Patents

Literature

171results about How to "Fully cooled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

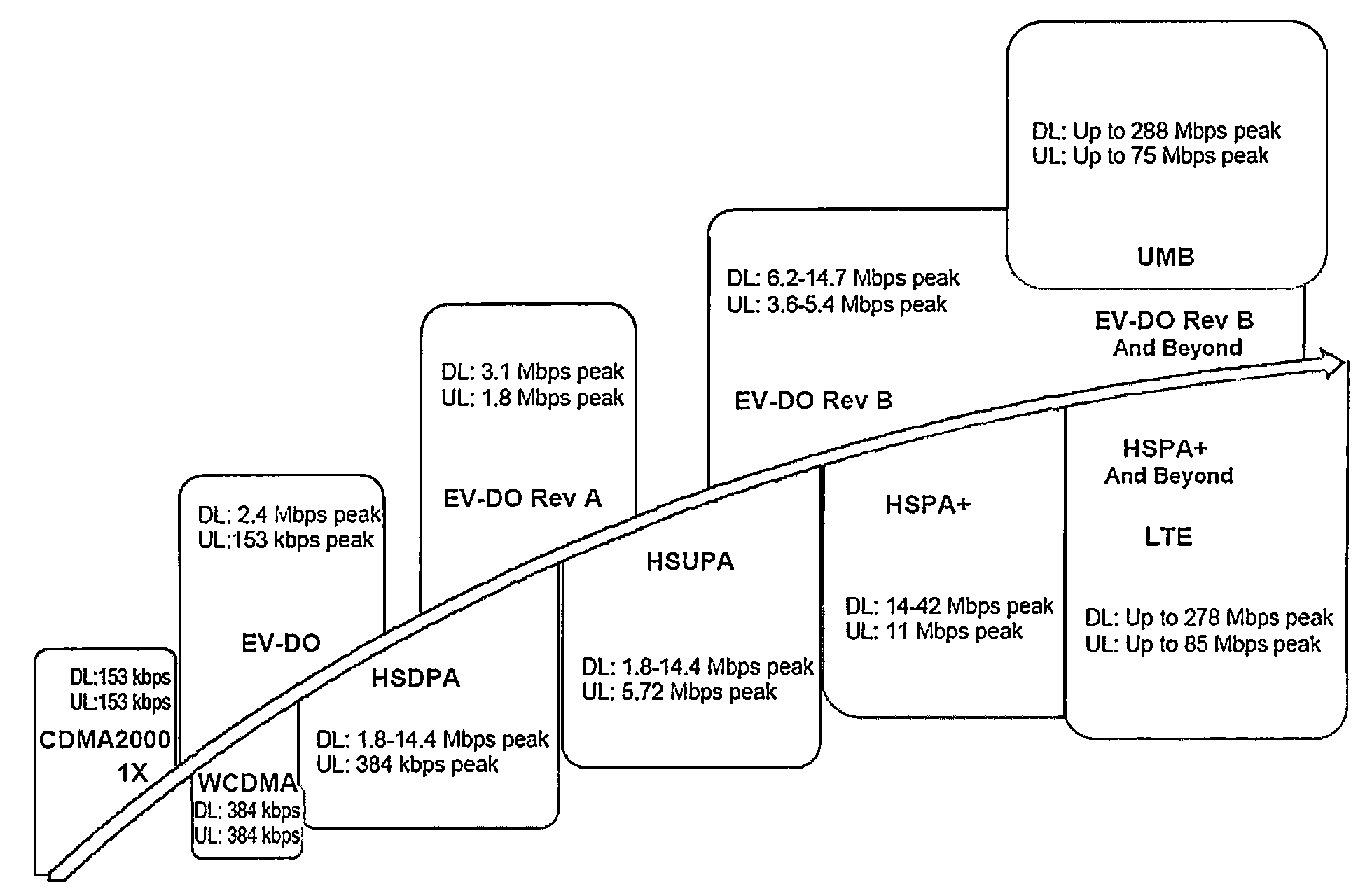

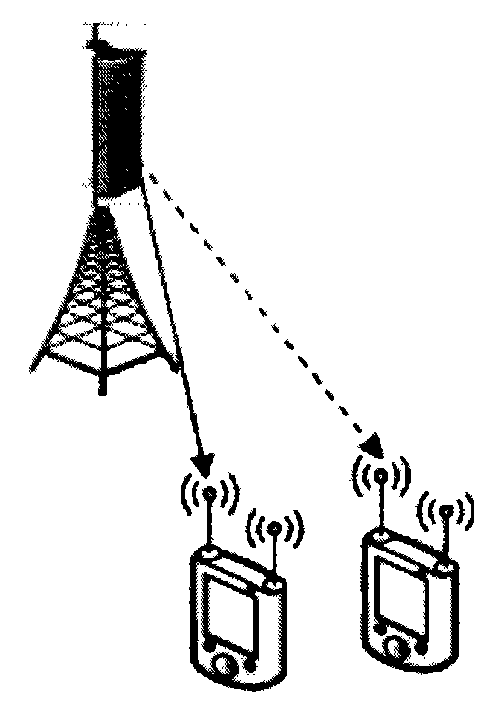

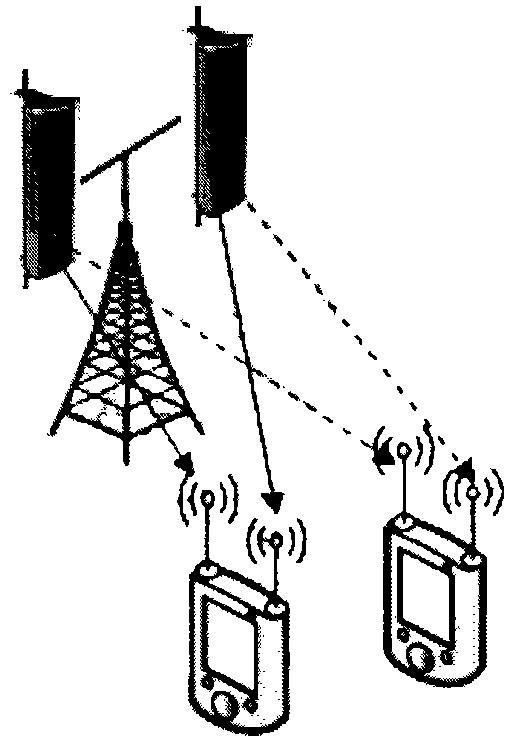

Wireless terminal and auxiliary antenna state control method thereof

InactiveCN101834644AAvoid overall overheatingImprove performanceSpatial transmit diversityLower limitContinuous use

The embodiment of the invention provides a wireless terminal and an auxiliary antenna state control method thereof. The method comprises the following steps of: acquiring the temperature of the wireless terminal; judging a relation between the temperature of the wireless terminal and a temperature threshold upper limit as well as a temperature threshold lower limit; when the temperature of the wireless terminal is higher than the temperature threshold upper limit, switching the auxiliary antenna off; or when the temperature of the wireless terminal is lower than the temperature threshold lower limit, switching the auxiliary antenna on. Due to the adoption of the method, overheat of the wireless terminal and potential safety hazards such as chip over-temperature, aging failure or short-circuit burning and the like caused by the overheat can be prevented. Simultaneously, continuous use of the wireless terminal by a user can be ensured and impacts (sudden change of flow speed, offline and the like) on the user during practical use are minimized.

Owner:HUAWEI DEVICE CO LTD

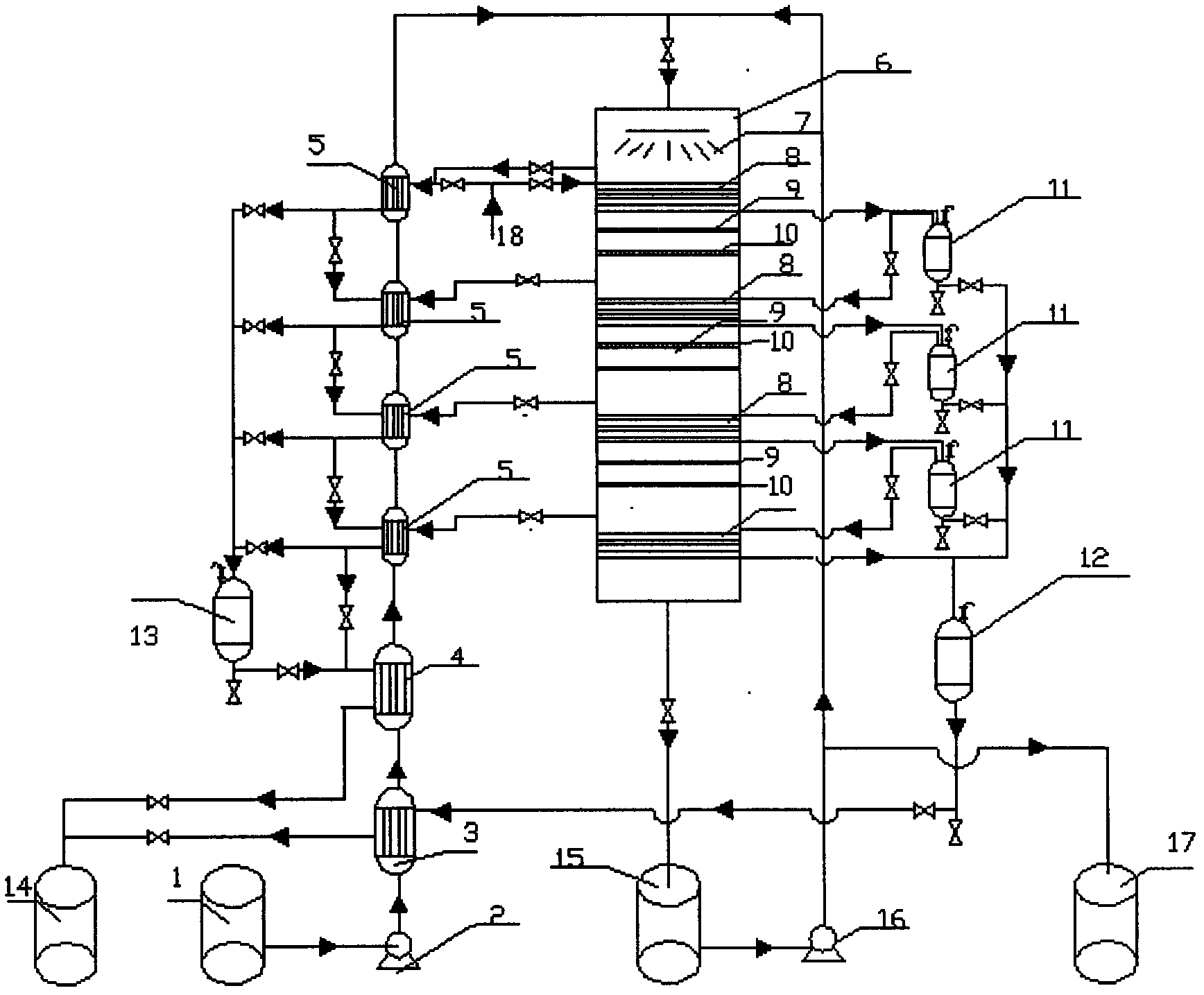

High-temperature seawater desalting and distillation device and method

ActiveCN102424436AHigh heating temperatureIncrease water production ratioGeneral water supply conservationSeawater treatmentHigh concentrationDistillation

