Liquid cooling source of secondary circulation cooling liquid

A secondary circulation, cooling liquid technology, applied in electric vehicles, charging stations, climate sustainability, etc., can solve the problems of poor reliability of the charging system, increased coolant temperature, large volume, etc., to achieve good heat dissipation, optimal Heat dissipation performance, the effect of satisfying the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

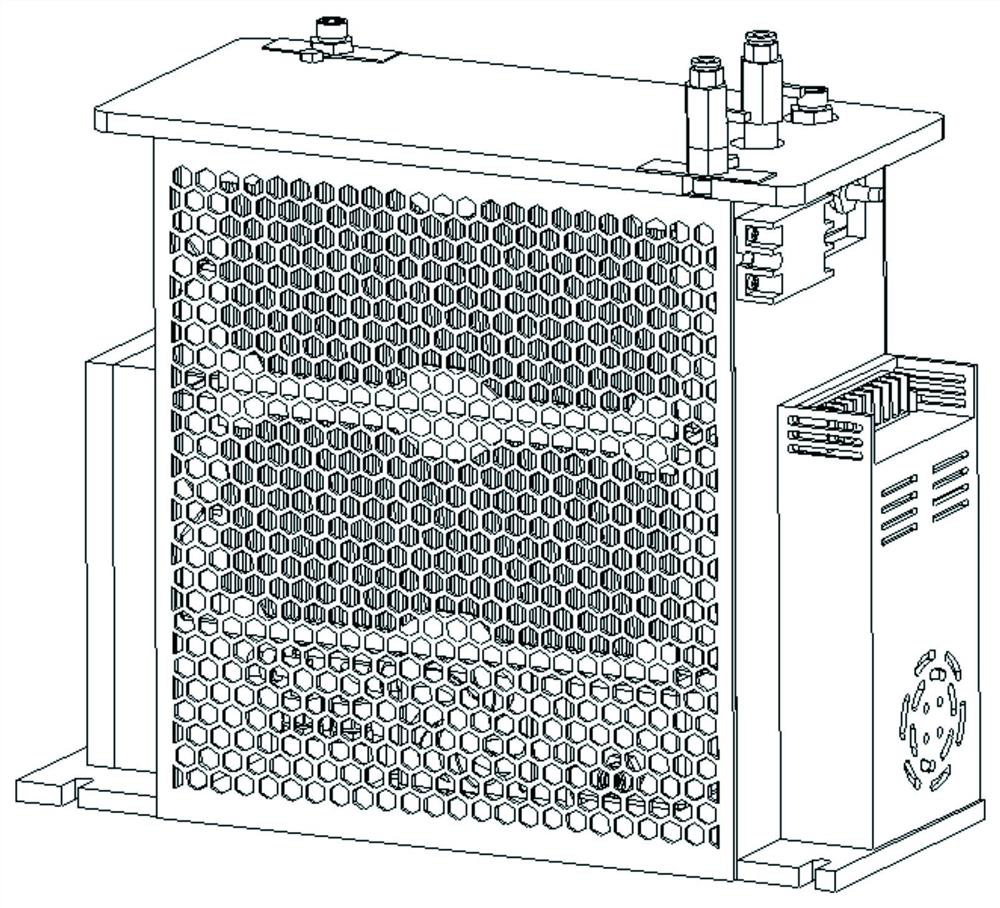

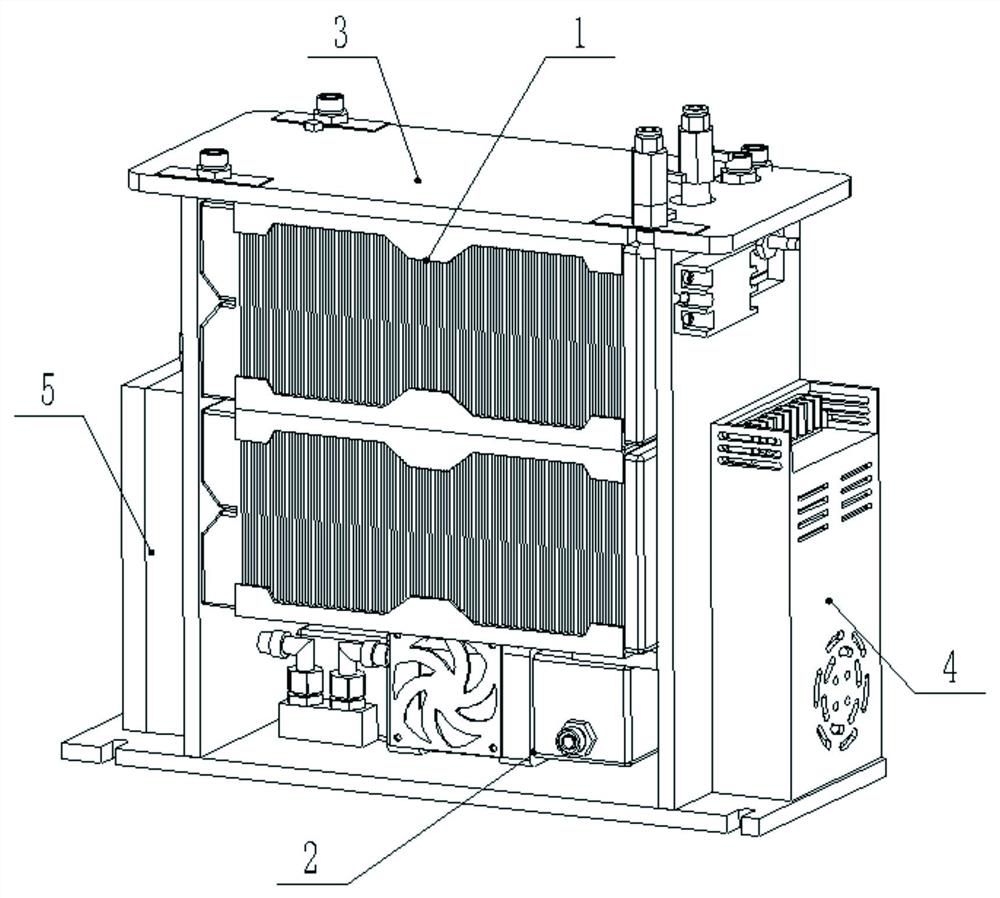

[0030] A liquid cooling source for a secondary circulating coolant, comprising a cooling unit 1, a power unit 2, a chassis 3, a power supply 4, and a control unit 5;

