Photographic film cooling device

A cooling device and film technology, which is applied in the field of film cooling devices and cooling devices, can solve the problems of affecting winding, rubber sheet conveying too fast, lifting to the top of the cooling liquid, etc., to prevent slipping or deviation, convenient and stable transmission , Improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

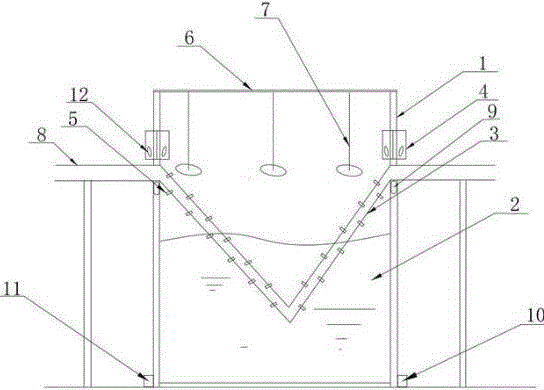

[0031] The film cooling device includes a frame 1 and a cooling pool 2 arranged below the frame 1, and also includes a guide rail 3 and a cooling box 4, one end of the guide rail 3 is connected to the frame 1, and the other end is also connected to the frame 1, and The middle part of the guide rail 3 is set in the cooling pool 2, and in addition, fixed cards 5 that can move freely are provided on both edges of the guide rail 3; A crossbeam 6 is provided on the frame 1, and a vertically downward spray nozzle 7 is arranged on the crossbeam 6.

Embodiment 2

[0033] The film cooling device includes a frame 1 and a cooling pool 2 arranged below the frame 1, and also includes a guide rail 3 and a cooling box 4, one end of the guide rail 3 is connected to the frame 1, and the other end is also connected to the frame 1, and The middle part of the guide rail 3 is set in the cooling pool 2, and in addition, fixed cards 5 that can move freely are provided on both edges of the guide rail 3; A crossbeam 6 is provided on the frame 1, and a vertically downward spray nozzle 7 is arranged on the crossbeam 6.

[0034] Preferably, the frame 1 is respectively provided with a conveyor belt 8 connecting the tablet press and the crimping device.

[0035] Preferably, the guide rail 3 is connected to the conveyor belt 8 on the frame 1 .

[0036] Preferably, the frame 1 is provided with a speed controller 9 for controlling the speed of the guide rail 3 .

[0037] Preferably, two guide rails 3 are arranged in parallel.

[0038] Preferably, the middle ...

Embodiment 3

[0045] The film cooling device includes a frame 1 and a cooling pool 2 arranged below the frame 1, and also includes a guide rail 3 and a cooling box 4, one end of the guide rail 3 is connected to the frame 1, and the other end is also connected to the frame 1, and The middle part of the guide rail 3 is set in the cooling pool 2, and in addition, fixed cards 5 that can move freely are provided on both edges of the guide rail 3; A crossbeam 6 is provided on the frame 1, and a vertically downward spray nozzle 7 is arranged on the crossbeam 6.

[0046] Preferably, the frame 1 is respectively provided with a conveyor belt 8 connecting the tablet press and the crimping device.

[0047] Preferably, the guide rail 3 is connected to the conveyor belt 8 on the frame 1 .

[0048] Preferably, the frame 1 is provided with a speed controller 9 for controlling the speed of the guide rail 3 .

[0049] Preferably, two guide rails 3 are arranged in parallel.

[0050] Preferably, the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com