Owner:天津海泽惠科技发展有限公司

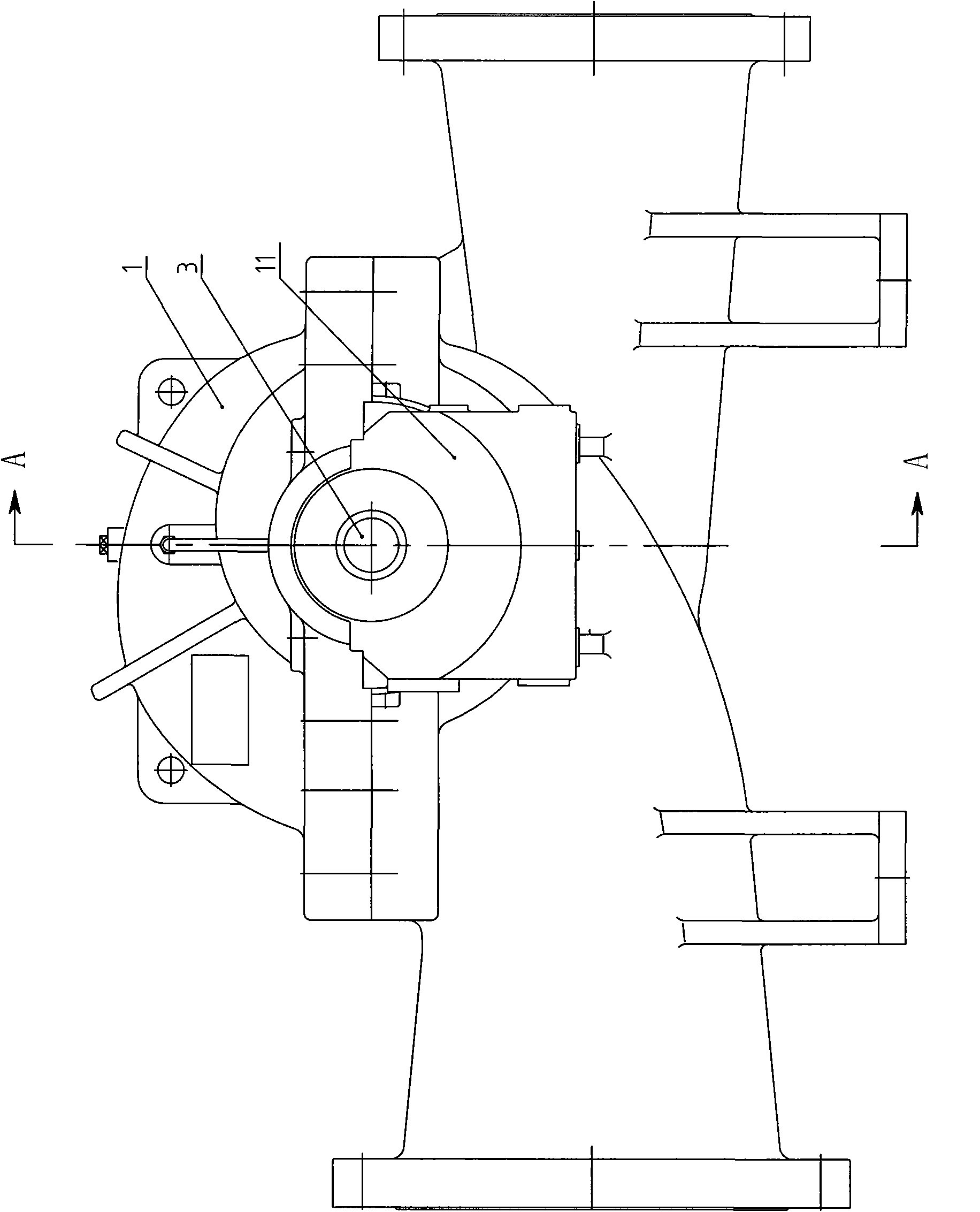

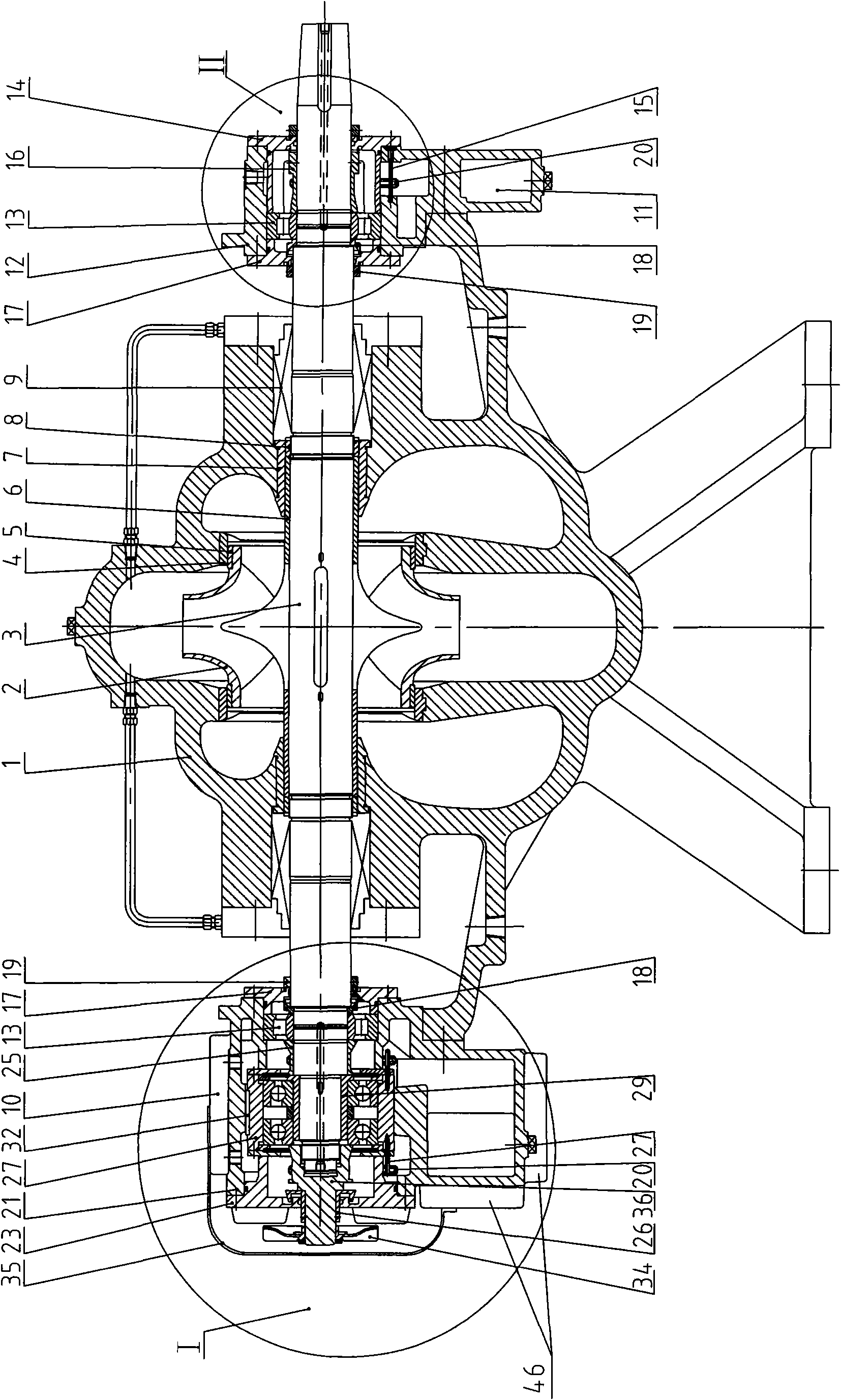

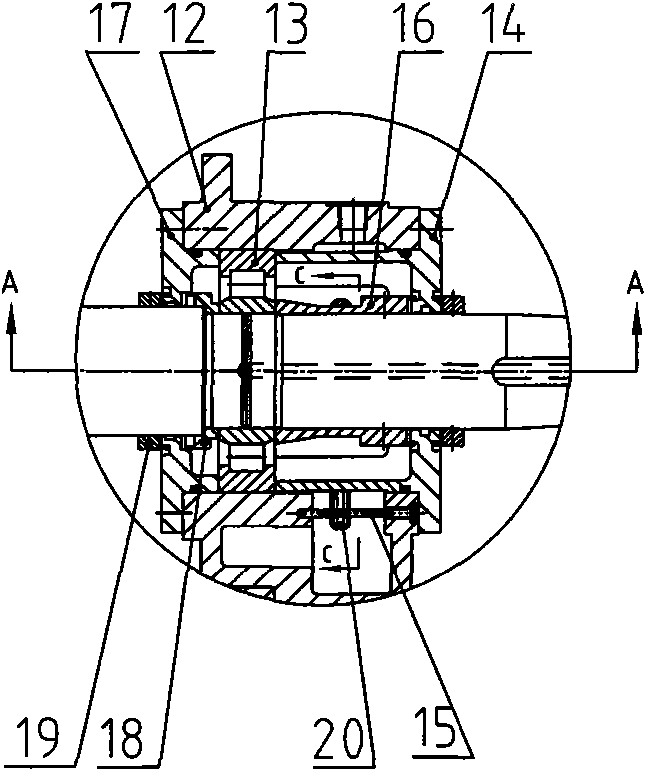

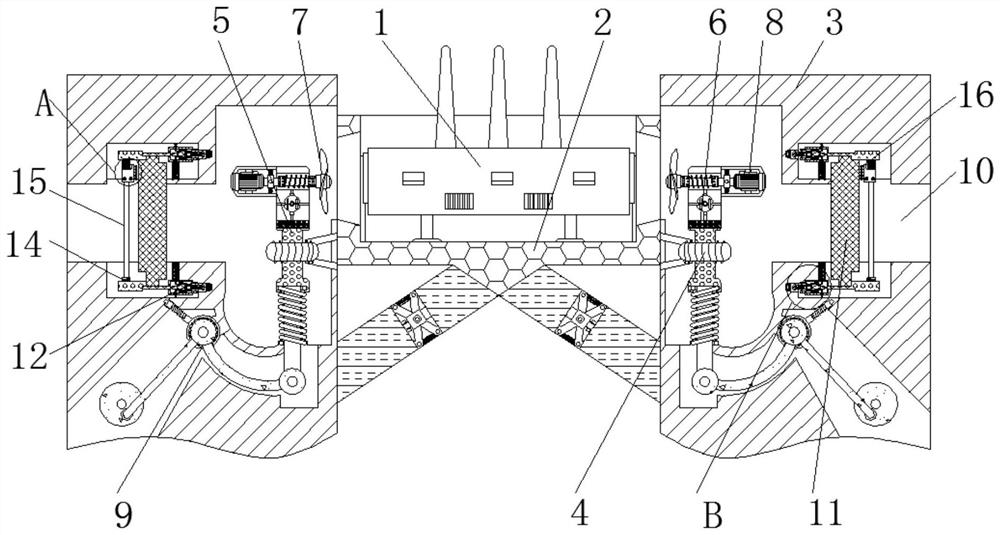

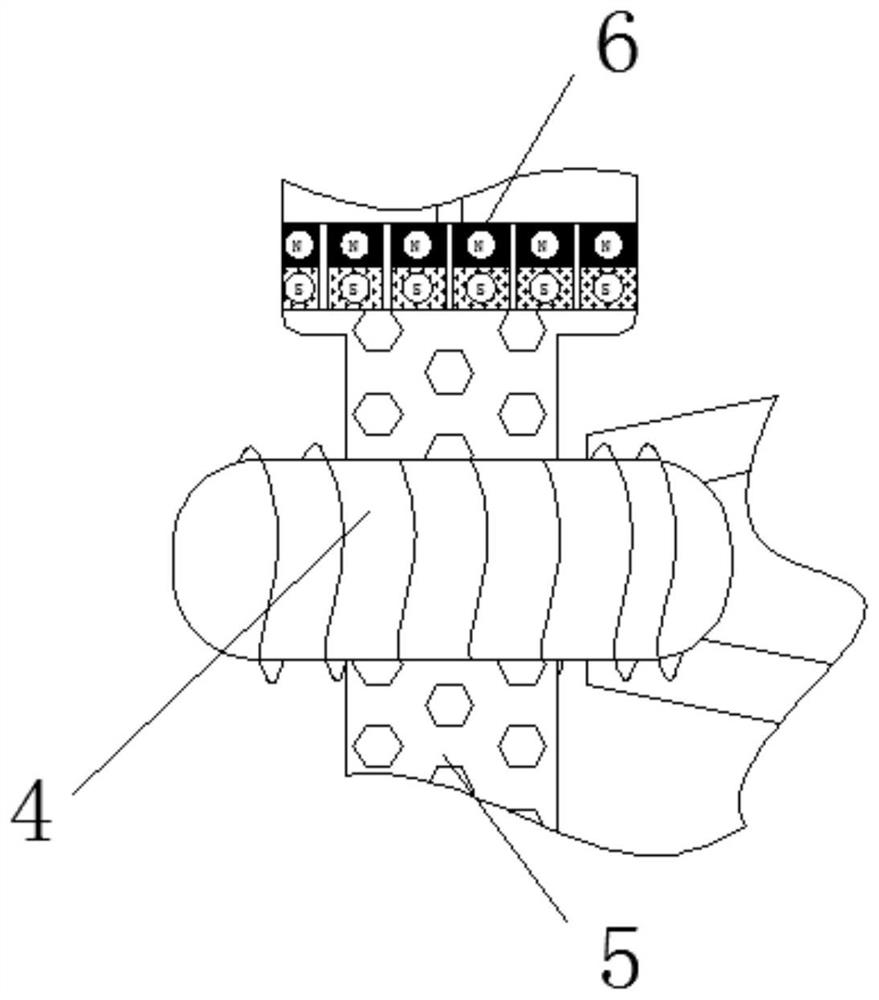

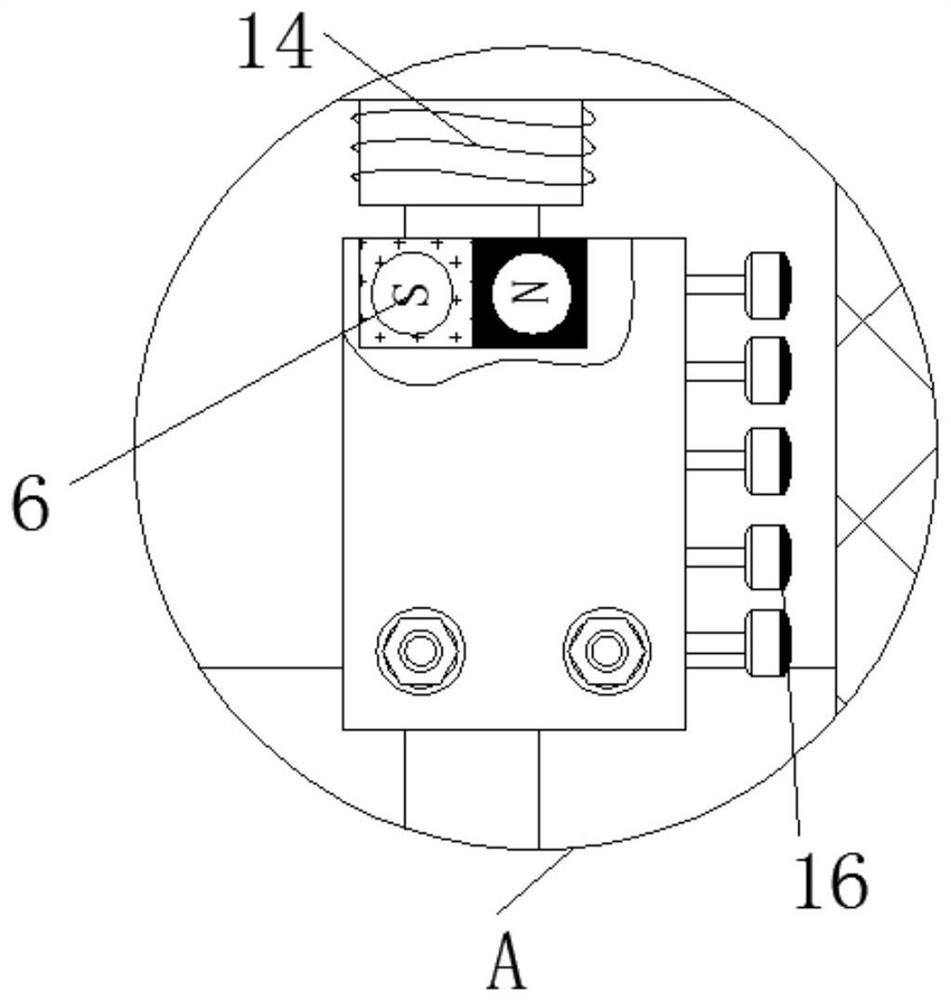

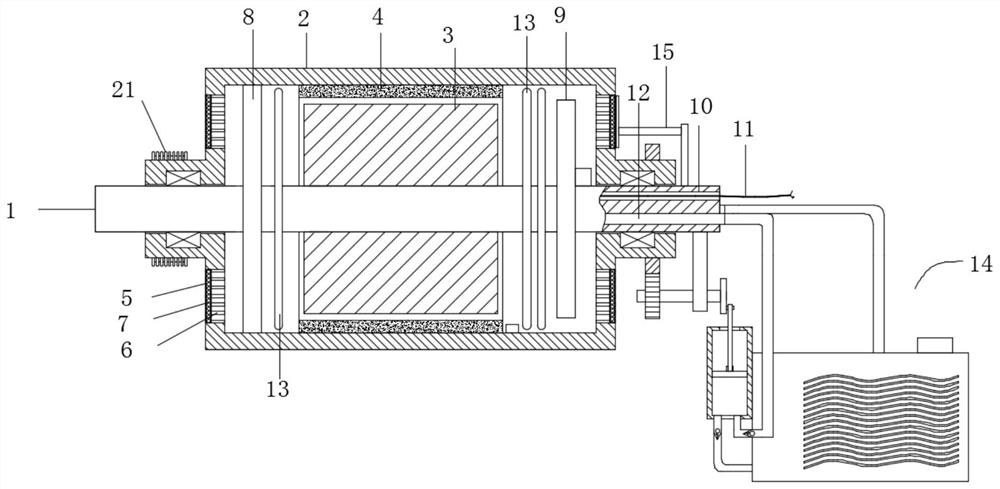

Pipeline delivery pump

ActiveCN101994701AEasy to disassembleShorten maintenance timePump componentsRadial flow pumpsImpellerDesalination

The invention relates to a pipeline delivery pump, which is suitable for the pipeline delivery of crude oil and natural gas and the sea water transportation in long distance in the field of desalination of sea water. The pump comprises a pump body, an impeller, a shaft, a left bearing device and a right bearing device; the impeller is arranged on the shaft in the pump body; two ends of the shaft extending out of the pump body are respectively provided with the left and right bearing devices which are connected with the pump body; the shaft end of the right bearing is connected with the outputshaft of a motor; two ends of the shaft are respectively provided with an axial hole; a shaft platform is arranged on the shafts of the first bearings of the left and right beating devices; and a circular groove is arranged in the middle of the shaft platform; and any part of the circumference of the circle groove is provided with a radial hole communicated with the axial hole. In the invention, the problems of difficult disassemble of the pipeline delivery pump bearing and unbalanced axial force are solved, and the bearing is extremely convenient and rapid to disassemble and maintain, a great amount of time is saved, and the work efficiency is greatly improved; and in addition, the impact of the axial force to the bearing is reduced and the service life of the bearing is improved by improving the structure of the bearing device.

Owner:辽宁恒星泵业有限公司

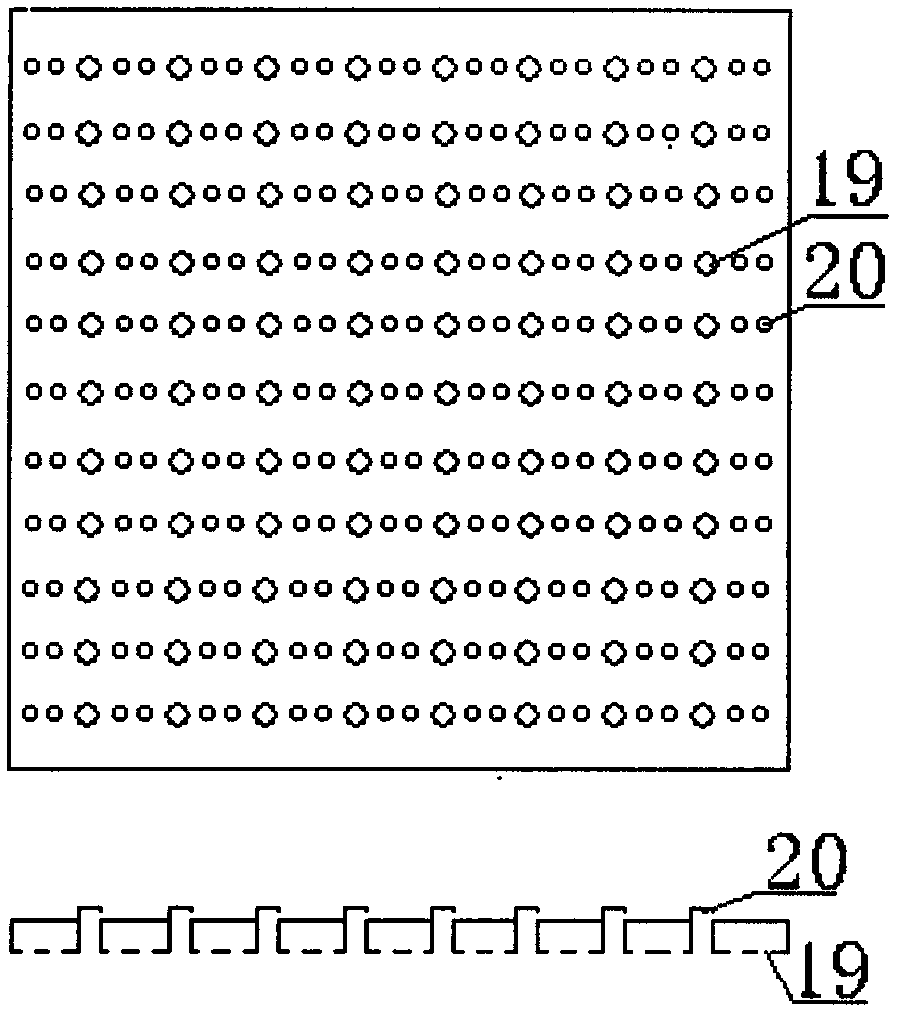

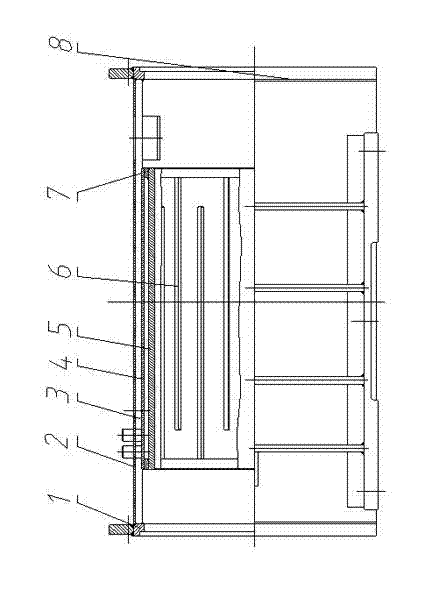

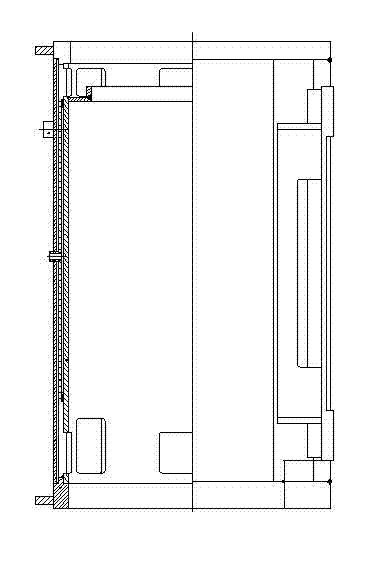

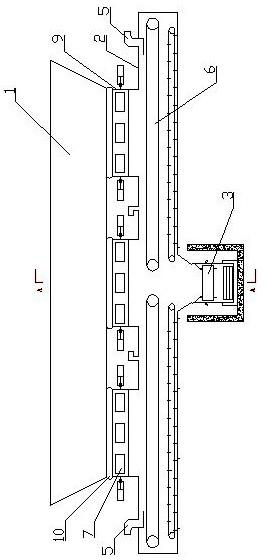

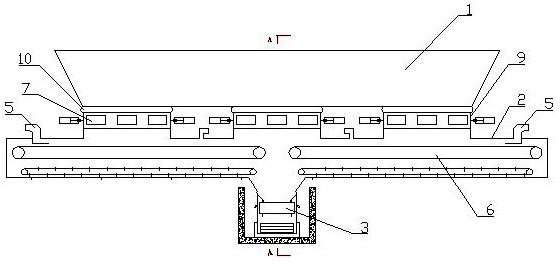

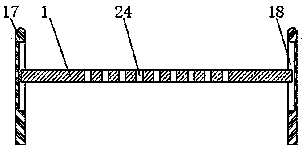

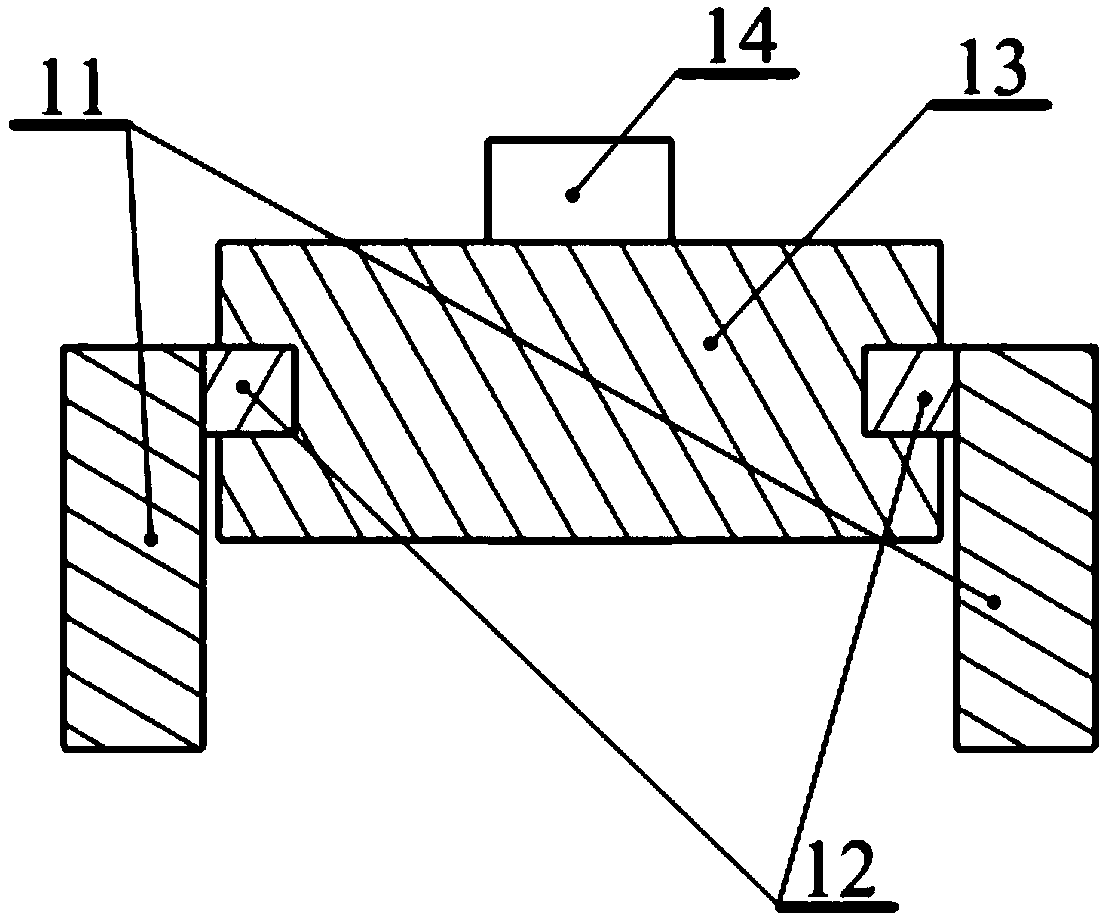

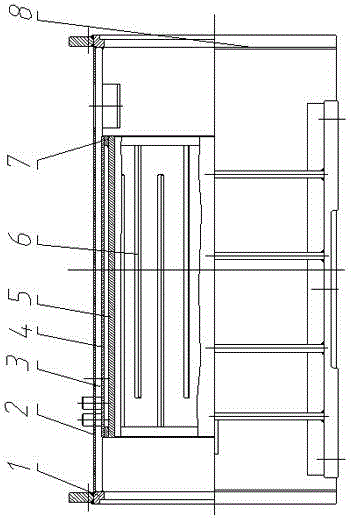

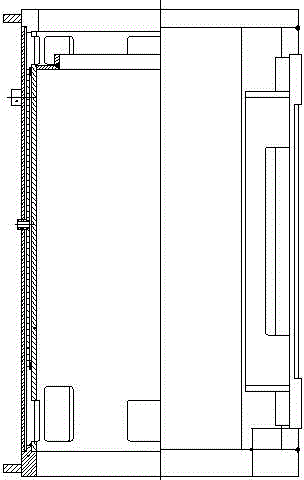

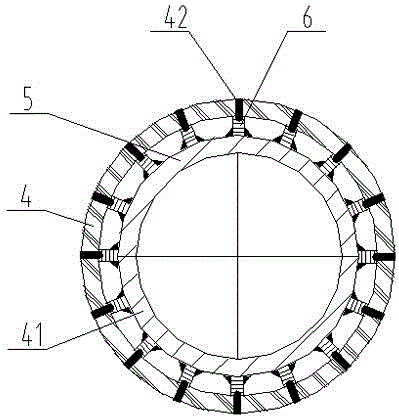

Novel low temperature rising water-cooling stator engine base and welding method thereof

ActiveCN102904371ASave materialReduce shakingManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringSpot welding

The invention relates to a novel low temperature rising water-cooling stator engine base and a welding method thereof. The novel low temperature rising water-cooling stator engine base comprises an outer cylinder, a middle cylinder, an inner cylinder and a machine leg component, wherein the length of the inner cylinder is the same as the length of a water-cooling stator and is less than the length of the outer cylinder; the welding method comprises the following steps of: positioning water channel ribs through a rib plate positioning die in sequence and fixing the water channel ribs in a spot welding mode; finding out the position of a blocked weld joint through a blocked weld joint template corresponding to a plurality of water channel ribs; positioning and welding the water channel ribs; and finding blocked weld joints corresponding to the water channel ribs. The welding method is accomplished through the rib plate positioning die and the blocked weld joint template, the error in line drawing positioning and aligning is effectively avoided, the following welding quality is improved, and the cooling performance of the engine base is ensured.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

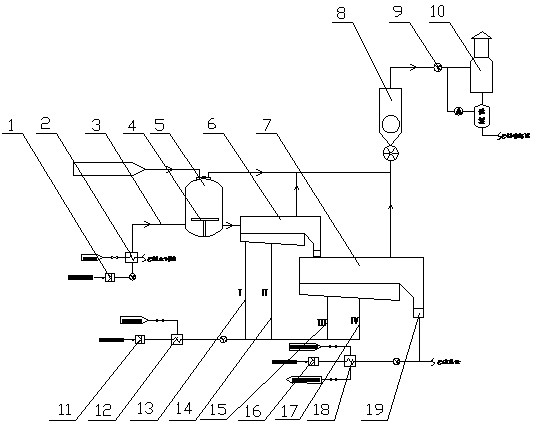

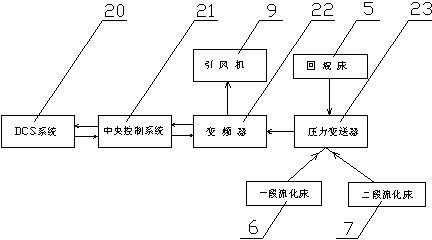

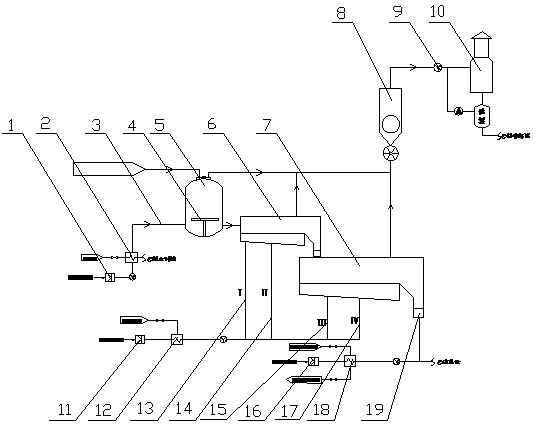

Anhydrous dextrose drying device and drying process

ActiveCN102435049AImprove continuityGuaranteed boiling effectDrying solid materials with heatHearth type furnacesFluidized bedChange color

The invention belongs to the technical field of biomedicine, in particular relates to an anhydrous dextrose drying device and a drying process. The technical scheme is that the anhydrous dextrose drying device comprises a fluidized bed and a back mixing bed. The fluidized bed comprises a first-section fluidized bed and a second-section fluidized bed. The lower portion of the back mixing bed is connected with an air inlet pipe I through an air feeder I, a heater I is arranged on the air inlet pipe I, an air inlet pipe II and an air inlet pipe III are respectively connected with the first-section fluidized bed, an air inlet pipe IV and an air inlet pipe V are respectively connected with the second-section fluidized bed, an air feeder II is respectively connected with the air inlet pipe II, the air inlet pipe III, the air inlet pipe IV and the air inlet pipe V through a heat exchanger II, so that the phenomena that finished products are apt to change colors and blocked caused by high temperature of materials caused by continuous drying can be avoided.

Owner:XIWANG PHARMA

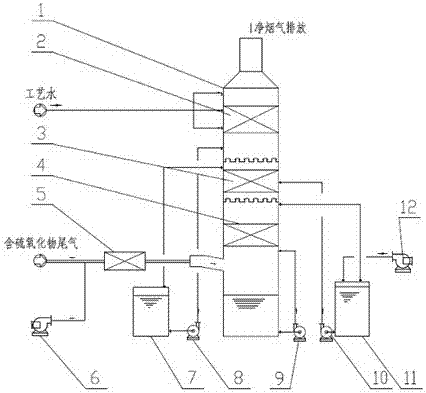

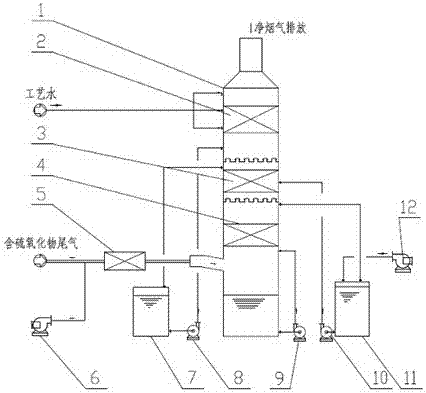

High humidity sulfur oxide tail gas treatment method and device

PendingCN107998844AFully absorbedReduce water contentGas treatmentDispersed particle separationParticulatesHigh humidity

The invention discloses a high humidity sulfur oxide tail gas treatment method and device. The content of water in tail gas is reduced by mixing air or other gases with the tail gas through a fan or directly contacting with the tail gas through an adsorbent, so that the purpose of reducing the absolute humidity of the tail gas is reached; the temperature of the tail gas is sufficiently reduced when the tail gas passes a cooling device, so that ammonia escape and aerosol caused by high temperature of glue gas entering a desulfurizing tower absorption region are avoided. Ammonium sulfite is taken as an absorbent, ammonia and oxidation air respectively react with the ammonium sulfite and absorption liquid thereof, so that sulfur oxide in the tail gas is sufficiently absorbed through multilayer spraying and washing; finally fog drips and particulate matter in the tail gas are removed through a washing device. The device solves the problem that ammonium sulfite in the absorption region is easy to decompose when an ammonia desulfurization process is adopted for high humidity sulfur oxide tail gas, and has high practicability and wide applicability.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

