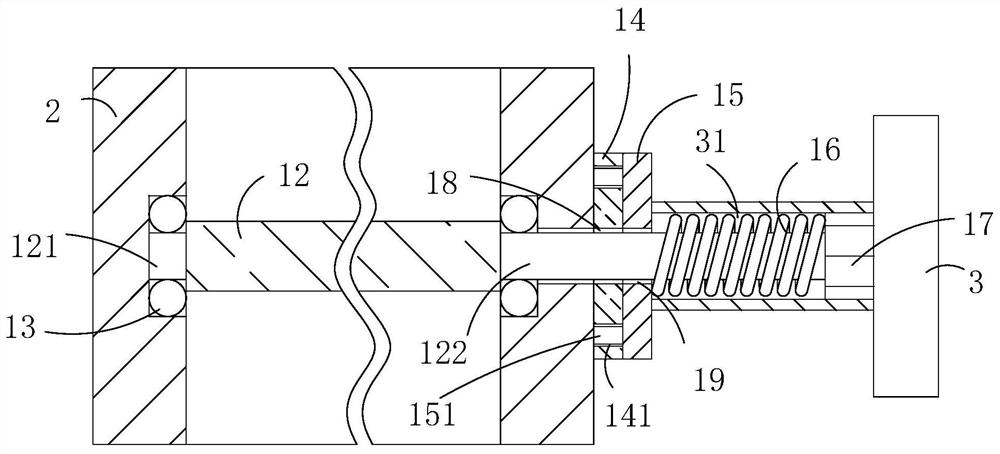

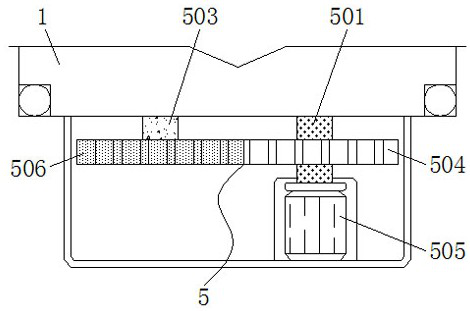

ActiveCN110153385AAdjust feed rateAdjust the height of the first nut and the second nut to adjust the feeding rateMaterials scienceCrystallization

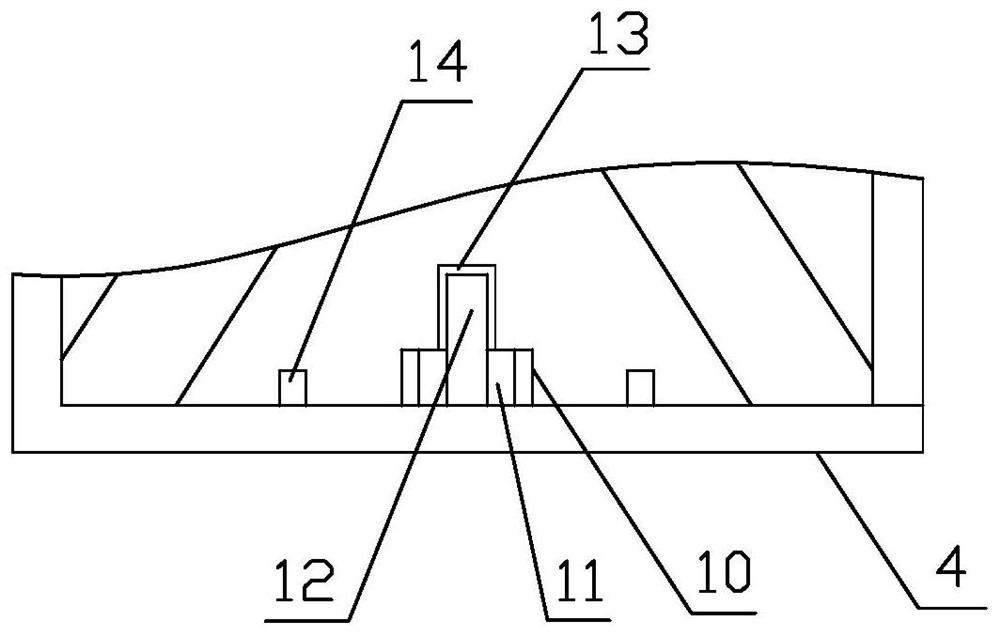

The invention relates to the technical field of iron and steel smelting and discloses a casting powder adding device. The device comprises a storage tank, a bearing cart and a conveying bin, wherein the output of the storage tank is arranged over the head end of the conveying bin, a filtering net is arranged in the middle of the storage tank, casting powder falls onto the conveying bin through theoutput of the storage tank, the head end of the conveying bin is rotationally connected with the bearing cart through a rotary screw, the tail end of the conveying bin is inclined downwards relativeto the head end of the conveying bin, the inclination degree can be adjusted, and a vibrating crystalization platform drives the tail end of the conveying bin to swing up and down so that the castingpowder can uniformly fall into a crystallizer in the center of the vibrating crystalization platform. According to the casting powder adding device, the inclination degree and the vibration amplitudeof the conveying bin can be adjusted by adjusting the height of a nut instead of by using extra media or consuming other energy, thus, the casting powder adding rate can be adjusted, requirements of different steel grades at different pulling rates can be met, and the device is simple in structure, convenient to operate and wide in application range and occupies little space.

