Novel low temperature rising water-cooling stator engine base and welding method thereof

A welding method and technology for cooling the stator, which are applied in welding equipment, welding accessories, electromechanical devices, etc., can solve the problems of complicated welding process, poor welding quality and low service life, and achieve good cooling effect through water and avoid scribing. Positioning and pinpointing errors, ensuring the effect of cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with drawings and embodiments.

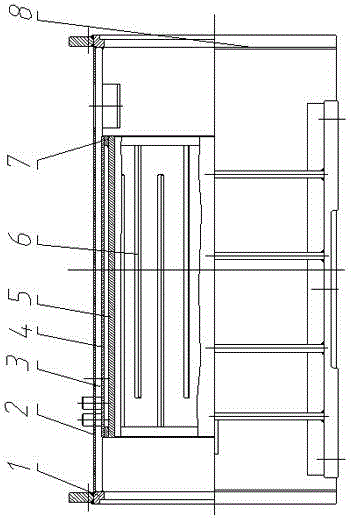

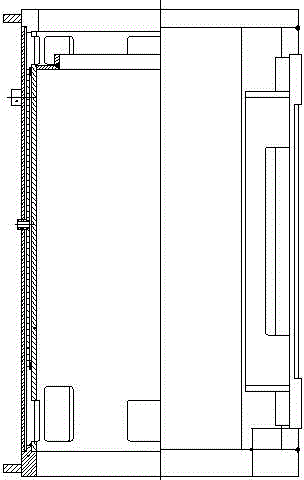

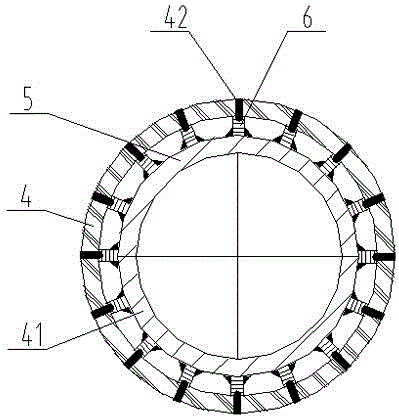

[0052] figure 1 , 6 As shown, a new type of low-temperature rise water-cooled stator base includes a flange 1, an outer cylinder 2, a reinforcement rib 3, a middle cylinder 4, an inner cylinder 5, a channel rib 6, a water retaining ring 7 and a machine foot assembly 8. Both ends of the outer cylinder 2 are connected with flanges 1, the inner wall of the outer cylinder 2 is connected to the outer wall of the middle cylinder 4 through a plurality of reinforcing ribs 3, the inner wall of the middle cylinder 4 is connected to the outer wall of the inner cylinder 5 through a plurality of water channel ribs 6, and the multiple water channel ribs 6 are in a labyrinth It is sequentially arranged in the cavity between the middle cylinder and the inner cylinder, the water channel ribs and the middle cylinder are in the same axial direction, and the two ends of the inner cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com