Patents

Literature

30results about How to "Improve air flotation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

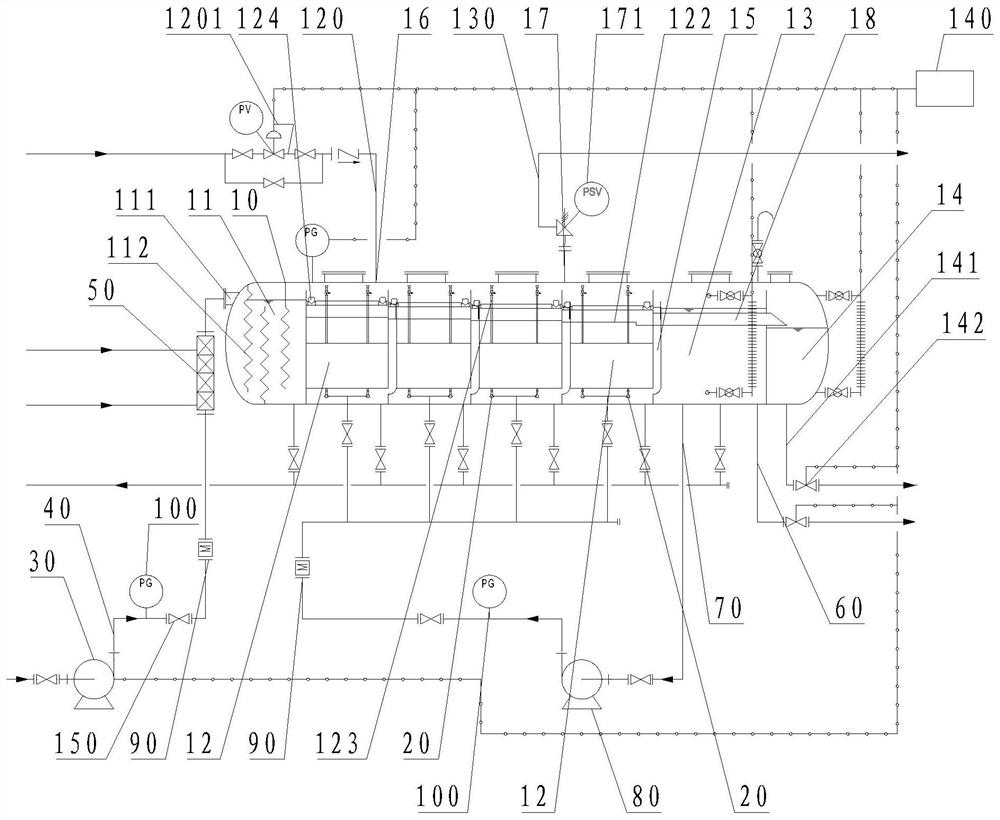

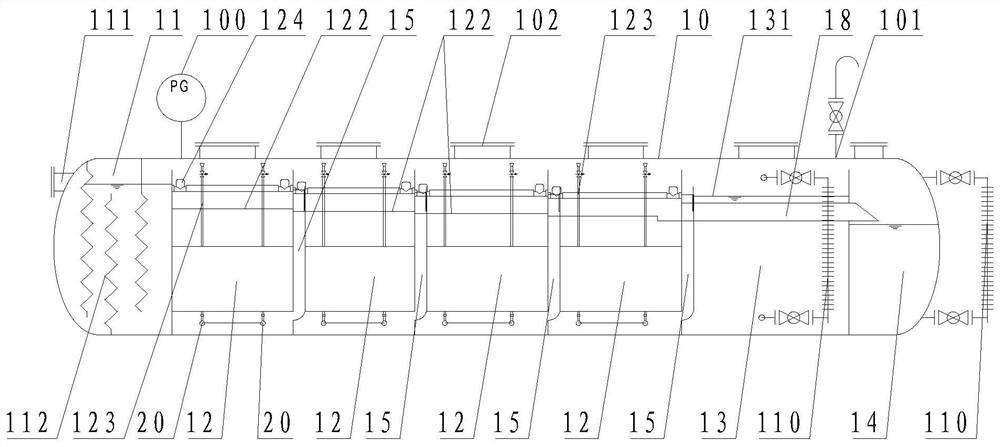

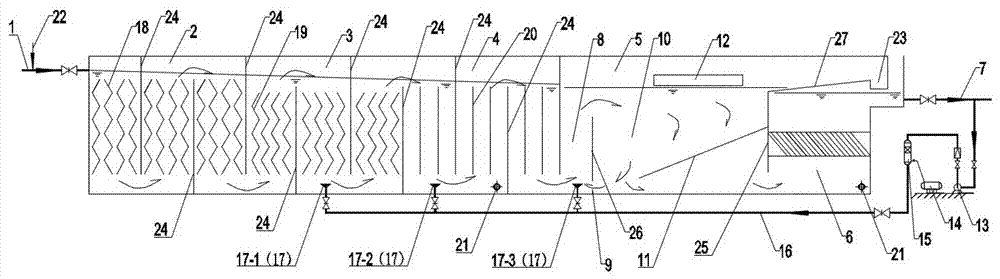

Copolymerization flotation-sedimentation tank and water purification method

ActiveCN105502549AExtended collision stick timeEnhanced interactionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationEngineeringEnvironmental geology

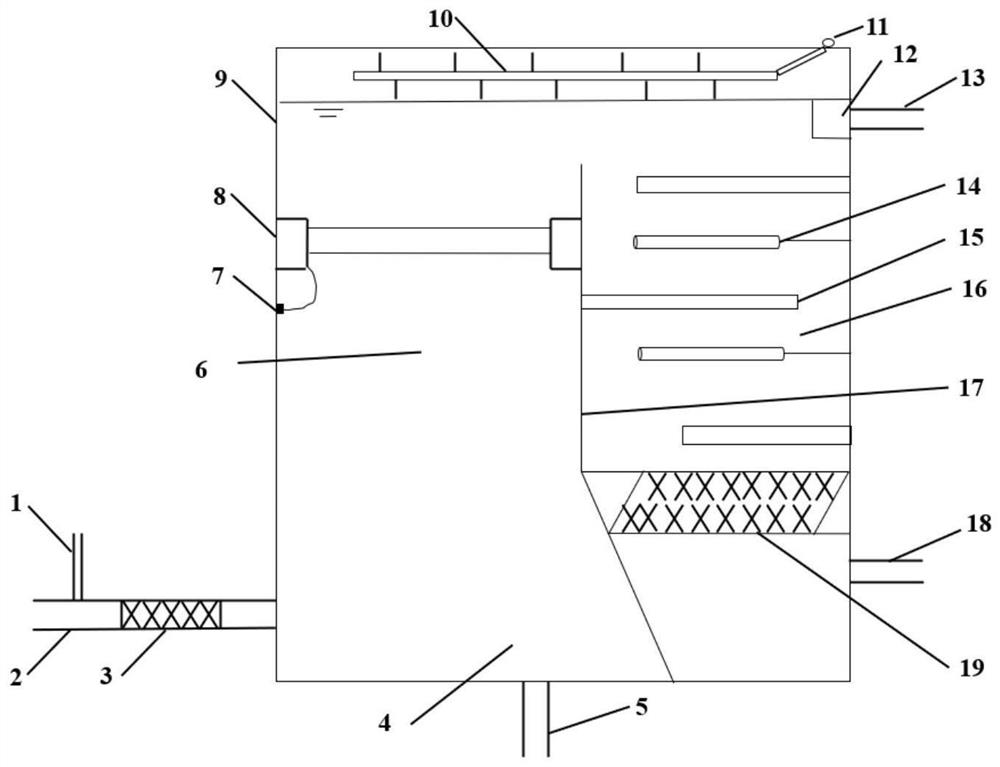

The invention relates to a copolymerization flotation-sedimentation tank. The copolymerization flotation-sedimentation tank comprises a multi-channel folded plate copolymerization flocculation basin, a flotation-sedimentation tank and an air dissolving system, wherein the multi-channel folded plate copolymerization flocculation basin is used for realizing the coagulation and the copolymerization of flocculates and microbubbles; the flotation-sedimentation tank is connected to the rear end of the multi-channel folded plate copolymerization flocculation basin and is used for separating foamed flocculates from water flow and precipitating settleable flocculates which cannot float; and the air dissolving system is connected with a water outlet end of the flotation-sedimentation tank and is connected with the multi-channel folded plate copolymerization flocculation basin and the flotation-sedimentation tank to supply high-pressure backflow gas dissolved water to the multi-channel folded plate copolymerization flocculation basin and the flotation-sedimentation tank. According to the copolymerization flotation-sedimentation tank, the high-pressure backflow gas dissolved water is fed for three times, by virtue of organic combination with a flocculation process, a microbubble and flocculate copolymerized environment is created, and the produced foamed flocculates are stable and are not easily separated, so that the problems that the adhesion efficiency of particles is low, the trapping effect is not ideal, the adhesion of the foamed flocculates is instable, and the like of a traditional dissolved air flotation process are solved, and the coagulation, air floatation and sedimentation processes are organically combined and integrated; and the copolymerization flotation-sedimentation tank has prominent superiority in the treatment of water quality in high-algae, low-turbidity and burst high-turbidity reservoirs.

Owner:SHANDONG JIANZHU UNIV

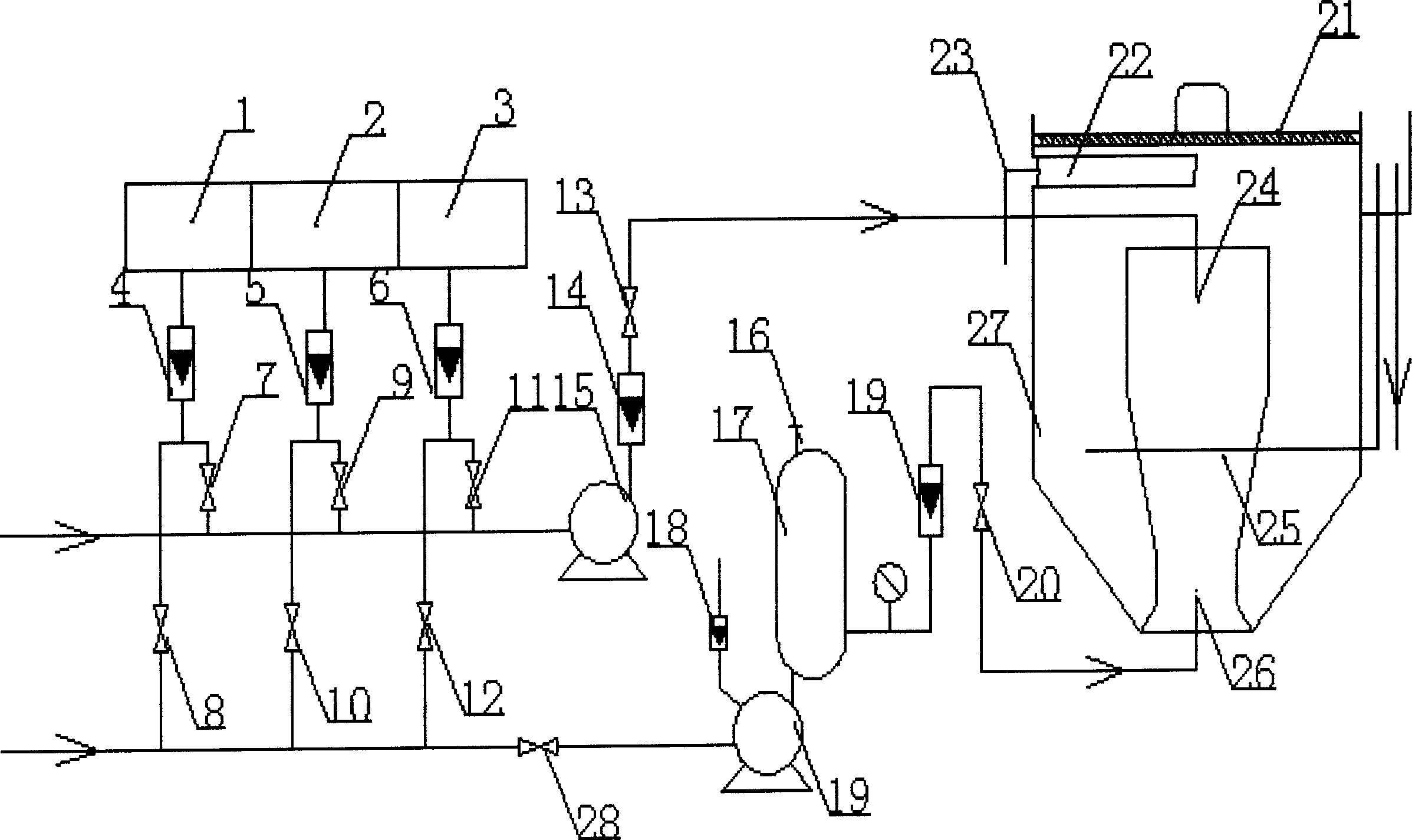

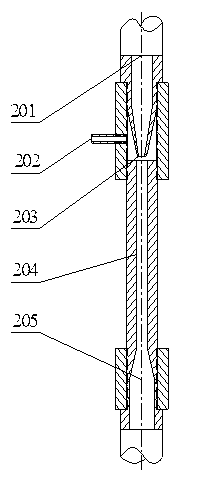

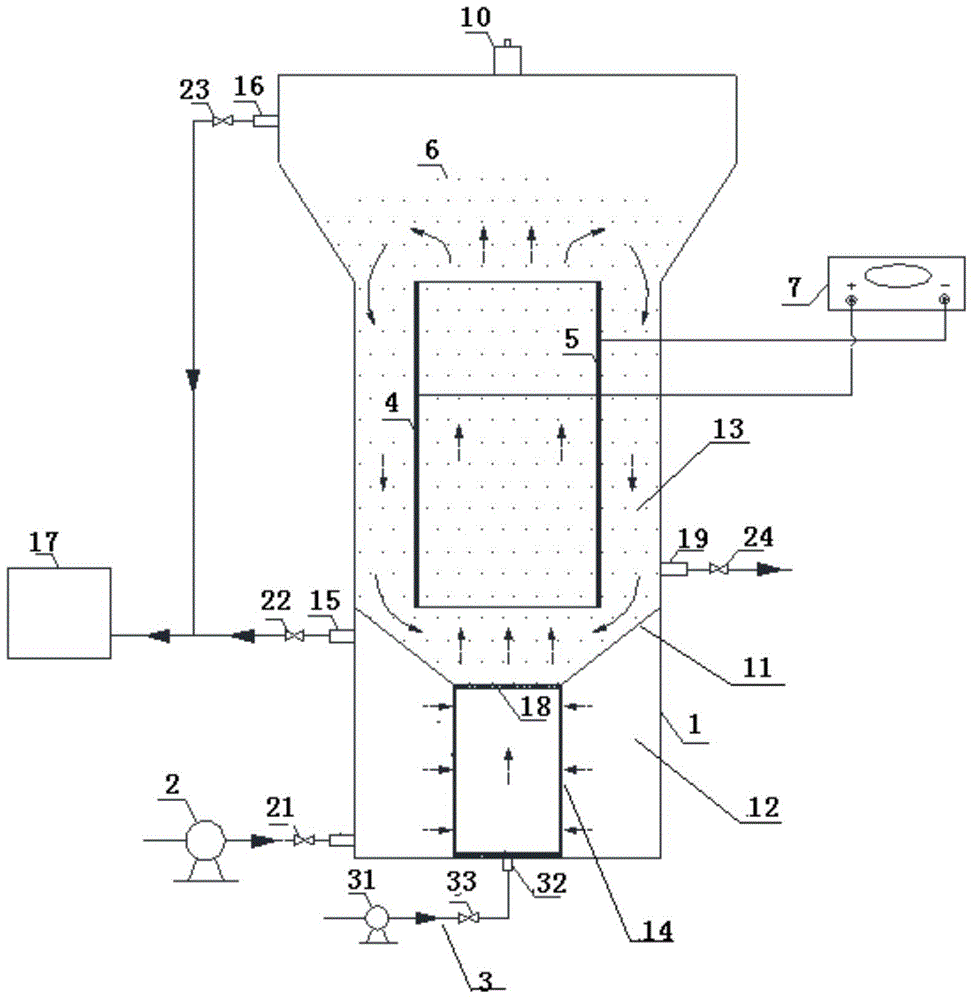

An ozone oxidation-air floatation combined treatment system and a process

ActiveCN104761088AShort stayImprove Ozone Oxidation AbilityMultistage water/sewage treatmentChemistryPollutant

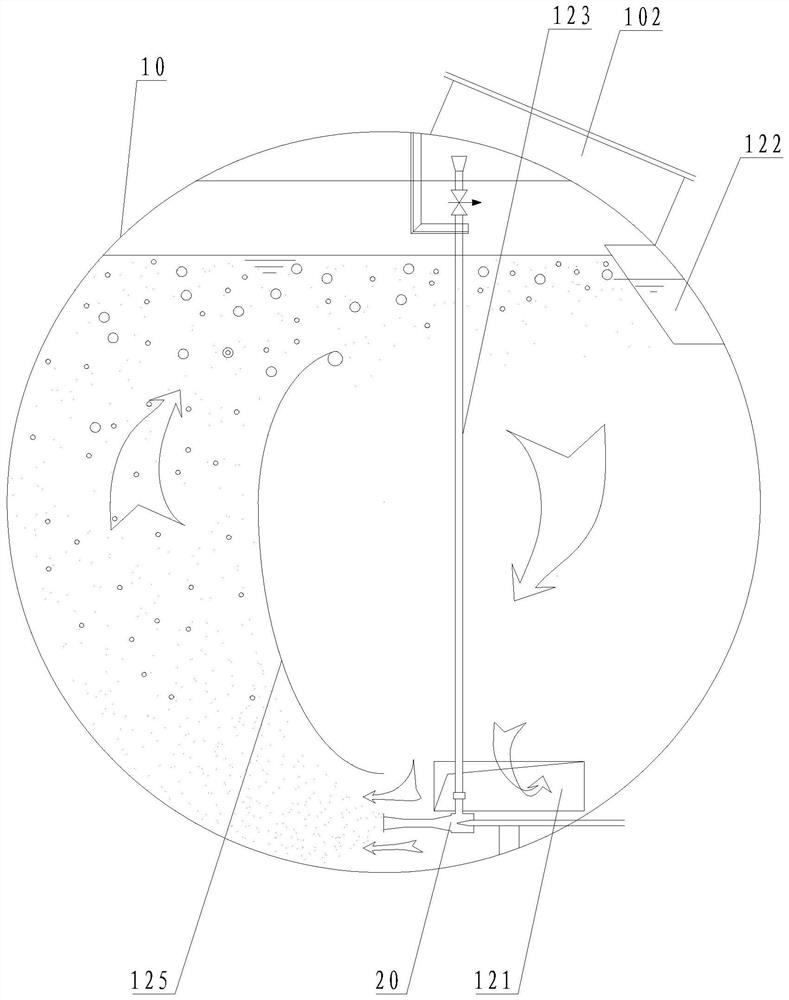

The invention relates to an ozone oxidation-air floatation combined treatment system and a process. The system comprises a reaction tank, a gas liquid mixer, a catalyst adding device and a whirl stream air floating tank. Ozone-containing gas and sewage are mixed into a gas-liquid mixture containing micro bubbles by the gas liquid mixer and then fed into the reaction tank. The reaction tank is provided with at least one ultrasonic wave cavitation device. The catalyst adding device is used for feeding a catalyst, ozone and the sewage into the reaction tank together. Then a catalytic oxidation reaction is performed under the action of ultrasonic wave cavitation. A stream guide pipe is vertically disposed in the center of the whirl stream air floating tank. The upper end of the stream guide pipe is open, and the lower end of the stream guide pipe penetrates the bottom of the whirl stream air floating tank. The bottom of the whirl stream air floating tank is also provided with a sewage outlet. The bottom of the stream guide pipe is provided with vortex plates. The whirl stream air floating tank is communicated with the reaction tank, and used for allowing the gas liquid mixture reacted in the reaction tank to react continuously under the whirl stream function and to be subjected to floatation, washing and separation treatment. The contact probability of the micro bubbles generated by the system with contaminants is large, the reaction is more thorough, the ozone utilization rate is high, retention time is short, and contaminant removing effects are good.

