Method for applying waste water of viscous oil after treated to low-pressure steam boilers

A technology of heavy oil sewage and low pressure steam, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult operation and insufficient pretreatment unit treatment, etc. To achieve the effect of fast action, simple regeneration method and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

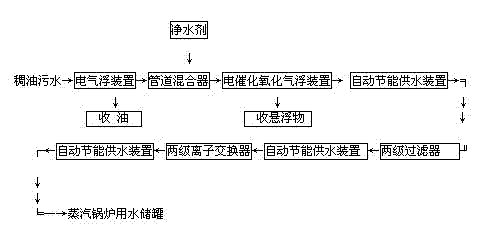

[0019] Such as figure 1 Shown, a kind of heavy oil sewage treatment is used in the method for low-pressure steam boiler, and its steps are as follows:

[0020] A. After heavy oily sewage is floated in traditional large tanks, most of the slick oil in the sewage is removed, and then enters the electric floating device to further remove the remaining slick oil, suspended oil and part of the emulsified oil in the sewage;

[0021] B. Water purifying agent is added to the effluent of the electric floatation device and mixed through the pipeline mixer before entering the electrocatalytic oxidation air floatation device; the electrocatalytic oxidation air floatation device is used to oxidize and reduce the COD of sewage, and the bubble diameter formed in situ by the electric floatation device is small, The advantages of large specific surface area and small limit particle size that can be absorbed and floated can realize efficient air flotation separation of mechanical impurities and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com