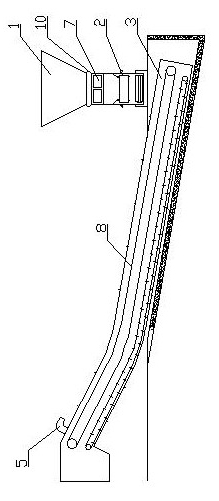

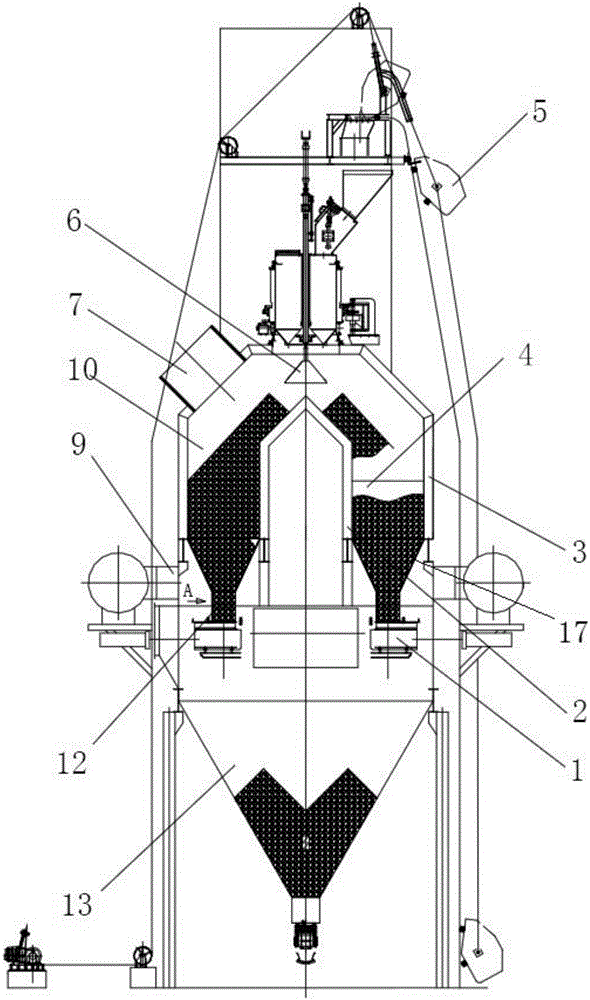

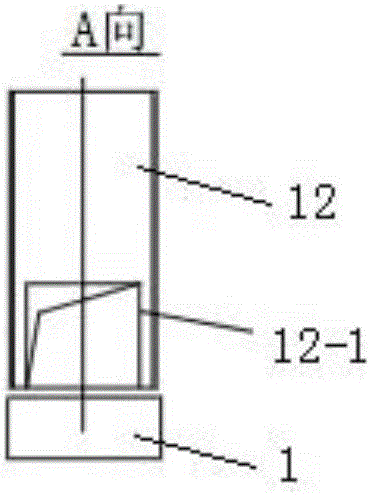

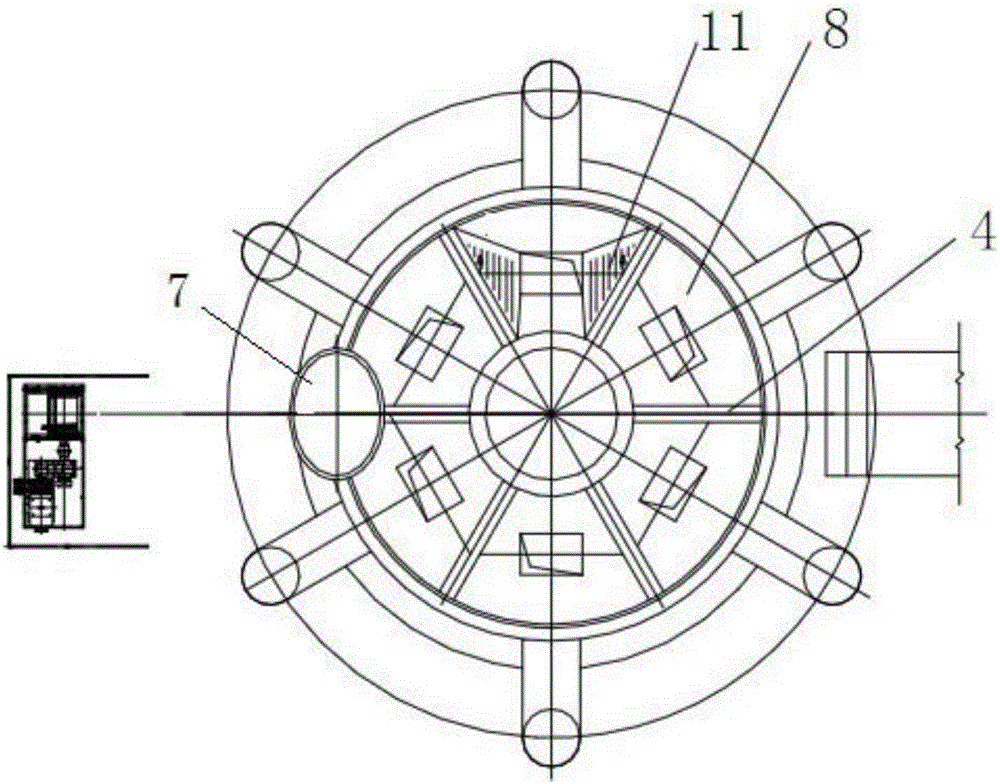

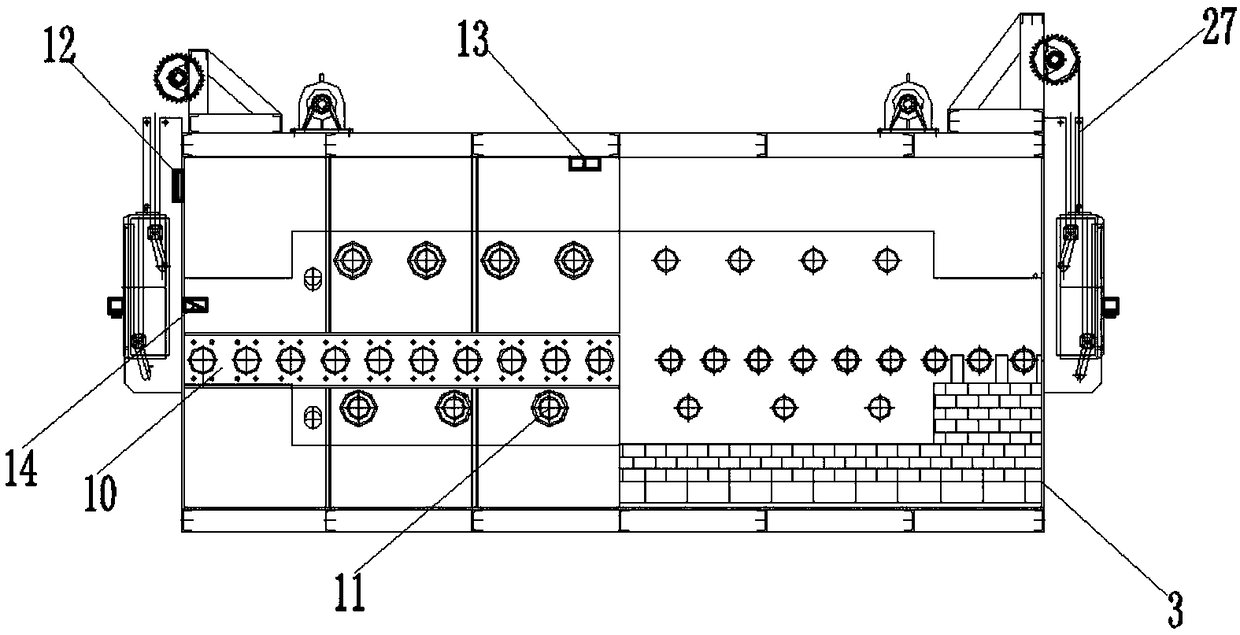

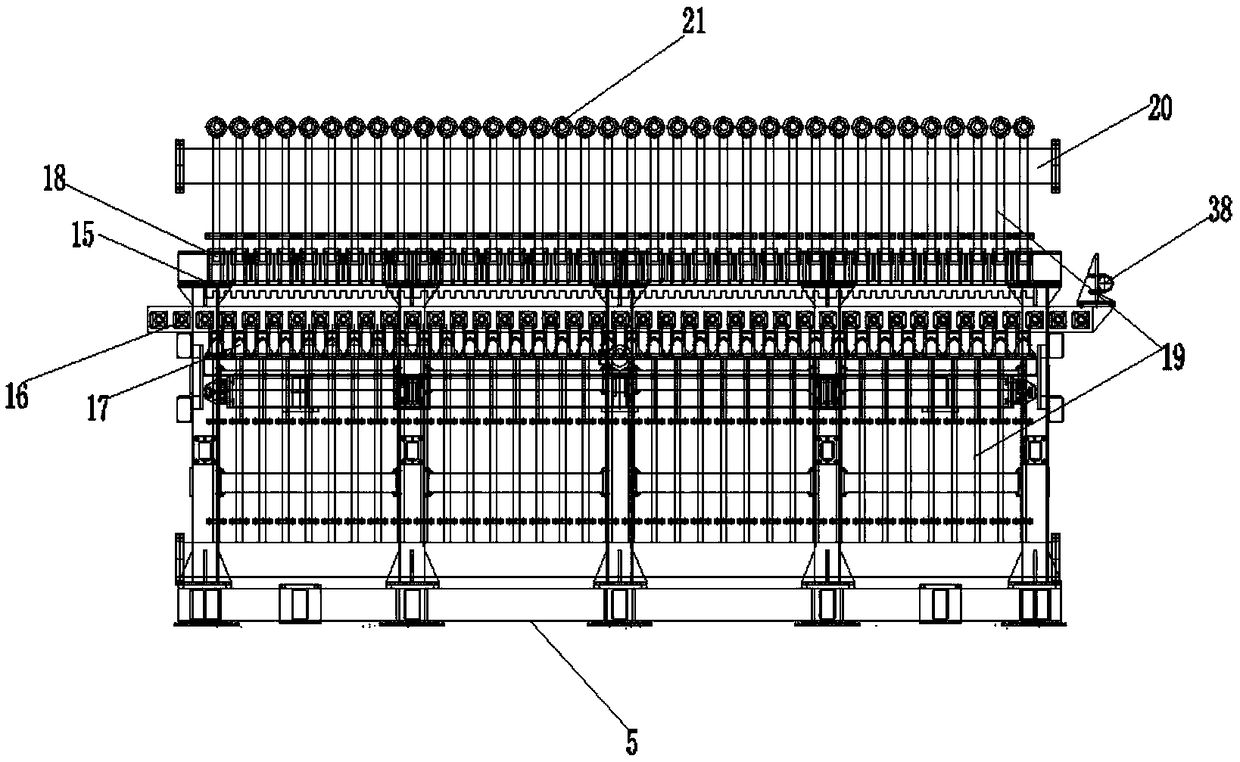

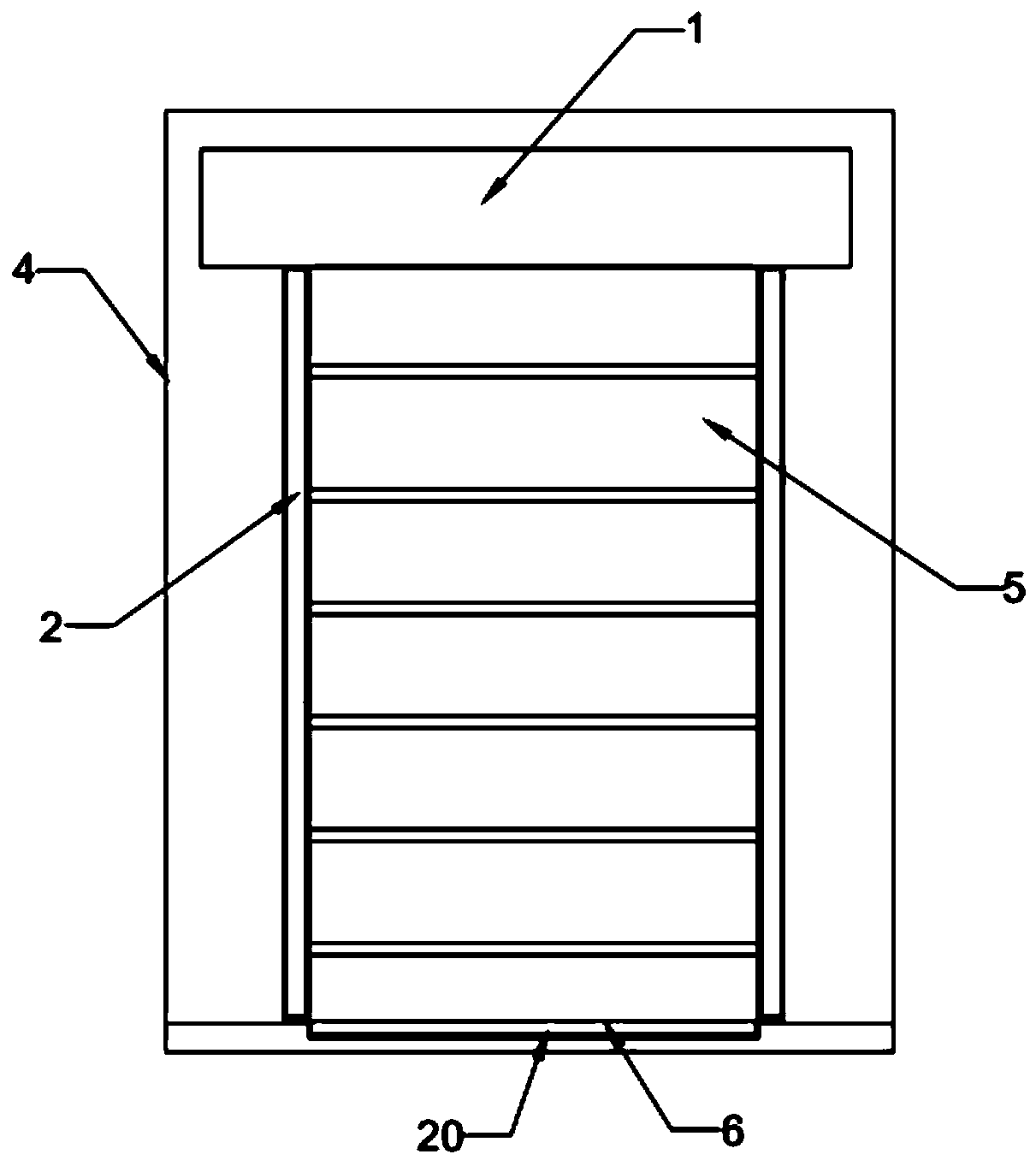

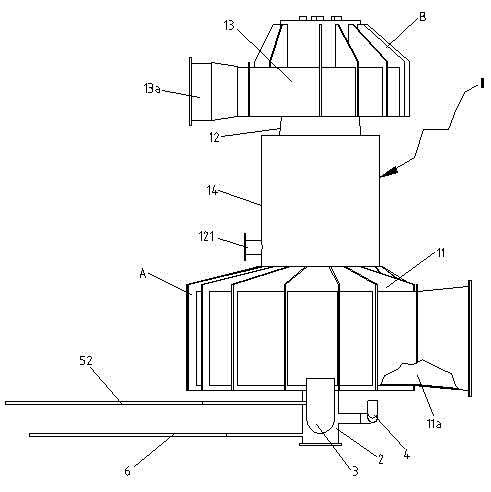

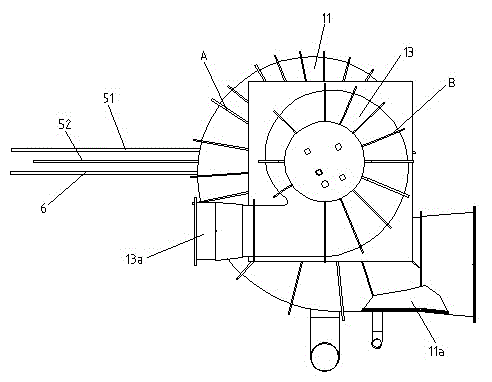

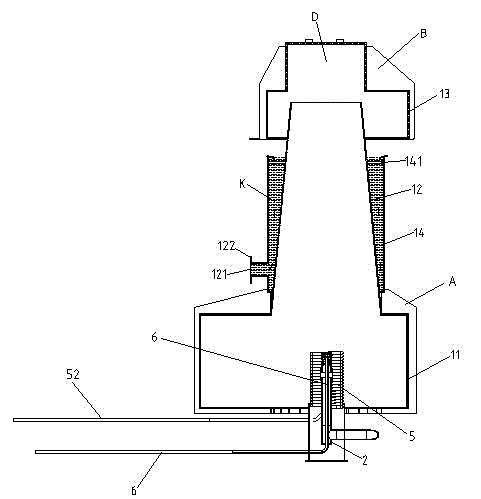

Air-cooled dry-type slag discharging system

ActiveCN102052686AFully cooledInitial Cooling AchievedLighting and heating apparatusSteel beltBoiler slag

The invention provides an air-cooled dry-type slag discharging system modified by a hydraulic slag removing system, which comprises a slag well and a sealed tank body of a steel-belt slag conveyor, wherein the upper end of the slag well is connected with a boiler slag discharging hole; the longitudinal cross section of the slag well is funnel-shaped; the top end of the sealed tank body of the steel-belt slag conveyor is communicated with the bottom end of the slag well; one or more air inlets are also formed on the sealed tank body of the steel-belt slag conveyor; the sealed tank body of the steel-belt slag conveyor is arranged in the length direction of the boiler slag discharging hole; two conveyor belts (for oppositely conveying slag) of the steel-belt slag conveyor are arranged in the sealed tank body of the steel-belt slag conveyor; a space for allowing the slag to fall into is formed between the two conveyor belts of the steel-belt slag conveyor; and a secondary slag discharging device is also included, wherein the secondary slag discharging device is arranged in the width direction of the boiler slag discharging hole, and a secondary conveyor belt of the steel-belt slag conveyor is arranged in the secondary slag discharging device and arranged below the space. The air-cooled dry-type slag discharging system has the advantages of evenly and fully cooled high-temperature slag, lower requirement to the space, simple structure and reasonably utilized space, and achieves the purpose of modifying the slag removing system into the dry-type slag discharging system.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Impact testing device for battery pack

ActiveCN106323577AAvoid influenceEffective fire extinguishing treatmentShock testingElectrical batteryPower apparatus

The present invention relates to an impact testing device for a battery pack. The device comprises a collision barrier used for placing the battery pack, a movable sliding table with an impact head, a hydraulic power device used for pushing the movable sliding table to slide, and a monitoring device in communication connection with a sensor inside the battery pack. The movable sliding table is positioned between the hydraulic power device and the collision barrier. The impact head of the movable sliding table is oriented towards a support assembly for placing the battery pack and positioned on the side surface of the collision barrier. The monitoring device controls the starting and the stopping of the hydraulic power device. The device further comprises a solution tank positioned right below the support assembly and used for the fire extinguishing of the battery pack. The monitoring device also controls the support assembly to release the battery pack so as to enable the battery pack to fall into the solution tank. According to the technical scheme of the invention, the fire extinguishing problem of the battery pack during the impact test in the prior art can be solved.

Owner:深蓝汽车科技有限公司

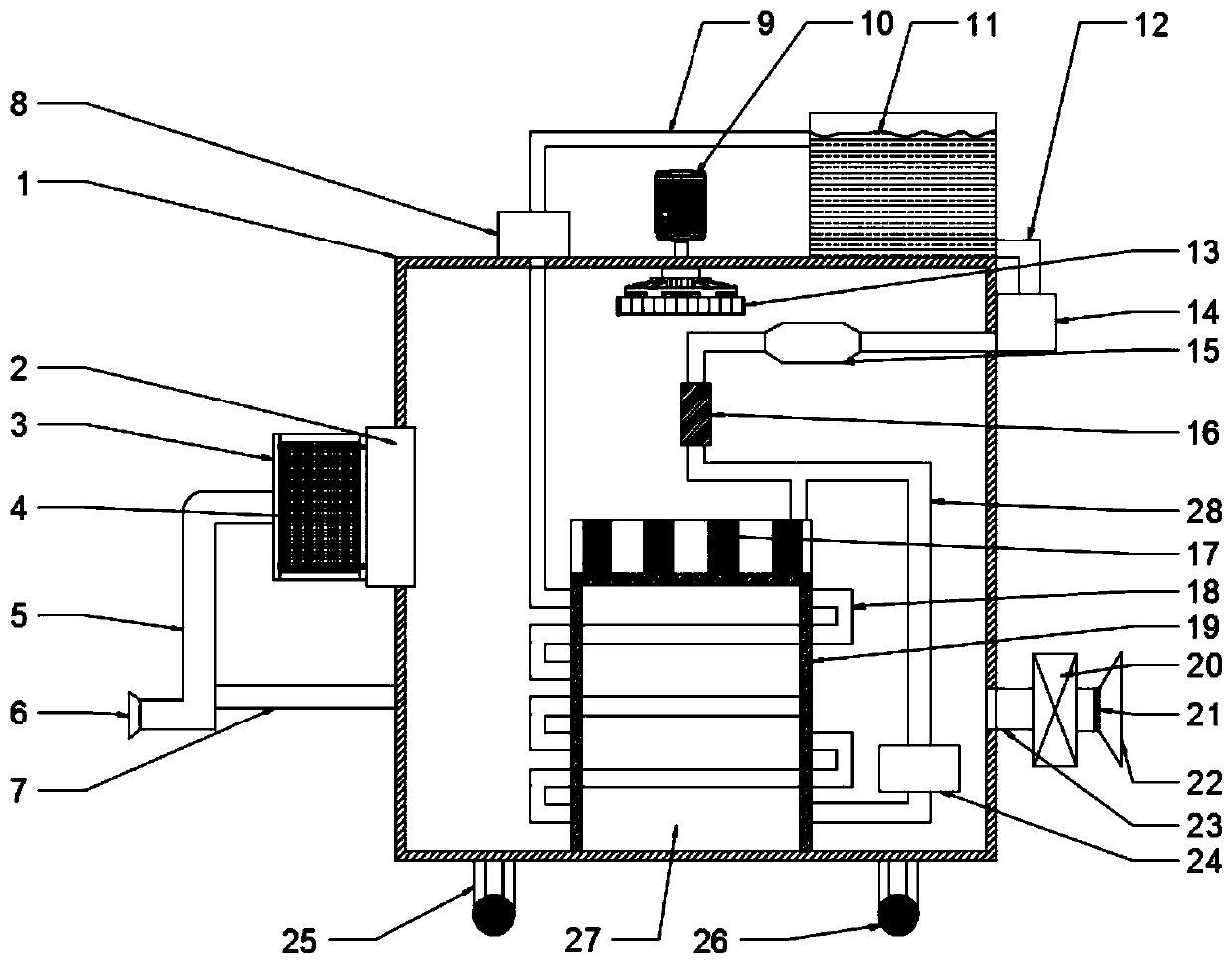

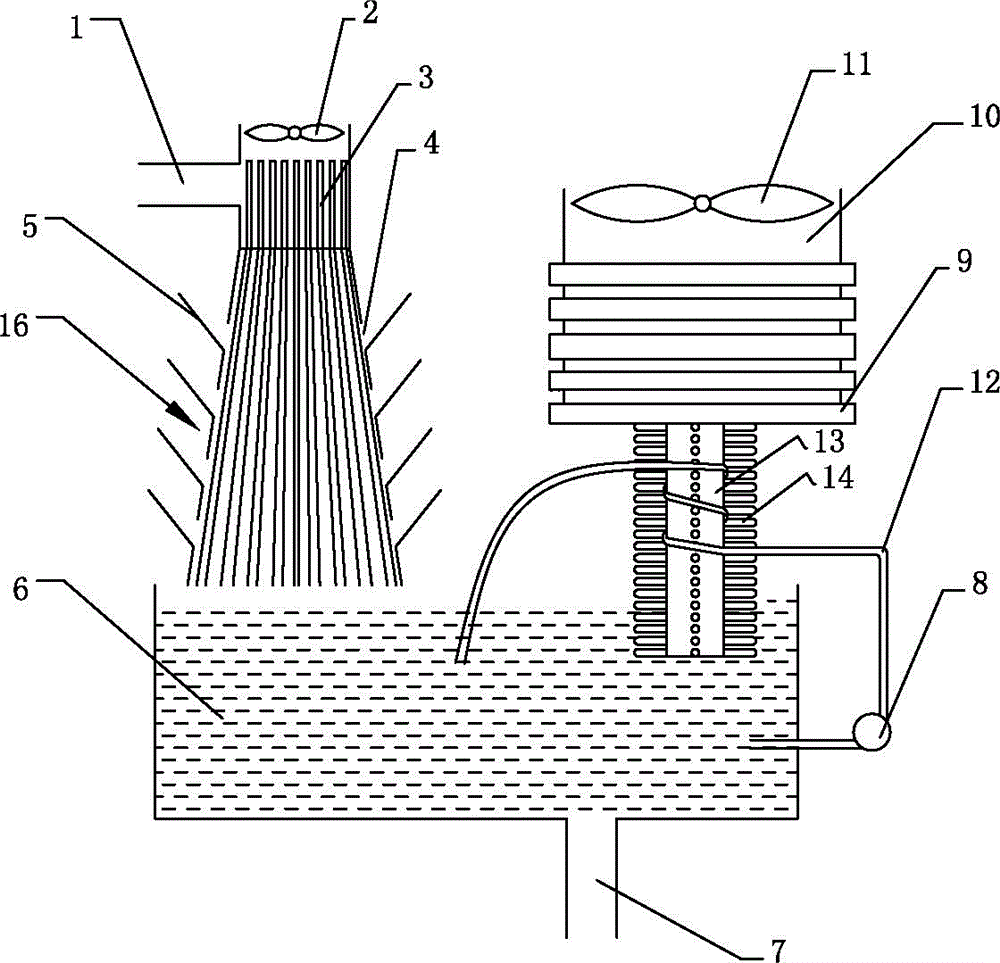

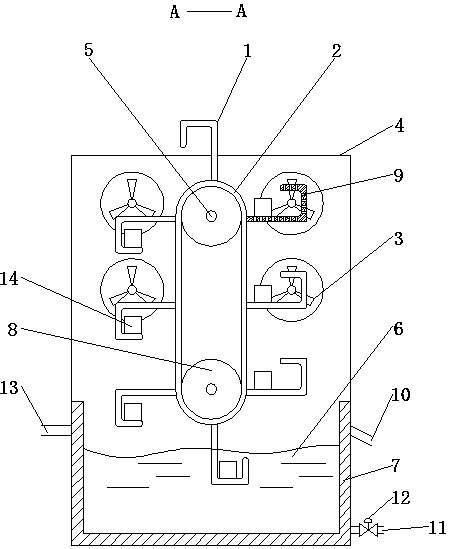

Heat dissipation device for power equipment

InactiveCN110890708AImprove cooling effectFully cooledSubstation/switching arrangement cooling/ventilationAir cycleElectric power equipment

The invention discloses a heat dissipation device for power equipment, and relates to the technical field of power equipment. The heat dissipation device comprises a heat dissipation box, a water tankis mounted at the top of the heat dissipation tank and is connected with a water outlet pipe, and the water outlet pipe is connected with a pressure water pump. The pressure water pump is connected with a gasification pipe, the gasification pipe is connected with a liquefaction device, and the liquefying device is connected with a branch pipeline. The branch pipeline is connected with a refrigerator, the refrigerator is connected with an annular water pipe, and the annular water pipe is connected with a water return pipe. The water return pipe is connected with a water supply pump, the watersupply pump is connected with the water tank, a suction fan is mounted on the surface of the right side wall of the heat dissipation box, and an air cooling device is mounted on the left side wall ofthe heat dissipation box. The water tank, the water outlet pipe, the pressure water pump, the annular water pipe, the water supply pump and the water return pipe are arranged to form a water circulation system, and the suction fan, an air exhaust adjusting box and the fan are arranged to form an air circulation system, so that the air in the heat dissipation box can fully flow. Through the mutual combination of the water circulation and the air circulation, the power equipment in the heat dissipation box are cooled.

