Heat dissipation device for power equipment

A technology for power equipment and cooling devices, which is applied in the cooling/ventilation direction of substations/switching devices, can solve problems such as power grid accidents, power grid paralysis, fires, etc., and achieve the effect of saving water resources and achieving good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

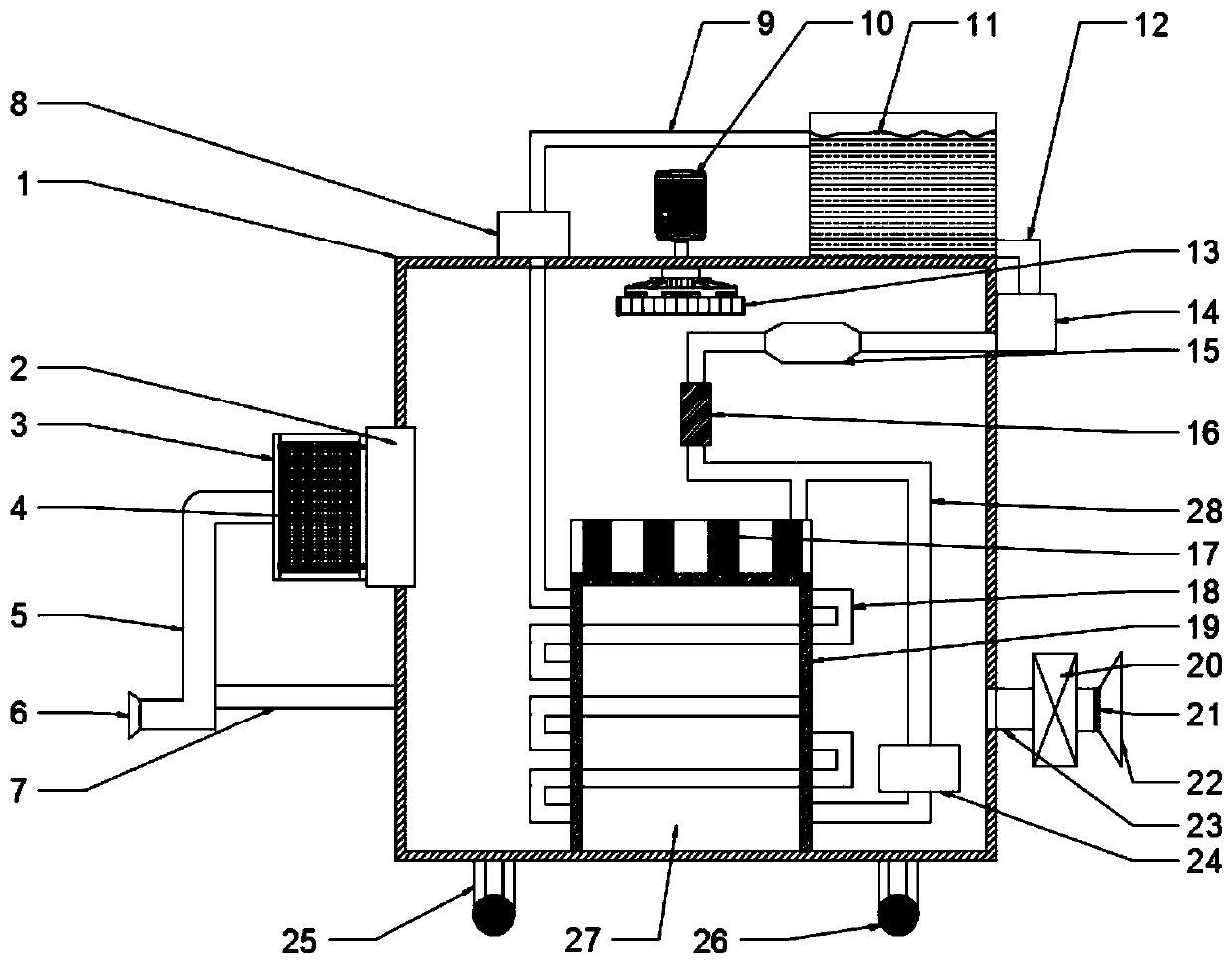

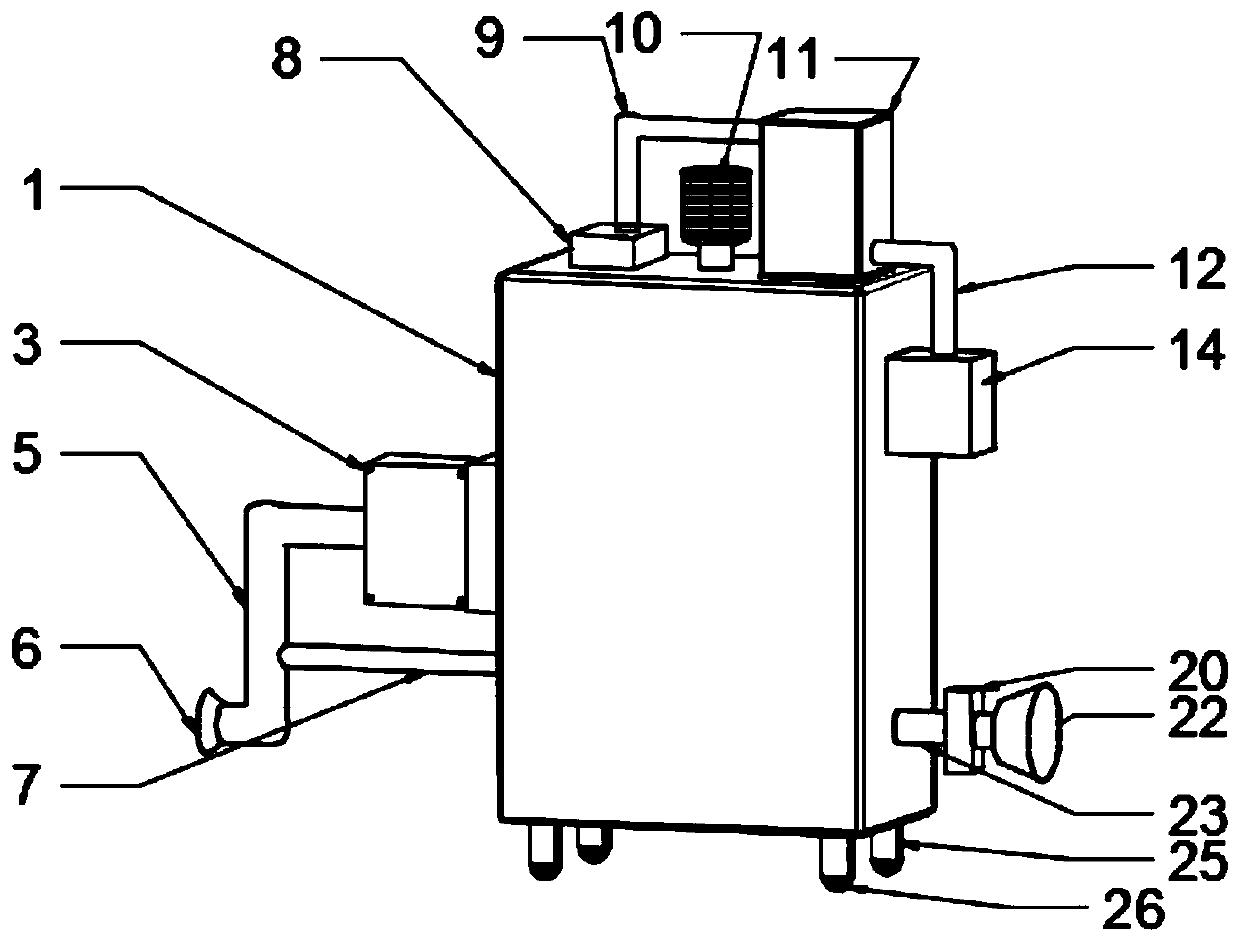

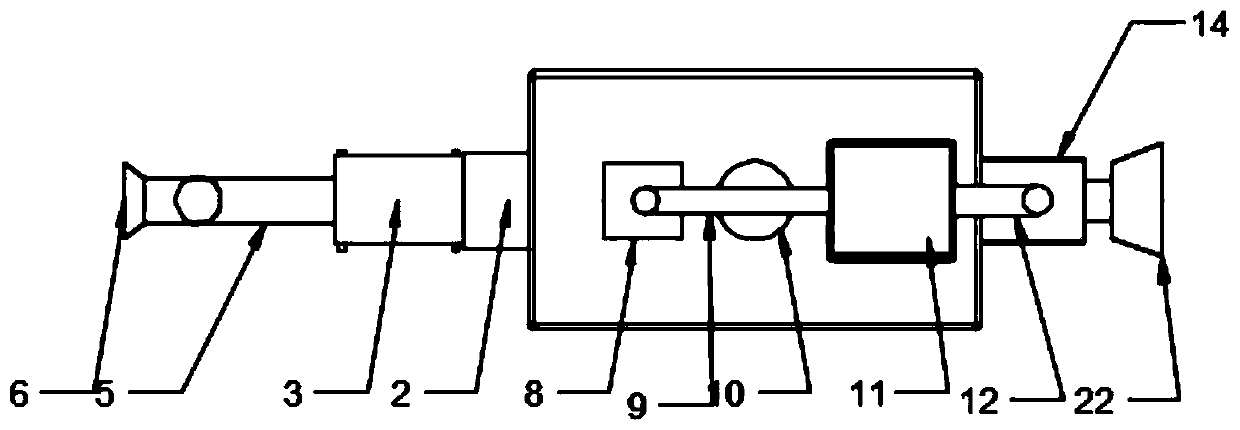

[0019] see Figure 1-3 , a heat dissipation device for electric power equipment, comprising a heat dissipation box 1, a water tank 11 is installed on the top right side of the heat dissipation box 1, the water tank 11 is connected to the top surface of the heat dissipation box 1 by bolts, and the right side wall of the water tank 11 is connected to a water outlet pipe 12 , the lower end of the water outlet pipe 12 is connected to a pressure water pump 14, and the pressure water pump 14 is connected to the right side surface of the cooling tank 1 by welding, and the pressure water pump 14 can make the pressure of the water extracted from the water tank 11 higher to ensure water circulation. The pressure water pump 14 is connected to the gasification pipe 15 through the water outlet pipe 12, and water can be vaporized in the gasification pipe 15 to absorb more heat. The gasification pipe 15 is connected to the liquefaction device 16 through the water outlet pipe 12, and the gaseo...

Embodiment 2

[0023] Such as Figure 1-3 , on the basis of embodiment 1, in order to exchange the cold and hot air in the heat dissipation box 1, the hot air is discharged, the cold wind is sucked into the heat dissipation box 1, and the air temperature in the heat dissipation box 1 is reduced. The air duct 23 is installed on the surface of the side wall, and the air duct 23 communicates with the inside of the cooling box 1. The right side of the air duct 23 is connected to the suction fan 20, and the right side of the suction fan 20 is equipped with a wind cover 22. The dust filter 21 is installed, the external cold air can be sucked into the cooling box 1 by the suction fan 20, the suction cover 22 can increase the air suction, and the dust filter 21 can filter out the dust in the air, so as not to affect the power of the electric equipment 27 In normal operation, the air cooling device 2 is installed on the left side wall of the heat dissipation box 1, and the wind cooling device 2 can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com