Owner:湖南华菱涟钢特种新材料有限公司 +2

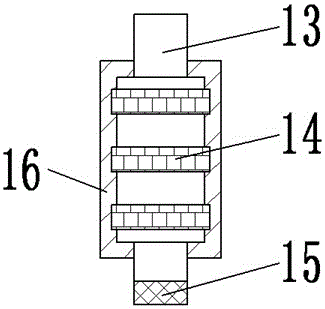

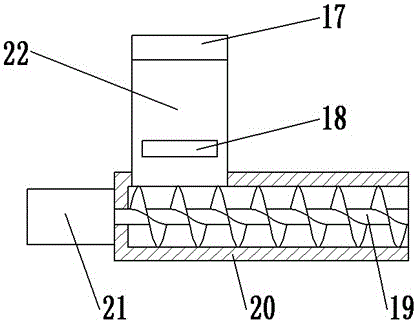

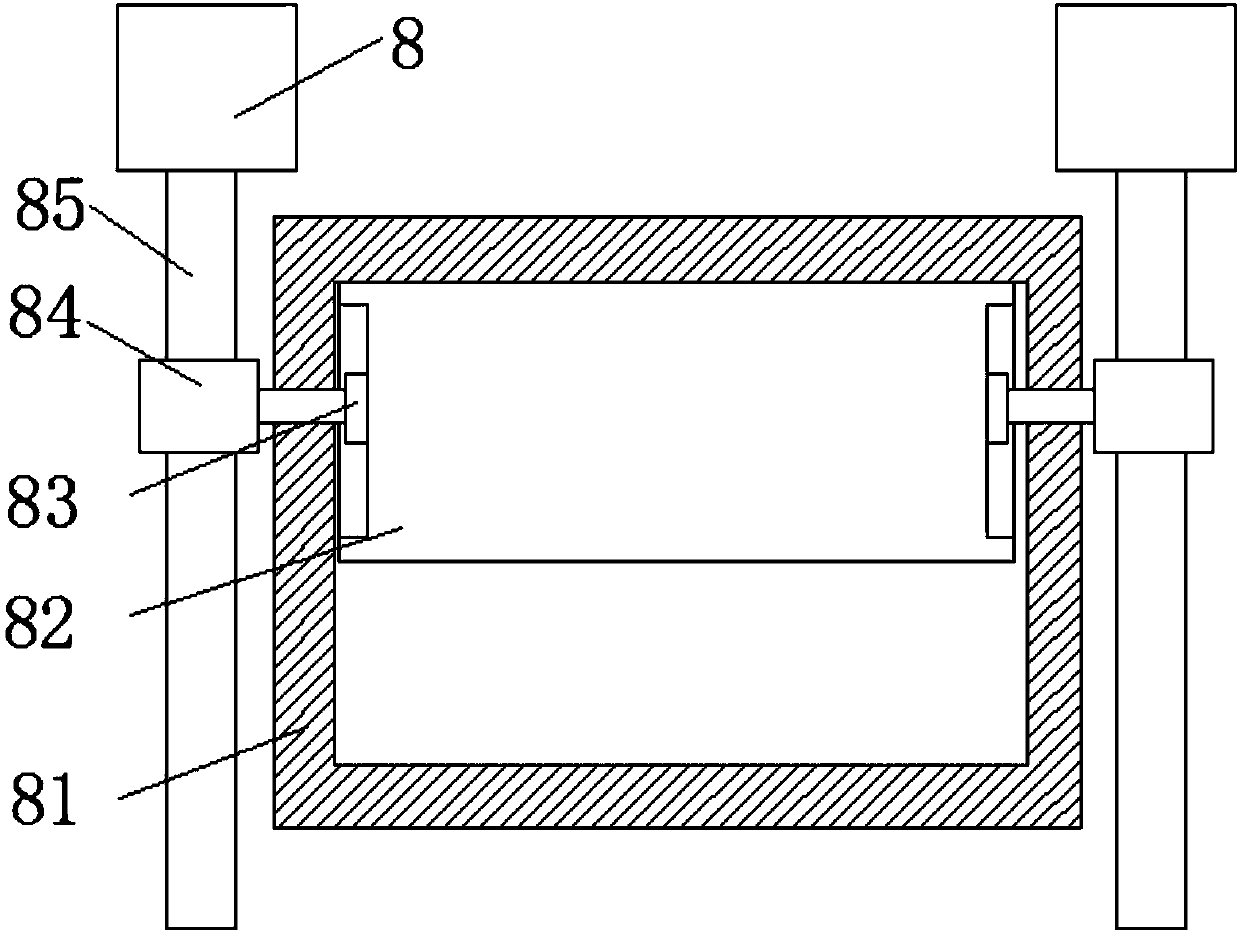