Owner:SHENZHEN CLEAR SCI & TECH

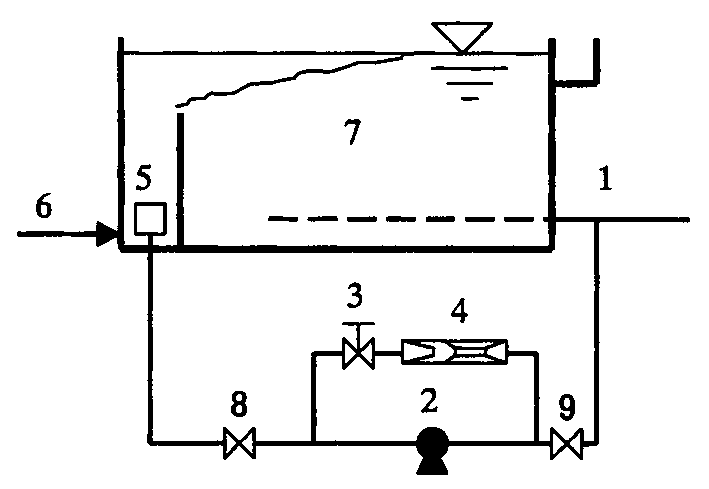

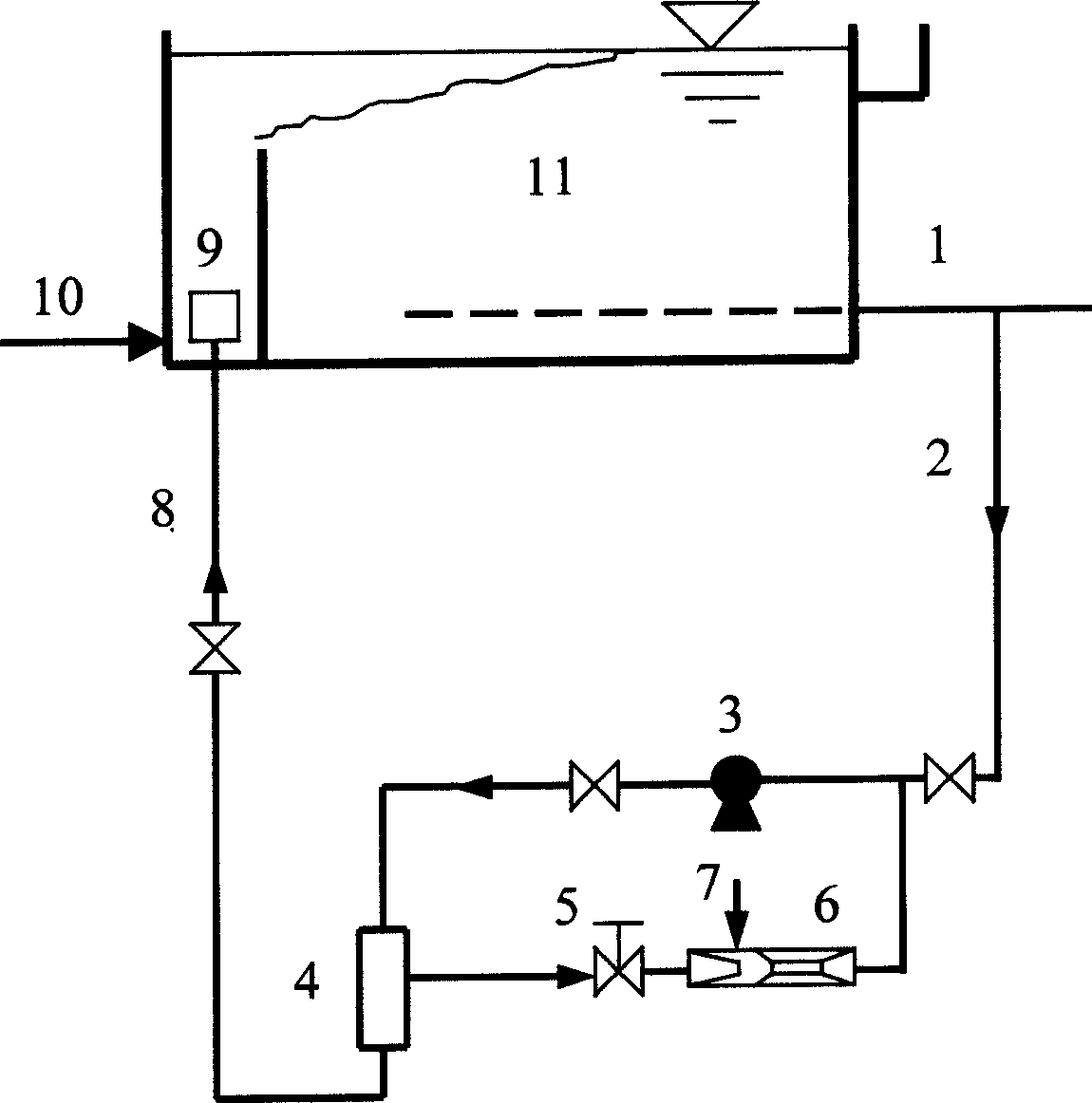

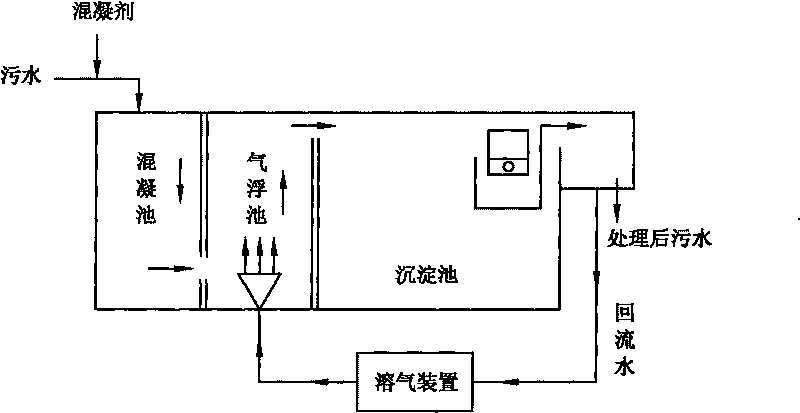

Co-coagulating gas-floating water purifying process

InactiveCN1837080AShorten the timeReduced footprintWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationEutrophicationSlag

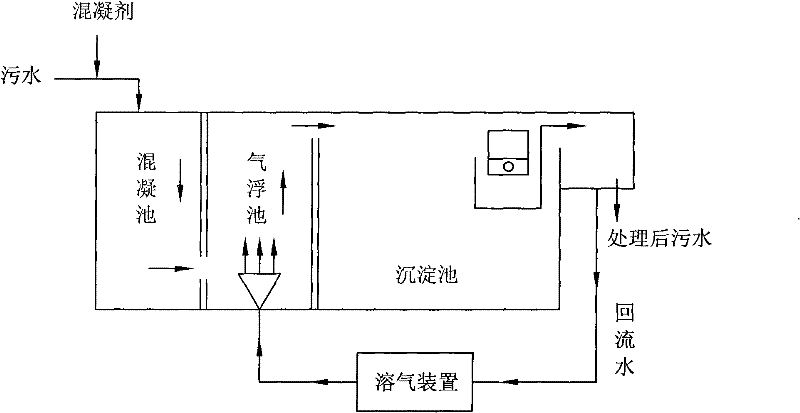

The invention provides a Coagglomeration air-float water quality purification process, belonging to water pollution control engineering. This technics is consisted of dissolved-air outgas system, drug adding system, reaction separation system. The dissolved-air adopting solution-air mixing pump and solution-air knockout drum pressurize the part yielding water of floatation pond to dissolvedair, injecting to enter from the bottom of floatation pond; the coagulating agent is imbibed before sewage pump, the mixing course was finished in pipeline and sewage pump, the mixed sewage affluxing from the head of floatation pond; the best distance of dissolved-air water and sewage is about 10cm. the adhesion of air bubble and floc is finished in reaction contact zone of floatation pond, the coagulant aid is added from dissolved-air system, the copolymer of air bubble and floc floating upward to the head of floatation pond from knock-out zone of floatation pond and scraped to slag groove by scum machine. This invention can used to purify nature water, colloid and suspended matter which is produced from the course of production and life, part soluble substance such as azote and phosphate and so on which can lead to eutrophication.

Owner:DALIAN JIAOTONG UNIVERSITY

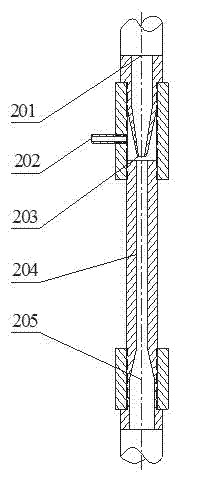

Mthod and device for injection dissolution of gas for circulation water

InactiveCN1420085AReduce dissolved airImprove air flotation efficiencyWater/sewage treatment by flotationDissolutionEnergy consumption

A jet method and apparatus for dissolving air in the circulated water is characterized by that the jetter in the path of circulated water, which has water pressurizing tube and water sucking tube, isused to dissolve air in the water by sucking and cutting actions, and a water pump is used to stir and mixthe water with air for dissolving air in water further. Its advantages are simple structure, high dissolving effect, and less energy consumption.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

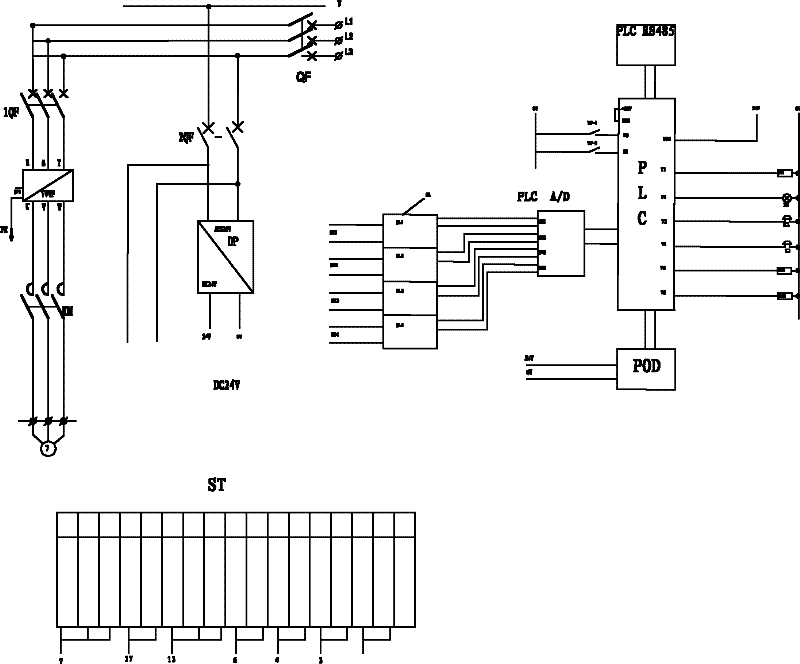

Micro nano bubble generator

InactiveCN102218275AIncrease profitImprove air flotation efficiencyFlow mixersMixing methodsMicro nanoSource type

The invention discloses a micro nano bubble generator which comprises a water intake pipe and a drainage pipe; one end of the water intake pipe is connected with a booster pump; the other end of the booster pump is connected with the top part of an air saturator in a sealing manner through a pipeline; an electromagnetic flowmeter is arranged on the pipeline; the top part of the air saturator is communicated with an air intake pipe in a sealing manner; an electromagnetic valve arranged on the air intake pipe is arranged in a control cabinet; an ejector nozzle, an ejector throat chamber, a liquid level floating ball, an air dissolved water absorption pipe are arranged in the air saturator; the ejector nozzle is connected with a pipeline; the ejector throat chamber is arranged on a position matched with the lower side of the ejector nozzle; an air liquid cavity is arranged between the ejector nozzle and the ejector throat chamber; a switch of the electromagnetic valve is controlled by a programmable controller; and the air dissolved water absorption pipe extends to the outside of the air saturator and is connected with the drainage pipe. The micro nano bubble generator can effectively remove dispersible oil uniformly dispersed in the water with an oil drop grain diameter equal to or less than 10 Mu m; meanwhile, oxidation desulfurising treatment on oily sewage or dissolved oxygen treatment by adding nitrogen is realized based on improving the air floatation oil by using different air source types.

Owner:大庆鑫禹科技有限公司

Pressure reduction release eddy flow air floatation tank

InactiveCN105060383ACompact structureFull hydraulic mixingWater/sewage treatment by flotationDissolutionPressure reduction

The invention belongs to a pressure reduction release eddy flow air floatation tank. An air dissolution water inlet, a waste water inlet, a scum discharge port, an exhaust port, a water outlet and a backflow port are formed in a tank body. A center pipe is arranged inside the tank body and is perpendicular to the tank bottom, a supporting plate is arranged at the bottom of the center pipe, a partition plate is arranged on the center pipe, blades are arranged on the upper portion of the partition plate, and small holes are formed in the pipe wall between the lower portion of the portion plate and an air dissolution water inlet pipe. A water outlet pipe is arranged on one side inside the thank and connected with the water outlet. A scum tank is arranged on the upper portion of the other side inside the tank and communicated with the scum discharge port. An exhaust pipe is arranged in the center of a tank body end socket. A unique structure is adopted for the air floatation tank, and all functional zones are independent in position and are closely combined in treatment function, so that waste water and agents are mixed more fully under hydraulic power, and the utilization rate of the agents is increased. Under the action of an eddy flow field, the scum-water separation process is intensified, and the scum separation efficiency is improved. The air floatation tank is simple in structure, the size of the air floatation tank can reduced, and the air floatation effect can be improved.

Owner:天津市振津石油天然气工程有限公司

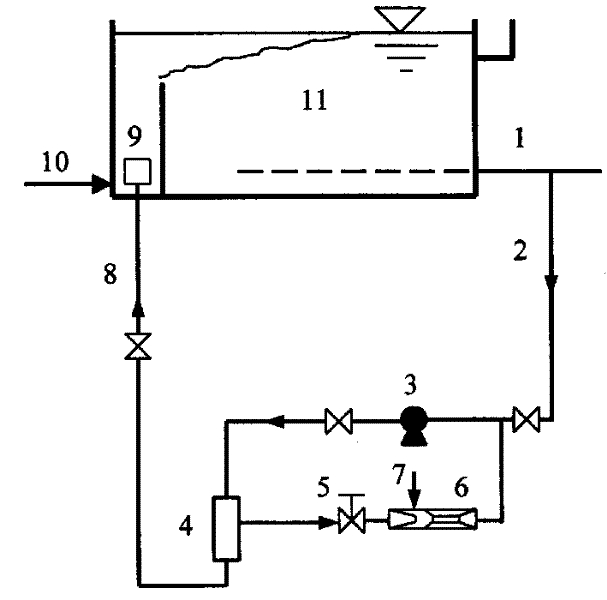

High efficiency circulating injection dissolved-air air-float method and apparatus

InactiveCN1631802AImprove air flotation efficiencyImprove solubilityWater/sewage treatment by flotationSprayerEngineering

The invention has supplied a high effective circumfluence spraying flotation method and its device, which includes spraying air by sprayer on circumfluence pipe-line of water stressing pipe and water absorbing pipe, absorb air to cut and resolve it into water by absorbing and mixing effects, then after agtating and mixing of water pump to resolve the air further more, which is sent to the air-releasing system to be released. Since the air-dissolving pipe in circumfluence pipe-line has increased the time of gas-liquid transmission, it is assured that the air absorbed can be dissolved into water completely, and the air-dissolving pipe is much smaller that the conventional, about one tenth of it. The method can make use of the pressure difference between water-stressing pipe and water-absorbing pipe, only little energy from water pump is needed. The device has simple structure, saves energy, has high efficiency of dissolvement, rapid start-up of system, stale operation and is easy to be controlled and operated.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