Owner:李裕谋

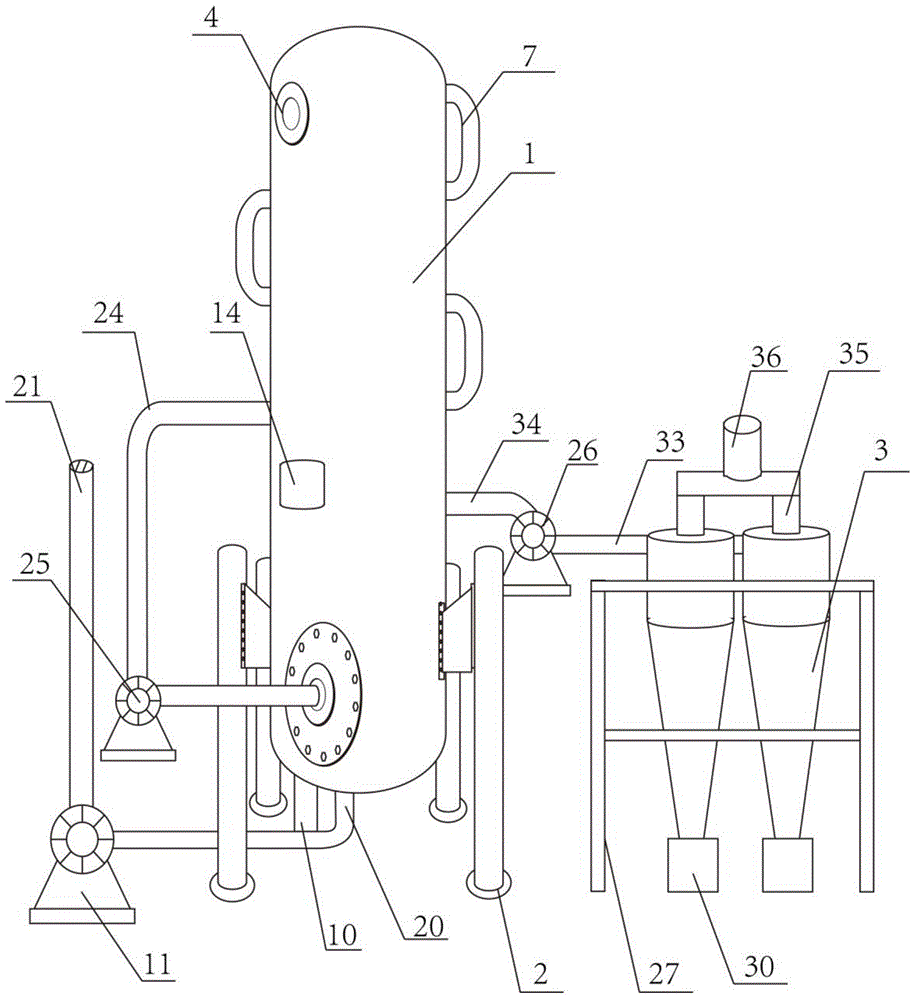

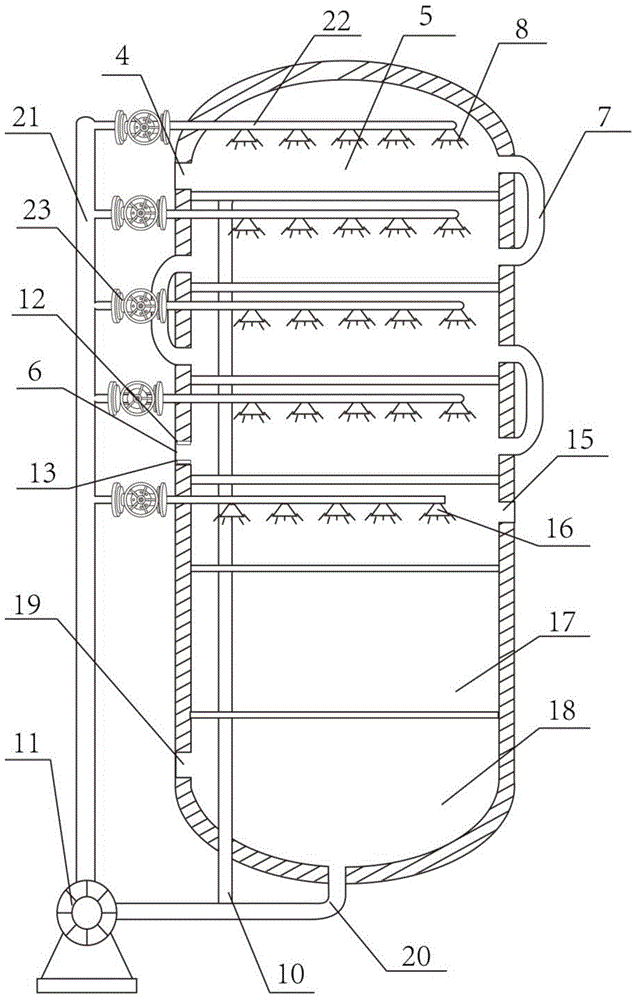

Pretreatment device of organic waste gas and use method of pretreatment device

ActiveCN104971614AImprove work efficiencyConserve waterAuxillary pretreatmentAir quality improvementThree levelPre treatment

The invention discloses a pretreatment device of organic waste gas and a use method of the pretreatment device. The pretreatment device comprises a cooling and deodorizing tower and a three-level dust chamber, wherein the cooling and deodorizing tower comprises a primary cooling chamber and a secondary deodorizing room, the primary cooling chamber comprises a hot gas inlet, a plurality of layers of spraying rooms and a wet gas outlet, the secondary deodorizing room comprises an odourless gas outlet, a deodorizing room spray head, a packing layer, a water collecting box and a wet gas inlet in sequence from top to bottom, the three-level dust chamber comprises a plurality of cyclone separators, and each cyclone separator comprises a shell, an odourless gas inlet, a lower hopper and a dustless gas outlet. According to the device provided by the invention, cooling, deodorizing and dust collection are orderly combined, the plurality of layers of spraying rooms can be used for guaranteeing that gas is sufficiently cooled, prewetting treatment is carried out for the further deodorizing process while cooling is carried out, and all used water is circulating water, so that the concept of economization and environmental protection is met.

Owner:海安绿云环境科技有限公司

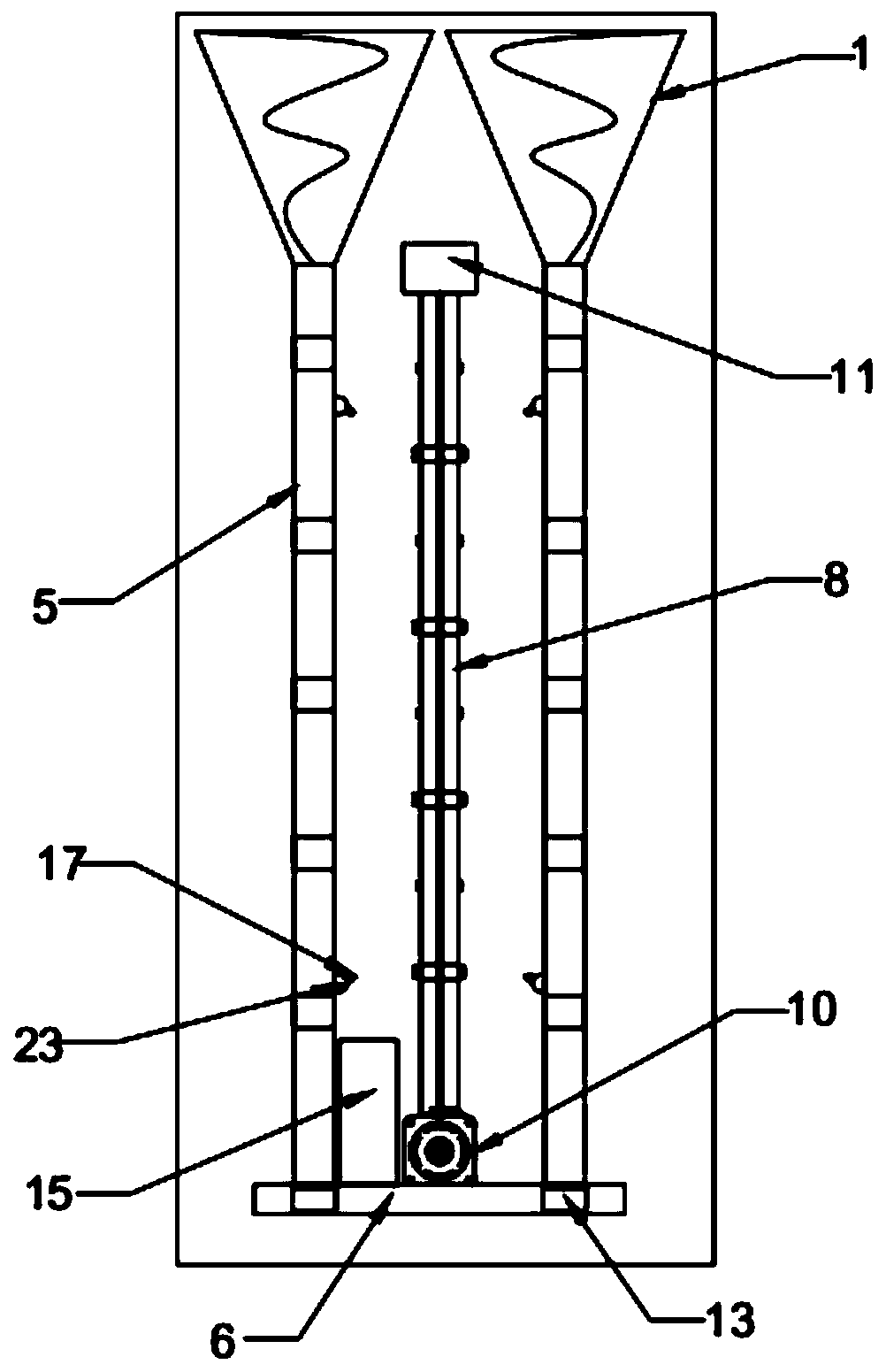

Chambered cooling device for sintered ore and pellet ore

The invention discloses a chambered cooling device for sintered ore and pellet ore. The chambered cooling device comprises a vertical furnace body, wherein the vertical furnace body comprises a furnace shell; an inner sleeve is arranged at the center of the furnace shell; an annular interlayer is formed between the inner sleeve and the furnace shell; a feeding valve group is arranged at the top of the annular interlayer; an air outlet is formed in the upper part of the annular interlayer; a plurality of partition walls are arranged at the lower part of the annular interlayer at intervals along the annular center; the lower part of the annular interlayer is divided into a plurality of material cooling chambers through the partition walls; funnel sections are arranged at the bottoms of the material cooling chambers; louver type air inlets are formed in the side surfaces of the funnel sections; air inlets are formed in the positions, corresponding to louver boards, of the furnace shell; the lower ends of the funnel sections are connected with material lateral discharge pipes; the material lateral discharge pipes are provided with lateral discharge holes; the lateral discharge holes are provided with drawer-type blow-off valves; a secondary cooling chamber is arranged below the drawer-type blow-off valves; and a blow-off valve is arranged at the bottom of the secondary cooling chamber. According to the chambered cooling device, materials can be subjected to chambered cooling and multi-point lateral pushing, discharge is achieved at the bottoms of the chambers through adopting the drawer-type blow-off valves, and the forced discharge is achieved.

Owner:MOUNTOP GRP CO LTD

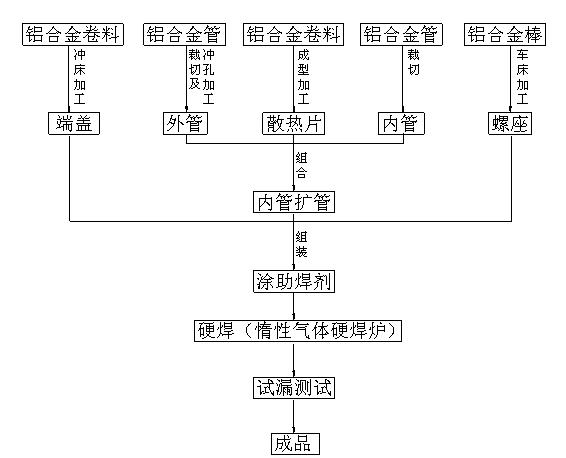

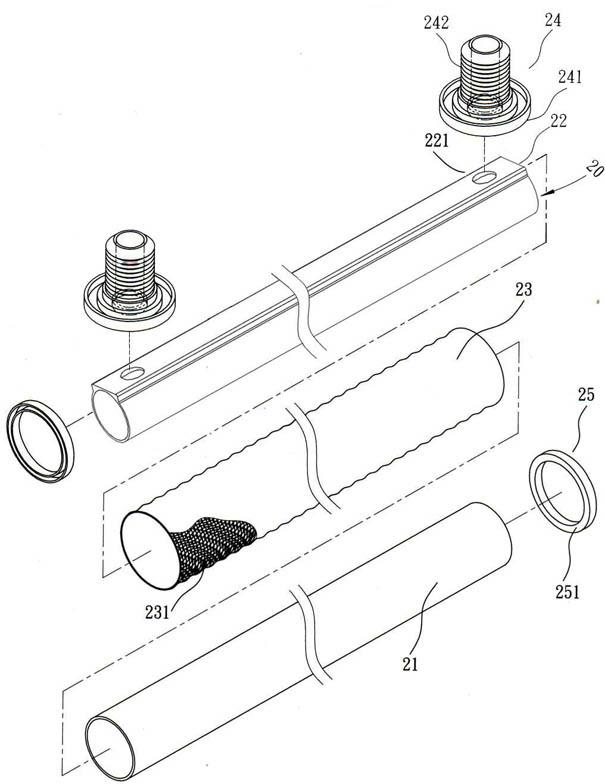

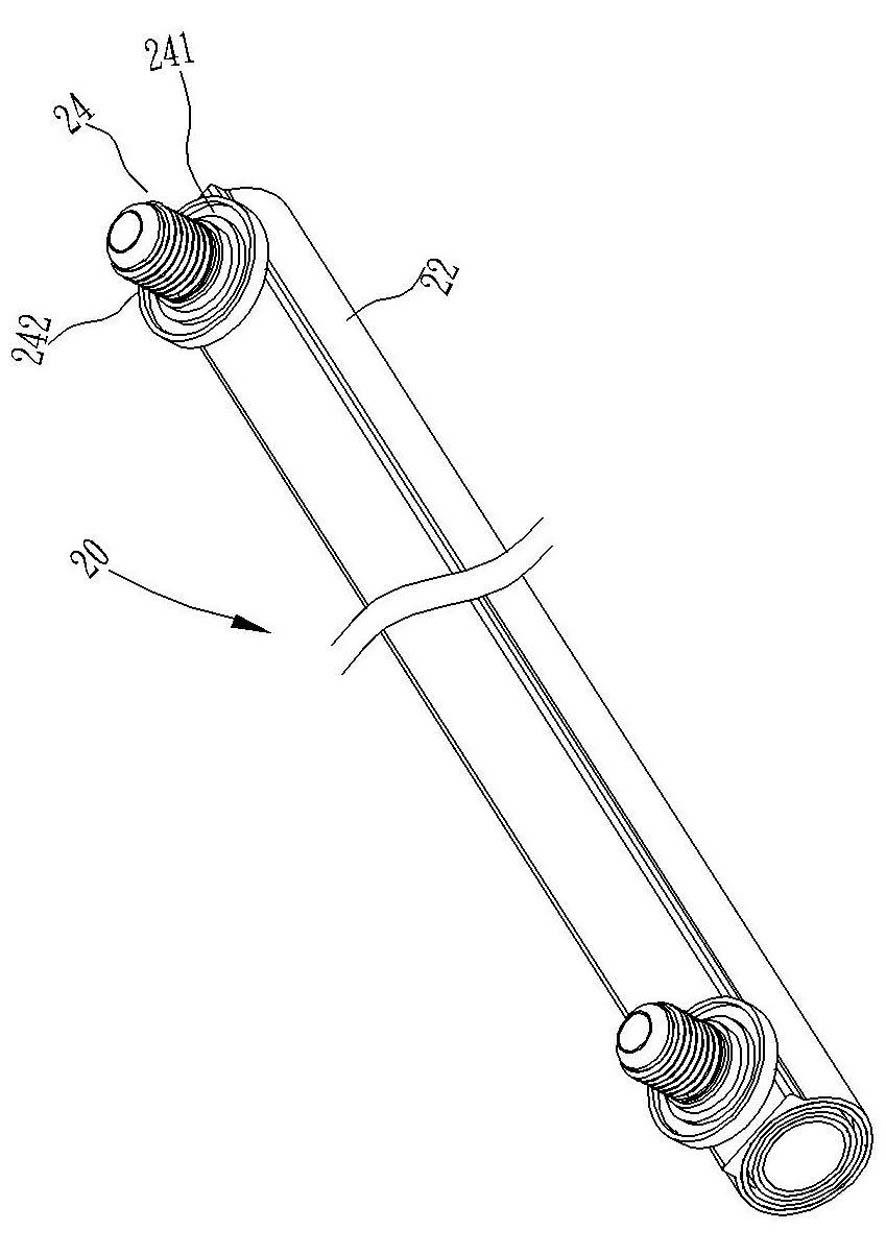

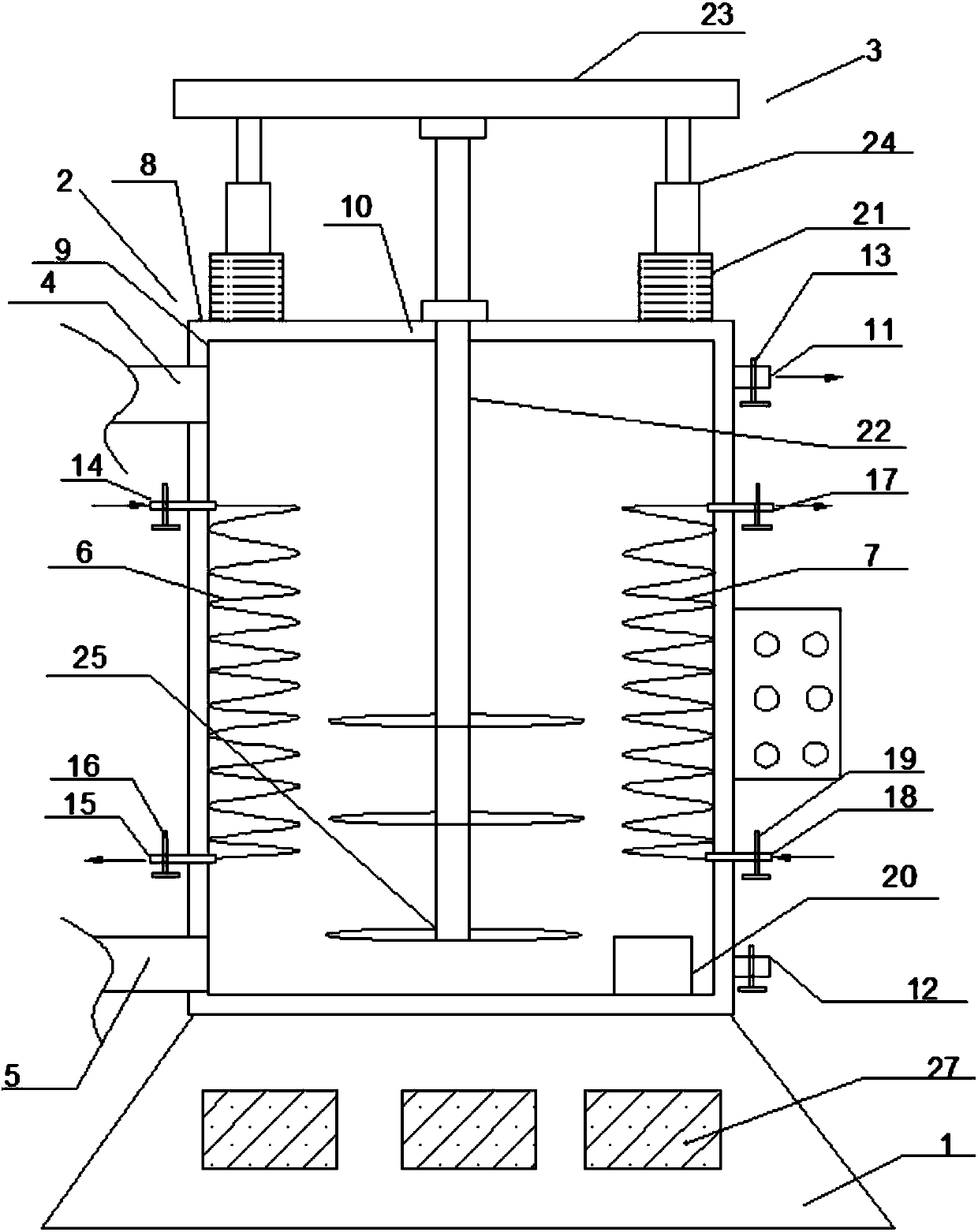

Processing process of cold oil pipe

InactiveCN102179666AImprove welding strengthSufficient gravitySoldering apparatusHeat sinkOil cooling

The invention relates to a processing process of a cold oil pipe, comprising the following steps of: manufacturing an inner pipe and an outer pipe from aluminum materials, and clamping a heat-radiating fin manufactured from the aluminum materials and provided with a plurality of heat-radiating holes between the inner pipe and the outer pipe; then matching with an oil cooling pipe with lighter weight, which is integrally combined in an inner pipe expanding manner; processing a plurality of screw seats and an end cover through the aluminum materials; and arranging a welding part and projecting a hollow combining end on the bottom end of the screw seat to form an oil inlet and an oil outlet which are communicated with an oil inlet pipe and an oil outlet pipe with through holes. The invention has the advantages of simplified manufacturing process, lower manufacturing cost, lower material cost and lighter product by being manufactured from the aluminum materials, higher heat-radiating efficiency, sufficient temperature reduction of engine oil, sufficient engine tractive force, reasonable conception, easy implementation, high practicability, popularization application, and the like.

Owner:东莞吉旺汽车零件有限公司

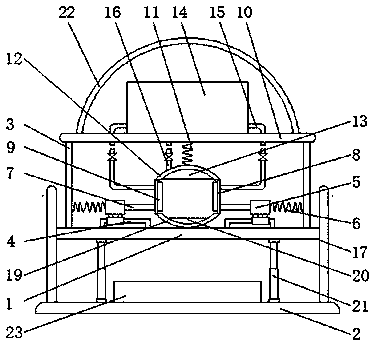

Temperature-controllable reaction kettle

InactiveCN107837772AUniform temperatureRapid coolingShaking/oscillating/vibrating mixersTransportation and packagingTemperature controlEngineering

The invention discloses a temperature-controllable reaction kettle. The reaction kettle comprises a support frame with a buffering effect, a kettle body arranged on the support frame, a stirring device arranged on a center line of the kettle body, a feeding opening formed in the upper part of the kettle body, a discharging opening formed in the lower part of the kettle body, a first spiral oil bath pipe and a second spiral oil bath pipe, wherein the kettle body comprises an outer-layer kettle body and an inner-layer kettle body; a cooling water tank is formed between the outer-layer kettle body and the inner-layer kettle body; a temperature sensor is arranged in the inner-layer kettle body. According to the temperature-controllable reaction kettle, oil bath flowing directions of the firstspiral oil bath pipe and the second spiral oil bath pipe are opposite, so that reactants in the reaction kettle can be uniformly heated; through adoption of the cooling water tank, the first spiral oil bath pipe and the second spiral oil bath pipe can be used for heating, the reactants can be heated and can also be used for cooling the mixture in the reaction process also can be cooled; the dual accurate temperature control of the inside and the outside of polymerization reaction is achieved.

