Butane exhaust recovery system for oil factory

A recovery system and butane technology, applied in the field of resource utilization and recovery, can solve environmental pollution and other problems, achieve the effects of ensuring normal operation, improving economic benefits, and reducing the production of air pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

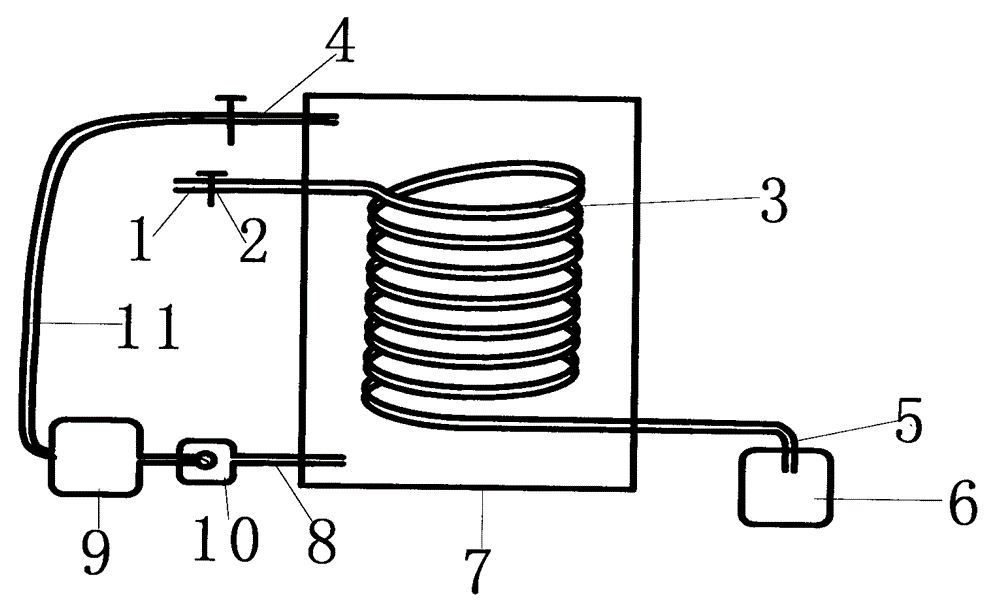

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] The butane emission recovery system of the oil factory is realized by the following steps. The butane gas produced in the oil factory during the process of production refining, deep processing, and technological innovation passes through the collection device. The whole device opens the valve (2) from top to bottom, and the butane The gas enters through the air inlet (1) on the upper part of the device, the gas flows through the serpentine condenser (3) in the condensate container (7), cools down and liquefies, and the liquefied butane exits from the serpentine condenser (3) The liquid pipe (5) enters the butane collection device (6) at the bottom of the device and gathers. The condensate uses cold brine, which can reduce the time for gas liquefaction. The brine flows from the condensate inlet (8) into the condensate formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com