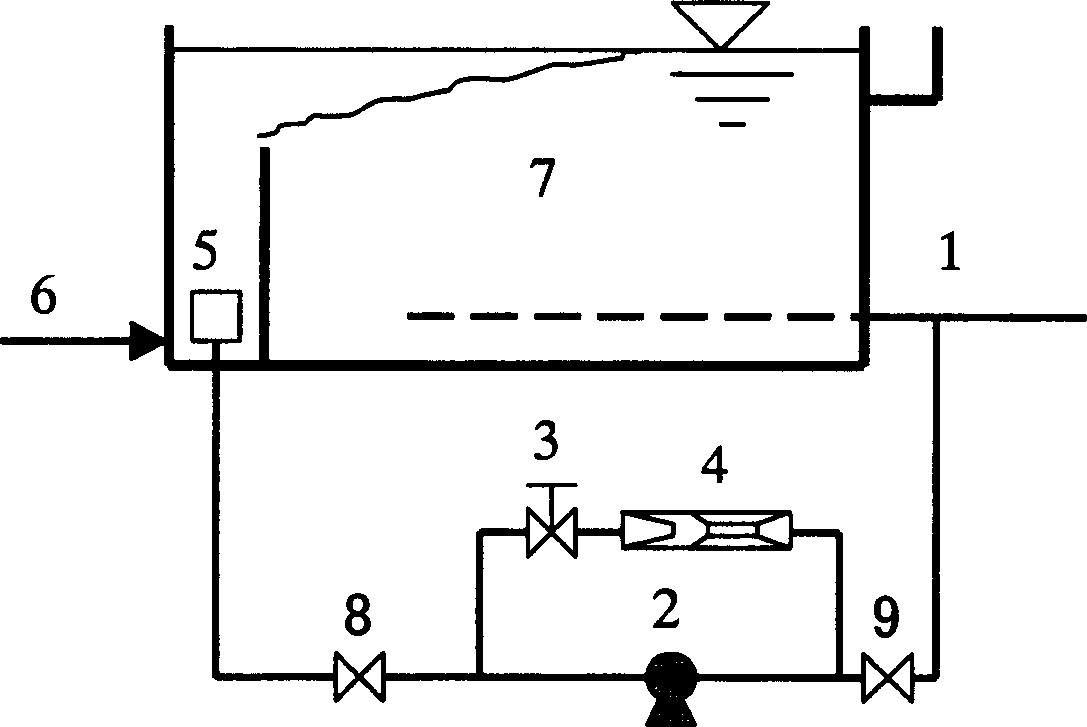

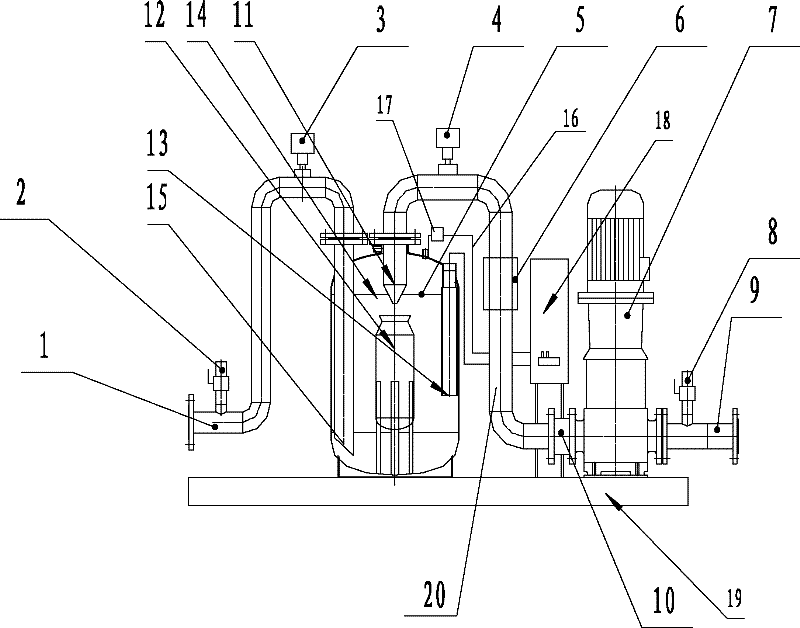

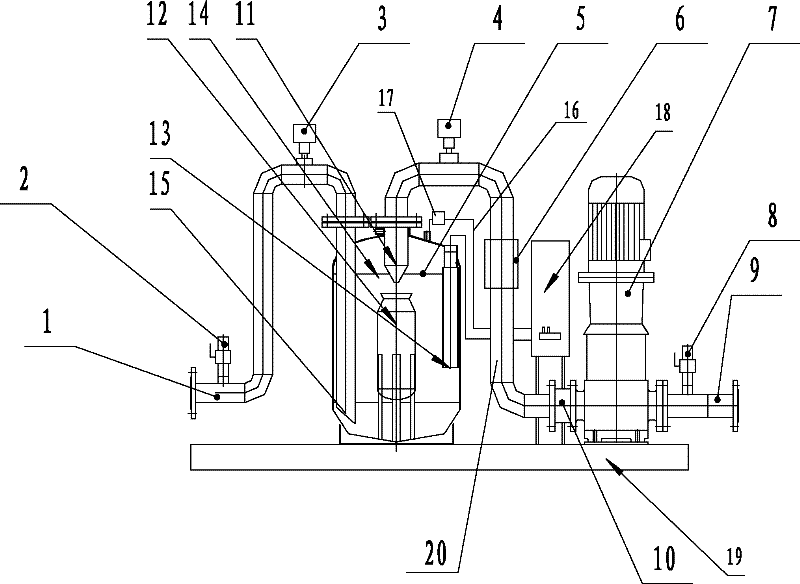

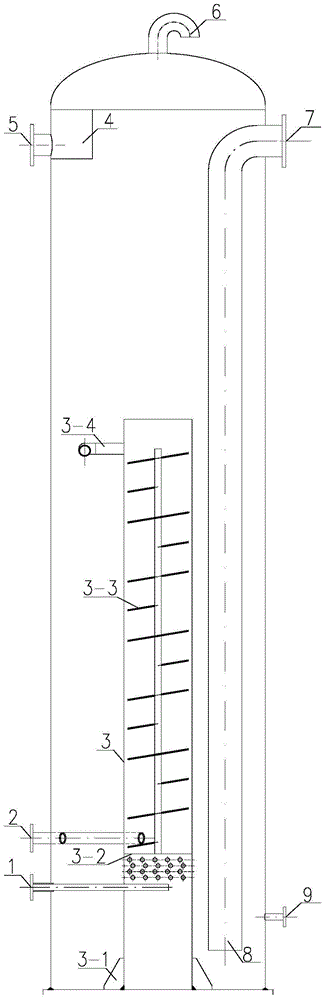

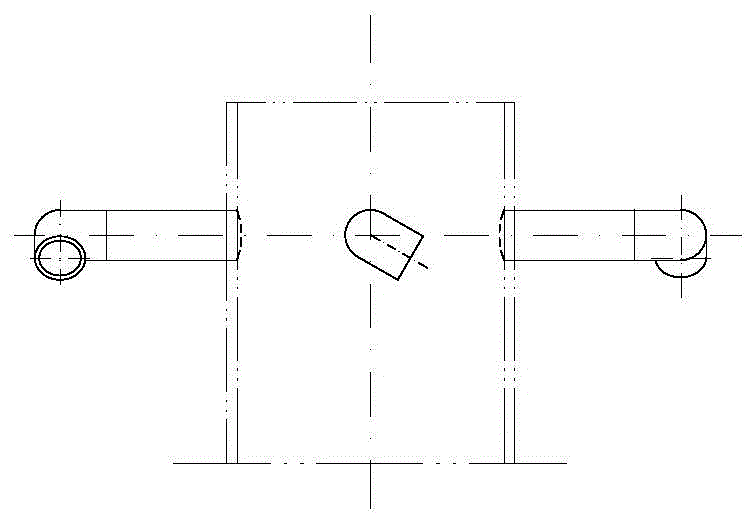

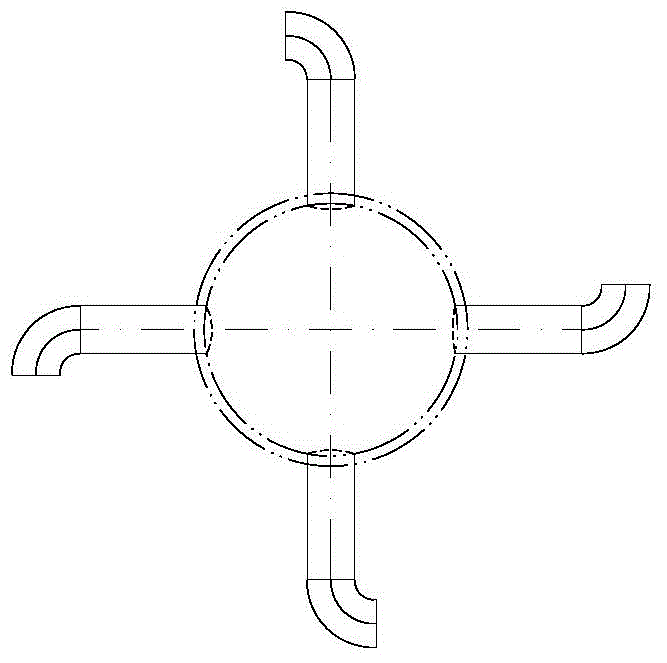

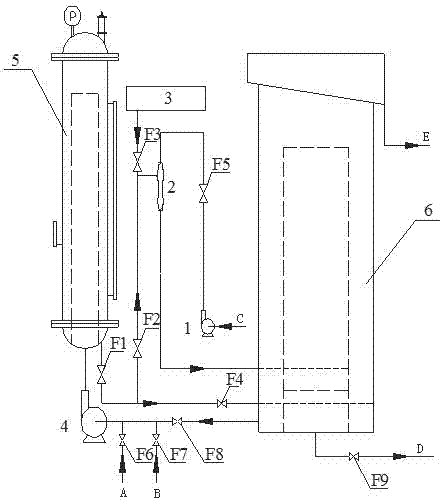

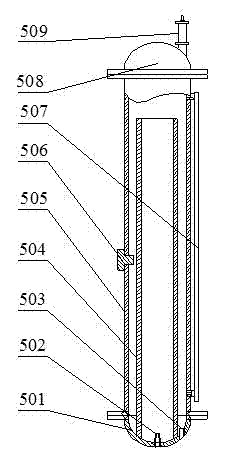

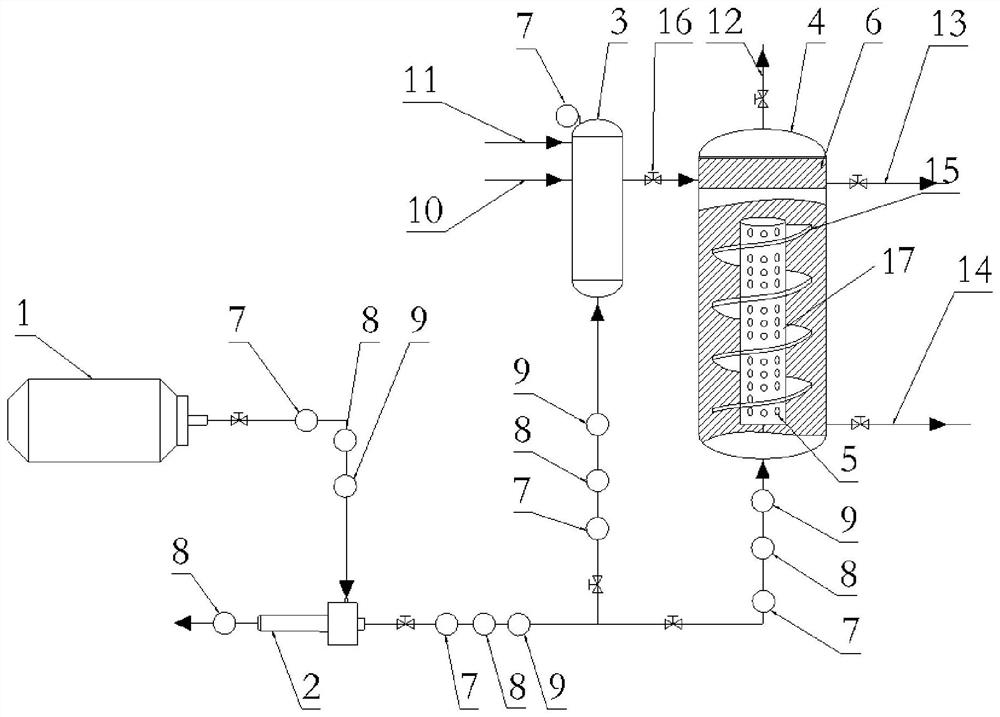

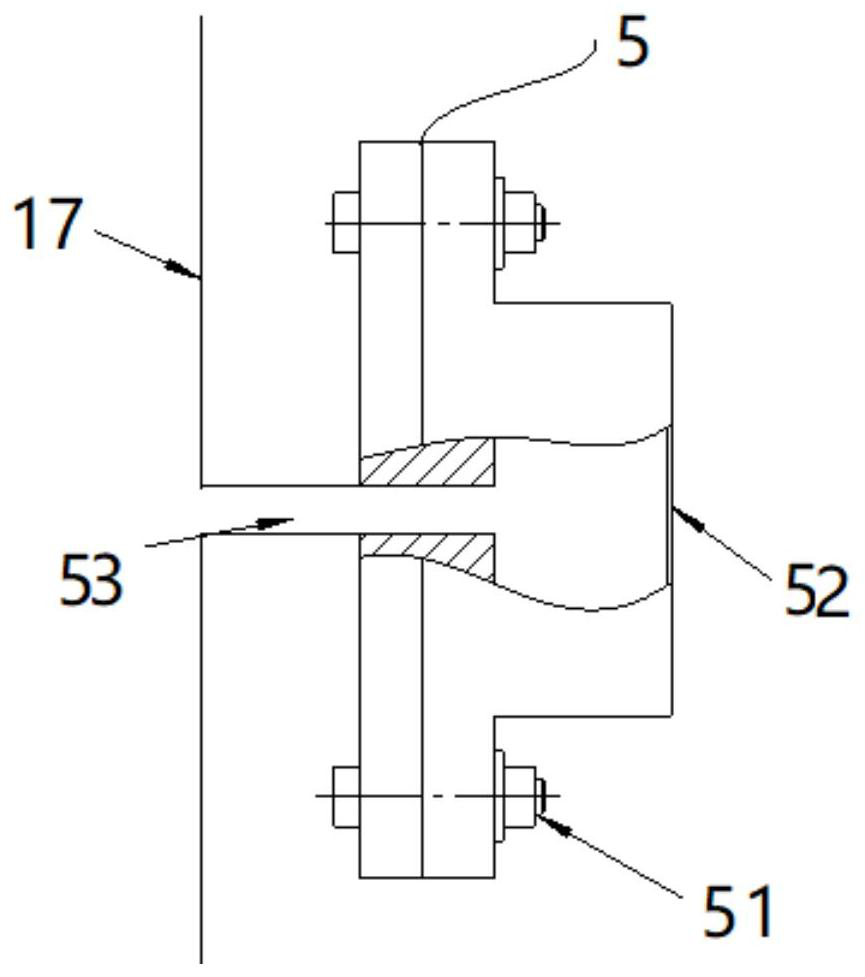

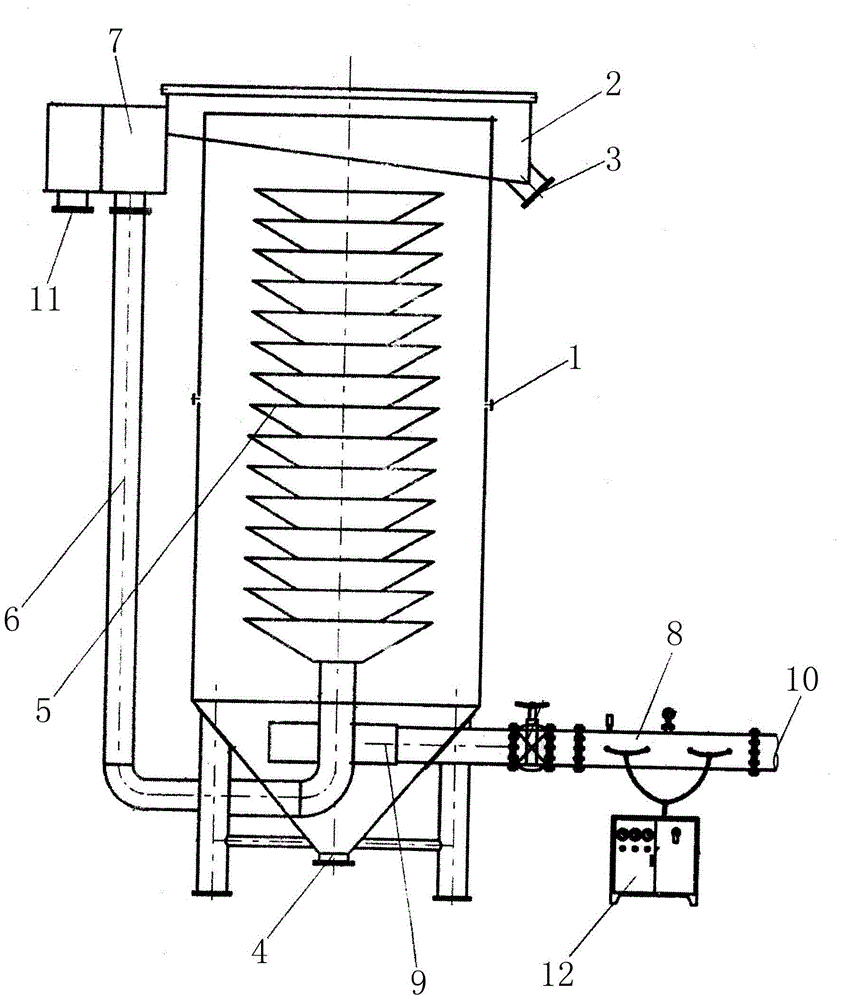

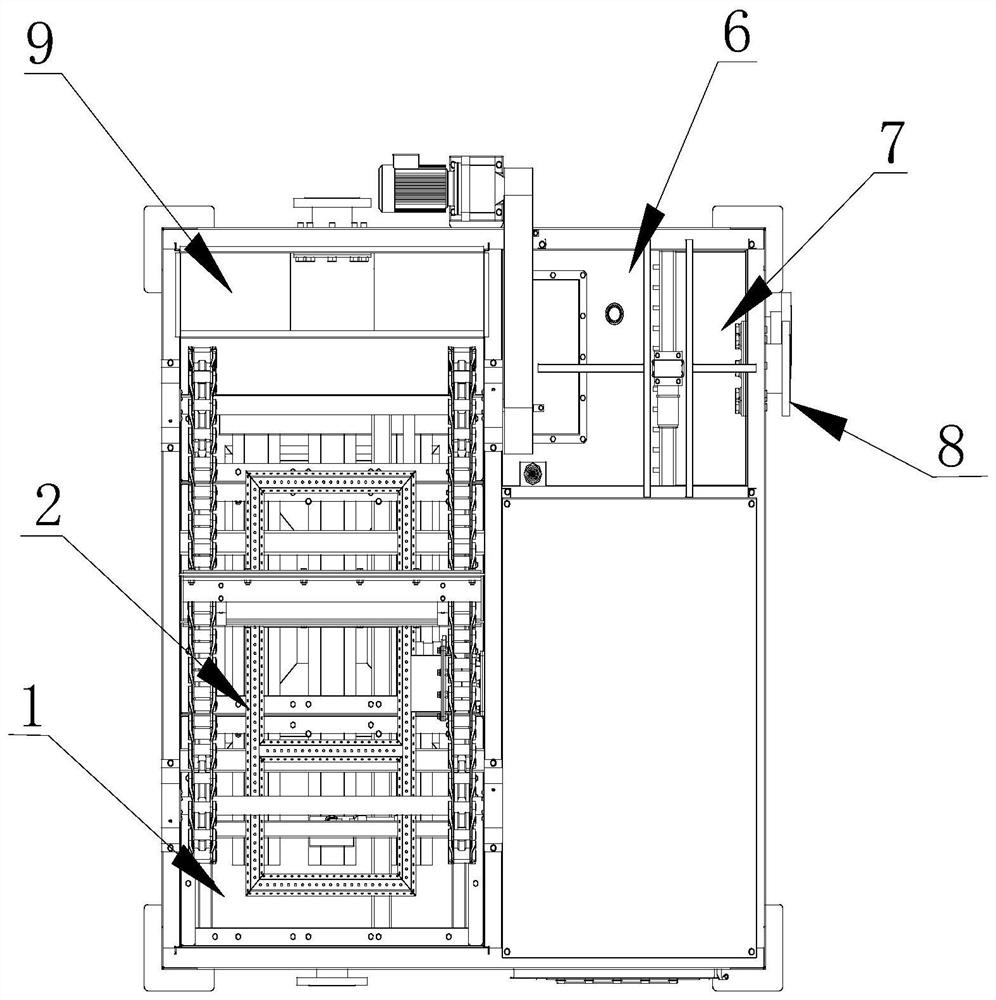

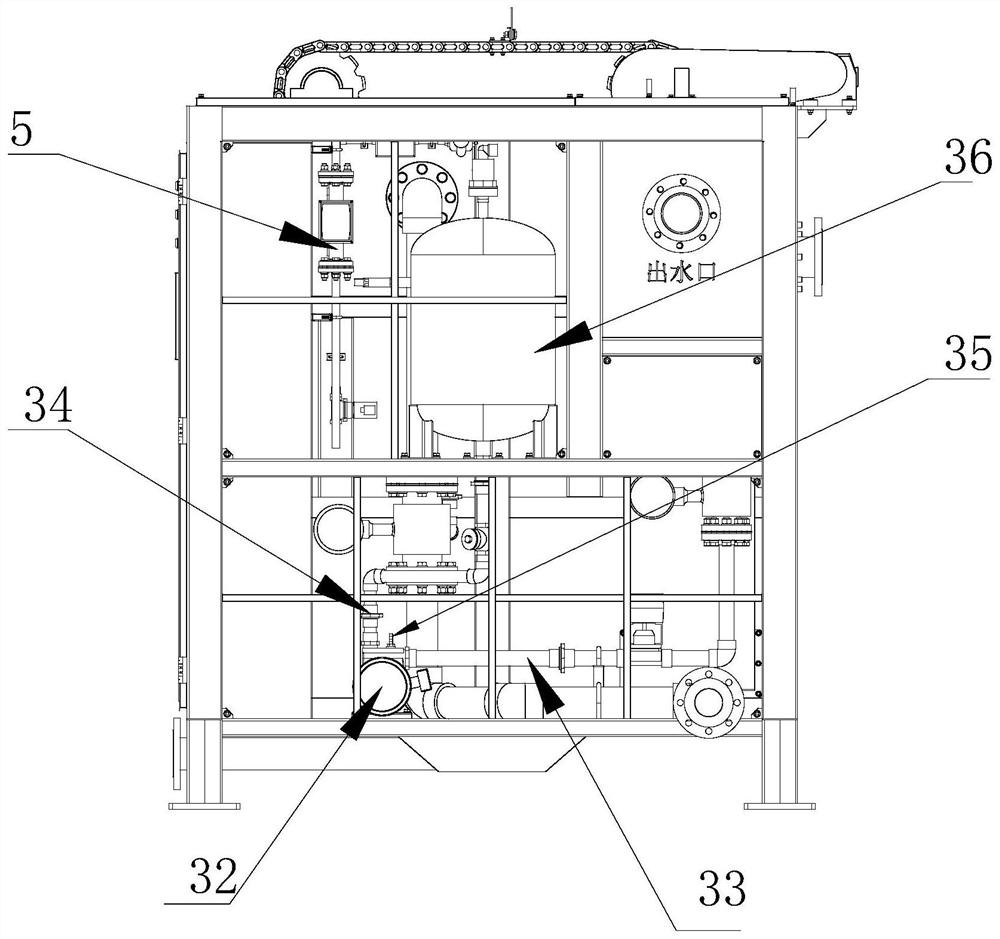

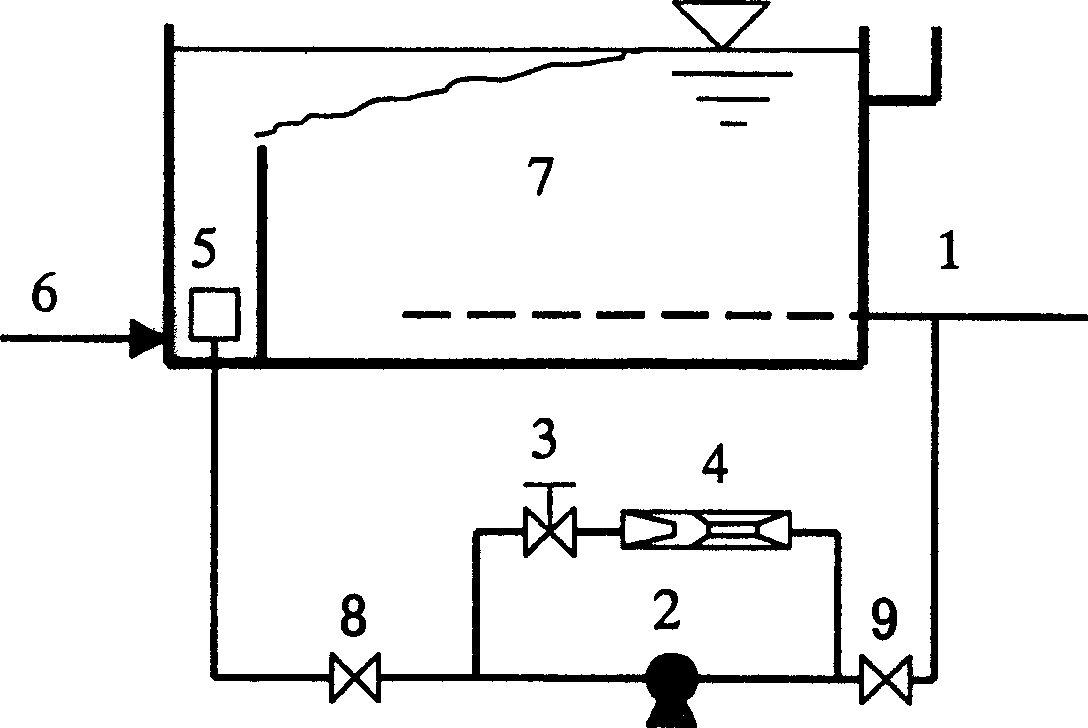

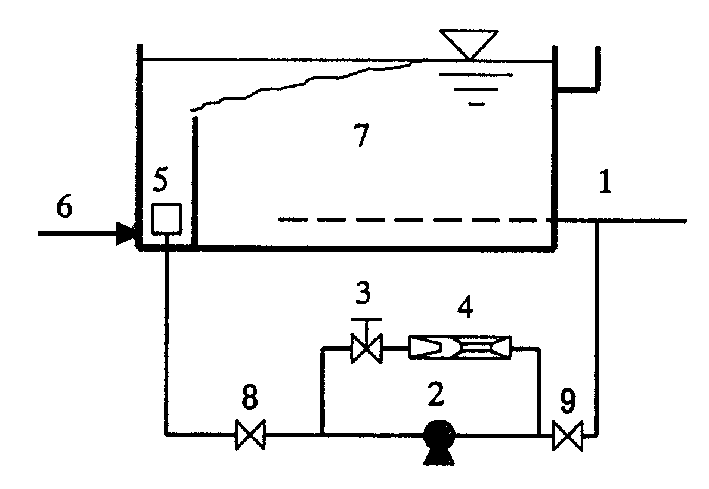

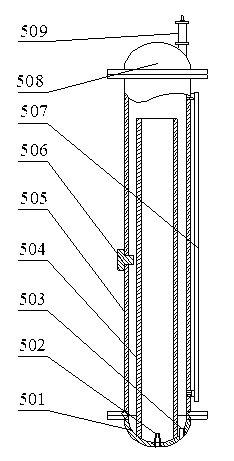

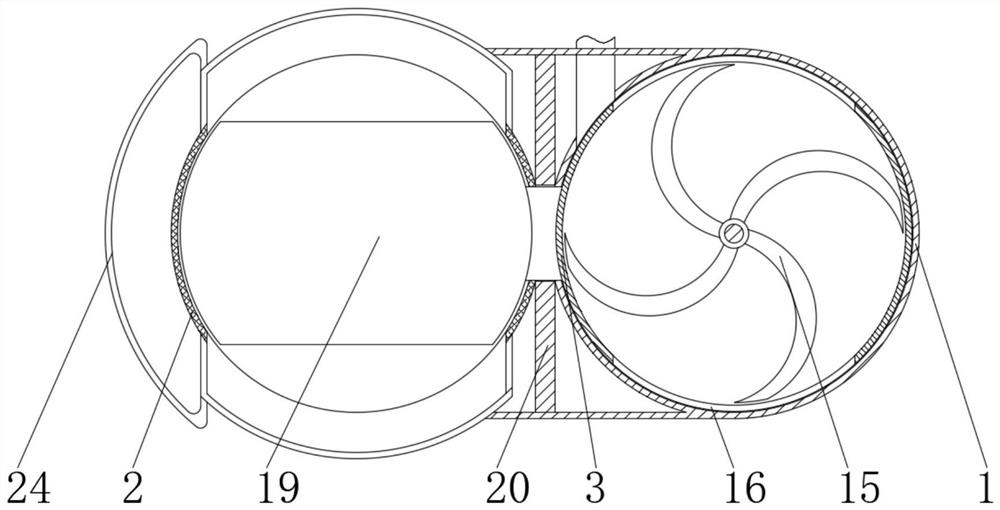

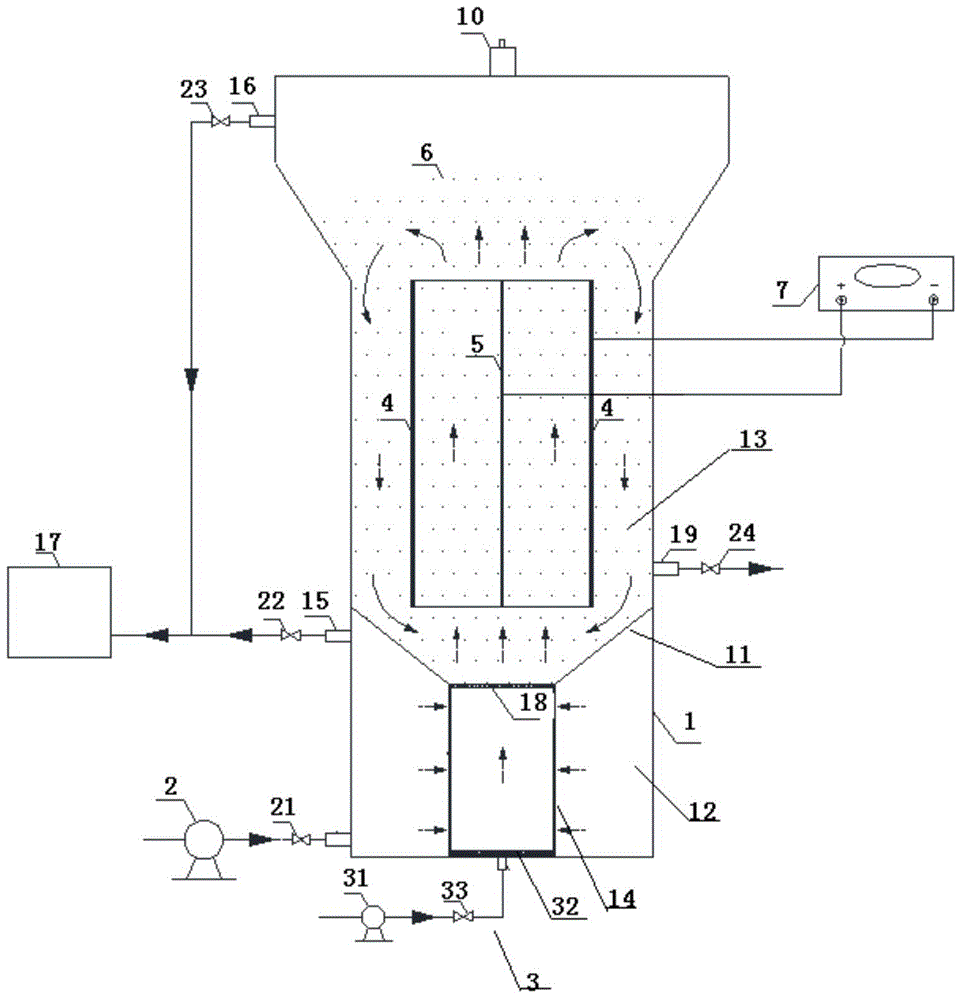

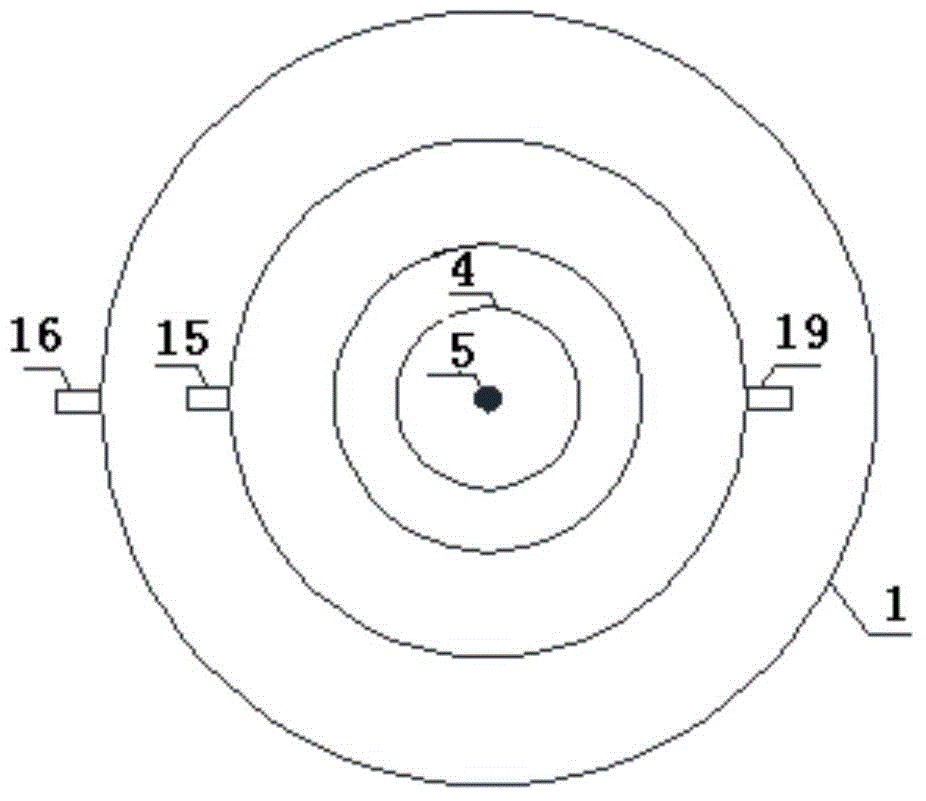

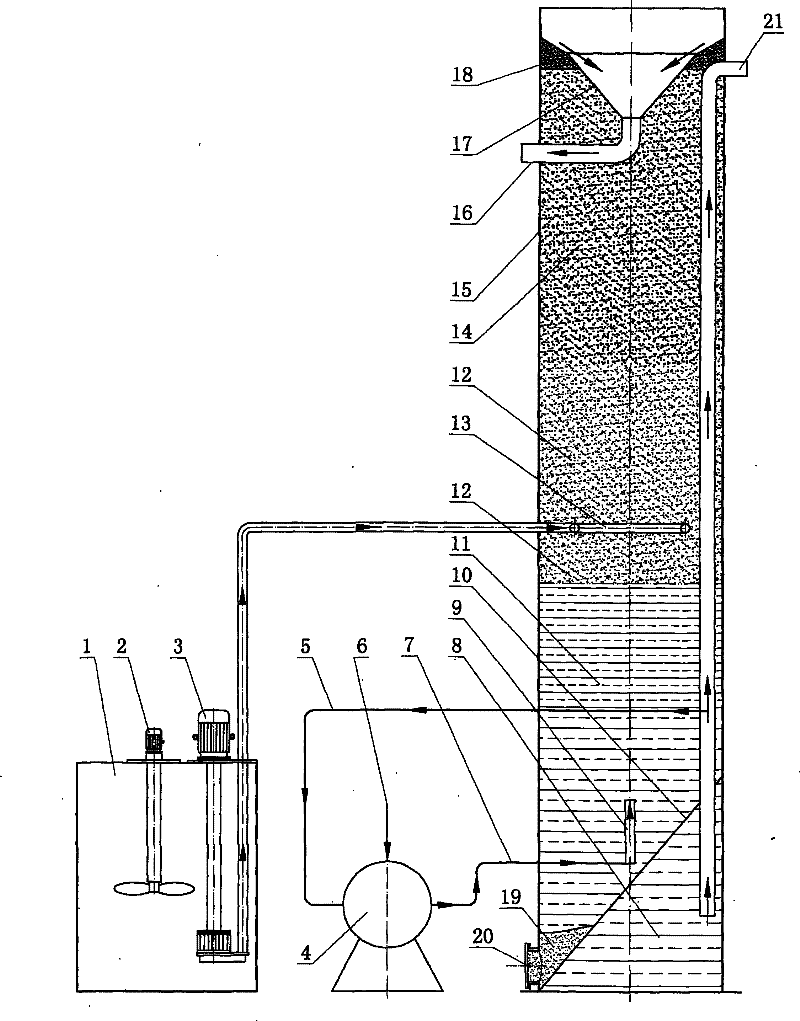

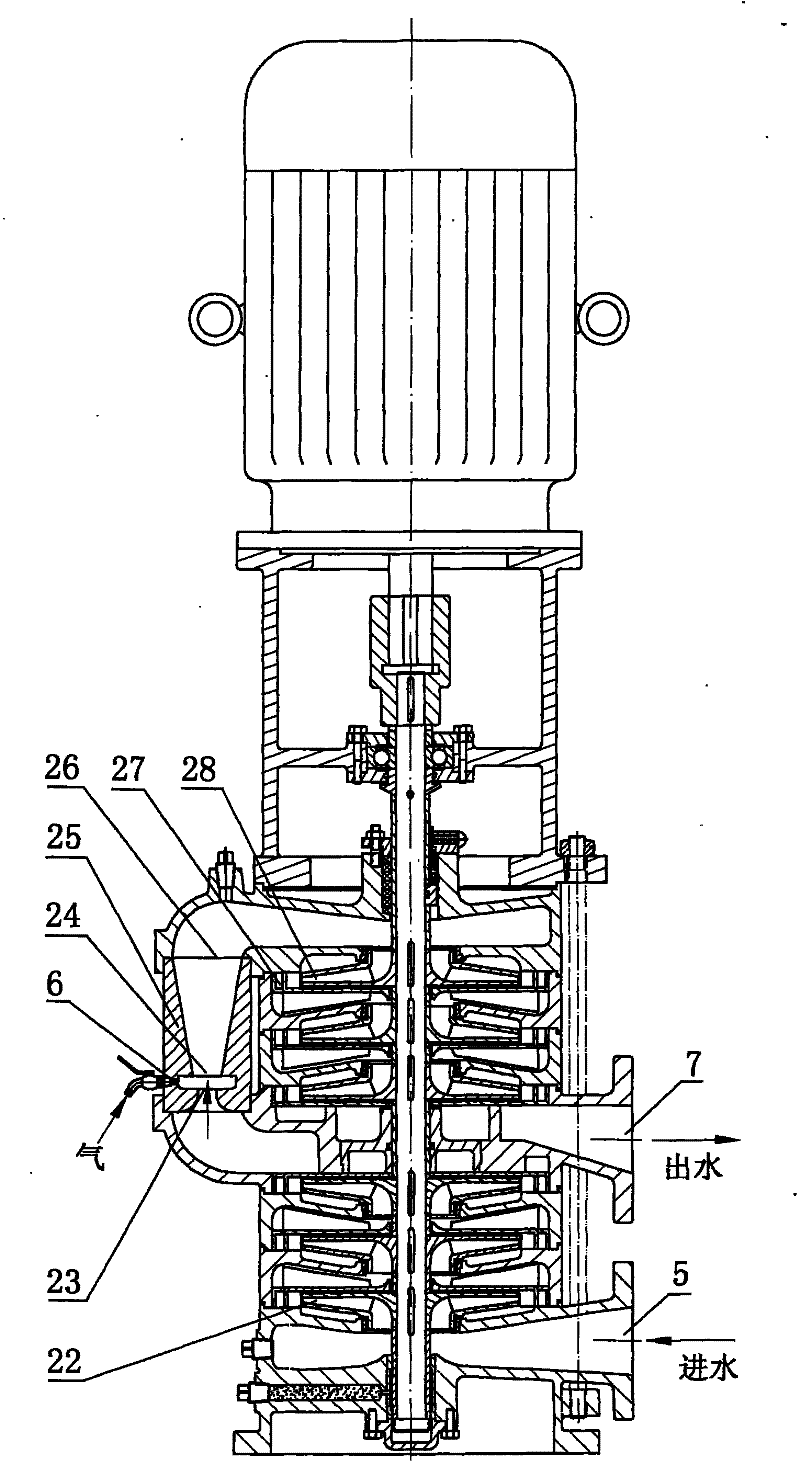

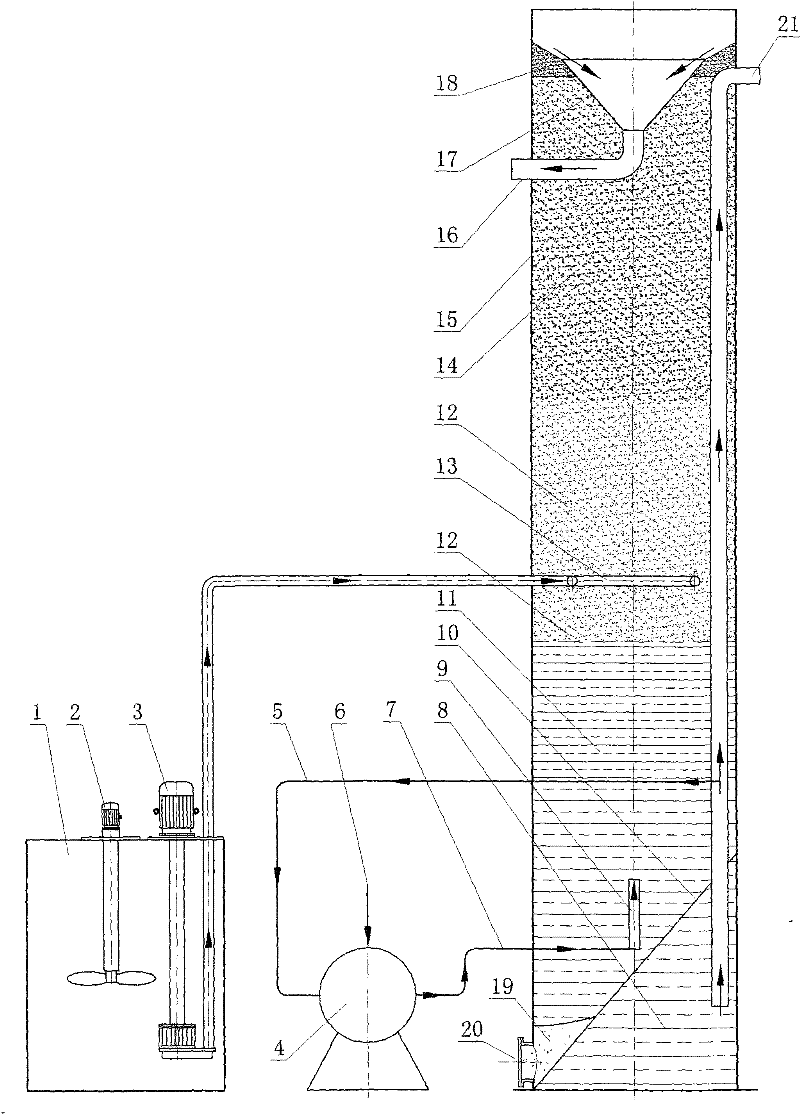

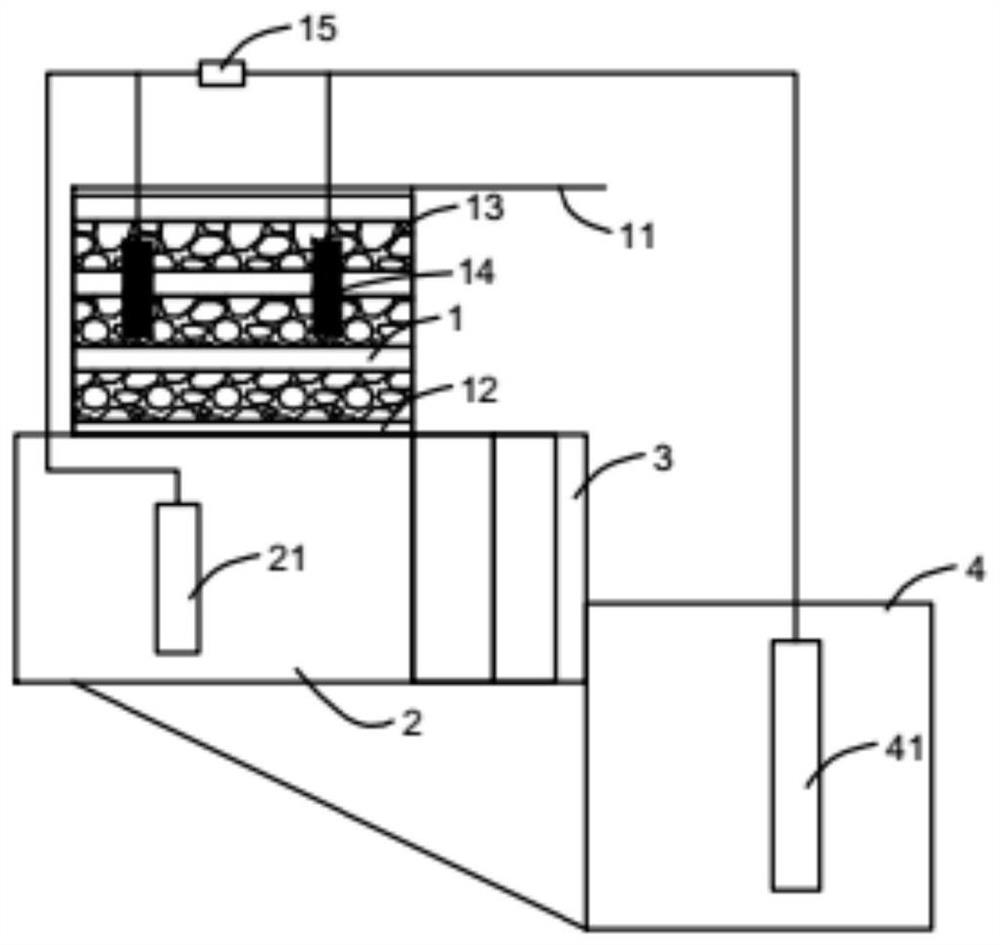