Owner:CHENGDU KECHUANGCHENG TECH

Router cooling device with automatic dust removal function

InactiveCN112468890AWith automatic dust removal functionFully cooledDispersed particle filtrationTransportation and packagingDust controlThe Internet

The invention relates to the technical field of the Internet, and discloses a router cooling device with an automatic dust removal function, which comprises a router, the outer part of the router is fixedly connected with a shell, the outer part of the shell is fixedly connected with a box body, and the inner part of the box body is fixedly connected with an annular coil; a supporting rod is movably sleeved with the annular coil, a permanent magnet is fixedly connected to the interior of the supporting rod, fan blades are movably connected to the upper end of the supporting rod, a reciprocating device is movably connected to the lower end of the supporting rod, an air inlet is formed in the box body, and a filter screen is movably connected to the interior of the air inlet; and a trigger device is movably connected to the upper end of the filter screen, an electromagnet is fixedly connected to the right end of the trigger device, a sliding rod is sleeved with the electromagnet, and a brush head is sleeved with the sliding rod. The device has the advantages that the temperature of the router can be reduced, and dust absorbed by the fan can be automatically removed.

Owner:广州云宁实业有限公司

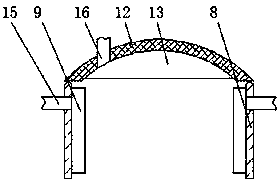

Convenient emergency nursing head cooling device

InactiveCN110840647AEasy to usePracticalTherapeutic coolingTherapeutic heatingHead coolingStructural engineering

The invention discloses a convenient emergency nursing head cooling device, which relates to the field of nursing cooling equipment and comprises a supporting plate and a bottom plate, wherein vertical plates are fixedly connected to both sides of the top of the supporting plate; sliding rails are fixedly connected to both sides of the top of the supporting plate and positioned between the two vertical plates; sliding blocks are slidably connected to the outer surfaces of the two sliding rails; first elastic pieces are fixedly connected to the opposite sides of the sliding blocks and the vertical plates; cross bars are fixedly connected to the opposite sides of the two sliding rails; first moving plates are fixedly connected to one end, far away from the sliding blocks, of the cross bars;first sponge layers are arranged on the opposite sides of the two first moving plates; and a top plate is fixedly connected to the top of the two vertical plates. The device can rapidly and fully coolthe head of a patient in the emergency nursing process, the use is facilitated, the device better ensures the cooling work of the head of the patient, has strong practicability, and can recycle waterin the cooling process to save water resources.

Owner:徐红玲

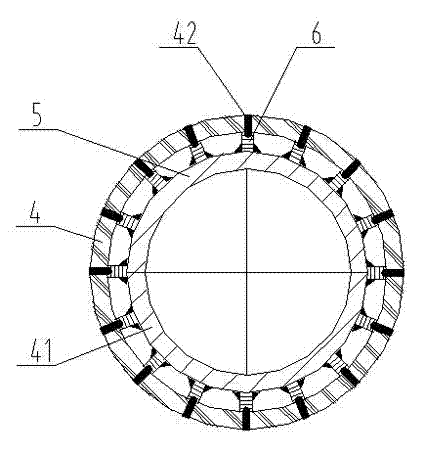

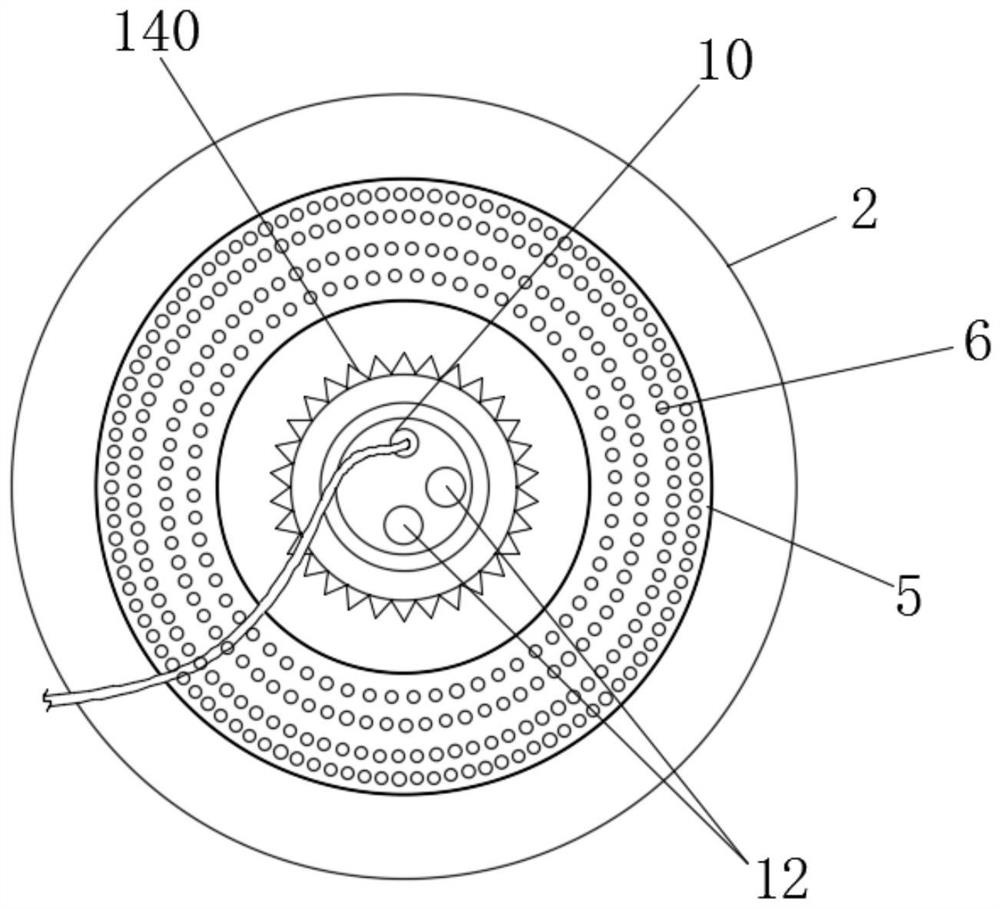

Outer rotor brushless motor heat dissipation assembly

ActiveCN113765298ADifferent cooling effectsImprove cooling effectElectric machinesCleaning using toolsBrushless motorsElectric machine

The invention relates to the technical field of motor heat dissipation, in particular to an outer rotor brushless motor heat dissipation assembly which comprises a motor shaft, a shell, a stator and a rotor, the left end opening and the right end opening of the shell are fixedly installed on the motor shaft through bearings, the stator is fixedly installed on the motor shaft, and the rotor is arranged on the periphery of the stator. The rotor is fixedly installed in the middle of the inner side of the shell, and a belt wheel is installed on a protruding pipe opening in the left side of the shell. Different from the prior art, according to the invention, the fan blades on the right side are improved to be electrically-driven heat dissipation fan blades, the rotating speed of the fan blades is not related to the rotating speed of the brushless motor, the fan blades are independently driven, the rotating speed of the fan blades can be adjusted according to needs to change the air inlet flow speed, and different heat dissipation effects are achieved; and according to the invention, the heat exchange pipes are arranged on the two sides of the motor shaft, and air cooling is combined, so that the air flow entering the shell is cooled, heat is directly taken away through the low-temperature air flow while cooling is conducted through heat exchange, and the heat dissipation effect of liquid cooling is greatly improved through the design mode.

Owner:安徽智鸥驱动科技有限公司

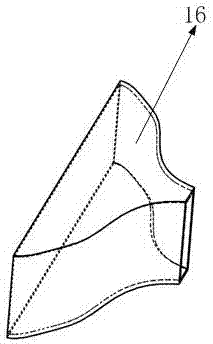

Shrinkage-type arc extinguishing mechanism for power circuit breaker

ActiveCN107039201AFully cooledExtinguish as soon as possibleElectric switchesPower circuitsElectrical and Electronics engineering

The invention belongs to the technical field of power circuit breakers, and especially relates to a shrinkage-type arc extinguishing mechanism for a power circuit breaker. The mechanism comprises an air cylinder, a push rod, a swinging rod, a power fixed end, an electric car guide plate, outer plates, inner plates, a fin, and a piston, wherein the swinging rod and the power fixed end are separated to generate an arc, and the arc moves to the fin. Meanwhile, the swinging rod pushes the piston to compress air to enter an air channel which is formed by the first outer and first inner plates and the second outer and inner plates, and the air flows into a cavity formed by the first and second inner plates through an air hole. When the arc makes contact with the fin, an insertion piece of the fin enables the arc to be isolated, and the discharged air carries out the cooling of the fin and the arc. The two sides can enable the arc to be fully cooled, and to be quickly distinguished. In addition, the insertion piece at the rear end of the fin can prevent arcs from joining together again, and enables the separated arcs to be further isolated by the fin at the rear end. The mechanism is better in use effect.

Owner:南京全屋电器开关有限公司

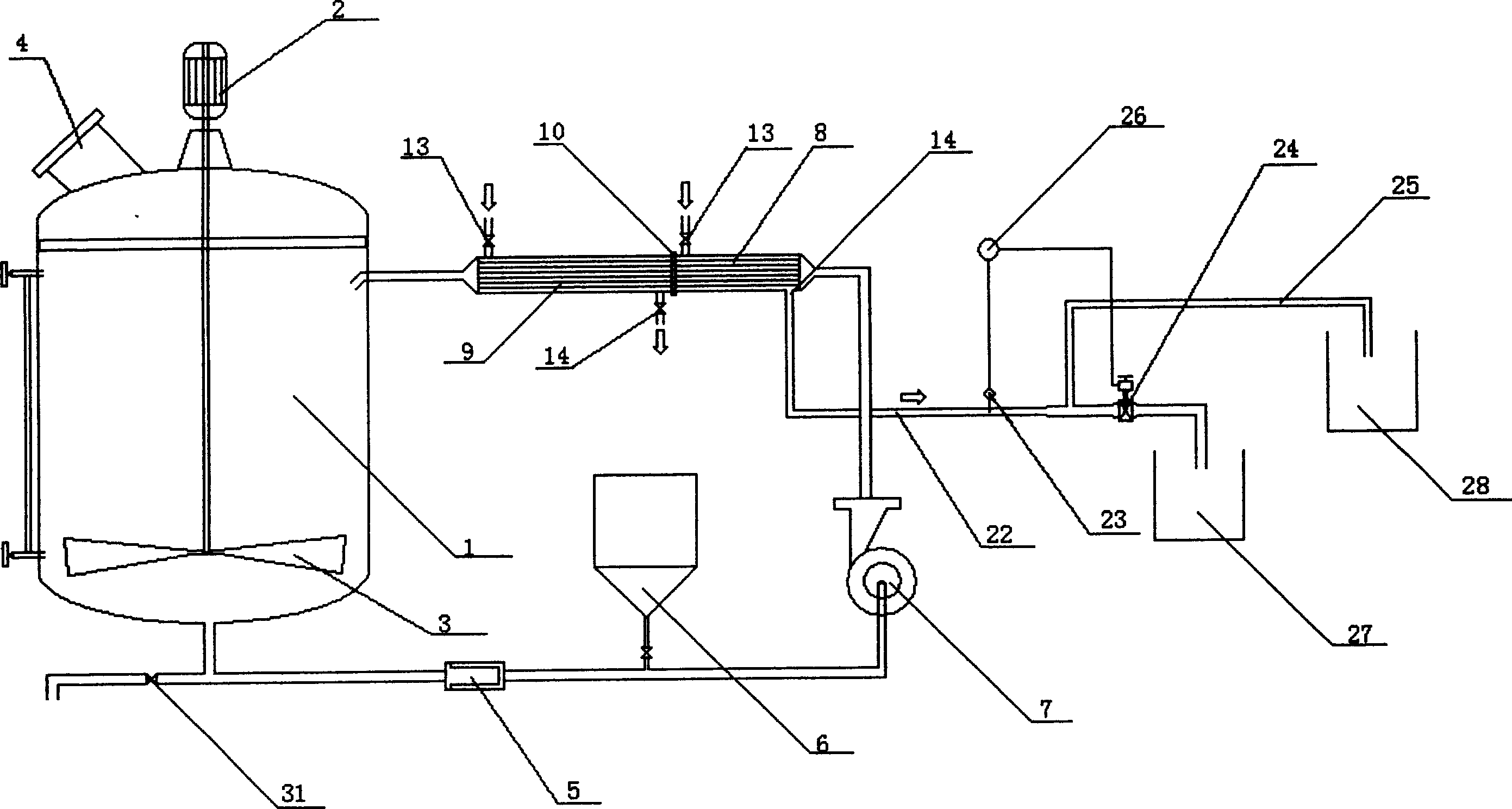

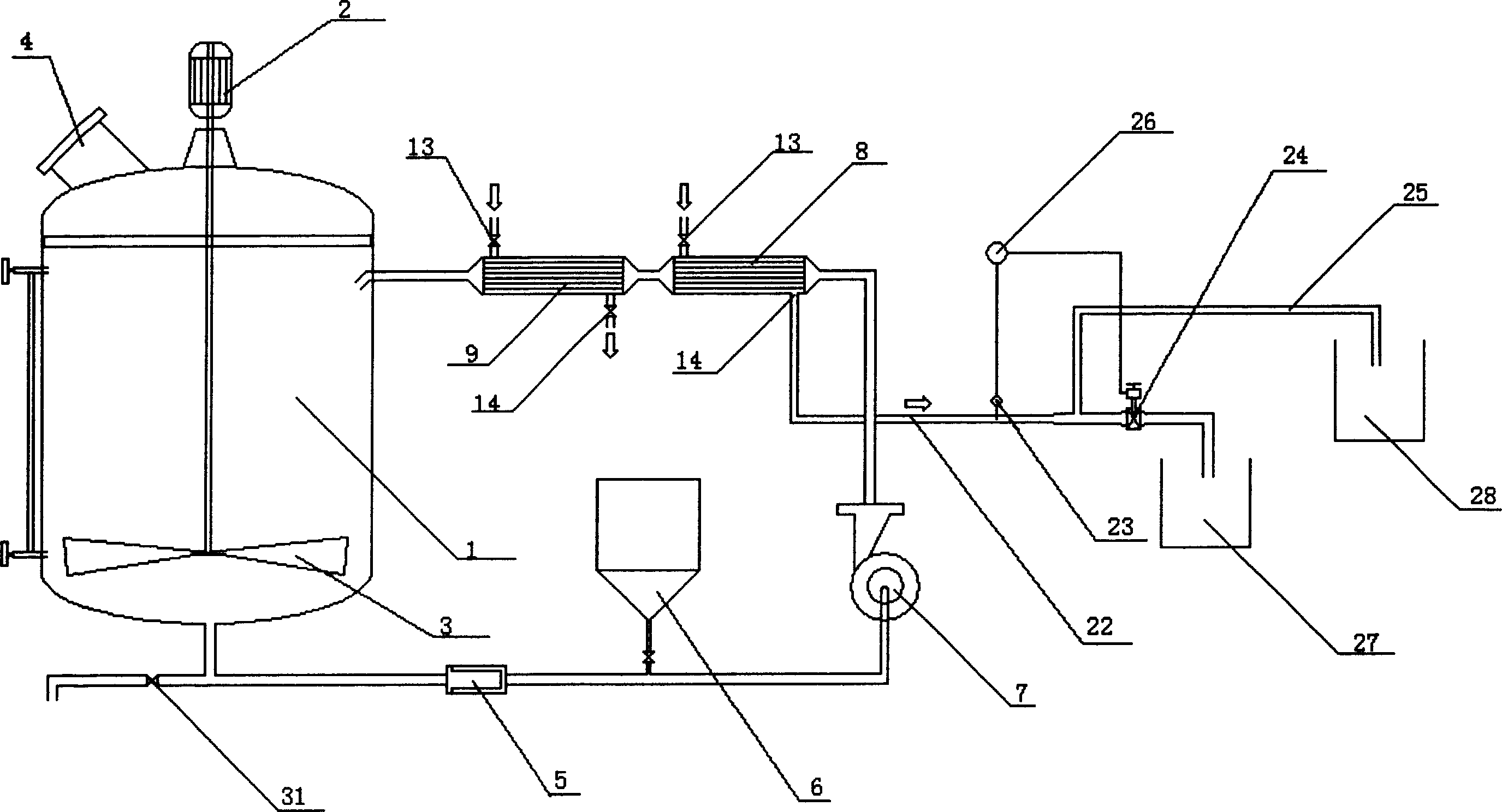

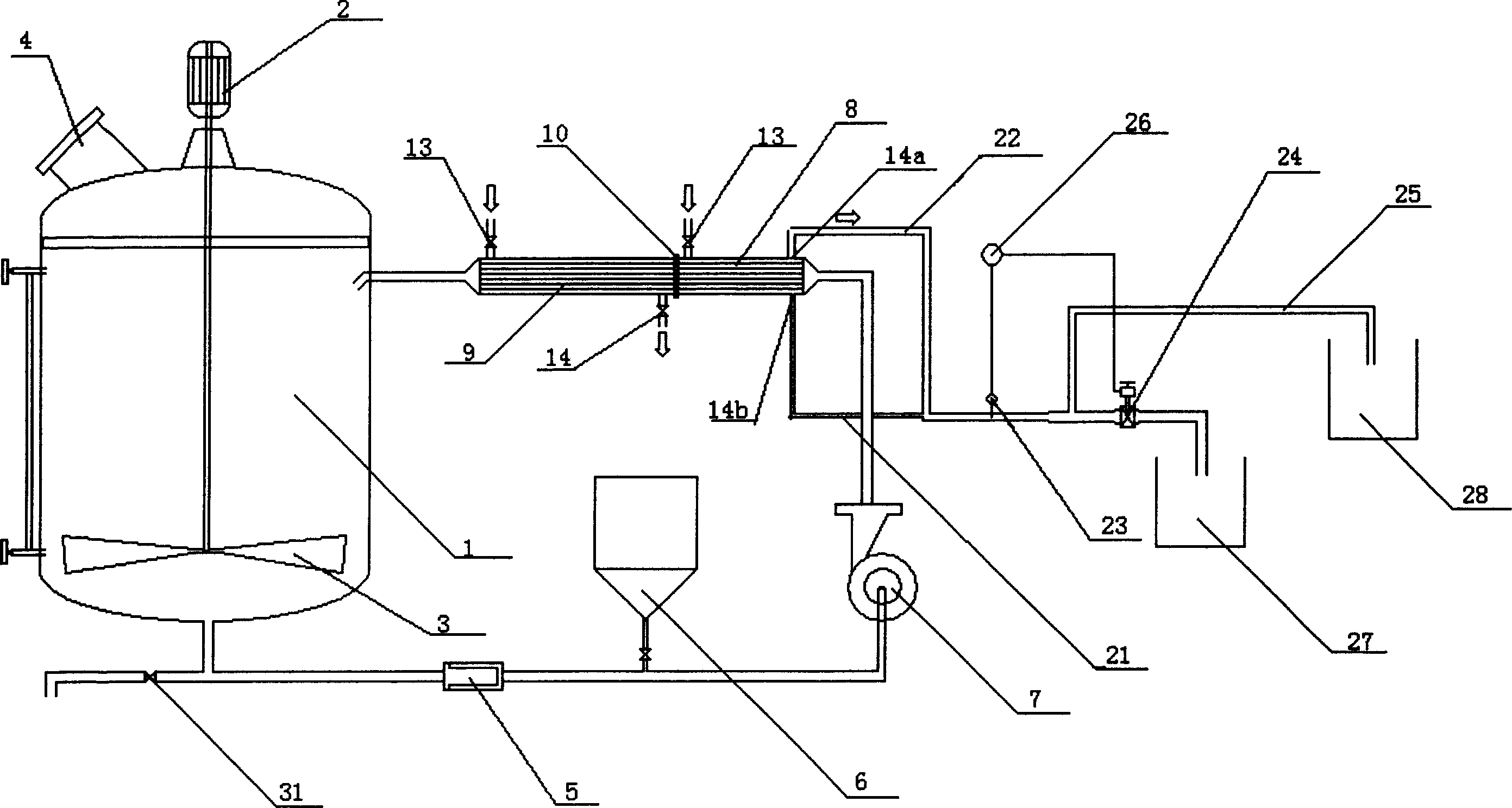

Oil heating and heat recovering reaction pot

InactiveCN1772367AReduce volumeRelieve pressureFlow mixersRotary stirring mixersThermal energyEngineering

The present invention discloses one kind of oil heating and heat recovering reaction pot, and belongs to the field of chemical material processing apparatus technology. The oil heating and heat recovering reaction pot includes a pot body, a filter and a circulating water pump connected successively, as well as combined or serially connected water cooling heat exchanger with shunt and oil heating heat exchanger connected between the pot body and the circulating water pump. By means of the water cooling heat exchanger and the oil heating heat exchanger, the mixed liquid may be cooled and heated to the required temperature, and the water exhausted from the heat exchanger may be made to flow into the hot water or cold water returning unit to utilize the heat energy fully.

Owner:劳关明

Generating set heat radiation apparatus

InactiveCN105050354AIncrease contact areaImprove absorption and deliveryCooling/ventilation/heating modificationsRadiationGenerating unit

The invention discloses a generating set heat radiation apparatus. The apparatus comprises a heat radiation water tank. The bottom of the heat radiation water tank is provided with a water tank outlet. A hollow cooling water tower with an open upper end and an open lower end is arranged above the heat radiation water tank. The upper part of the cooling water tower is provided with a water tank inlet. A cooling water fan is arranged in the upper end opening of the cooling water tower. A diversion tower is connected inside the cooling water tower. The diversion tower is arranged under the water tank inlet. A heat conduction column is arranged on the heat radiation water tank. Radiation poles are connected on the heat conduction column. The top of the heat conduction column is connected with a cooling water tank. Cooling water rings are communicated on the circumference of the cooling water tank. The invention aims to provide the generating set heat radiation apparatus which achieves multi-way heat radiation and improves the heat radiation speed.