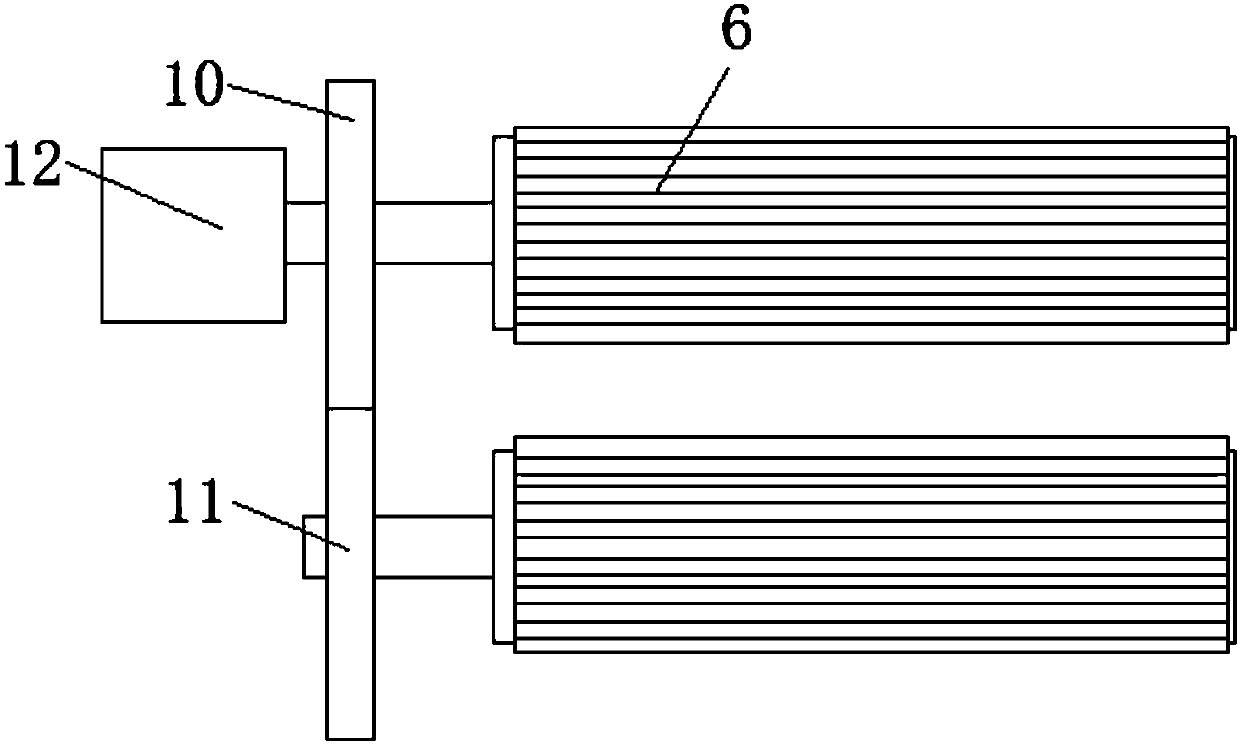

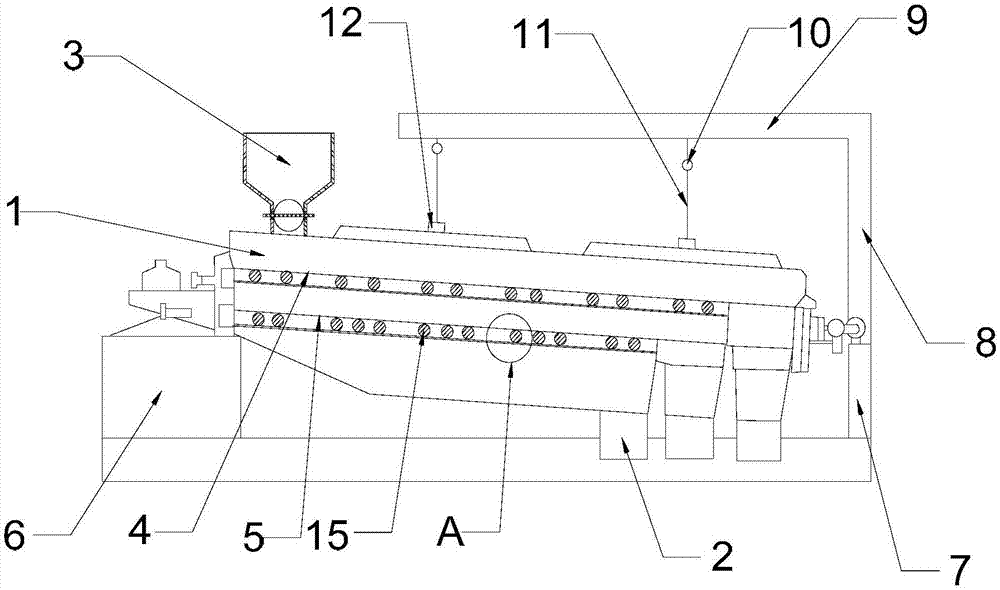

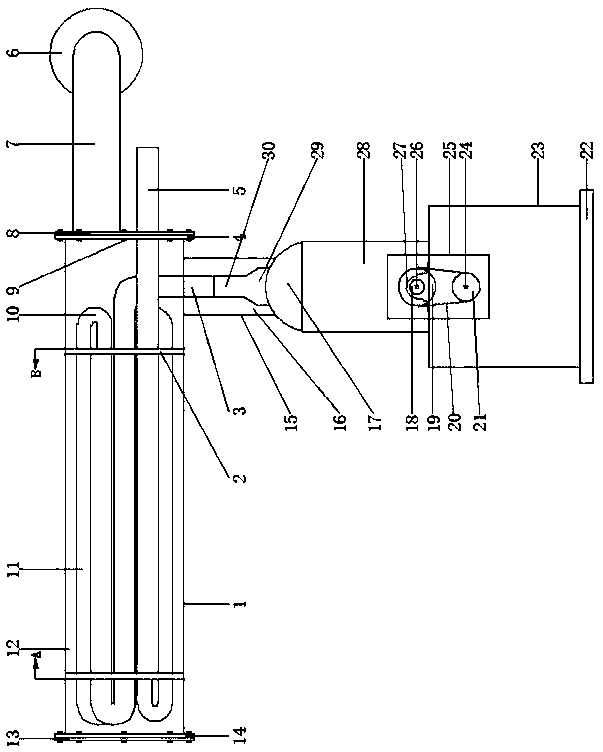

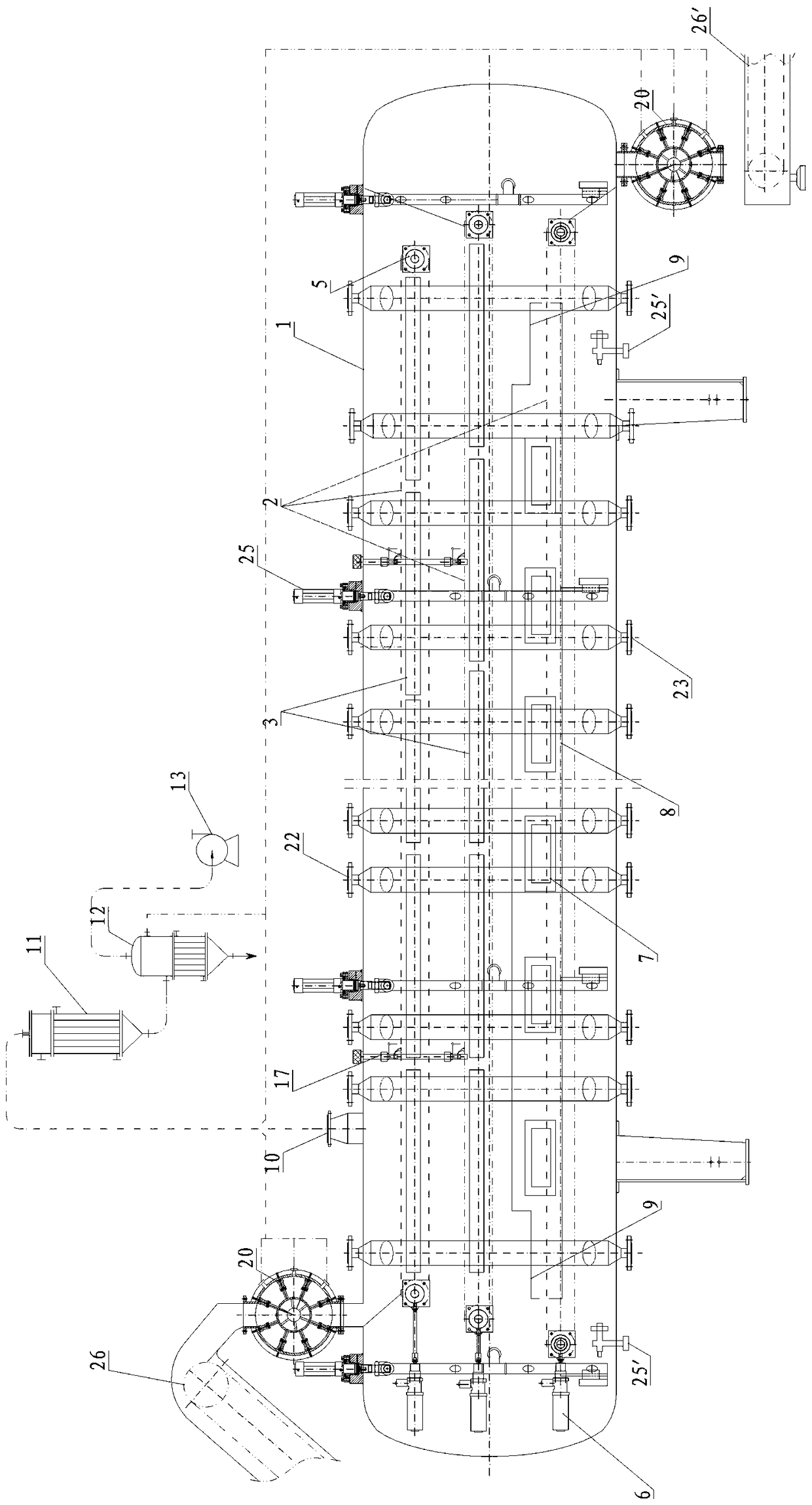

A High Efficiency Continuous Vacuum Microwave Dryer

ActiveCN105258480BAdjustable drying temperatureSmooth runningEngine sealsPharmaceutical product form changeMicrowaveLiquid state