Circular current dissolved air copolymerization flotation system and technology

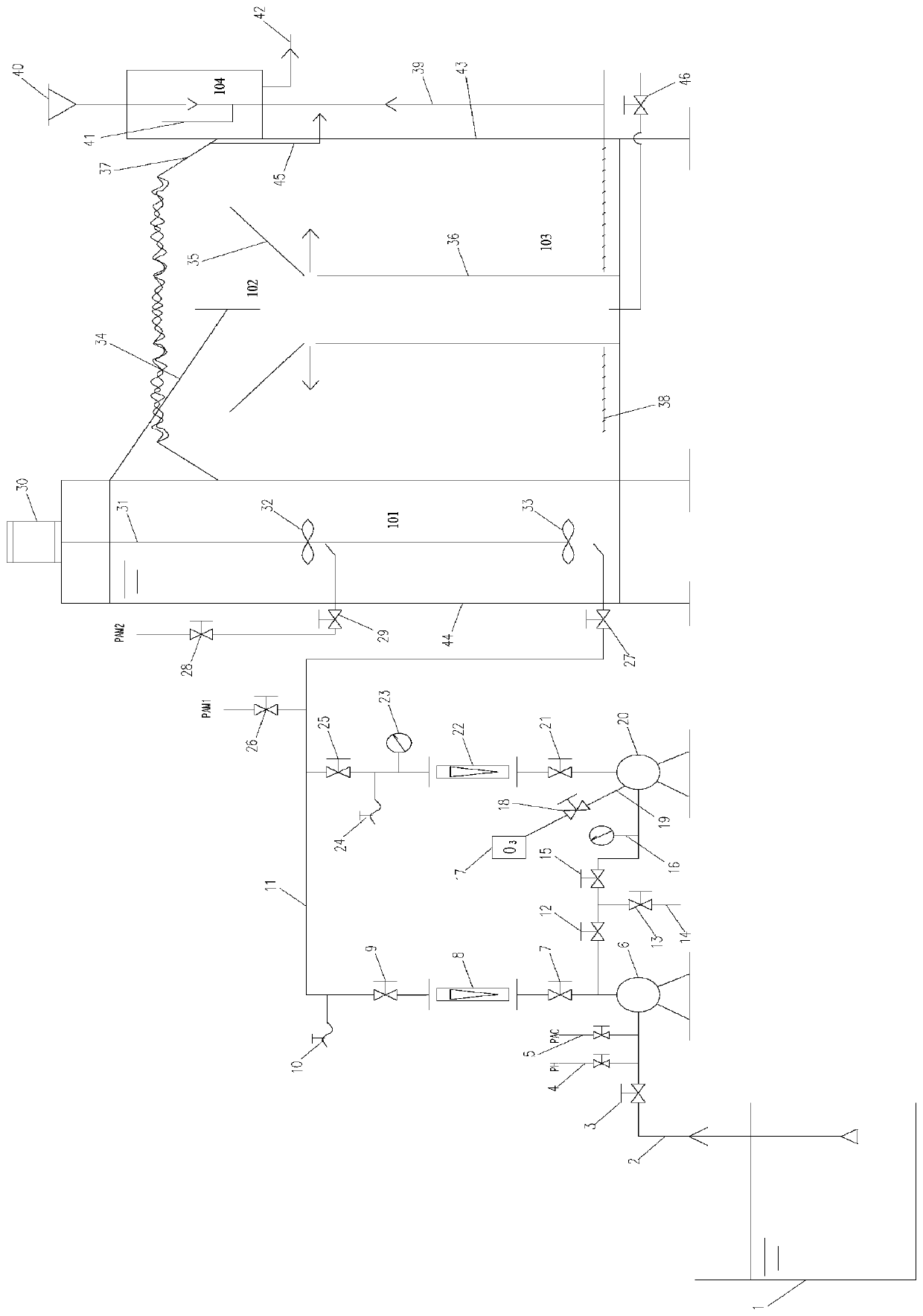

InactiveCN102730781AThe water output index is stableSimple processWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationGas solidAutomatic control

The invention discloses a circular current dissolved air copolymerization flotation system and a circular current dissolved air copolymerization flotation technology. The system mainly comprises a feeding pump, a jet pump, a doser, a gas-liquid mixing pump, a bubbling air dissolving tank and a flotation column. Because a gas-liquid mixing pump-bubbling air dissolving tank technology is adopted, the effluent index of dissolved air water is stable; the synchronous integration of medicine mixing and gas-solid-liquid three-phase coagulation copolymerization is realized by the jet pump, a coagulation technology unit does not need to be independently set, a flow is simplified, a