Owner:SUIYANG HUAFENG ELECTRICAL APPLIANCE

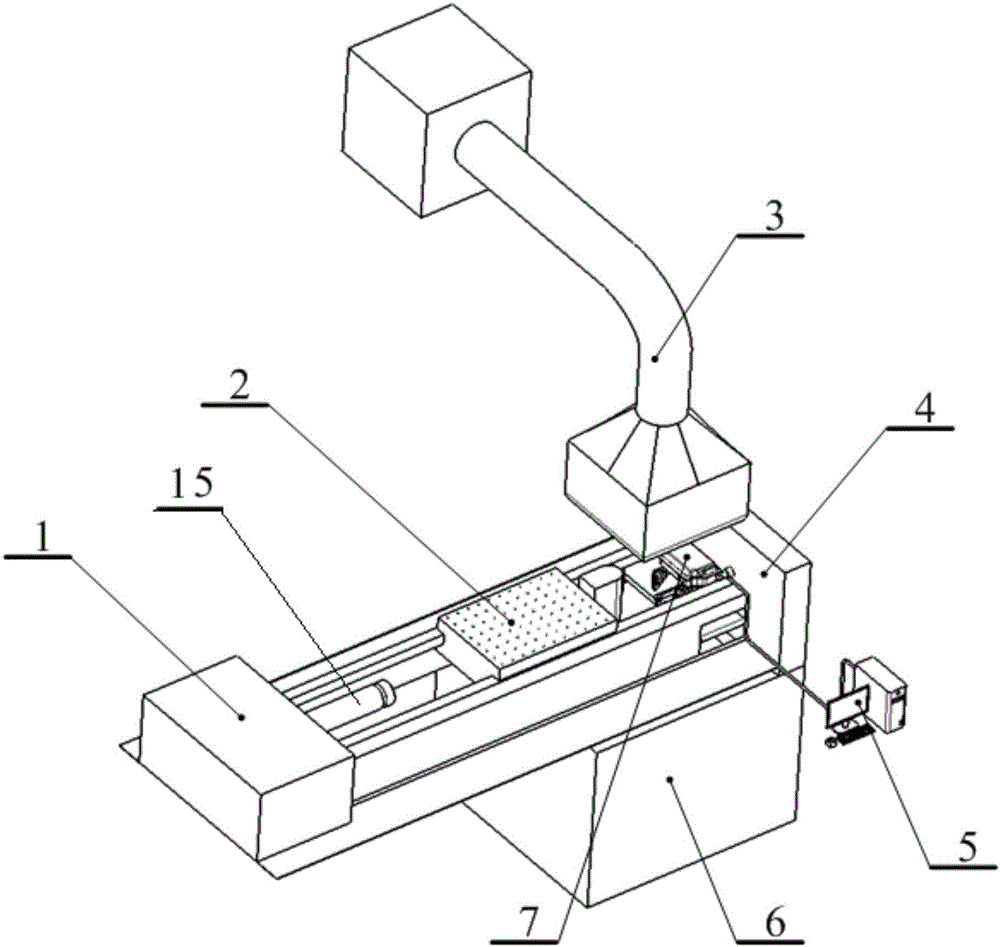

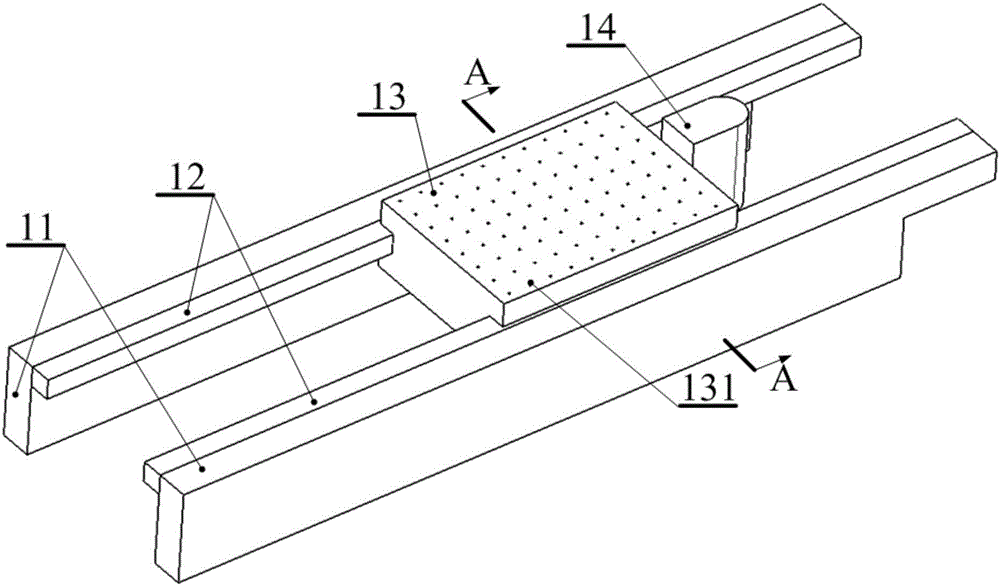

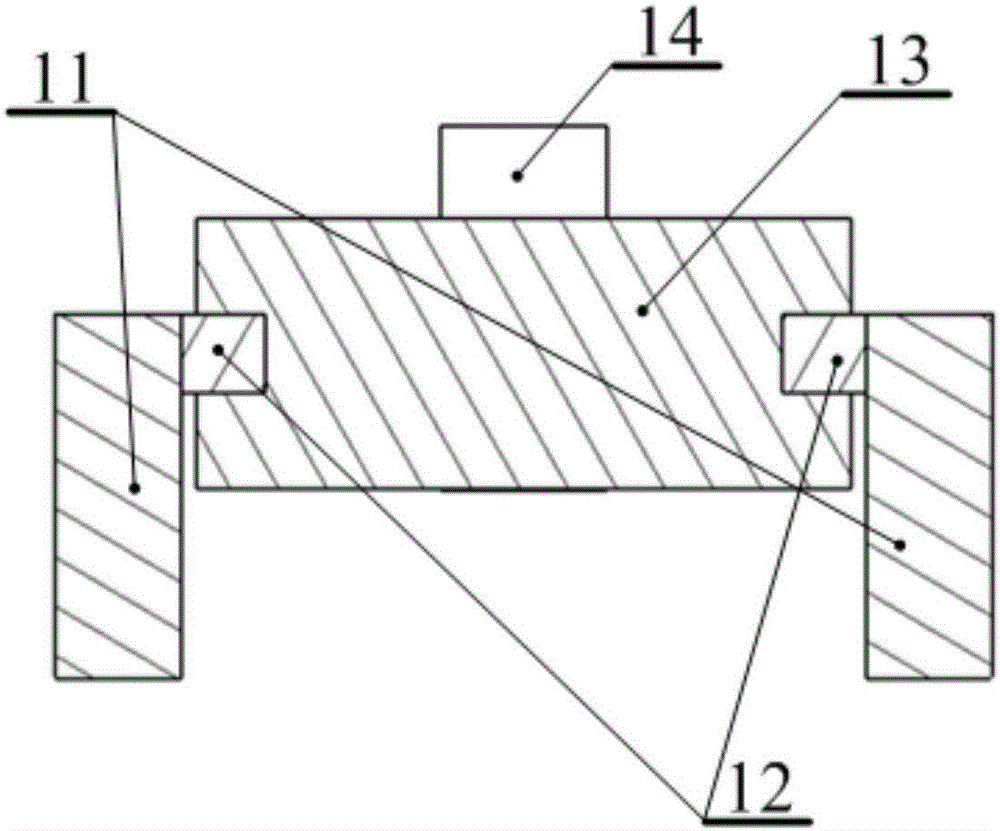

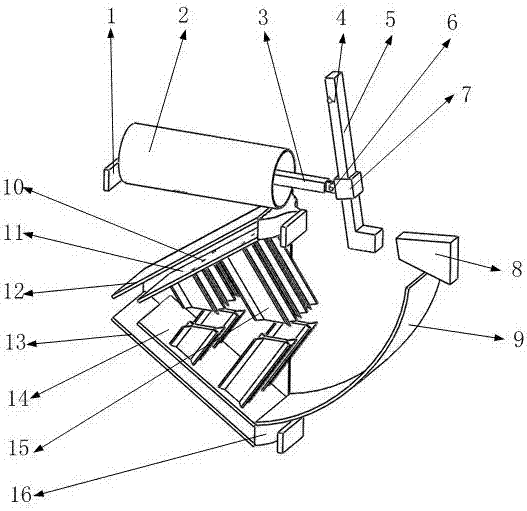

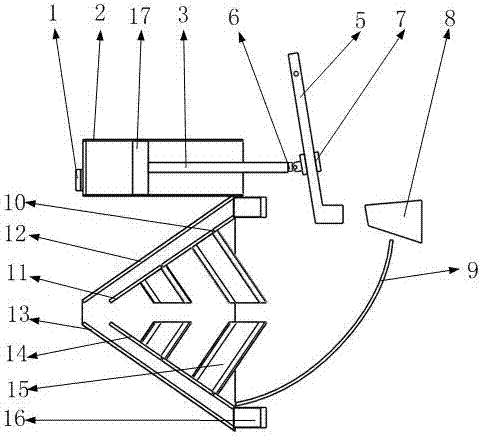

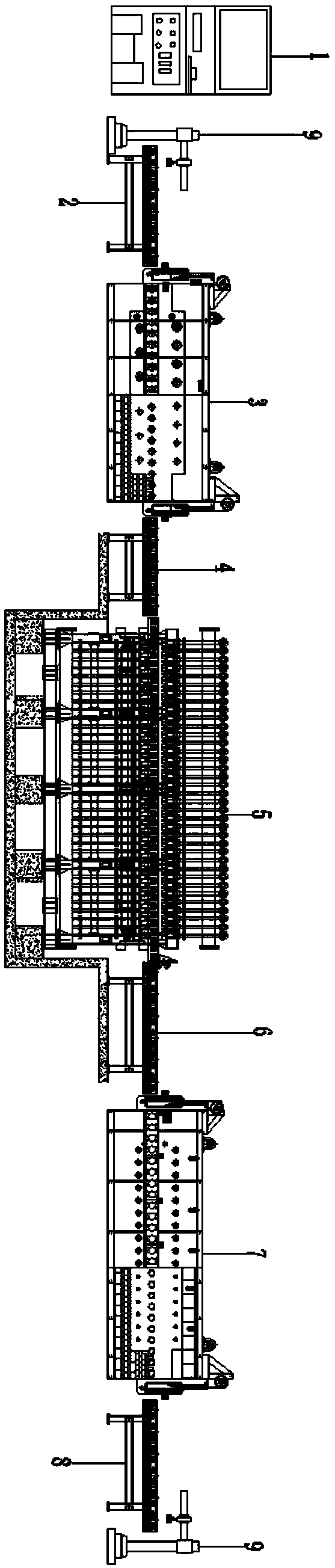

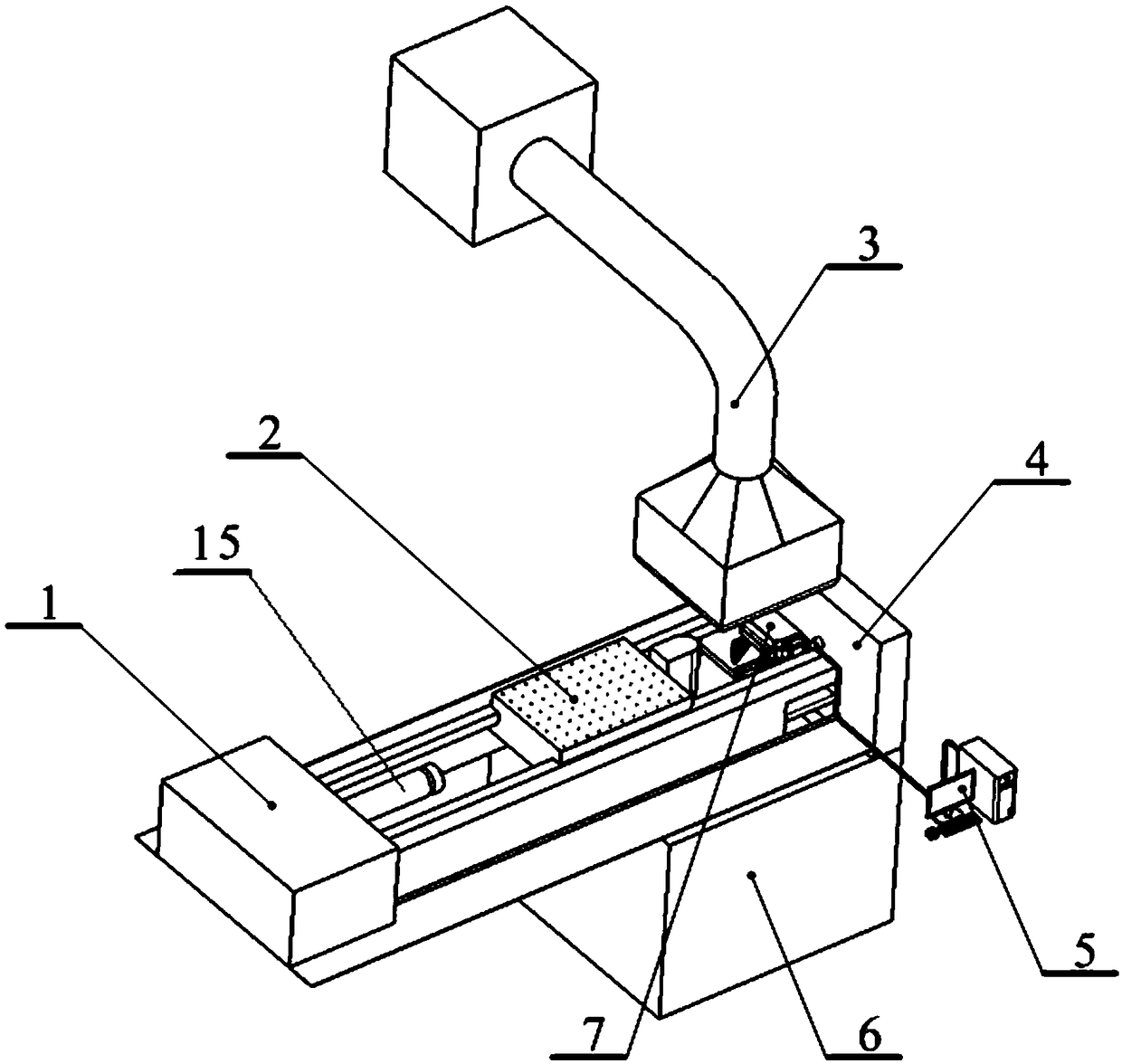

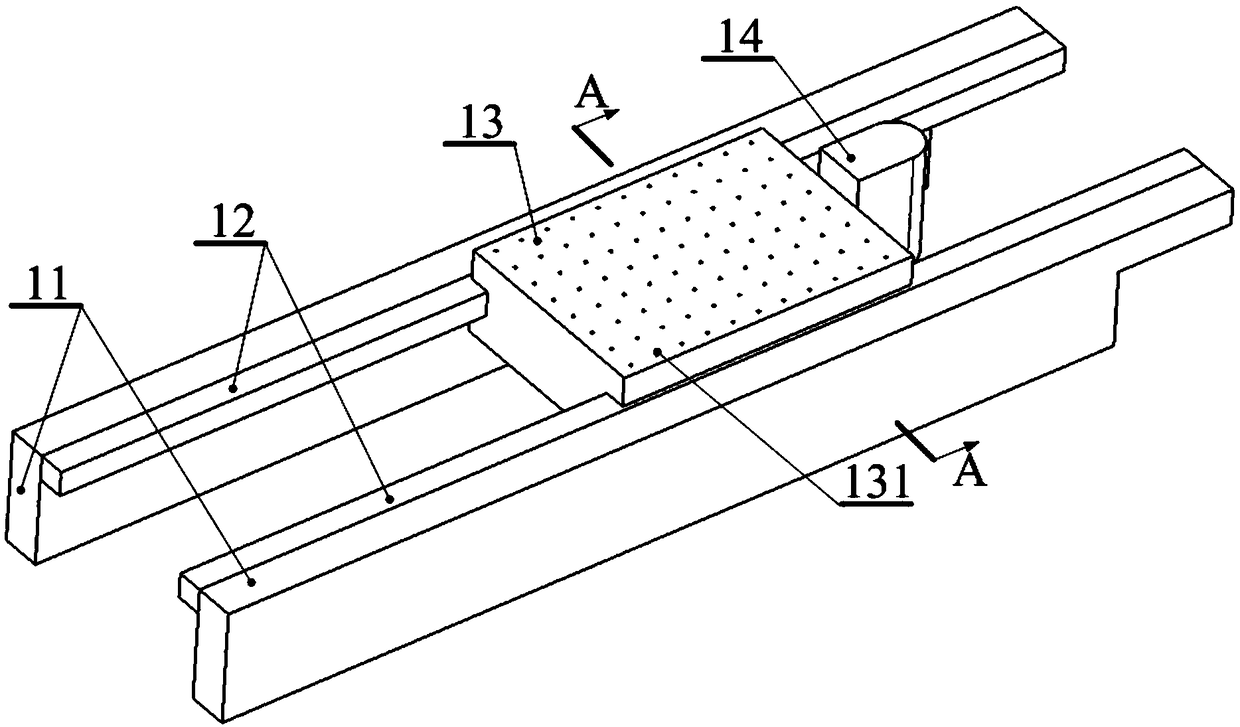

Heat treatment production line for high-strength stainless steel plate

InactiveCN108929939ARealize full-line automatic operationImprove the level of intelligenceFurnace typesHeat treatment furnacesProduction lineSheet steel

The invention discloses a heat treatment production line for a high-strength stainless steel plate. Middle control using heat treatment operation terminal and feeding and discharging using grabbing manipulators cooperate with a sensing device on every apparatus, so full-line automatic running and unattended production are realized, the intelligent level is high, the heat treatment efficiency is high, the production capacity reaches 3800 tons / year, the heat treatment quality is high, and the flatness is not more than 2 mm / m<2>. The production line has the advantages of novel overall design, properness in material selection, perfect structure, high working stability, and realization of automatic heat treatment of 420J2 and other ultrathin high-strength stainless steel plates, effectively controls the quenching deformation to ensure that the flatness meets use requirements, fills in a domestic technical gap, reduces the use cost of related users, gets rid of the import dependence on Germany and Japan, has great industrial values, and is a production line suitable for steel plate heat treatment.

Owner:京港工业炉科技(苏州)有限公司

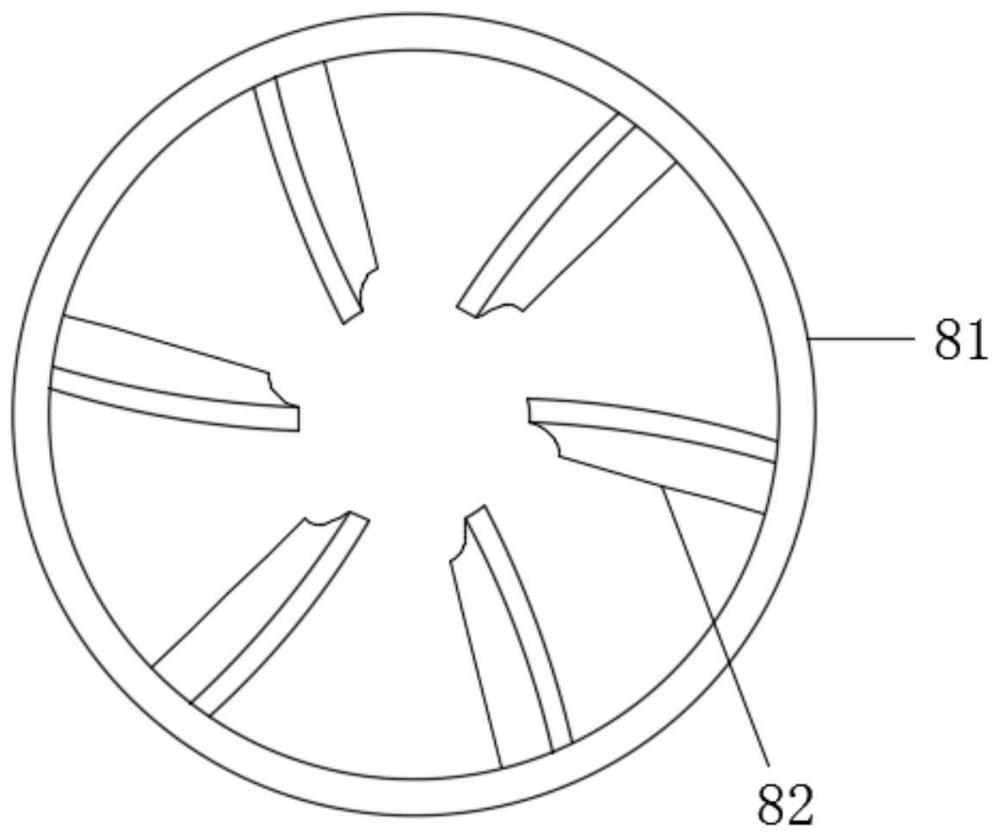

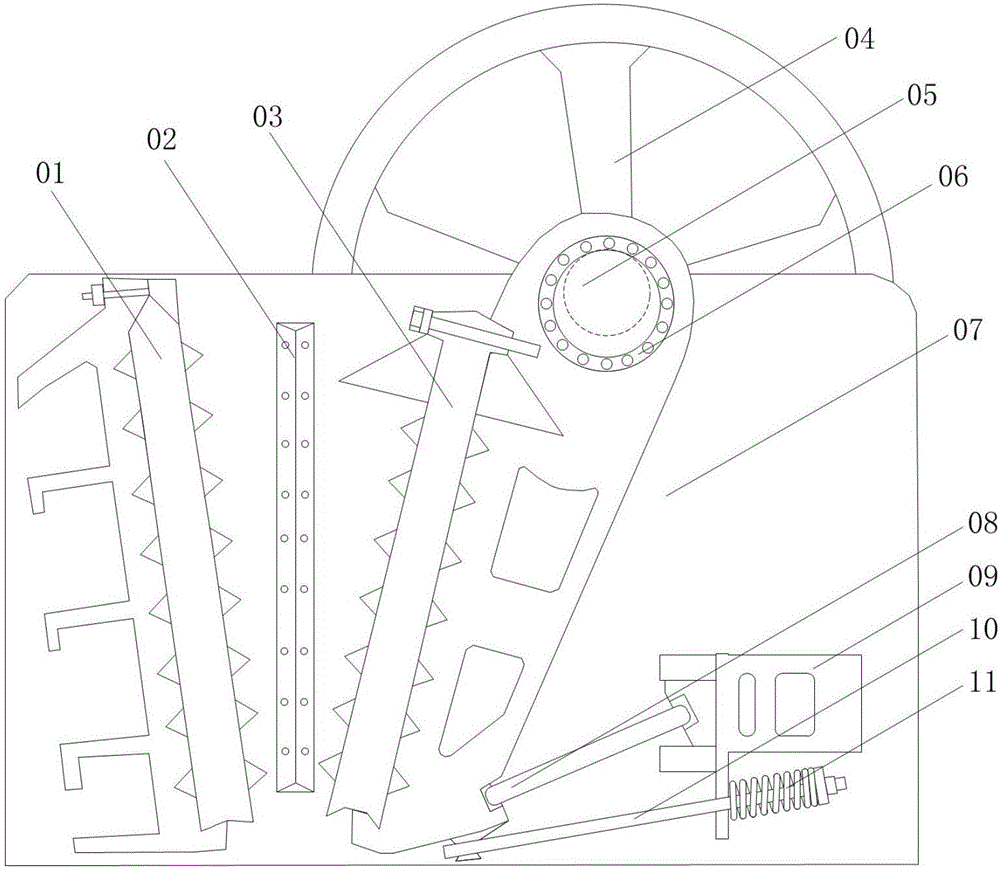

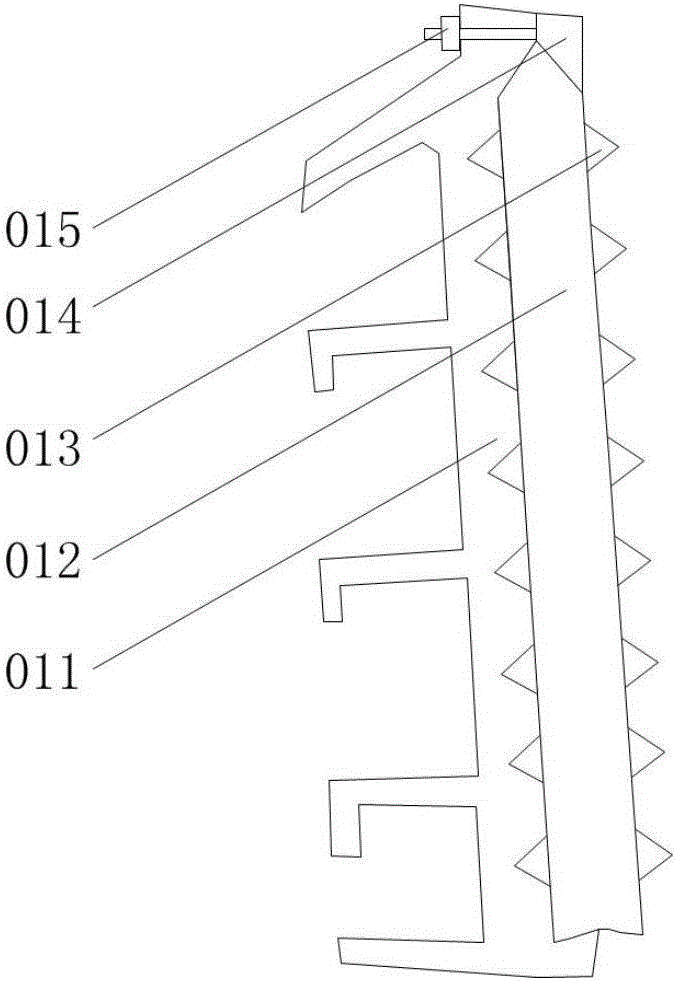

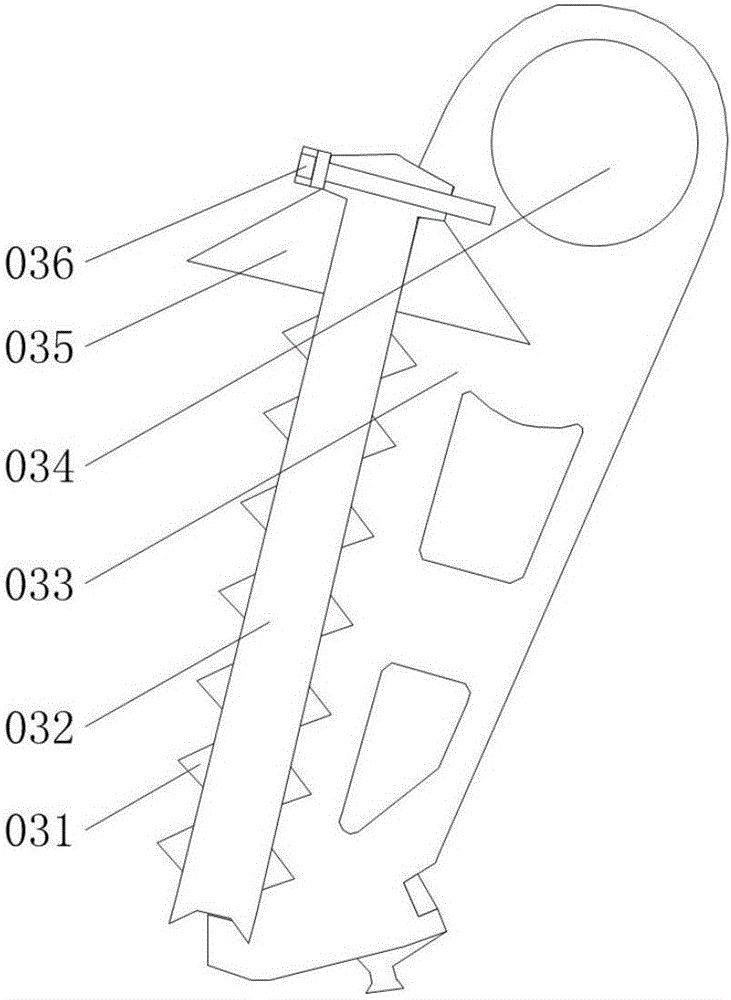

Jaw crusher

PendingCN106622460AImprove crushing effectImprove crushing efficiencyGrain treatmentsMoving jawEngineering

The invention discloses a jaw crusher. The jaw crusher comprises a rack, a motor, a belt pulley, an eccentric shaft, a bearing, a moving jaw set, a fixed jaw set, a wrist plate, an adjusting seat, a pull rod, a spring, water spray pipes, saw blades and saw blade bolts. The water spray pipes are vertically arranged on the inner plate surfaces of side plates of the two sides of the rack correspondingly and located between moving jaw plates and fixed jaw plates. The water spray pipes are each provided with a row of first water spray holes facing the moving jaw plates and a row of second water spray holes facing the fixed jaw plates. First clamping grooves corresponding to the saw blades are formed in moving jaws at the gaps between the moving jaw plates. Second clamping grooves corresponding to the saw blades are formed in mixed jaws at gaps between the fixed jaw plates. Sawteeth of the first saw blade protrude out of the plate surfaces of the moving jaw plates. Sawteeth of the second saw blade protrude out of the plate surfaces of the fixed jaw plates. The jaw crush can improve the crushing efficiency, reduce heating deformation of jaw plates and decrease materials returning from a feed port.