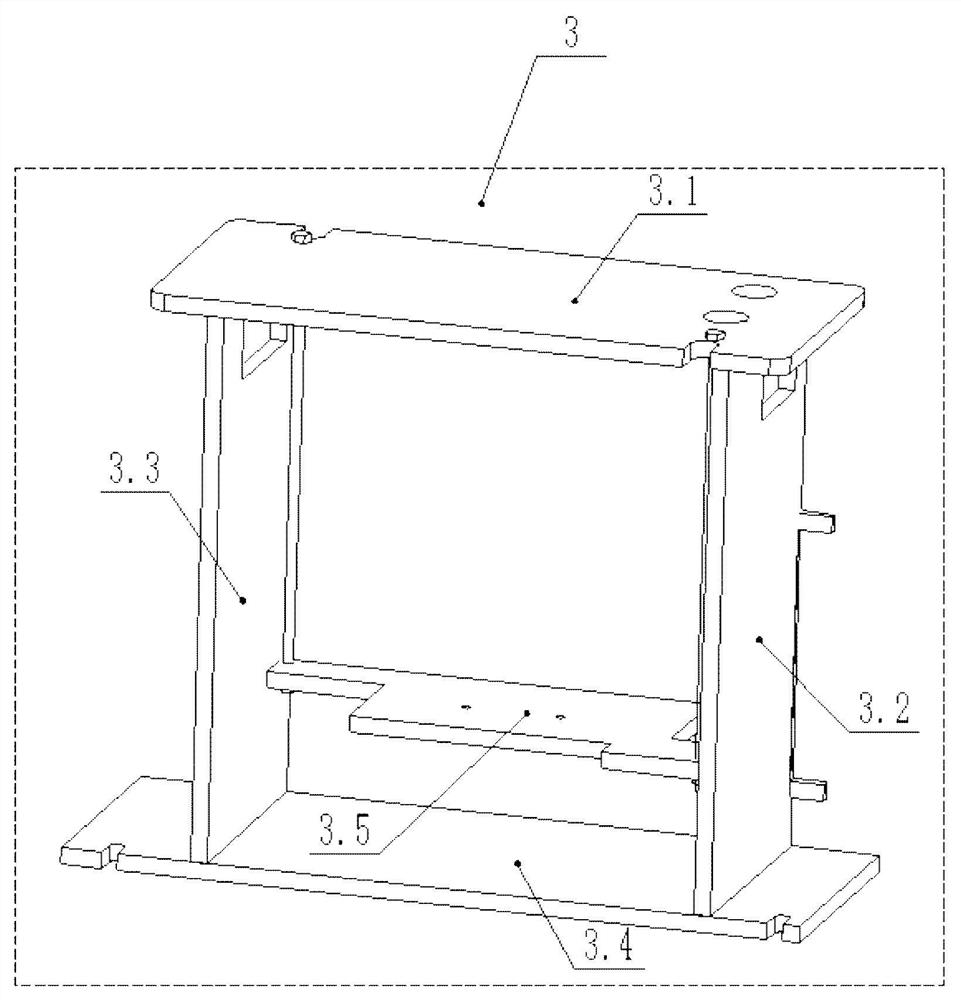

[0031] The chassis 3 includes a chassis top plate 3.1, a chassis right side panel 3.2, a chassis left side panel 3.3, a chassis bottom plate 3.4, and a cooling unit support plate 3.5; the chassis top plate 3.1 and the cooling unit support plate 3.5 are fixedly connected by screw rods to form a cooling unit fixing frame; The right panel 3.2 of the chassis, the left panel 3.3 of the chassis, and the bottom panel 3.4 of the chassis are fixedly connected to form a support frame; the cooling unit fixed frame is fixedly connected to the chassis support frame to form a chassis 3; the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com