stable gas-solid-liquid three-phase flocculating constituent can be generated, the floatation efficiency is improved,and the floatation effect is stabilized. A double-layer sleeve columnar floatation tank is adopted, so that a floor space is small, automatic control is easy to realized, coagulation copolymerizationfloatation can be realized, dissolved air energy consumption is lowered, the floatation efficiency is improved, the floatation technology process is simplified, and the automatic control is easy to realize. The circular current dissolved air copolymerization flotation system disclosed by the invention has the advantages of simple technology, no noise pollution, low energy consumption and good floatation effect.

Owner:CHINA UNIV OF MINING & TECH

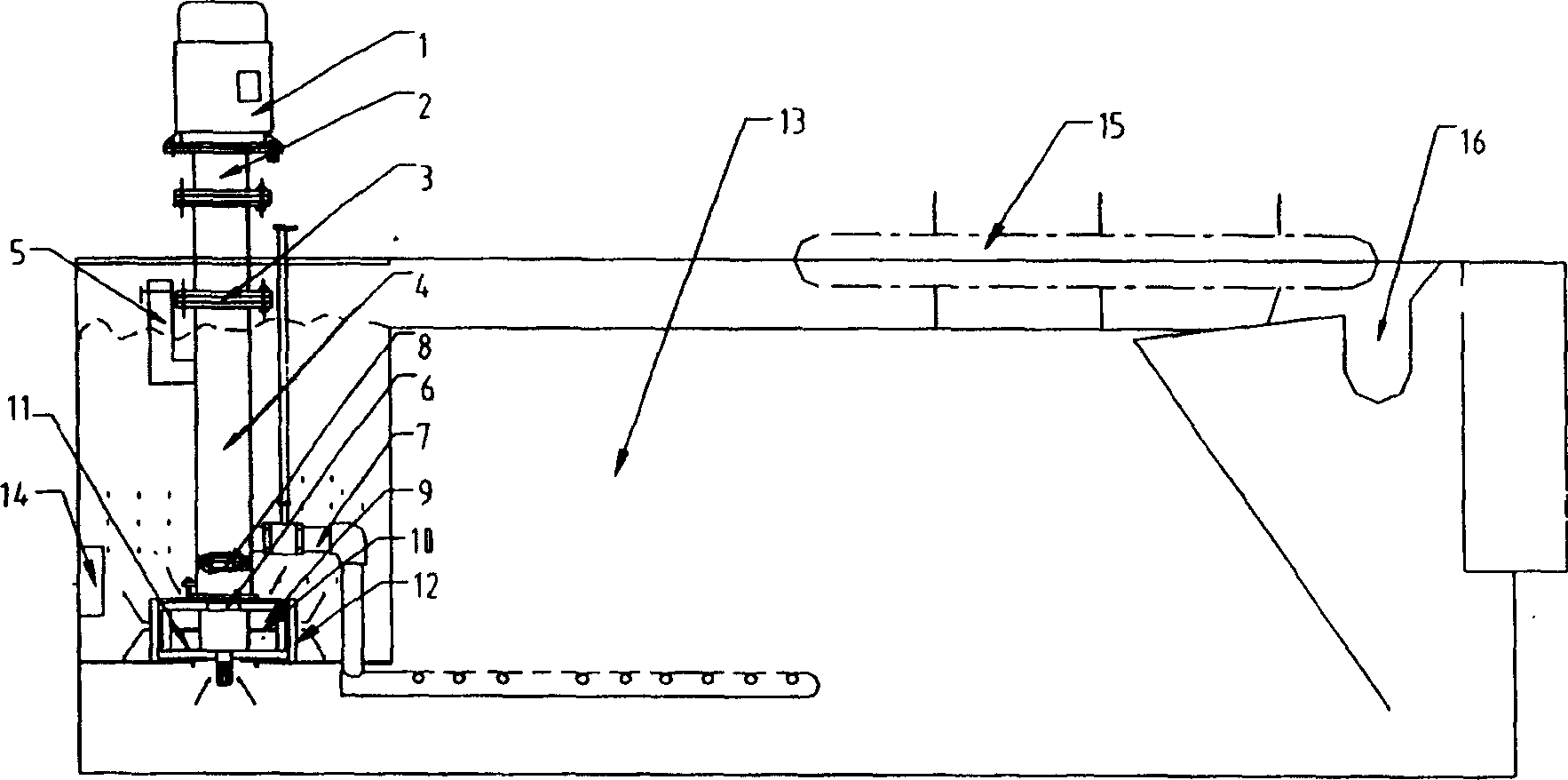

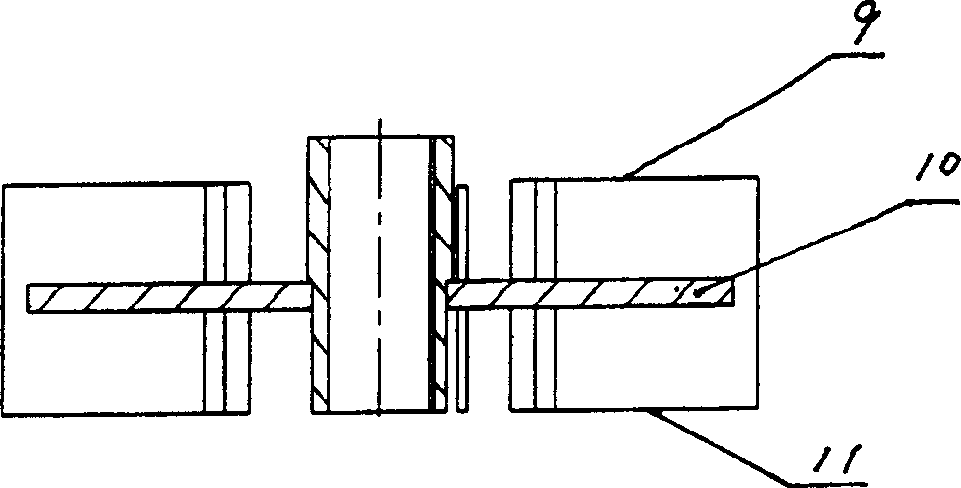

High-efficiency, circulation flow jetting and air dissolved in water type flotation method, and equipment therefor