Owner:湖南山瑞重工科技有限公司

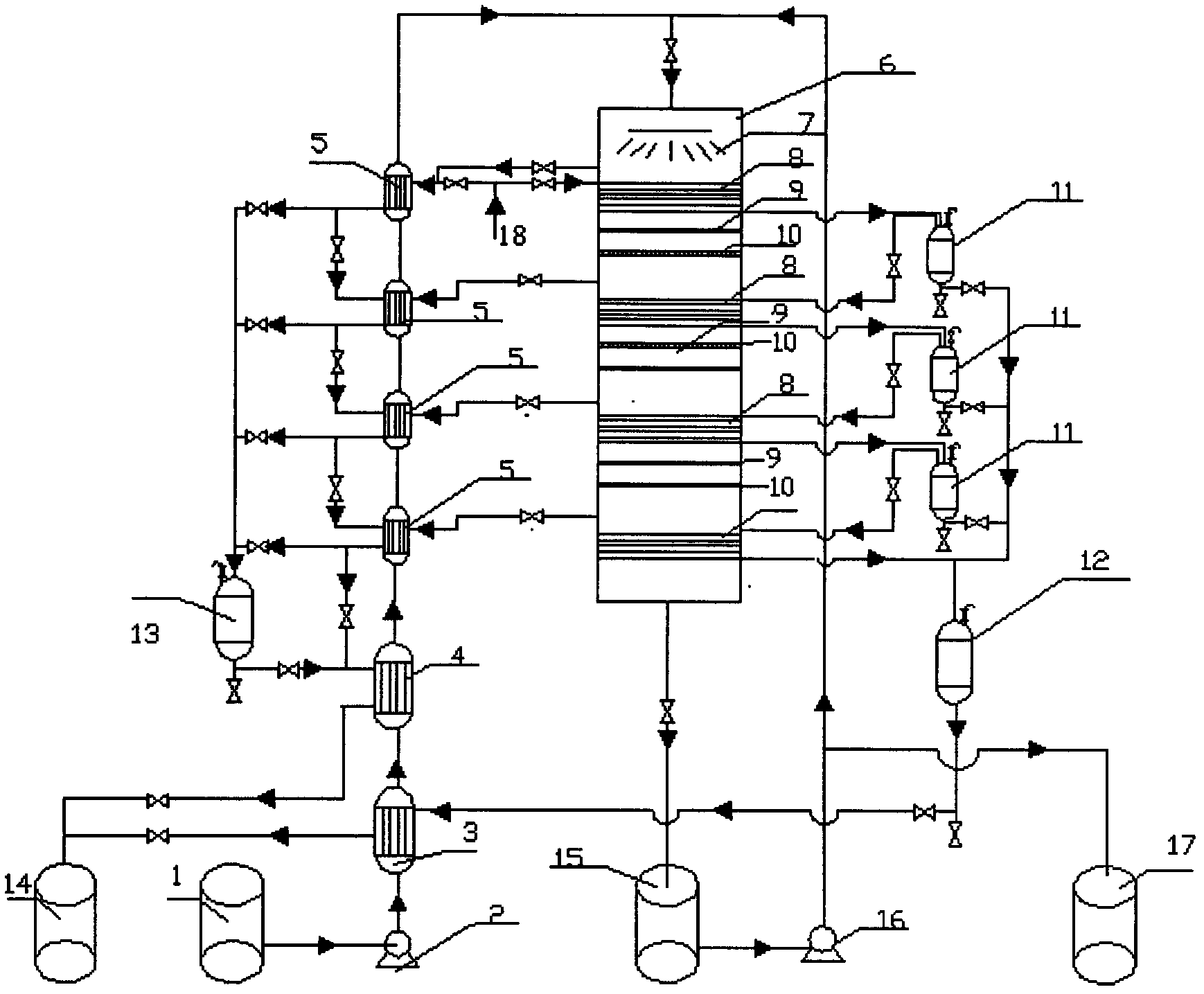

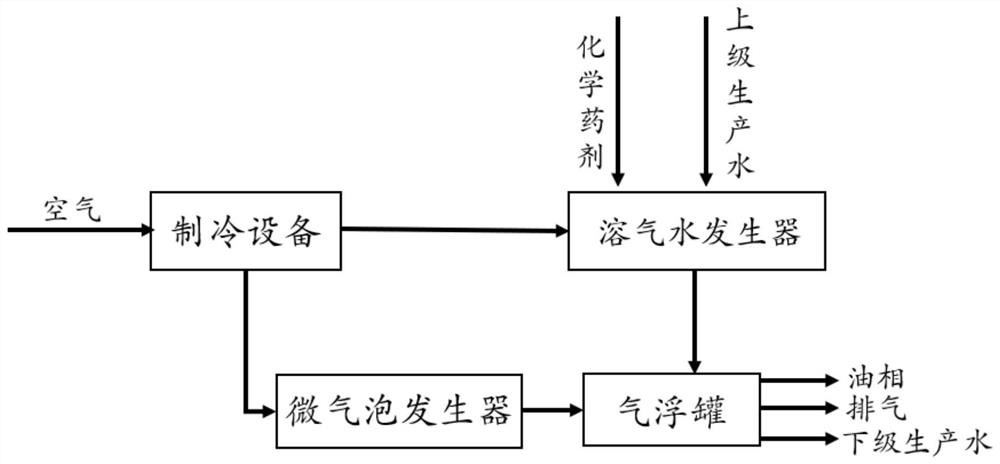

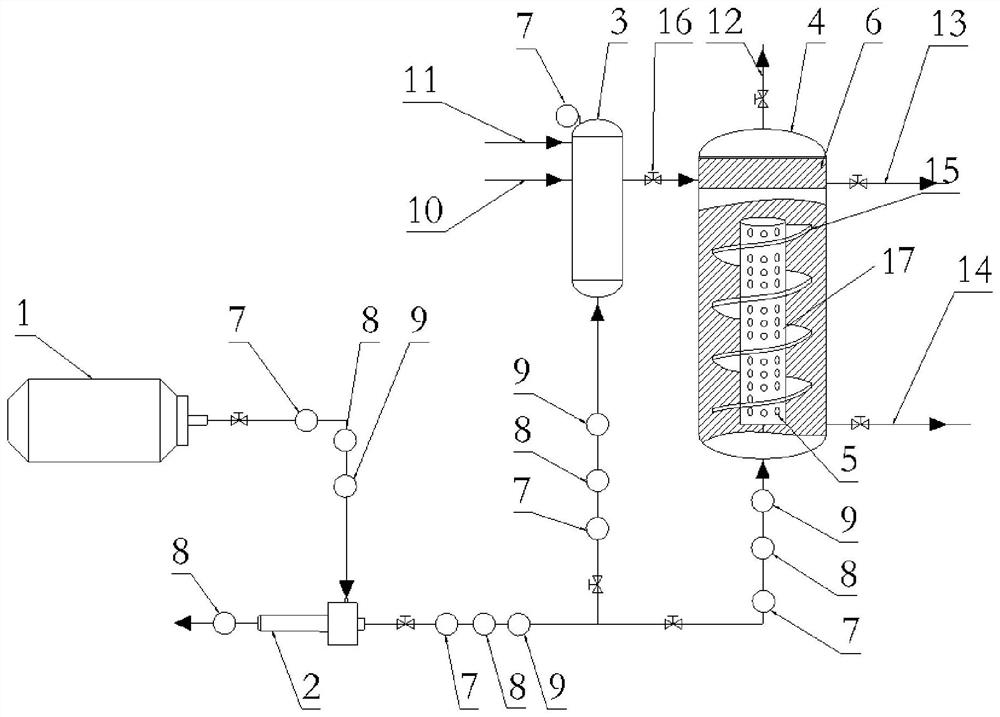

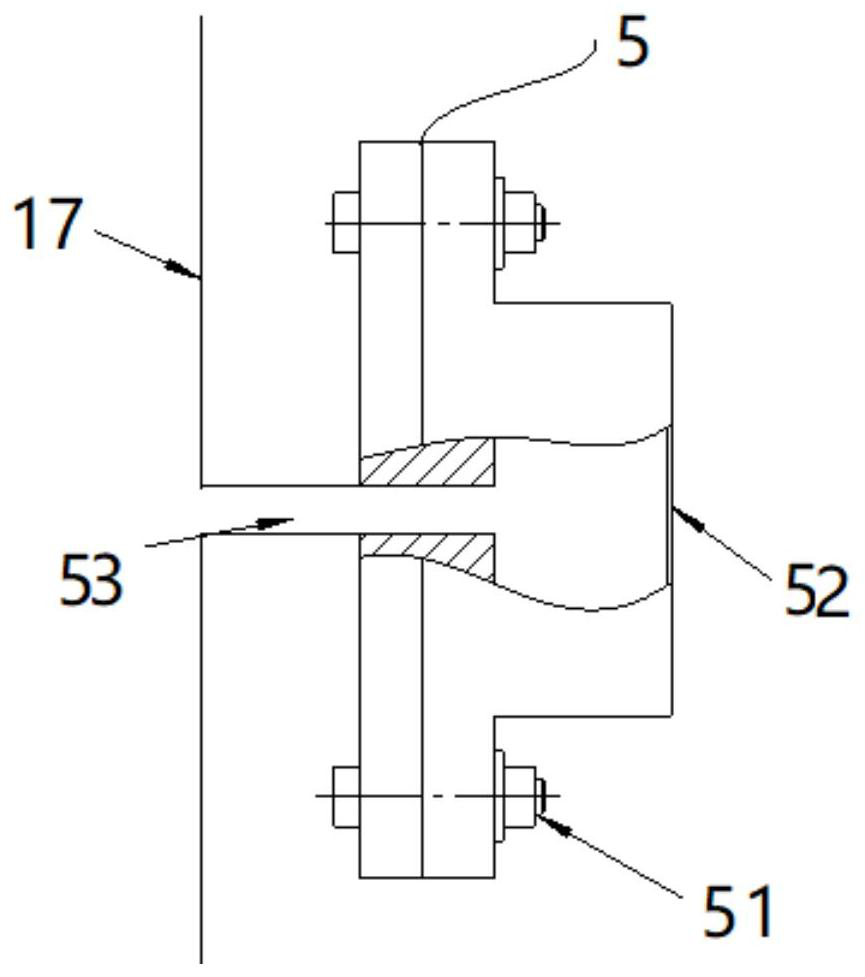

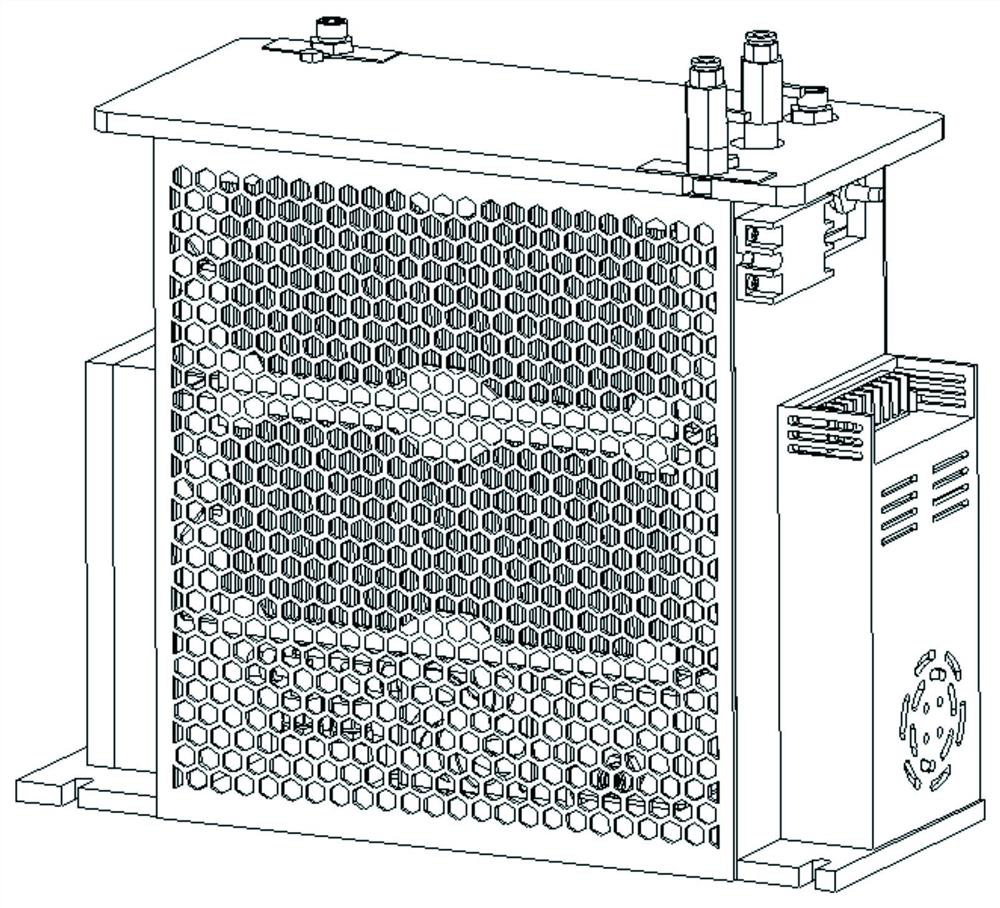

Method and device for removing oil by cold air flotation

PendingCN112357994AImprove air flotation efficiencyReduce usageWater treatment parameter controlFatty/oily/floating substances removal devicesRefrigeration plantMicrobubbles

The invention provides a method and a device for removing oil by utilizing cold air flotation, the method comprises the following steps: cold air prepared by refrigeration equipment is divided into two paths, the first path of cold air is led to a dissolved air water generator containing production water, and the second path of cold air is led to an air flotation tank through a microbubble generator; wherein dissolved oil is separated out from the production water under the action of the first path of cold air, and the first path of cold air is dissolved into the production water under high pressure and released into the air floatation tank through a pressure reducing valve; the second path of cold air generates low-temperature micro-bubbles in the micro-bubble generator, and the low-temperature micro-bubbles enter the air floatation tank to further separate out dissolved oil in the production water; the dissolved-state oil is adhered to the microbubbles, rises and is discharged through the air floatation tank; and the treated production water is discharged from the lower part of the air floatation tank. The device comprises refrigeration equipment, a dissolved air water generatorand a micro-bubble generator which are respectively connected with the refrigeration equipment, and an air floatation tank which is respectively connected with the dissolved air water generator and the micro-bubble generator. The device is simple in structure, economical, efficient and high in adaptability.