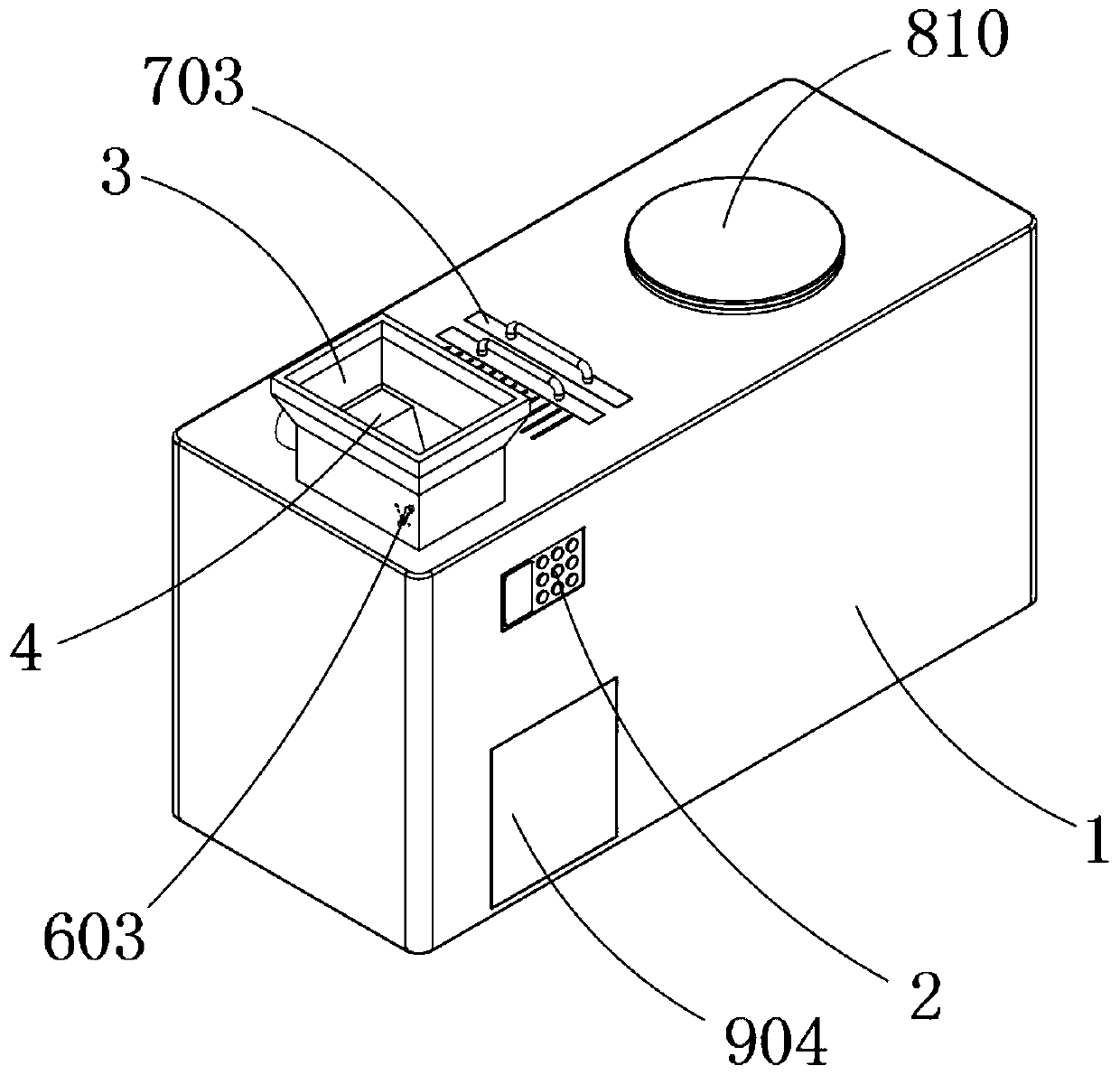

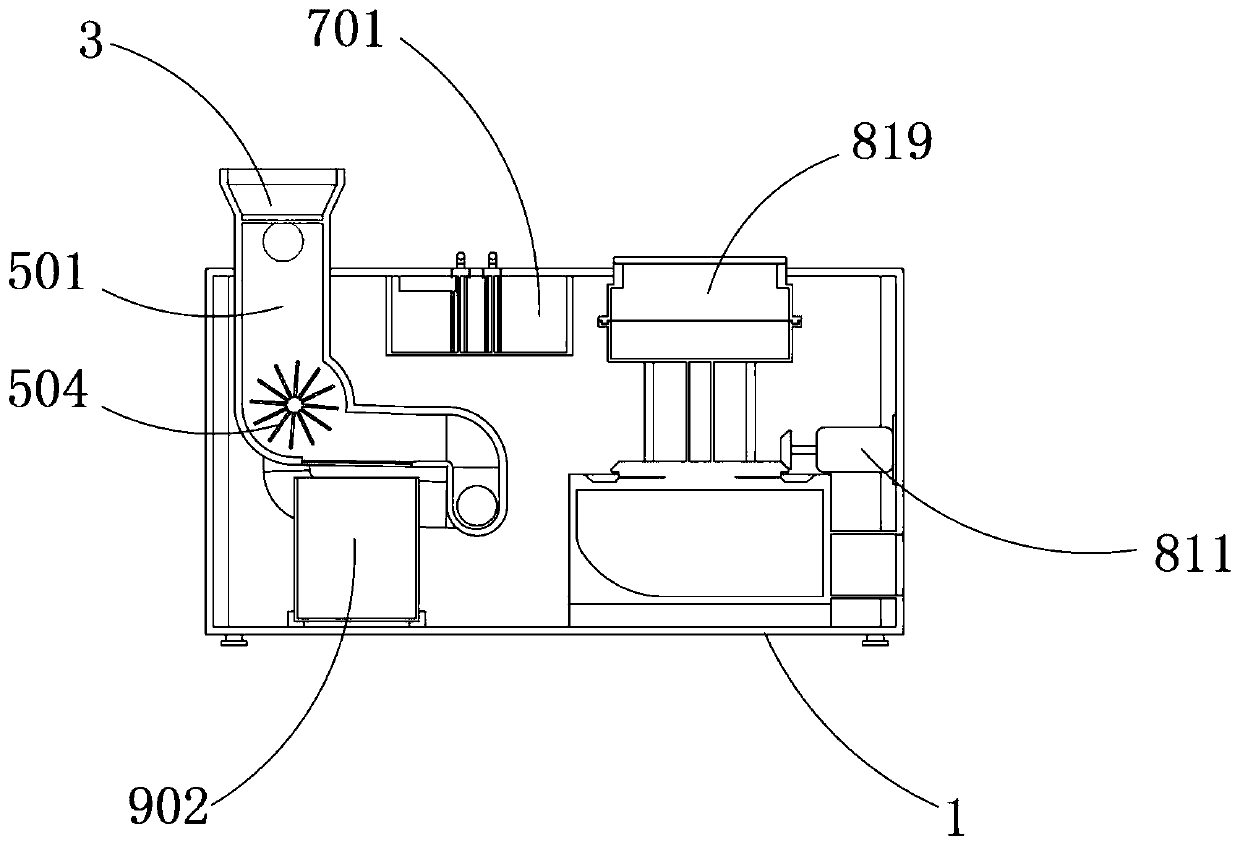

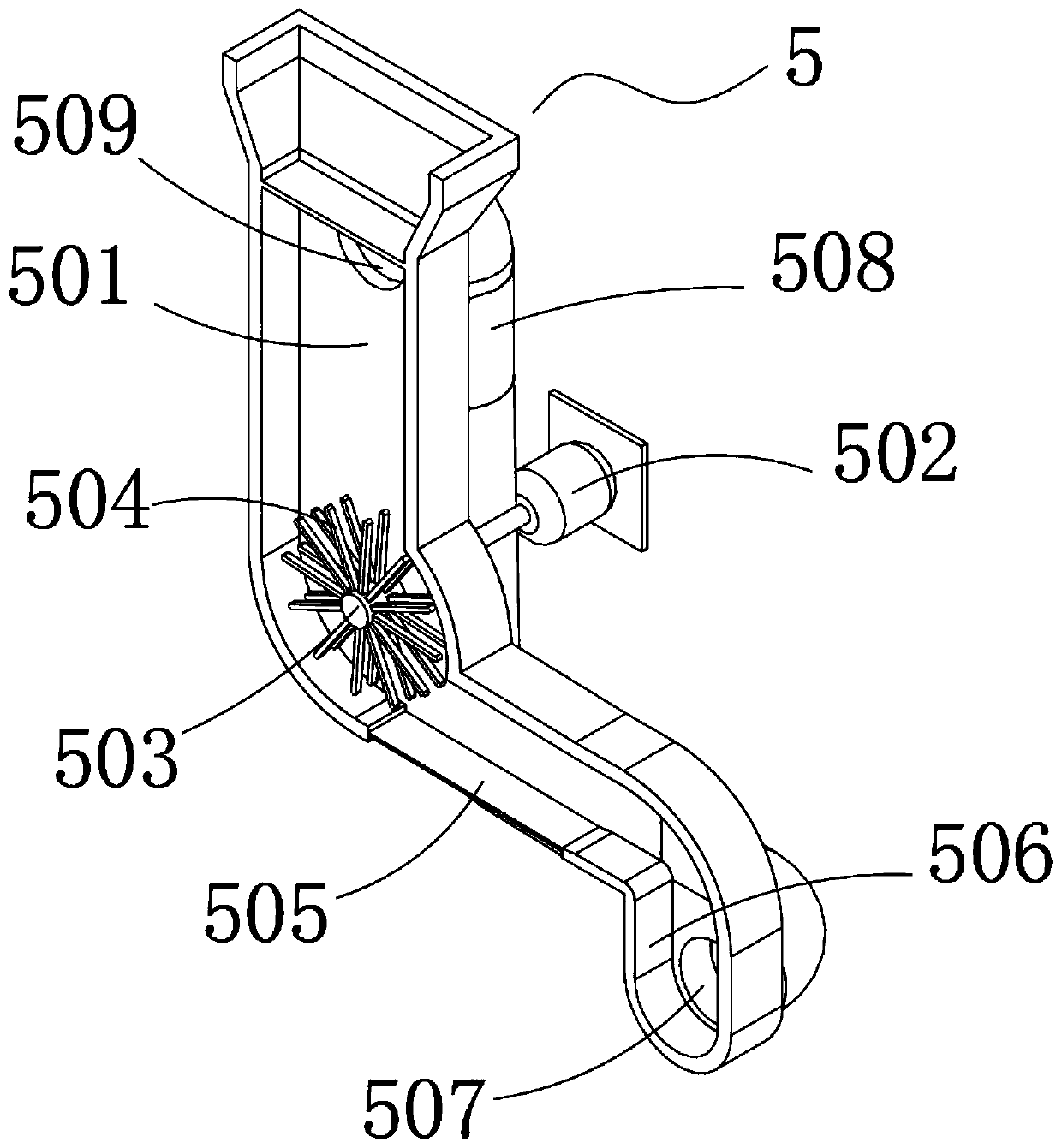

The invention discloses an efficient continuous vacuum microwave drying machine and belongs to the field of drying processing machines which can keep the vacuum degree under the condition of continuous feeding and discharging of materials in a solid state or a semi-liquid state or other states of food products, Chinese herbal machine products, chemical products and agricultural and sideline products. The efficient continuous vacuum microwave drying machine is mainly provided with a feeding conveying belt, a rotary drum type feeding / discharging sealing device, a vacuum chamber, a heating device, a microwave magnetic-control device, a material conveying belt, a material turning device, a vacuum recovering system and a cleaning device. According to the drying machine, by the adoption of a steam and microwave combined heating drying way, energy and time can be saved by over 20%-30% compared with a single microwave heating drying way or a single steam heating drying way; the material turning device and the cleaning device for processing solid materials and semi-liquid materials are arranged, a condensation recovering device is added into the vacuum system, in this way, fragrant gas can be collected and converted into liquid, beneficial gas, poisonous and harmful gas, inert gas, gas prone to oxidation, combustible and explosive gas and the like can be recycled, high quality and high benefits of processed products can be achieved, environment protection is facilitated, and social comprehensive benefits are also facilitated.