InactiveCN1418824AImprove air flotation efficiencyImprove solubilityWater/sewage treatment by flotationIt equipmentEngineering

The present invention provides a high-effective circulating injection air-dissolving air-float method and its equipment. It is characterized by that it utilizes the jetter on the water-pressing pie and water-sucking pie circulating pipeline to inject air, and utilizes entrainment and mixing action to suck air, and cut and dissolver air in water, then uses the stirring and mixing action of water pump to further dissolver air, and pressure-conveys the dissolved air into the air-releasing system to release. Because the air-dissolving pipe in the circulating pipeline increases the air-liquid mass-transferring time, so that it can ensure that the sucked-in air be fully dissolved in the pressure air-dissolving water. Said invention is simple in structure and its dissolving efficiency is high.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

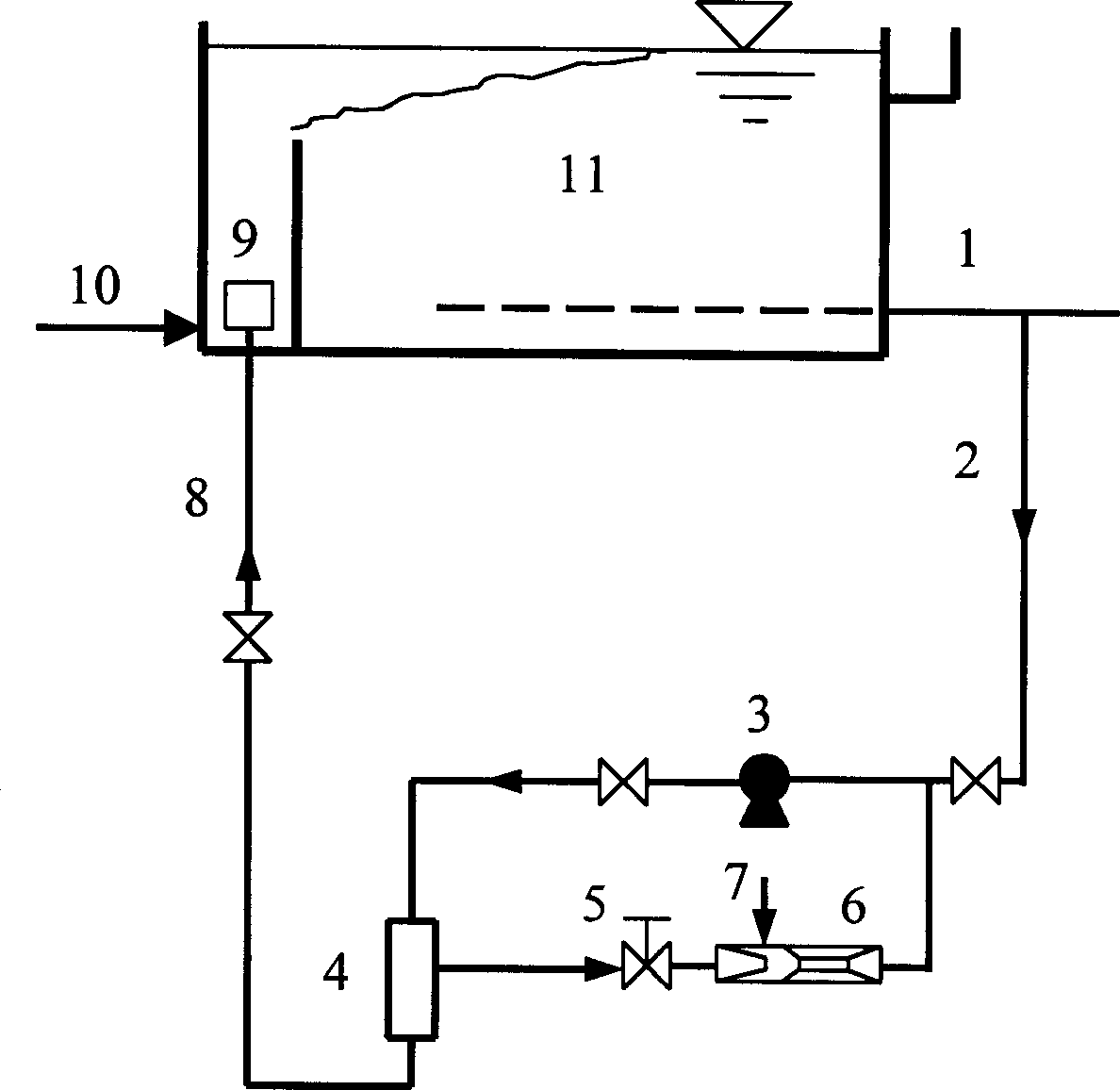

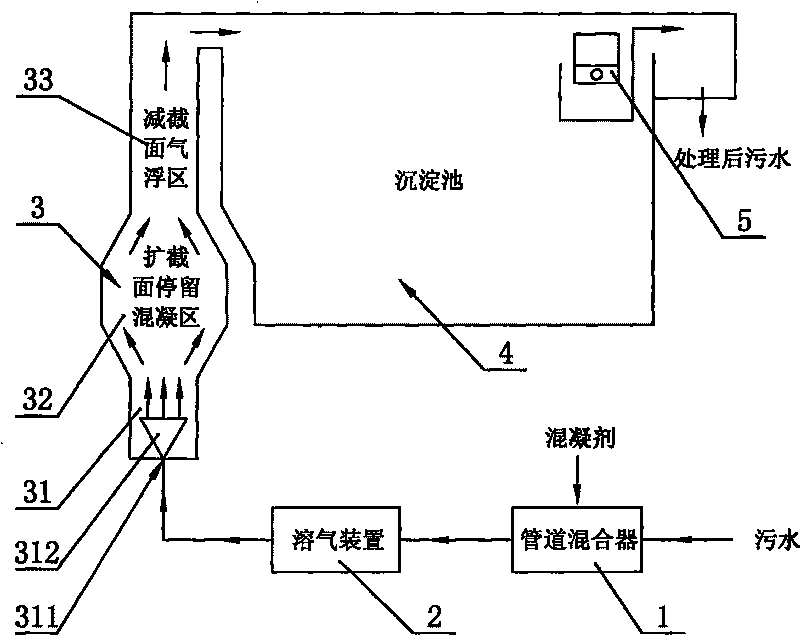

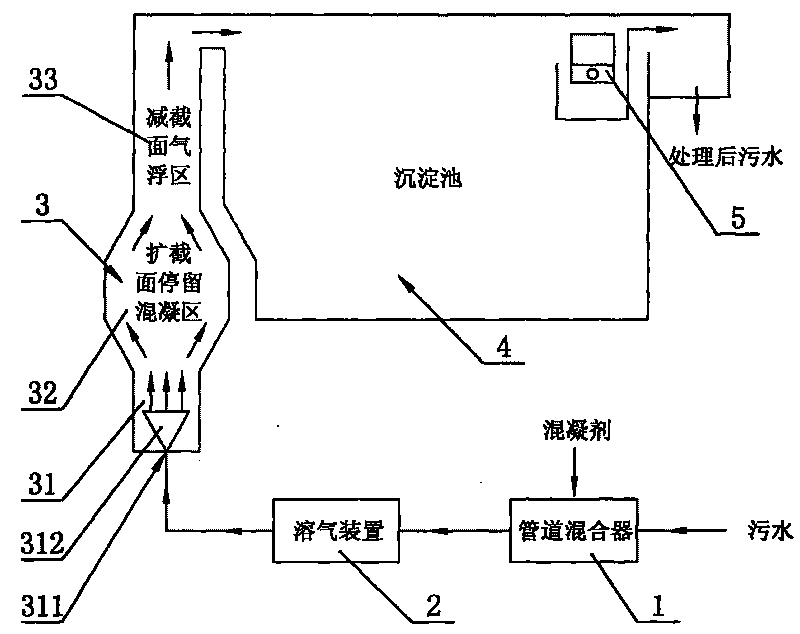

Sewage disposal plant combining coagulation and air flotation

InactiveCN101708910ASmall footprintReduce energy consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSmall footprintSewage treatment

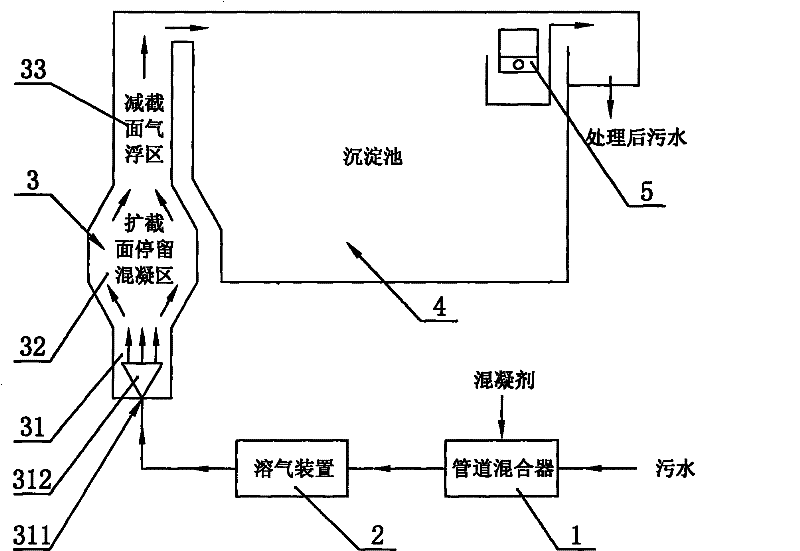

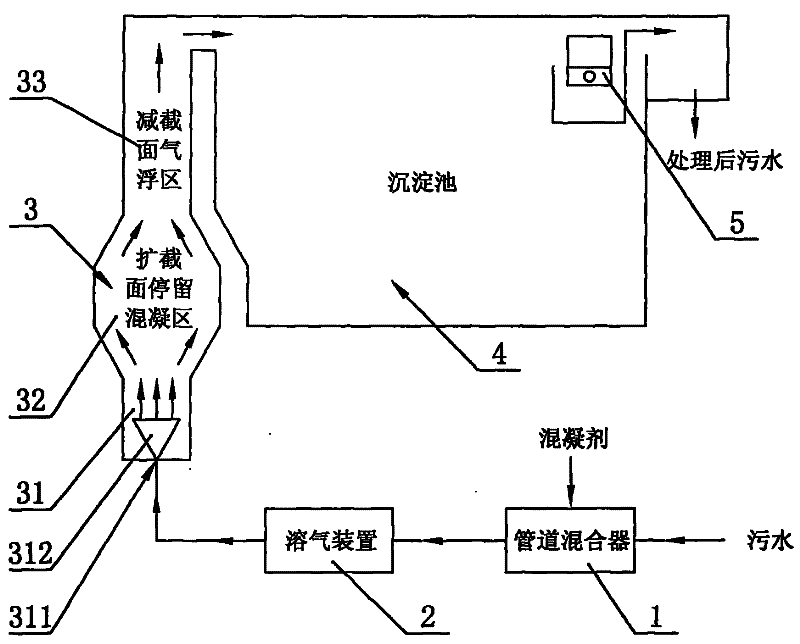

The invention discloses a sewage disposal plant combining coagulation and air flotation, comprising a pipeline mixer, a gas dissolving device, an extending section remaining coagulation zone and a decreased section air flotation area; sewage passes through the device to directly enter a desilter so as to realize solid-liquid separation. The invention has the characteristics of simple equipment, small floor area, low energy consumption, easy control, high air flotation efficiency and the like and is especially suitable for processing sewage with smaller flow.

Owner:WENZHOU UNIVERSITY

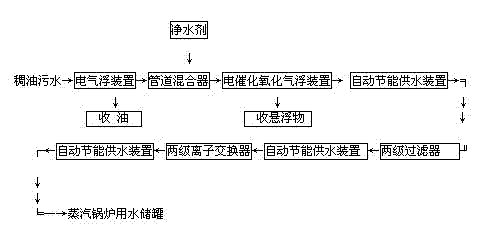

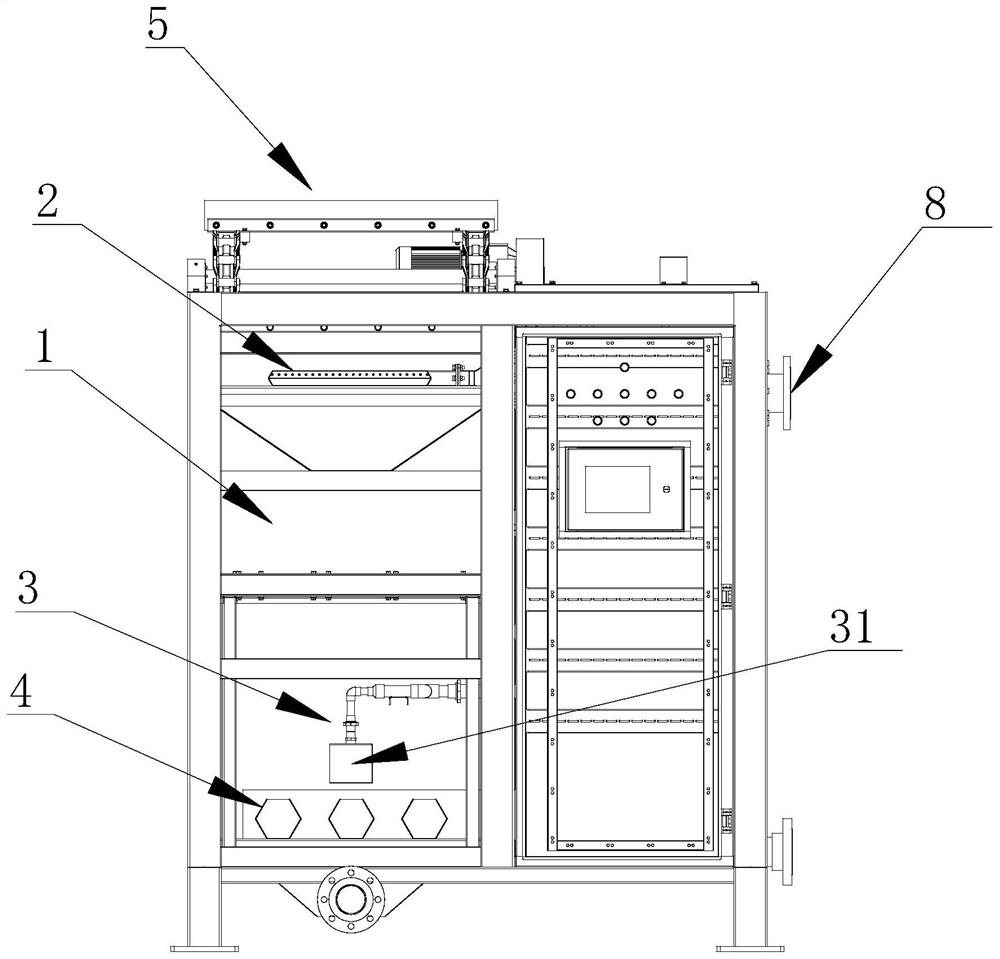

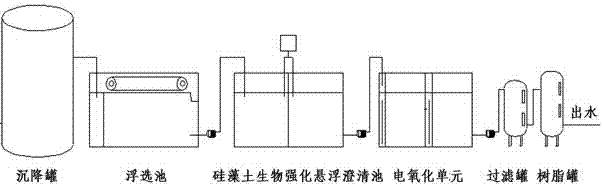

Method for applying waste water of viscous oil after treated to low-pressure steam boilers

InactiveCN103112976ASmall critical particle sizeReduce deliveryWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentElectricityDihydrogen oxide

The invention discloses a method for applying waste water of viscous oil after treated to low-pressure steam boilers. The method mainly comprises the following steps: A, floating oil operation is carried out on the waste water of the viscous oil, and then the waste water of the viscous oil enters an electric floating device so as to further remove the oil; B, the outlet water after added with water purifier passes through a mixer, and then enters an electric catalytic oxidation floating device to carry out electric floating operation; C, the outlet water of the electric catalytic oxidation floating device passes through a filter device to be filtered; and D, the filtered waste water enters an ion-exchange tower to be softened, and then the softened waste water is applied to the low-pressure steam boilers. The treated waste water can replace the clear water to be applied to the low-pressure steam boilers, so that clean water which is in increasing shortage can be saved, and the problems that the waste water of the viscous oil cannot be discharged and the environment is polluted can be solved.

Owner:杭州广联新能源科技有限公司

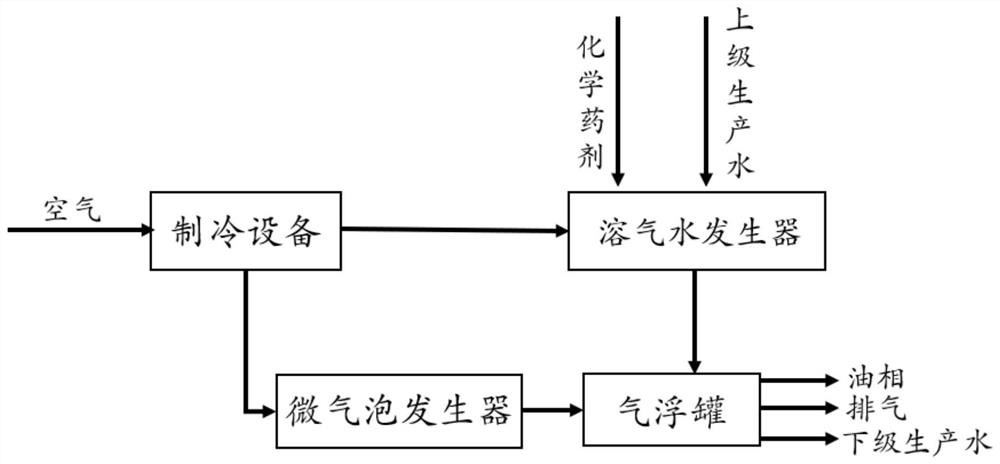

Method and device for removing oil by cold air flotation

PendingCN112357994AImprove air flotation efficiencyReduce usageWater treatment parameter controlFatty/oily/floating substances removal devicesRefrigeration plantMicrobubbles

The invention provides a method and a device for removing oil by utilizing cold air flotation, the method comprises the following steps: cold air prepared by refrigeration equipment is divided into two paths, the first path of cold air is led to a dissolved air water generator containing production water, and the second path of cold air is led to an air flotation tank through a microbubble generator; wherein dissolved oil is separated out from the production water under the action of the first path of cold air, and the first path of cold air is dissolved into the production water under high pressure and released into the air floatation tank through a pressure reducing valve; the second path of cold air generates low-temperature micro-bubbles in the micro-bubble generator, and the low-temperature micro-bubbles enter the air floatation tank to further separate out dissolved oil in the production water; the dissolved-state oil is adhered to the microbubbles, rises and is discharged through the air floatation tank; and the treated production water is discharged from the lower part of the air floatation tank. The device comprises refrigeration equipment, a dissolved air water generatorand a micro-bubble generator which are respectively connected with the refrigeration equipment, and an air floatation tank which is respectively connected with the dissolved air water generator and the micro-bubble generator. The device is simple in structure, economical, efficient and high in adaptability.