Owner:EAST CHINA UNIV OF SCI & TECH

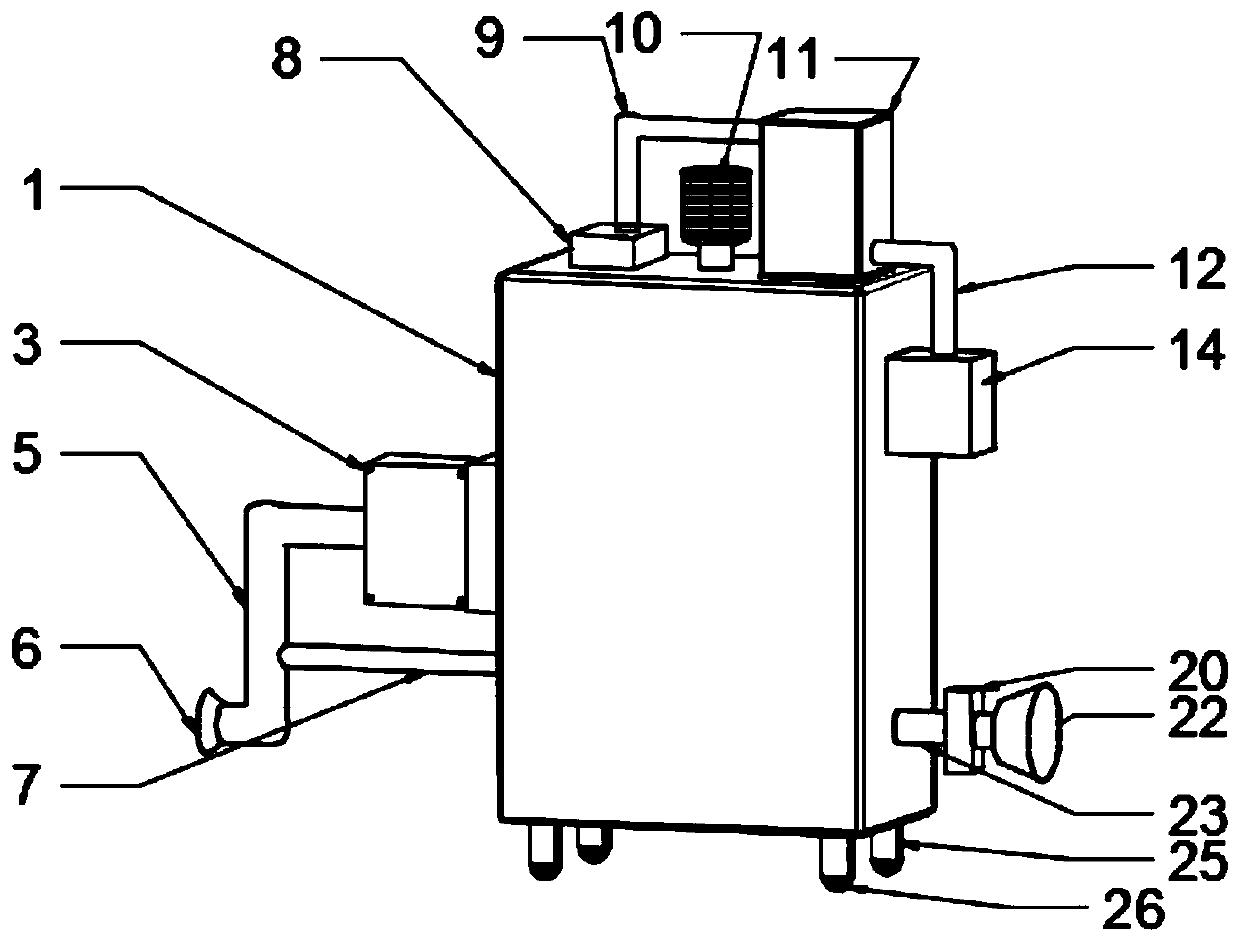

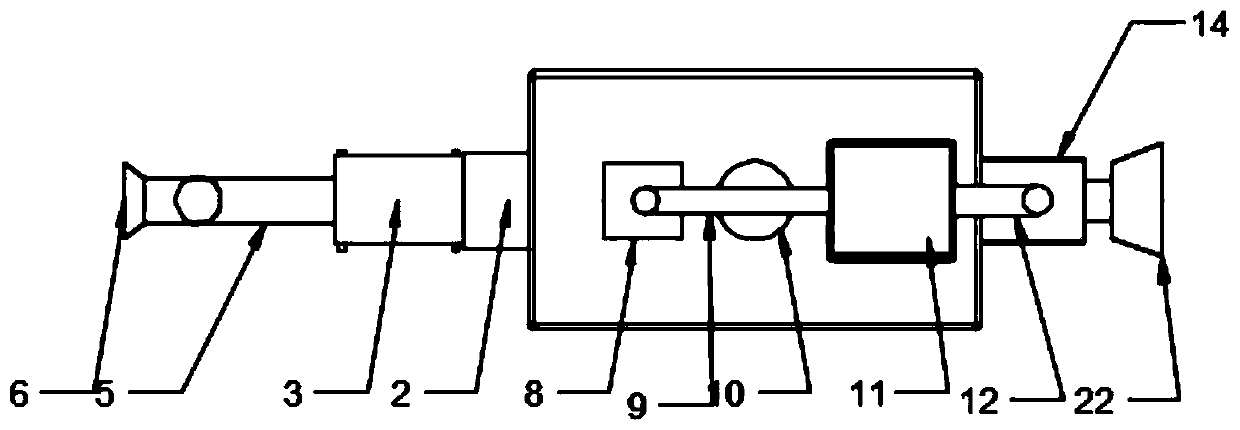

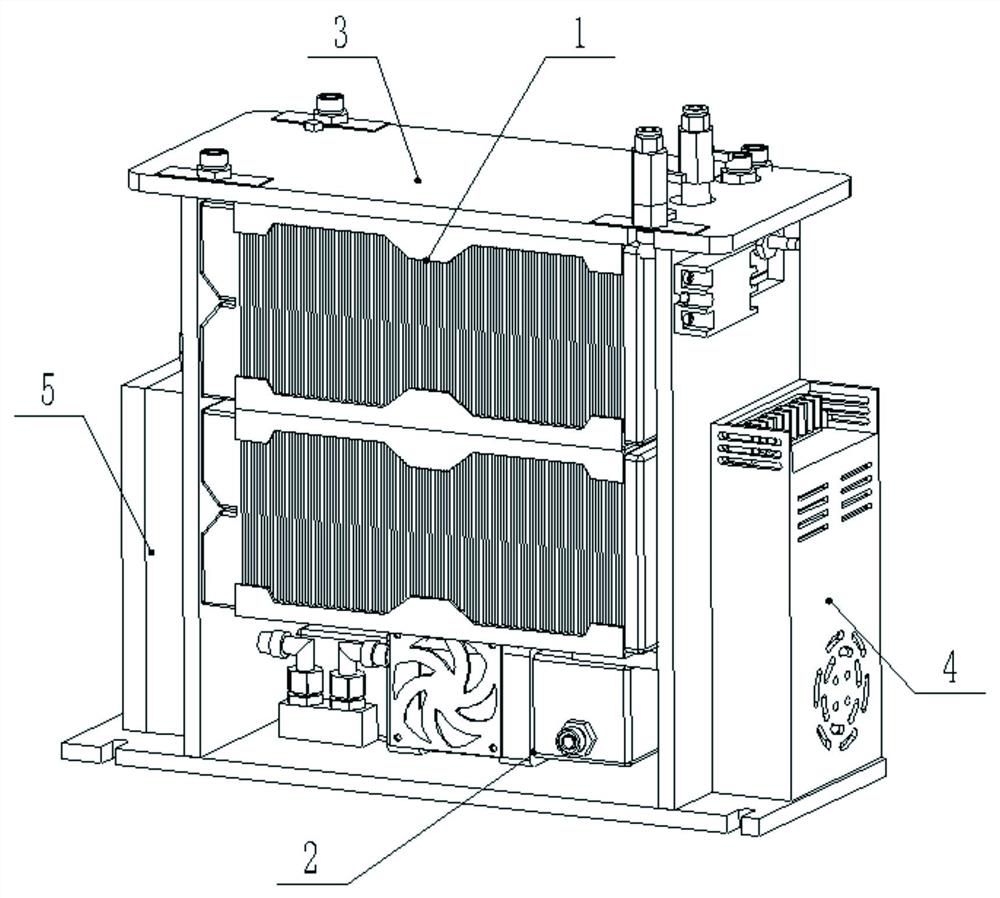

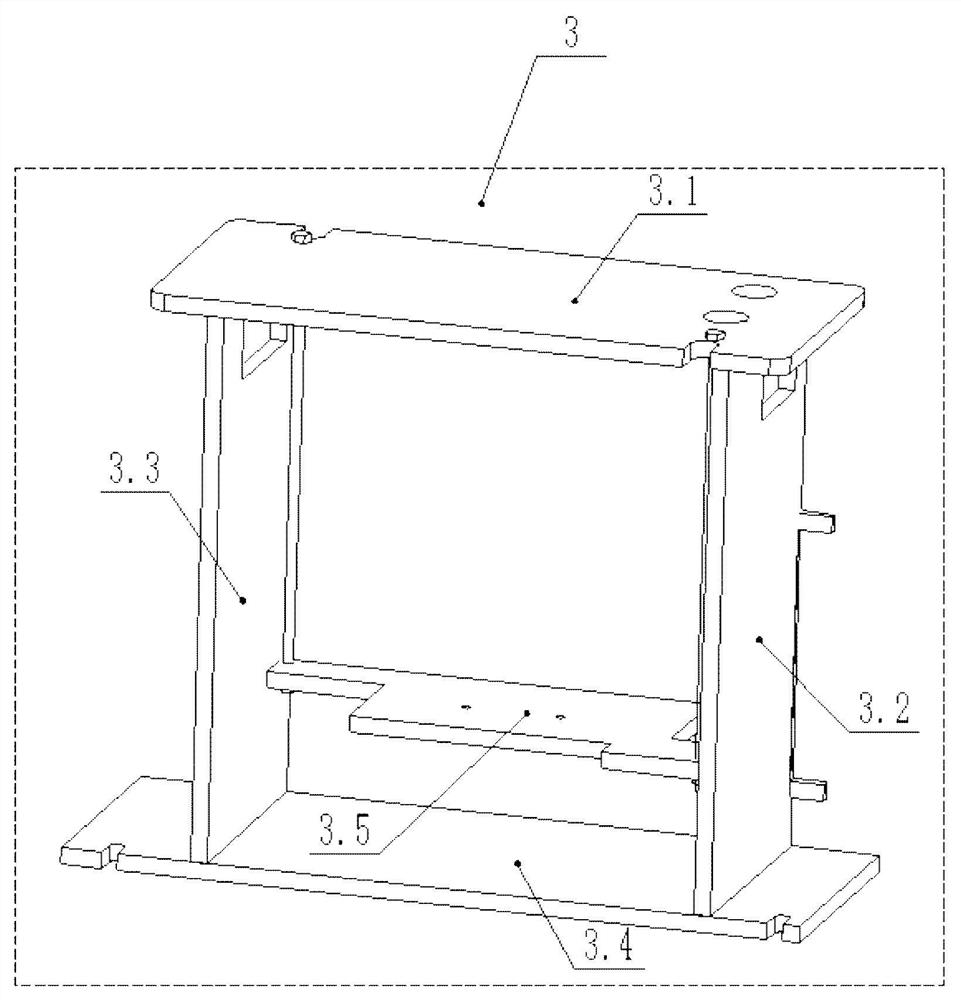

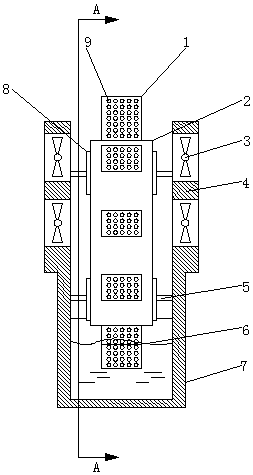

Liquid cooling source of secondary circulation cooling liquid

PendingCN114261295AFully cooledReduce volumeCharging stationsElectric vehicle charging technologyThermodynamicsLiquid storage tank

A liquid cooling source of secondary circulation cooling liquid comprises a cooling unit, a power unit, a case, a power supply and a control unit. According to the power unit, a motor drives a main pump and an auxiliary pump to work at the same time, the main pump drives the cooling liquid to circulate among the liquid cooling source, a liquid cooling charging gun and a cable, the auxiliary pump drives the cooling liquid to circulate and dissipate heat in the liquid cooling source for the second time, and the cooling liquid is fully cooled through the two circulations. According to the liquid cooling source of the secondary circulation cooling liquid, a traditional liquid storage tank structure is removed, a plurality of micro-channel radiators are arranged in the cooling unit, and the multiple micro-channel radiators and the cooling liquid stored in pipelines of a system are utilized, so that the liquid cooling source has the advantage of being small in size, and the liquid cooling source can be perfectly integrated in the charging pile; the micro-channel radiator arranged in the cooling unit has excellent heat dissipation performance, and the requirements of the charging pile for the volume, cooling efficiency, working energy consumption and working reliability of the liquid cooling source are fully met.

Owner:LUOYANG ZHENGQI MACHINERY

A battery pack impact test device

ActiveCN106323577BEffective fire extinguishing treatmentInsulate the airShock testingElectrical batteryPower apparatus

The present invention relates to an impact testing device for a battery pack. The device comprises a collision barrier used for placing the battery pack, a movable sliding table with an impact head, a hydraulic power device used for pushing the movable sliding table to slide, and a monitoring device in communication connection with a sensor inside the battery pack. The movable sliding table is positioned between the hydraulic power device and the collision barrier. The impact head of the movable sliding table is oriented towards a support assembly for placing the battery pack and positioned on the side surface of the collision barrier. The monitoring device controls the starting and the stopping of the hydraulic power device. The device further comprises a solution tank positioned right below the support assembly and used for the fire extinguishing of the battery pack. The monitoring device also controls the support assembly to release the battery pack so as to enable the battery pack to fall into the solution tank. According to the technical scheme of the invention, the fire extinguishing problem of the battery pack during the impact test in the prior art can be solved.

Owner:深蓝汽车科技有限公司

Die casting cooling mechanism

The invention discloses a die casting cooling mechanism. The die casting cooling mechanism comprises a cooling plate, a conveyor belt, a conveying roller, fans and a water tank, wherein a J-shaped cooling plate is arranged on the conveyor belt, a die casting is put in from the cooling plate on the right side, a fan is arranged in front of and behind the conveyor belt respectively, and the water tank is arranged at the lower part of the conveyor belt. The die casting cooling mechanism provided by the invention has a vertical structure, saves factory spaces, is more compact in structure and saves the land cost, and die castings are subjected to air cooling at first, and then water cooling, are cooled more uniformly and fully, and then are further subjected to air cooling while drying the moisture on the die castings.

Owner:成都恒西亚机械工业有限责任公司

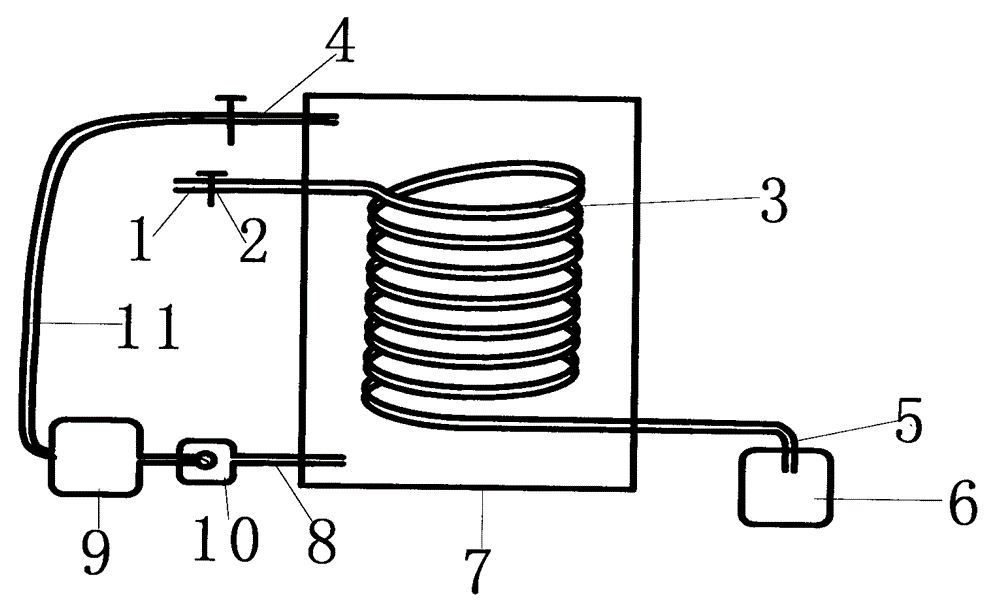

Butane exhaust recovery system for oil factory

The invention discloses a butane exhaust recovery system for an oil factory. Exhausted butane is recovered and utilized in a centralized manner. The system consists of coiled condensation pipe cooling equipment, a condensate container and a butane recovery device. The exhausted butane enters the system from a gas inlet, and is cooled to be liquefied by a coiled condensation pipe, liquefied butane flows into the butane recovery device from top to bottom along the condensation pipe, and the condensate consisting of salt and water can be recycled through a condensate recycling device to promote the liquefaction of butane. The butane exhaust recovery system is easy to operate, gas pollution is greatly reduced, and environmental pollution is also reduced; the system is simple, novel and unique in structure and convenient to operate, and economic benefits, social benefits and environmental protection benefits of the oil factory industry are improved.

Owner:HENAN POLYTECHNIC UNIV

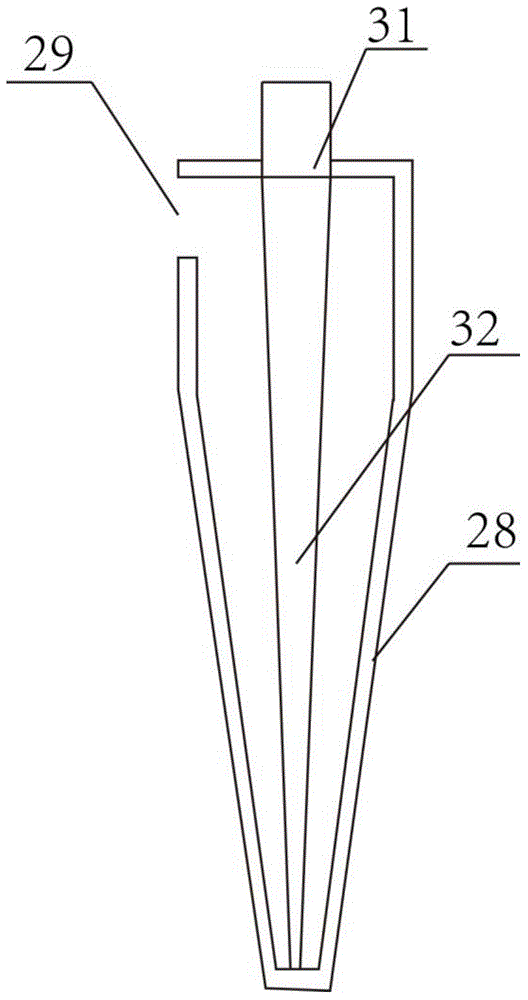

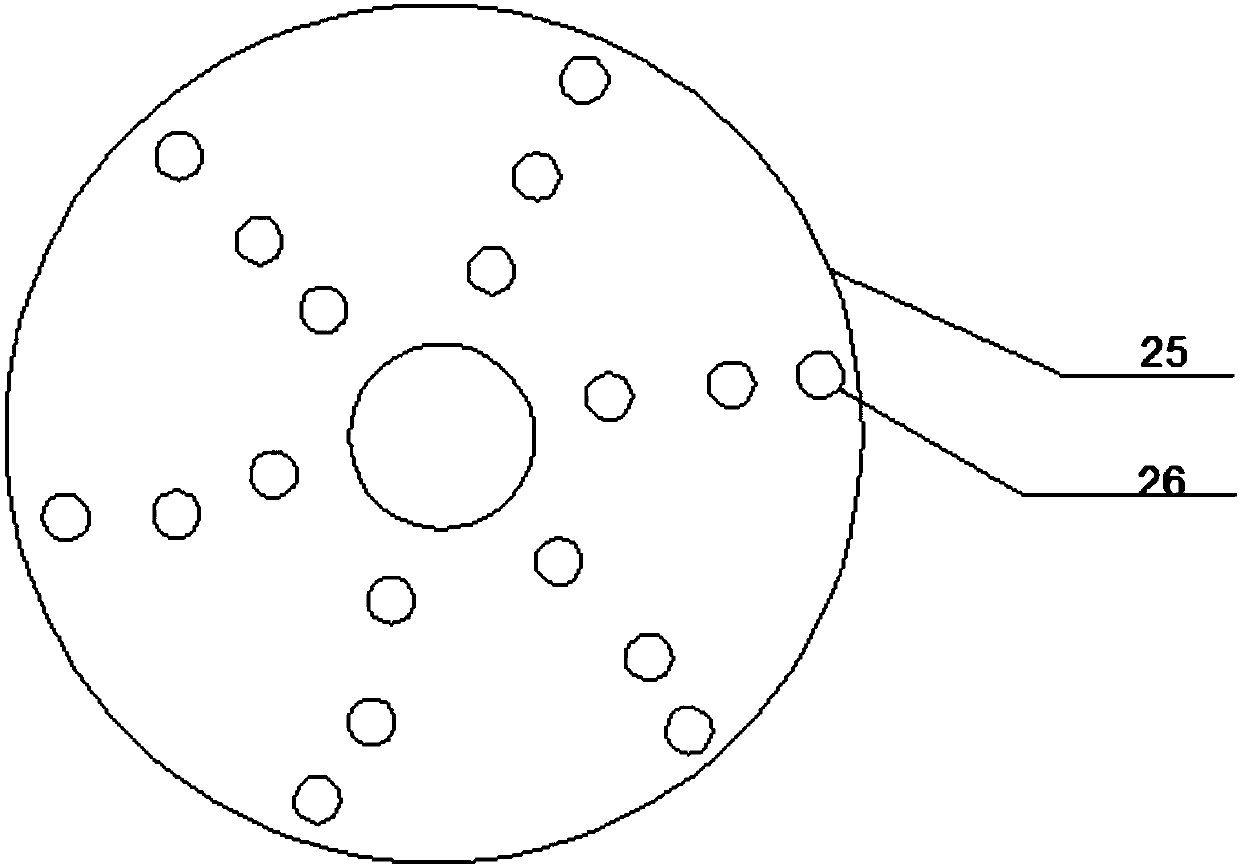

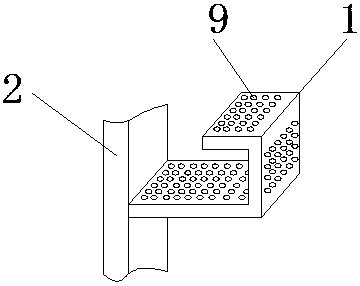

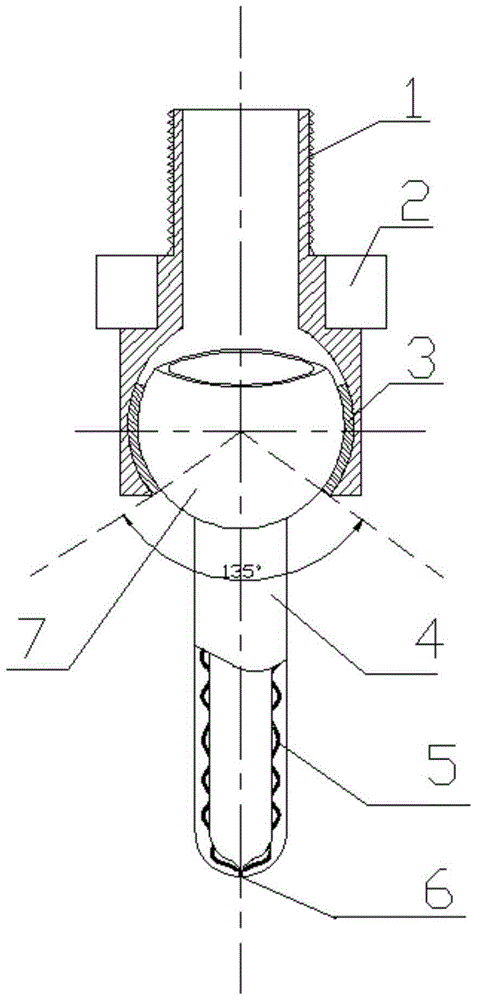

Flexible high-speed cutting pressurized cooling jet nozzle

ActiveCN105215784AFully cooledSolve poor coolingMaintainance and safety accessoriesSpray nozzleAerospace engineering

The invention provides a flexible high-speed cutting pressurized cooling jet nozzle. The flexible high-speed cutting pressurized cooling jet nozzle comprises a hollow ball auxiliary mechanism, a jet nozzle base body, a spherical face arc-shaped sealing ring and a jet nozzle pipe. A round cavity is formed in one end of the jet nozzle base body, and the hollow ball auxiliary mechanism is arranged in the round cavity; the spherical face arc-shaped sealing ring is arranged between the jet nozzle base body and the hollow ball auxiliary mechanism, and the jet nozzle pipe is connected with the hollow ball auxiliary mechanism; a jet nozzle outlet is formed in the tail end of the jet nozzle pipe, and sealing tubular threads are arranged at the other end of the jet nozzle base body; and a hexagonal face convenient to dismount is arranged on the outer side of the jet nozzle base body. A changeable-angle spiral guide groove is designed in an internal cavity of the jet nozzle guide pipe so as to be through with the jet nozzle outlet, so that cooling media jetted out after pressurization are evenly wound on the position nearby a high-speed cutting tool in a spiral cloud shape, and the full cooling effect is achieved; and the problem of the poor effect on cutting heat generated in the high-speed machining cooling on tool cooling is solved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

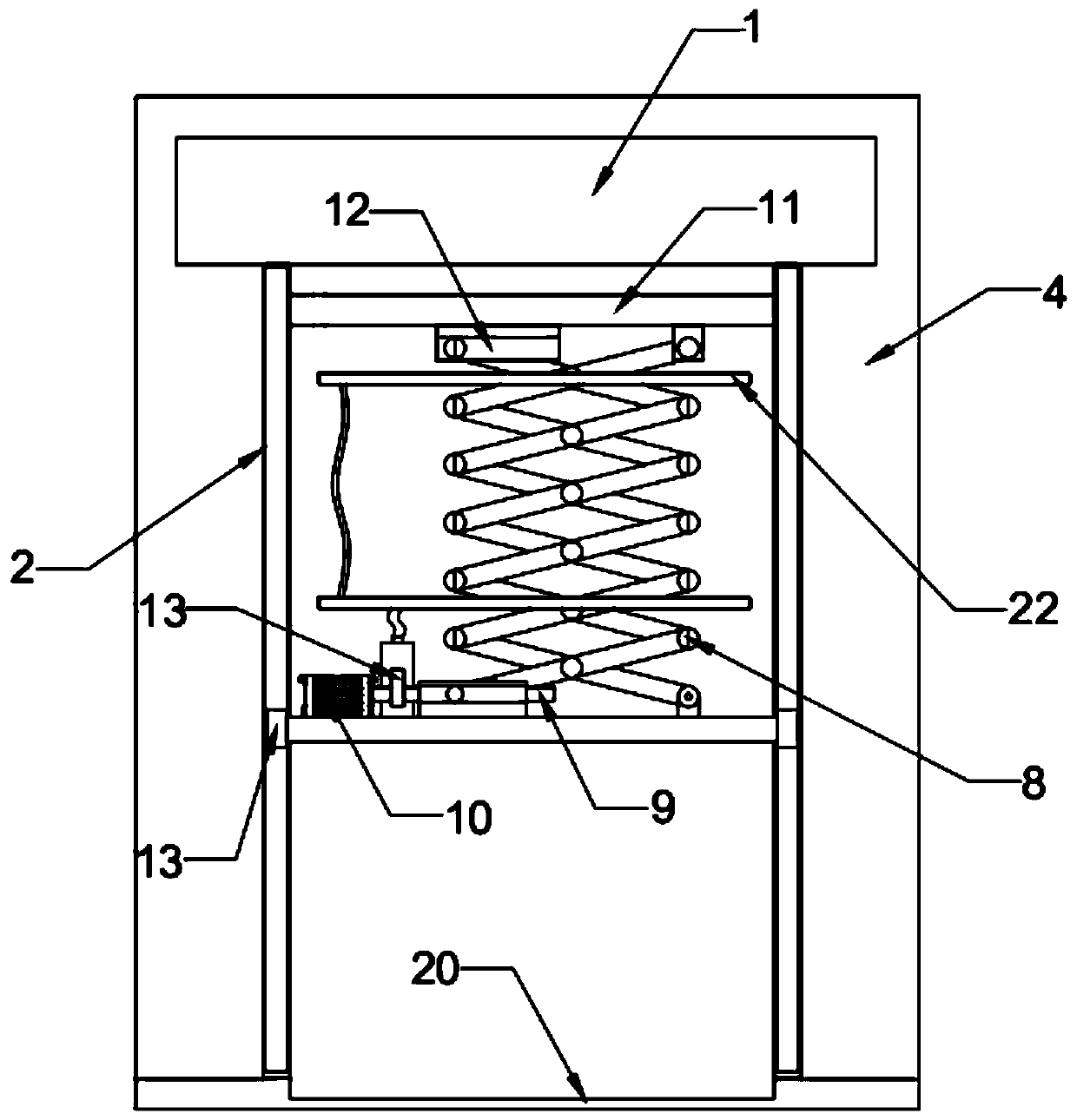

Shear type fireproof door lifting mechanism

InactiveCN110067490AReduce difficultyAvoid damageDoor/window protective devicesFireproof doorsEngineeringBlock match

Owner:BENGBU COLLEGE

Immersed combustor

ActiveCN103335310AImprove heating efficiencyReasonable heating efficiencyGaseous fuel burnerCombustorEngineering

The invention discloses an immersed combustor. The combustor comprises a furnace housing, wherein the furnace housing comprises a main combustion cone, a top volute and a cooling water jacket, wherein the main combustion cone is integrally communicated at the top surface of a bottom volute, the top volute is provided with a main tangential air inlet and is fixedly arranged at the upper end of the main combustion cone, and the cooling water jacket encircles the peripheral surface of the main combustion cone and is used for cooling the main combustion cone by circulating water; the bottom volute is internally provided with a combustion nozzle which is respectively connected with an auxiliary air inlet pipe and a fuel supply pipe, a circulation cooling water coiled pipe is sleeved on the periphery of the combustion nozzle, and an inner fuel passageway of the combustion nozzle is provided with an atomizing water pipe which jets water mist outwards to cool the combustion nozzle; a smoke removal channel is formed in the bottom volute in a tangent direction, the furnace housing is immersed and arranged in cooling bath water in such ways of feeding air at the upper part of the furnace housing and discharging smoke at the lower part of the furnace housing, the immersed depth of the furnace housing in the cooling bath water is more than the height of the furnace housing multiplied by one second, and the horizontal plane of the cooling bath water is lower than the edge of the upper opening of the cooling water jacket.

Owner:宁波中能连通机械有限公司

Novel low temperature rising water-cooling stator engine base and welding method thereof

ActiveCN102904371BReduce vibrationSave materialManufacturing dynamo-electric machinesSupports/enclosures/casingsWater channelEngineering

The invention relates to a novel low temperature rising water-cooling stator engine base and a welding method thereof. The novel low temperature rising water-cooling stator engine base comprises an outer cylinder, a middle cylinder, an inner cylinder and a machine leg component, wherein the length of the inner cylinder is the same as the length of a water-cooling stator and is less than the length of the outer cylinder; the welding method comprises the following steps of: positioning water channel ribs through a rib plate positioning die in sequence and fixing the water channel ribs in a spot welding mode; finding out the position of a blocked weld joint through a blocked weld joint template corresponding to a plurality of water channel ribs; positioning and welding the water channel ribs; and finding blocked weld joints corresponding to the water channel ribs. The welding method is accomplished through the rib plate positioning die and the blocked weld joint template, the error in line drawing positioning and aligning is effectively avoided, the following welding quality is improved, and the cooling performance of the engine base is ensured.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com