Immersed combustor

A submerged burner and main combustion technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of reducing the service life of the burner, energy waste, etc., to reduce resistance, reduce heat loss, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

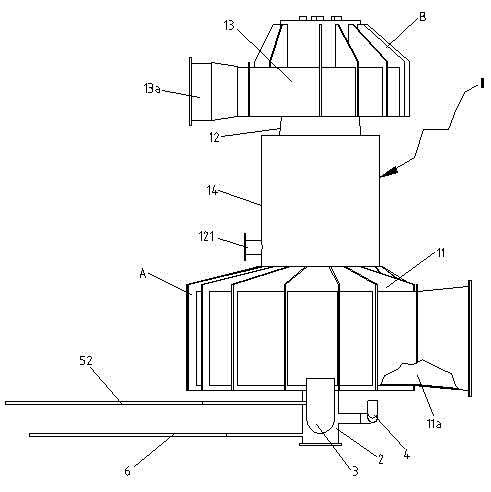

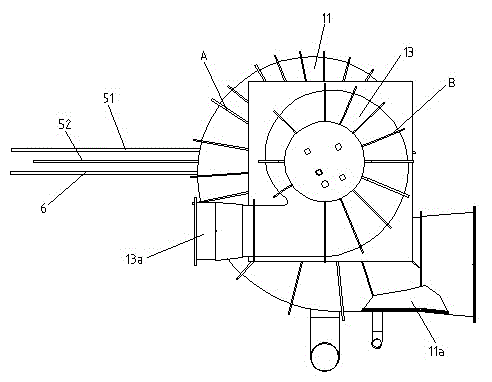

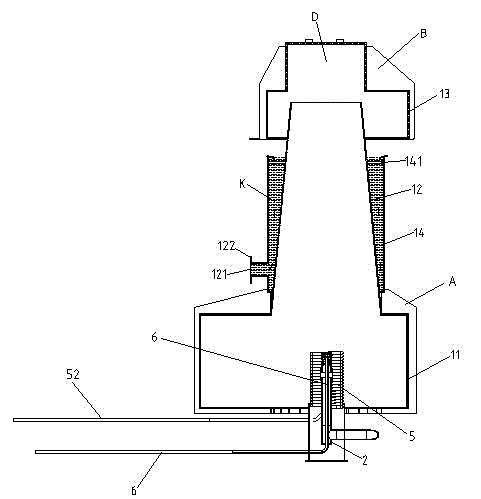

[0024] Figure 1 to Figure 7 Shown is a schematic diagram of the principle structure of the present invention.

[0025] The reference signs are: bottom volute reinforced rib A, top volute reinforced rib B, gas gathering chamber D, cooling water chamber K, furnace shell 1, bottom volute 11, smoke exhaust channel 11a, main combustion chamber Cone 12, cooling water inlet 121, connecting flange 122, top volute 13, main air inlet 13a, cooling water jacket 14, reinforcing plate 141, burner 2, air nozzle 21, fuel nozzle 22, fuel inflow Road 22a, spray hole 22b, cooling spray hole 22c, spray head 221, auxiliary intake pipe 3, fuel supply pipe 4, cooling circulating water coil 5, cooling water inlet pipe 51, cooling water outlet pipe 52, spray water pipe 6, spray head 61 .

[0026] Such as Figures 1 to 7 As shown, a submerged burner of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com