Owner:陈长清

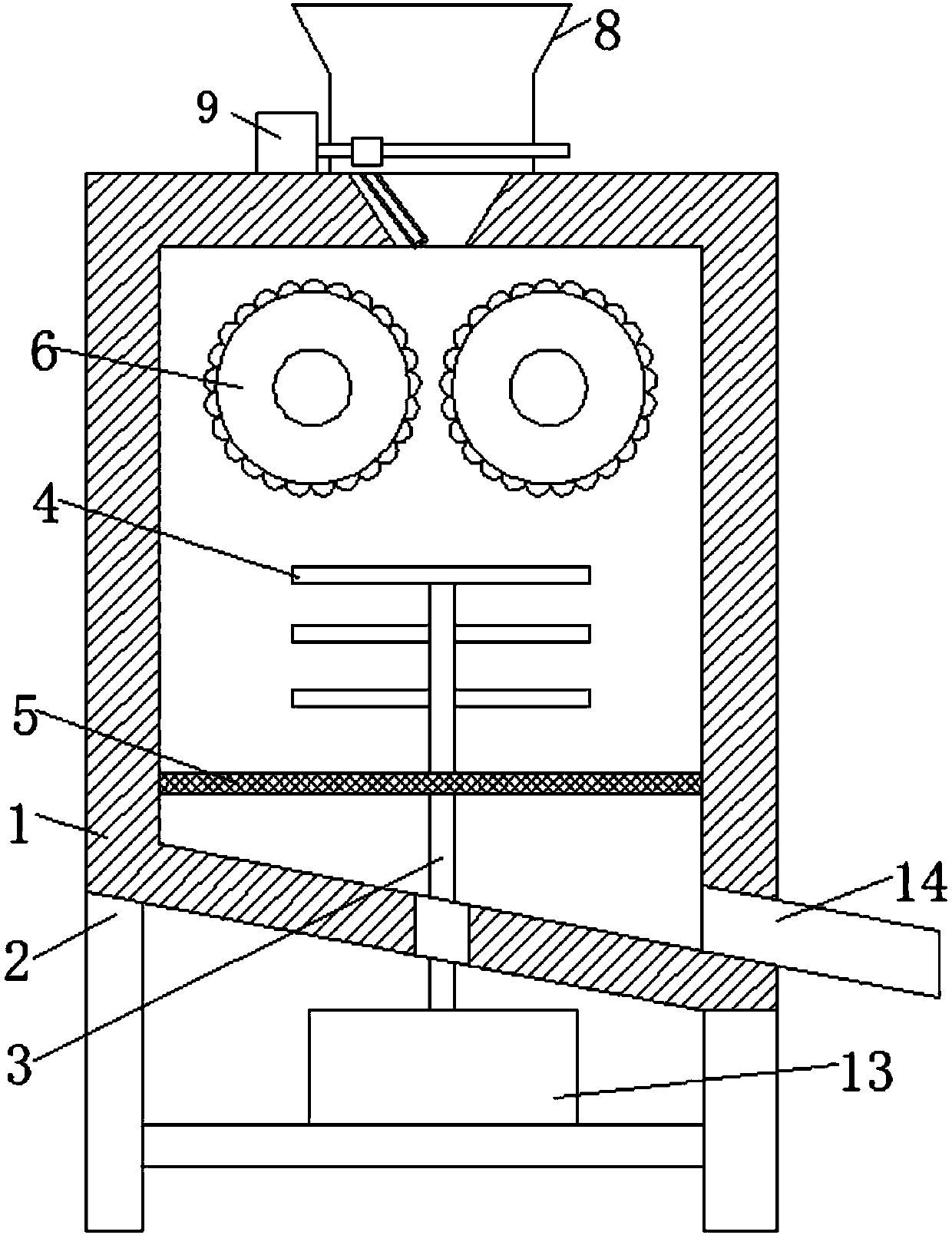

Raw material crushing equipment for microbial feed processing

PendingCN114570509AAvoid accumulationImprove crushing effectFood processingDirt cleaningEngineeringFodder

The invention relates to the technical field of microbial feed, in particular to raw material crushing equipment for microbial feed processing, which comprises a crushing box, a control row key is fixed on the surface of the crushing box, a feeding cylinder is fixed on one side of the top of the crushing box, and an adjusting mechanism is arranged in the feeding cylinder. A primary crushing mechanism is arranged on the surface of the crushing box on one side of the feeding cylinder, a secondary crushing mechanism is arranged on the surface of the crushing box, and a dust collecting mechanism is arranged on one side of the top of the crushing box. According to the crushing equipment, the phenomenon that raw materials are stacked when the crushing equipment is used is avoided, the crushing effect of the raw materials when the crushing equipment is used is improved, and the phenomenon that dust flies when the crushing equipment is used is avoided.

Owner:DANYANG SHANGDE BIOTECH CO LTD +1

Blender capable of eliminating bubbles

PendingCN114160037AEasy to useEasy to mix and handleTransportation and packagingMixer accessoriesEngineeringGas bubble

Owner:南通瑞隆新材料有限公司

Method for producing inositol by fermenting recombinant escherichia coli

ActiveCN113957101AReduce the effect of enzyme productionImprove conversion rateMicrobiological testing/measurementMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses a method for producing inositol by fermenting recombinant escherichia coli, and belongs to the technical field of biological fermentation engineering and enzyme engineering. The invention discloses a method for producing inositol by fermenting recombinant escherichia coli, the recombinant escherichia coli is used as a starting strain, an OUR and RQ feedback regulation fermentation mechanism is established, and the method specifically comprises the following steps of: regulating the fed-batch feeding rate according to the OUR change trend of a thallus index growth stage at the early stage of fermentation and a thallus survival stage at the later stage of fermentation; according to the change of the RQ value, the glucose feeding rate can be quickly adjusted, the generation and accumulation of acetic acid in the fermentation liquor are reduced, the influence of acetic acid on the enzyme production of escherichia coli is reduced, and the conversion rate of inositol is improved. According to the invention, the concentration of inositol produced in fermentation liquor is 110-130 g / L, glucose is converted into inositol, the conversion rate reaches 70%, an inositol finished product is crystallized, and the yield is 70%.

Owner:山东福洋生物科技股份有限公司

Multifunctional mixing machine with self-cleaning function

InactiveCN112957992AWith self-cleaning functionAdjust feed rateRotary stirring mixersTransportation and packagingProcess engineeringIndustrial engineering

The invention relates to mixing equipment, in particular to a multifunctional mixing machine with a self-cleaning function. The machine comprises an automatic discharging mechanism, a stirring and cleaning mechanism and an automatic dumping and foundation mechanism. The machine can automatically feed, can adjust the feeding speed, can mix raw materials and automatically dump the raw materials, can assist in knocking and dumping finished products, and can perform self-cleaning. The automatic discharging mechanism is connected with the stirring and cleaning mechanism, and the stirring and cleaning mechanism is connected with the automatic dumping and foundation mechanism.

Owner:付耀有

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com