Owner:EAST CHINA UNIV OF SCI & TECH

Device and method for recycling and treating drilling and completion waste liquid through ultrasonic technology

PendingCN113845257AA large amountSmall diameterWaste water treatment from quariesFatty/oily/floating substances removal devicesUltrasonic cavitationUltraviolet lights

The invention provides a device and method for recycling and treating drilling and completion waste liquid through ultrasonic technology. The device comprises a shell, and is characterized in that an inclined baffle is arranged in the shell and divides the shell into a cavitation air flotation area and a photocatalytic oxidation area; a slag scraping plate, a slag discharging groove and a slag discharging pipe are arranged at the top of the shell; an inclined plate filter and a water outlet pipe are arranged at the lower part of the photocatalytic oxidation area; and a photocatalytic partition plate and an ultraviolet light tube are arranged in the photocatalytic oxidation area. The device has the advantages that a hydrodynamic cavitation device and an ultrasonic cavitation device are integrated, so that the problem of instability of tiny bubbles generated by an air flotation device is solved. According to the device and method, hydrodynamic cavitation, ultrasonic wave, ozone catalysis and photocatalysis technologies are combined, and ozone is promoted to be quickly decomposed to generate more oxidized free radicals, so that the degradation rate of organic matters is increased, meanwhile, the ozone adding amount is reduced, the waste liquid treatment operation cost is reduced, the treatment process procedure is optimized, and the device and method have important significance on construction of ecological oil fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

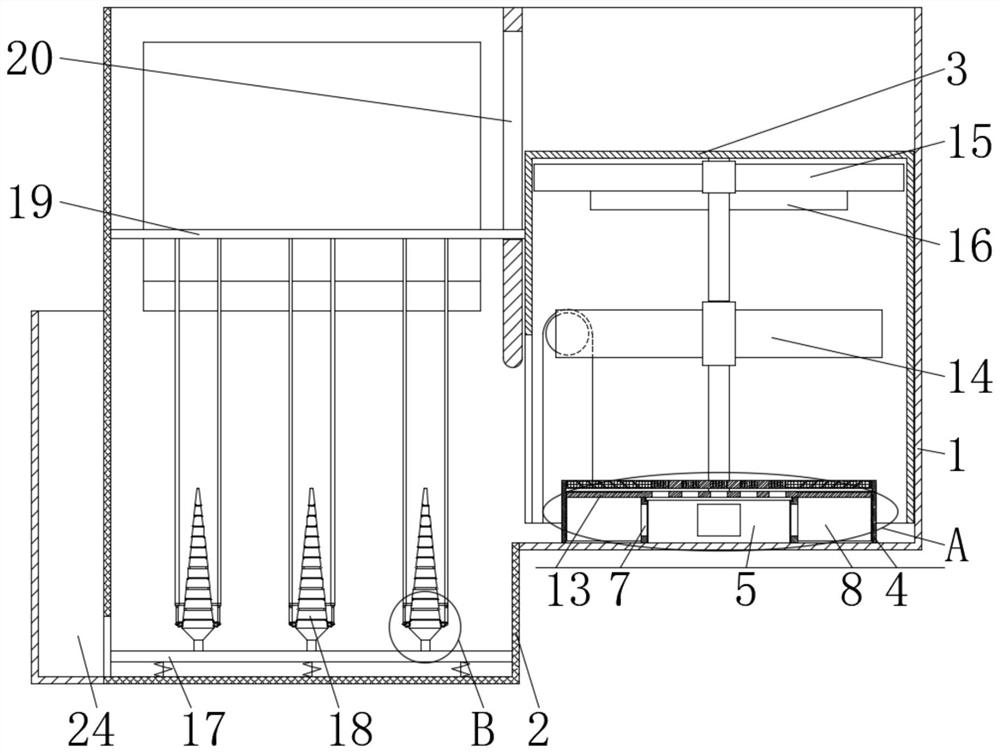

Ultra-extensive micro-bubble air-flotation machine

InactiveCN104150554ASave powerLarge amount of processingWater/sewage treatment by flotationMicro bubbleSludge

The invention discloses an ultra-extensive micro-bubble air-flotation machine which is characterized in that a dross collecting tank is mounted on the top of a tank body; a dross discharge tube is arranged at the bottom of one side of the dross collecting tank; a sludge discharge hole is formed in the bottom of the tank body; a group of inverted conical flow guide water collection pieces are arranged in the middle inside the tank body; the bottoms of the inverted conical flow guide water collection pieces are connected with a high-level tank which is arranged at the upper part of one side of the tank body through a U-shaped clean water pipeline; an air dissolving device is arranged on the other side of the tank body; the air dissolving device is connected with a water distributor through a pipeline; the water distributor is arranged at the bottom inside the tank body. Due to the components, the ultra-extensive micro-bubble air-flotation machine is capable of dissolving air into sewage directly, the dross can be discharged by virtue of self-flowing, the sludge at the bottom of the tank body can be discharged automatically, and thus both the power is saved and the processing amount is increased. The ultra-extensive micro-bubble air-flotation machine is small in occupied space, simple to operate and debug and high in air-flotation efficiency.

Owner:台东蛟

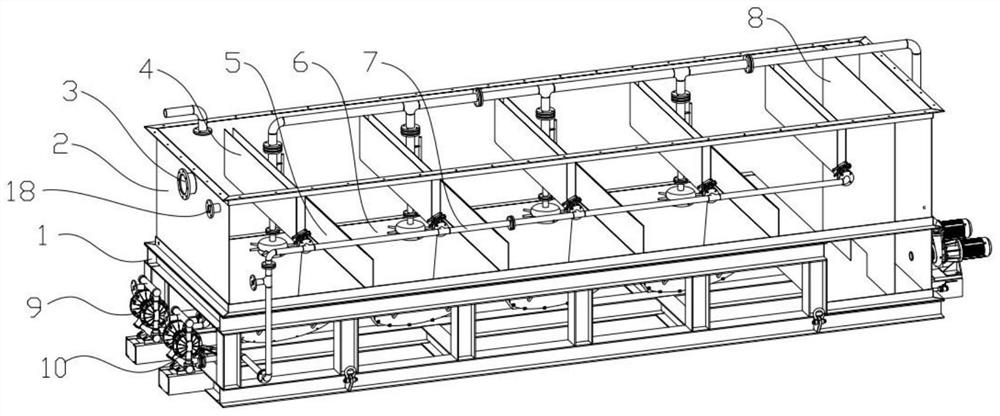

Micro-power flotation separation equipment

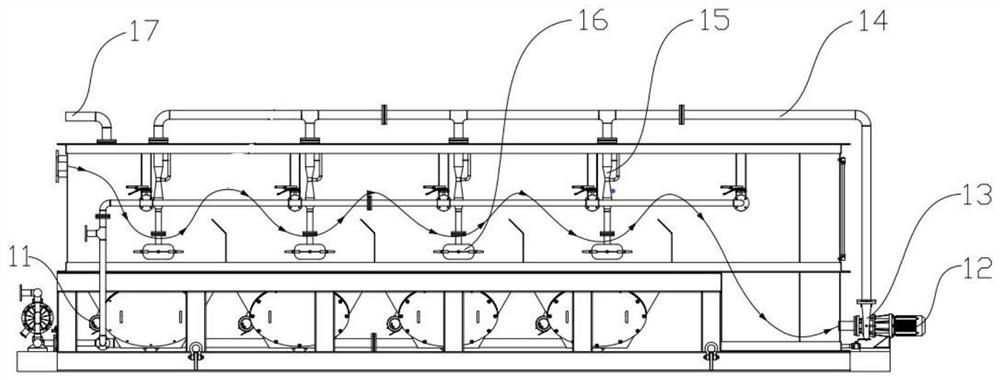

PendingCN113830913AIncrease the air flotation treatment timeLarge amount of processingFatty/oily/floating substances removal devicesMultistage water/sewage treatmentDiaphragm pumpSludge

The invention relates to the technical field of sewage treatment, in particular to micro-power flotation separation equipment, wherein micro-power gas-liquid mixing is achieved by utilizing a Venturi principle, a large amount of micro-bubbles are generated through efficient jet injection, an oil liquid is aerated into floating oil foam floating on the upper layer of a mixed turbid liquid, the mixed turbid liquid is blocked by a box body high partition plate and a U-shaped oil collecting tank to form loopback flow in a circulating treatment process of the mixed turbid liquid so as to increase the air flotation treatment time of the mixed turbid liquid and improve the air flotation efficiency, and a slag collecting hopper at the bottom of the box body can rapidly precipitate slag and mud and discharge the slag and mud out of a box body through a bottom slag discharging opening so as to facilitate slag and sludge separation. The equipment comprises a supporting base, a box body, a mixed turbid liquid injection port, a U-shaped oil collecting tank, a box body low partition plate, a bottom slag collecting hopper, an oil collecting manifold, a box body high partition plate, a slag mud diaphragm pump, an oil liquid diaphragm pump, a slag mud vibration motor, a clear water centrifugal pump, a circulating water centrifugal pump, a circulating manifold, a Venturi tube, an efficient jet ejector, a ventilation port and a clear water injection port, wherein an inner cavity is formed in the box body.

Owner:山东华伊环境技术有限公司

Coagulation-air flotation-agglomeration rapid separation system

ActiveCN109956587AEasy to handleEfficient removalWater treatment parameter controlMultistage water/sewage treatmentFiberSuspended particles

The invention relates to the technical field of environmental engineering. The invention particularly discloses a coagulation-air flotation-agglomeration rapid separation system which comprises: a sewage tank, a sewage inlet pipe, an acid and alkali adding pipe, a coagulant adding pipe, a sewage pump, a first connecting pipe, a first drainage pipe, a gas dissolving pump, a gas inlet nozzle, a second drainage pipe, a first coagulant aid adding pipe, a copolymerization reactor box body, a second coagulant aid adding pipe, a stirrer, a stirring rod, a flow guide pipe, a separation device box body, a partition plate, a sludge collecting pipe, a scum collecting tank, a purified water collecting pipe, a third connecting pipe, a purified water collecting tank and a water outlet pipe. The system can effectively treat residual impurities in the sewage treated by the coagulating sedimentation tank, is simple in treatment operation and low in treatment cost, can effectively remove suspended particles, emulsified oil, fibers, heavy metals and other impurities in the sewage, and is environment-friendly and pollution-free.

Owner:DALIAN JIAOTONG UNIVERSITY

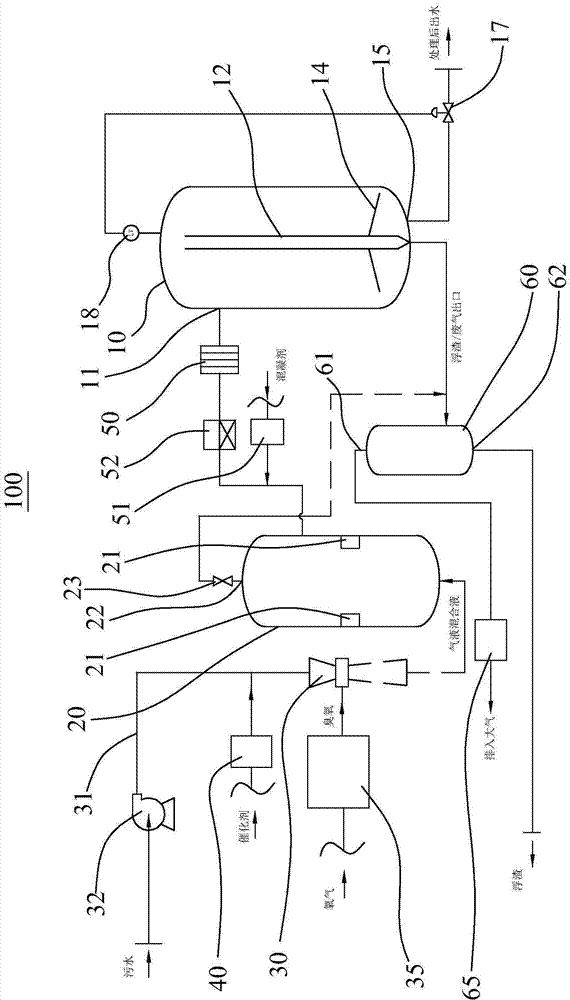

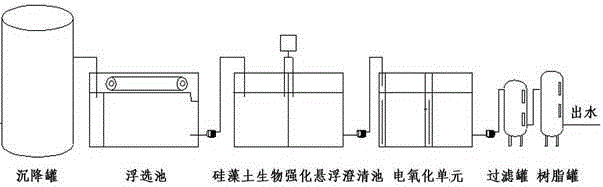

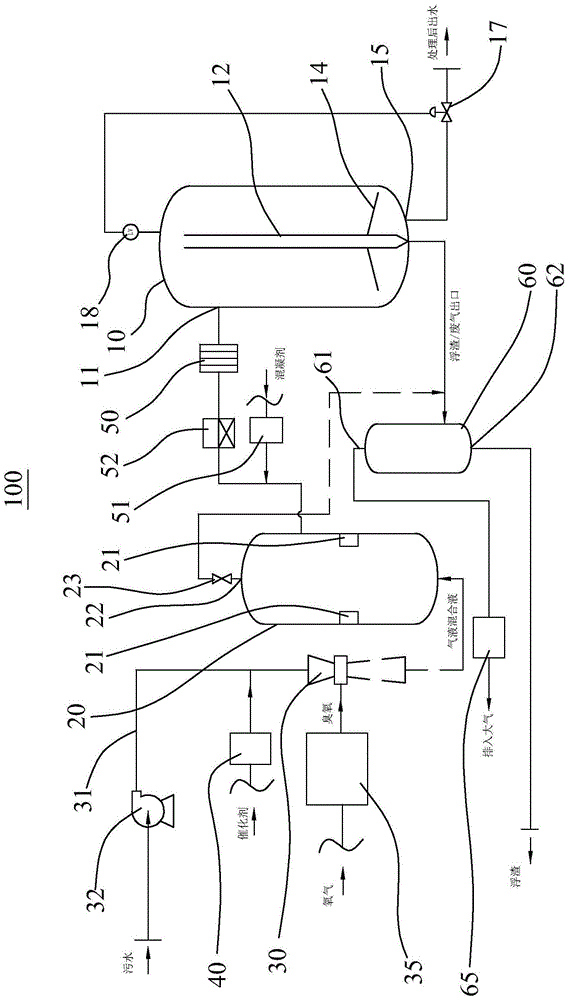

Method and device for treating degradation-resistant oil extraction sewage of oil field

InactiveCN105174662AReduce outputLow costMultistage water/sewage treatmentResource recoveryOil field

The invention discloses a method and device for treating degradation-resistant oil extraction sewage of an oil field. The treatment device and method aim at deep treatment, up-to-standard drainage or reuse of the oil extraction sewage of the oil field, the problem that in the process of treating degradation-resistant oil extraction sewage of an oil field, a traditional treatment process technology is poor in effectiveness is solved, the treatment device and method have the advantages of being low in treatment cost, good in effect and the like and can be widely applied to the field of degradation-resistant oil field oil extraction sewage deep treatment and reuse, the technical difficult problem of treating the degradation-resistant oil extraction sewage of the oil field can be solved fundamentally, and the resource recovery of the oil field sewage is achieved.

Owner:BEIJING SANDI HENGTIAN PETROLEUM SCI & TECH

Sewage air floatation treatment method

ActiveCN111847563AImprove air flotation efficiencyWater treatment parameter controlSpecific water treatment objectivesSewageDrainage tubes

The invention belongs to the field of wastewater treatment, and discloses a sewage air floatation treatment method which specifically comprises the following steps: inputting sewage into a main chamber through a water distribution module, and discharging treated purified water through a well drainage pipe, wherein the hydraulic load is 2-12m <3> / m<2>. H, the pressure in the dissolved air tank is controlled to be 2-6 bar, and the diameter of micro-nano bubbles of the micro-nano bubble generator is 100 to 500 nm. According to the method, a vertical flow type air floatation treatment mode is combined with a micro-nano bubble fluid generated by a mode of further treatment through a bubble generator after cutting through a machine pump, the air flotation efficiency can be effectively improved,organic matters and micro-solids in a water body can be subjected to air flotation treatment, and the air flotation efficiency is relatively high as primary treatment equipment and method for sewage.

Owner:广东蓝绿科技有限公司

Closed air floatation device and air floatation method

ActiveCN112759022ANo emissionsAvoid pollutionWater treatment parameter controlSpecific water treatment objectivesMicro nanoExhaust fumes

The invention belongs to the technical field of air floatation, and discloses a closed air floatation device and an air floatation method. The air floatation device comprises a closed reactor and a micro-nano bubble generator, and the closed reactor is sequentially provided with a reaction chamber, a multi-stage separation chamber, a clear water chamber and a scum chamber in the water inlet direction; flow guide channels are respectively arranged between two adjacent stages of separation chambers and between the last stage of separation chamber and the clear water chamber, the side surface of each stage of separation chamber is provided with a water passing hole communicated with the flow guide channel, the upper layer of each stage of separation chamber is connected with the scum chamber through a scum collecting channel, and the tops of stages of separation chambers are communicated; the micro-nano bubble generator is arranged in the closed reactor and is communicated with the bottom of the separation chamber. The full-closed reactor is adopted, the multi-stage separation chambers are arranged in the full-closed reactor to perform air flotation treatment on sewage, the air flotation efficiency is high, nitrogen and other inert gases can be filled, intrinsic safety of an air flotation equipment body is achieved, emission of VOCs and other foul waste gas is avoided, and VOCs waste gas is prevented from polluting the environment.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

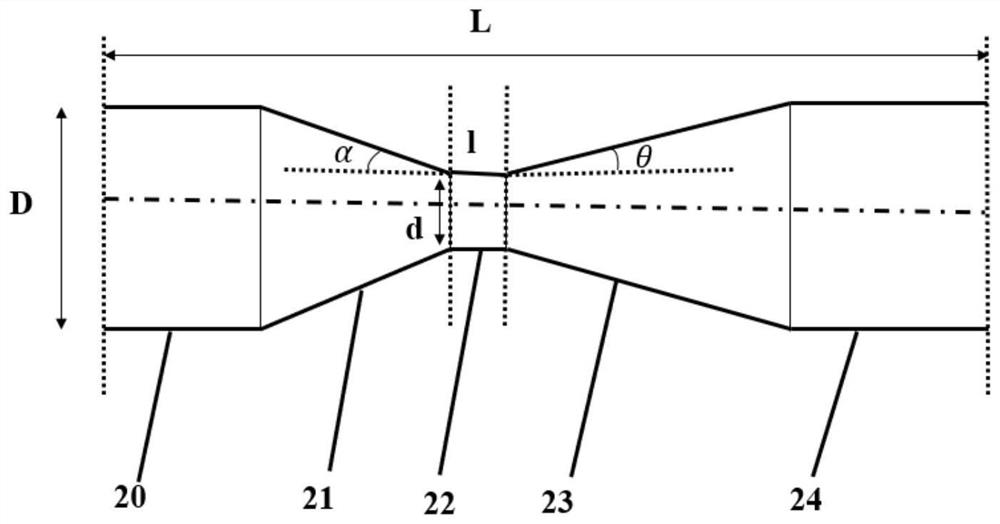

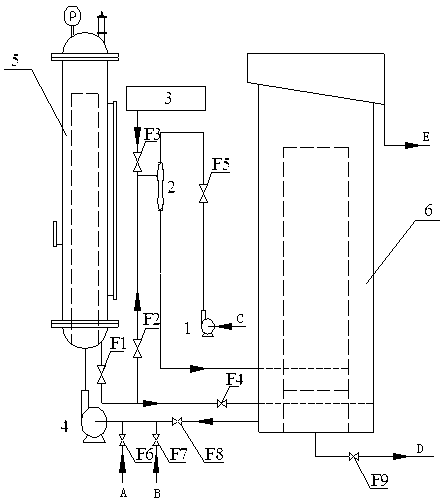

A sewage treatment device integrating coagulation and air flotation

InactiveCN101708910BSmall footprintReduce energy consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationResidenceSewage

The invention discloses a sewage treatment device integrating coagulation and air flotation. The device comprises four parts: a pipe mixer, an air dissolving device, an enlarged section retention coagulation area and a reduced section air flotation area. After passing through the device, the sewage directly enters the sedimentation tank to achieve the purpose of solid-liquid separation. The invention has the characteristics of simple equipment, small floor area, low energy consumption, easy control, high air flotation efficiency, etc., and is especially suitable for sewage treatment with small flow.

Owner:WENZHOU UNIVERSITY

Ozone oxidation and air flotation combined treatment system and process

ActiveCN104761088BIncrease chance of contactGood removal effectMultistage water/sewage treatmentCavitationRetention time

The invention relates to an ozone oxidation-air floatation combined treatment system and a process. The system comprises a reaction tank, a gas liquid mixer, a catalyst adding device and a whirl stream air floating tank. Ozone-containing gas and sewage are mixed into a gas-liquid mixture containing micro bubbles by the gas liquid mixer and then fed into the reaction tank. The reaction tank is provided with at least one ultrasonic wave cavitation device. The catalyst adding device is used for feeding a catalyst, ozone and the sewage into the reaction tank together. Then a catalytic oxidation reaction is performed under the action of ultrasonic wave cavitation. A stream guide pipe is vertically disposed in the center of the whirl stream air floating tank. The upper end of the stream guide pipe is open, and the lower end of the stream guide pipe penetrates the bottom of the whirl stream air floating tank. The bottom of the whirl stream air floating tank is also provided with a sewage outlet. The bottom of the stream guide pipe is provided with vortex plates. The whirl stream air floating tank is communicated with the reaction tank, and used for allowing the gas liquid mixture reacted in the reaction tank to react continuously under the whirl stream function and to be subjected to floatation, washing and separation treatment. The contact probability of the micro bubbles generated by the system with contaminants is large, the reaction is more thorough, the ozone utilization rate is high, retention time is short, and contaminant removing effects are good.

Owner:SHENZHEN CLEAR SCI & TECH

Mthod and device for injection dissolution of gas for circulation water

InactiveCN1158221CReduce dissolved airImprove air flotation efficiencyWater/sewage treatment by flotationEngineeringDissolution

A jet method and apparatus for dissolving air in the circulated water is characterized by that the jetter in the path of circulated water, which has water pressurizing tube and water sucking tube, is used to dissolve air in the water by sucking and cutting actions, and a water pump is used to stir and mixthe water with air for dissolving air in water further. Its advantages are simple structure, high dissolving effect, and less energy consumption.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Circular current dissolved air copolymerization flotation system and technology

InactiveCN102730781BReduce energy consumptionImprove air flotation efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationAutomatic controlPhysical chemistry

The invention discloses a circular current dissolved air copolymerization flotation system and a circular current dissolved air copolymerization flotation technology. The system mainly comprises a feeding pump, a jet pump, a doser, a gas-liquid mixing pump, a bubbling air dissolving tank and a flotation column. Because a gas-liquid mixing pump-bubbling air dissolving tank technology is adopted, the effluent index of dissolved air water is stable; the synchronous integration of medicine mixing and gas-solid-liquid three-phase coagulation copolymerization is realized by the jet pump, a coagulation technology unit does not need to be independently set, a flow is simplified, a stable gas-solid-liquid three-phase flocculating constituent can be generated, the floatation efficiency is improved, and the floatation effect is stabilized. A double-layer sleeve columnar floatation tank is adopted, so that a floor space is small, automatic control is easy to realized, coagulation copolymerization floatation can be realized, dissolved air energy consumption is lowered, the floatation efficiency is improved, the floatation technology process is simplified, and the automatic control is easy to realize. The circular current dissolved air copolymerization flotation system disclosed by the invention has the advantages of simple technology, no noise pollution, low energy consumption and good floatation effect.

Owner:CHINA UNIV OF MINING & TECH

Method and device for treating refractory oil extraction sewage in oilfield

InactiveCN105174662BReduce outputLow costMultistage water/sewage treatmentResource recoveryOil field

The invention discloses a method and device for treating degradation-resistant oil extraction sewage of an oil field. The treatment device and method aim at deep treatment, up-to-standard drainage or reuse of the oil extraction sewage of the oil field, the problem that in the process of treating degradation-resistant oil extraction sewage of an oil field, a traditional treatment process technology is poor in effectiveness is solved, the treatment device and method have the advantages of being low in treatment cost, good in effect and the like and can be widely applied to the field of degradation-resistant oil field oil extraction sewage deep treatment and reuse, the technical difficult problem of treating the degradation-resistant oil extraction sewage of the oil field can be solved fundamentally, and the resource recovery of the oil field sewage is achieved.

Owner:BEIJING SANDI HENGTIAN PETROLEUM SCI & TECH

Graded dual-mode air flotation device

InactiveCN114275838AEasy to cleanMeet clean upWater/sewage treatment by flotationElectrolysisProcess engineering

The invention relates to the technical field of wastewater treatment, and discloses a graded dual-mode air flotation device which comprises a first air flotation box, a second air flotation box is fixedly installed on the left portion of the first air flotation box, and a partition plate is fixedly installed between the first air flotation box and the second air flotation box. Through the arrangement of the partition plate, the first air flotation box and the second air flotation box are classified, firstly, a large number of bubbles generated by air in the first air flotation box are used for conducting air flotation on a large number of particles contained in waste water, the waste water is cleaned for the first time, and most heavy particles are removed; in the second air flotation box, an anode plate and a cathode column are used for electrolyzing the wastewater, tiny bubbles generated by electrolysis are used for air flotation and deep cleaning, two different bubble generation modes are combined for cleaning suspended matters in the wastewater, the energy consumption generated by electrolysis is reduced, and the suspended matter cleaning effect is improved; the air flotation device can meet the cleaning of wastewater with different concentrations.

Owner:胡宏亮

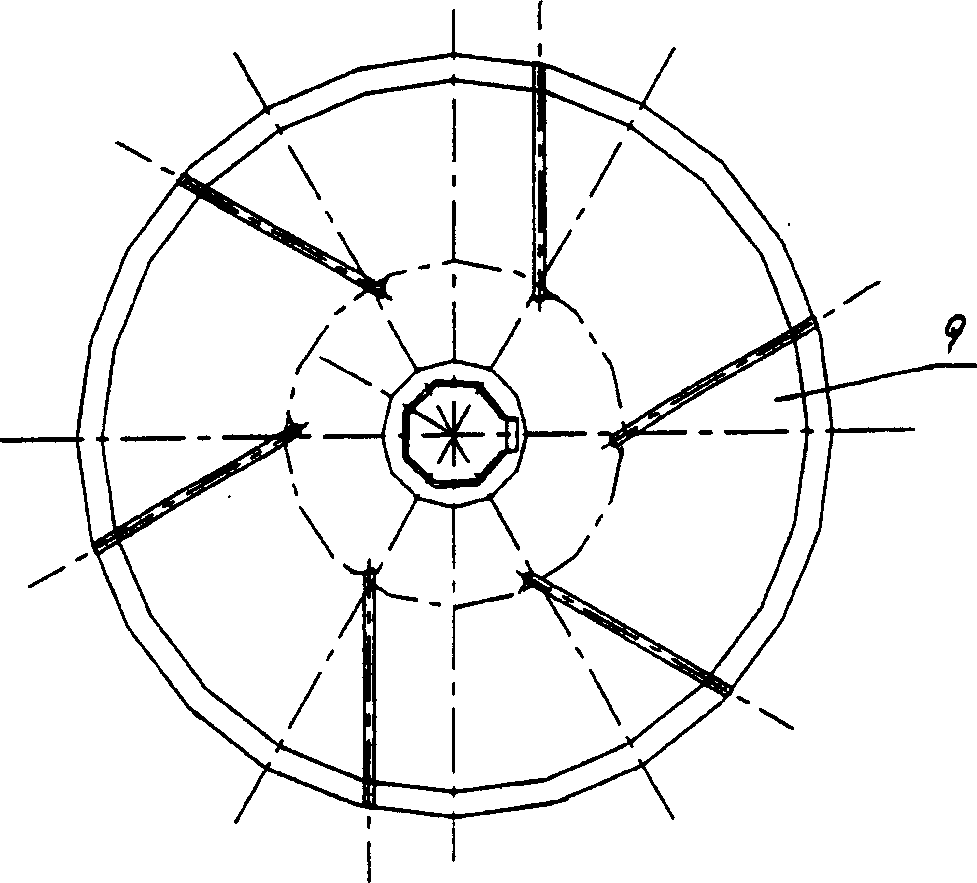

Air float machine through airbleed by using mechanism with two blades

InactiveCN1240621CIncrease vacuumWell mixedWater aerationSustainable biological treatmentImpellerPlain bearing

Owner:邢士修 +1

A kind of oily wastewater treatment method and equipment

InactiveCN103771639BEasy to handleAchieve degradationMultistage water/sewage treatmentSmall footprintPorous particle

Owner:HOHAI UNIV

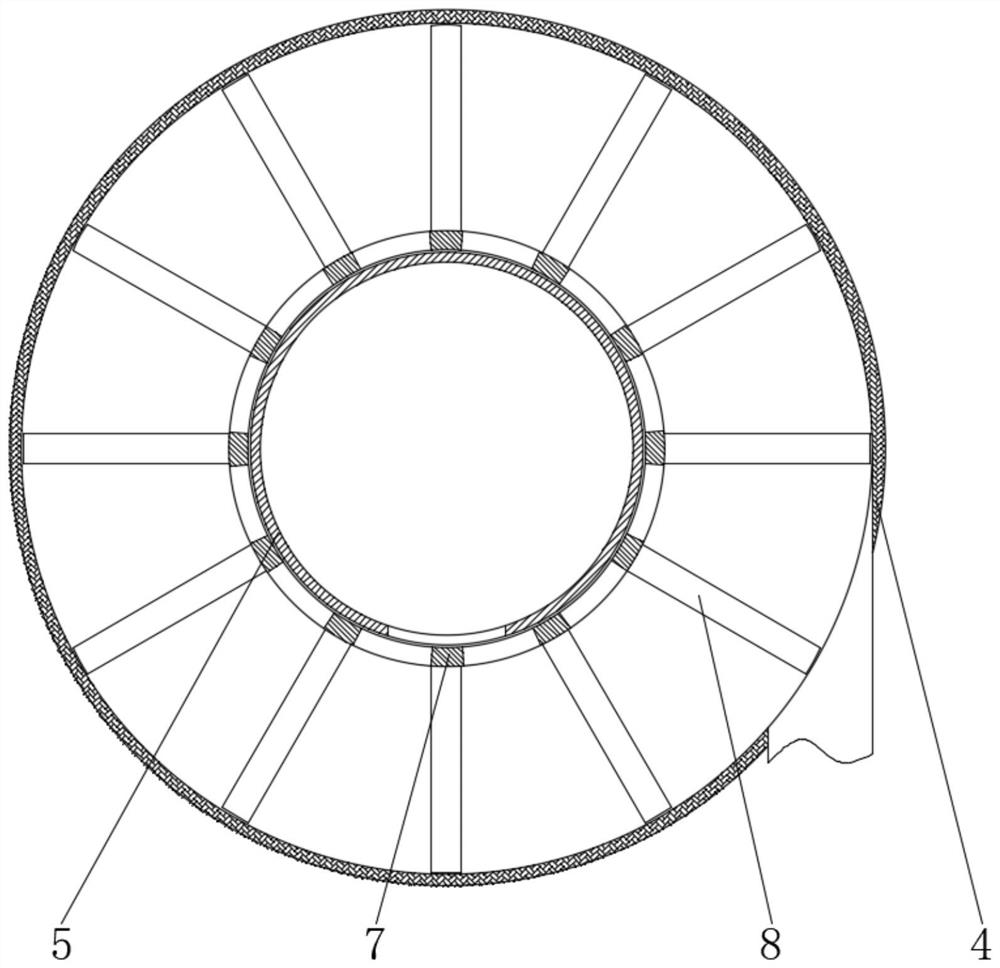

Self-discharging cylinder micro/nano-grade sieve air-flotation system for sewage treatment

ActiveCN101704590BIncrease distanceImprove air flotation efficiencyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSuspended particlesImpeller

The invention relates to a self-discharging cylinder micro / nano-grade sieve air-flotation system for sewage treatment. The system is provided with a vertical air-flotation cylinder for the sewage treatment; a desilting and filtering sloping plate is arranged at the bottom of the air-flotation cylinder which contains the sewage; a rotary-cutting releaser which generates a micro / nano-grade air-flotation filter sieve is arranged over the sloping plate; a loop of sewage-distributing pipes is arranged over the rotary-cutting releaser and the sewage-distributing pipes are communicated with a sewage-flocculating barrel; clean water which is filtered by the desilting and filtering sloping plate is conveyed to an impeller-symmetrical air-water mixing all-in-one machine which is arranged outside the air-flotation cylinder by a water-inlet pipe; micro / nano-grade bubble groups form a filter sieve consisting of microbubbles in the continuously ascending process; the filter sieve encloses and captures suspended particles in the sewage in the bubble groups so as to carry the suspended particles up to the water surface; the air-flotation efficiency is greatly increased so that equipment becomes miniaturized, which is particularly applied to the refreshing treatment of the sewage of 1-50 cubic meters in one hour; and in a similar way, the small equipment can be applied to a high-oxygen milk bath machine so that micro / nano-grade bubble bath can be realized at home, and the medium-sized equipment can be used for high-efficiency air cascade at water bottom.

Owner:KUNMING SHUIXIAO TECH

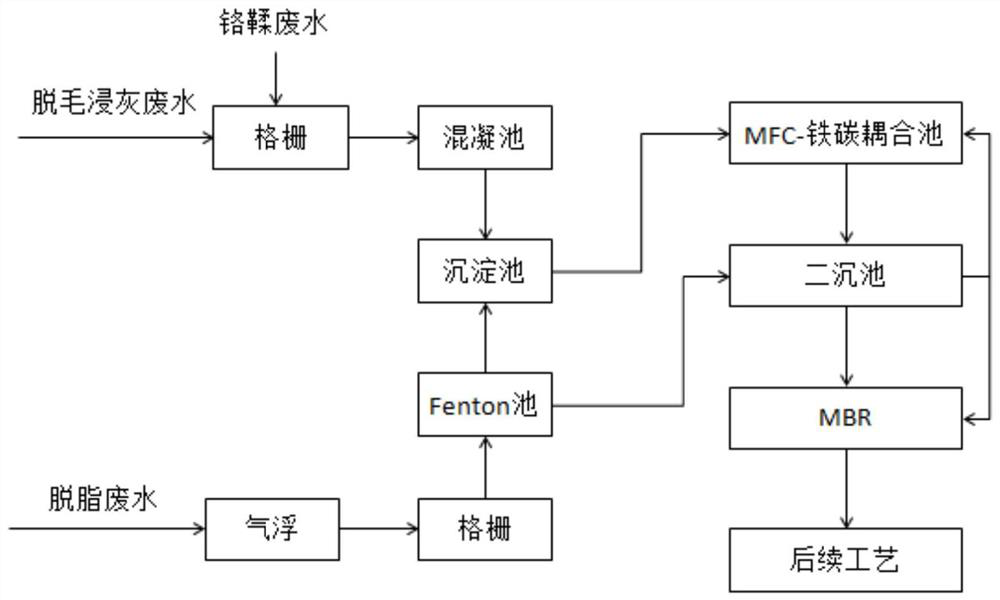

Novel tannery wastewater treatment process

PendingCN112250256AReduce the temperatureImprove air flotation efficiencyTreatment by combined electrochemical biological processesWater contaminantsProcess engineeringWater treatment

The invention provides a novel tannery wastewater treatment process which comprises the steps that unhairing liming wastewater and chrome tanning wastewater are conveyed to a grid at the same time, and mixed wastewater treated by the grid is conveyed to a coagulating basin; carrying out air floatation treatment on degreased wastewater, carrying out grid treatment on the wastewater subjected to airfloatation, conveying the treated wastewater to a Fenton tank, carrying out advanced oxidation treatment, removing heavy metal ions in the wastewater, conveying the mixed wastewater to an MFC-iron-carbon coupling tank, carrying out degradation treatment, and finally, carrying out conventional biochemical treatment.

Owner:张家港市杨舍丝印工艺厂

A kind of copolymerization floating sink and water purification method

ActiveCN105502549BEnhanced interactionImprove adhesionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationFlocculationPurification methods

The copolymerization floating-settling tank of the present invention includes a multi-channel folded-plate copolymerization flocculation tank for realizing coagulation and copolymerization of flocs and micro-bubbles; Separation, sedimentation of sedimentary flocs that cannot be air-floated; and a dissolved air system connected to the water outlet of the floating and sinking tank. The flocculation tank and the floating sink tank provide backflow high-pressure dissolved air water. The copolymerization floating-sinking tank will add backflow high-pressure dissolved air water three times, and organically combine it with the flocculation process to create a copolymerization environment for micro-bubbles and flocs. Problems such as low adhesion efficiency, unsatisfactory capture effect, and unstable adhesion of foam flocs make the coagulation, air flotation, and sedimentation processes organically combined and integrated to deal with high algae, low turbidity, and sudden high turbidity in reservoir water quality Has outstanding advantages.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com