Preparation method of cod-liver oil emulsion

A technology of cod liver oil emulsion and cod liver oil, which is applied in the direction of chemical instruments and methods, mixers, dissolution, etc., can solve the problems of poor local heat transfer, difficult sealing of the working space, and inconvenient quality between batches, etc., to achieve the particle size of the dispersed phase Controllable, low heat generation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

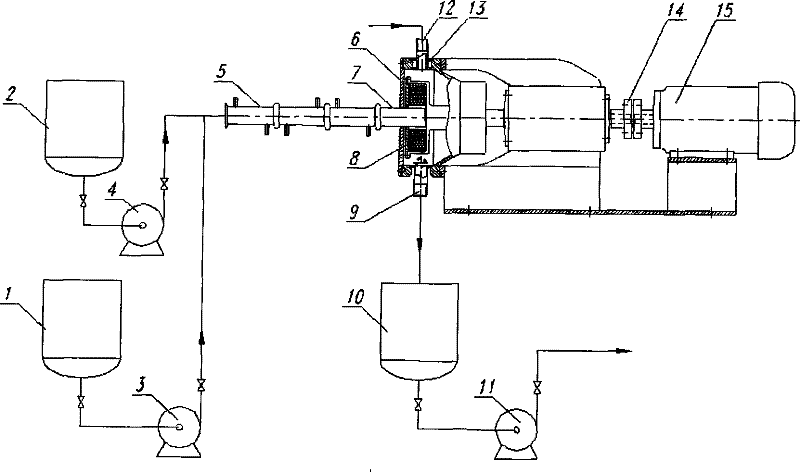

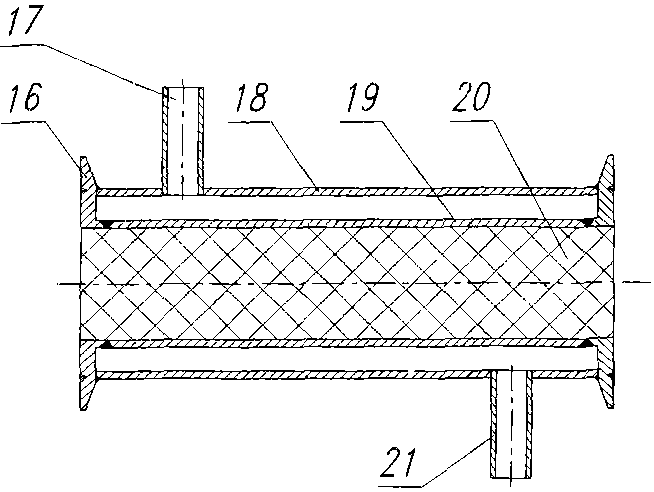

[0028] Example 1: The oil phase cod liver oil and the water phase are prepared. The water phase includes water and a certain formula of auxiliary materials. Use as figure 1 The continuous emulsification process shown. Use oil phase pump 3 and water phase pump 4 to send the cod liver oil in oil phase tank 1 and the water in water phase tank 2 into the tubular reactor 5 at a ratio of 1:2, and the oil flow rate is 1 m 3 / h, the flow of B is 2m 3 / h, the total flow is 3m 3 / h. The tubular reactor is composed of 5 pipe sections with a length of 5cm. The pipe sections are filled with pressurized packing. The porosity of the packing is 80% and the length-to-diameter ratio of the packing is 10. The pipe sections are connected by quick-opening flanges. . The tubular reactor achieves pre-emulsification and is sprayed into the inner edge of the rotor 8 of the rotating packed bed 6 through the liquid distributor 7. The rotor is connected to the motor 15 through the shaft 14 and rotates to...

Embodiment 2

[0029] Example 2: Prepare 10L grease in the oil phase tank, and prepare an aqueous solution containing 0.1% (wt / v) sodium lauryl sulfate and 0.05% (wt / v) lecithin in the water phase tank. The method described in Example 1 emulsifies the oil and water phases in a ratio of 1:2, the porosity of the filler in the filler tube is 90%, and the rotating bed speed is set to 1000 rpm. The production temperature is controlled at 60~65℃. The resulting product has a creamy white color and an average droplet size of 0.72μm; at least 90% of the particle size distribution is 0.3~2.0μm. Image 6 (b) Shown.

Embodiment 3

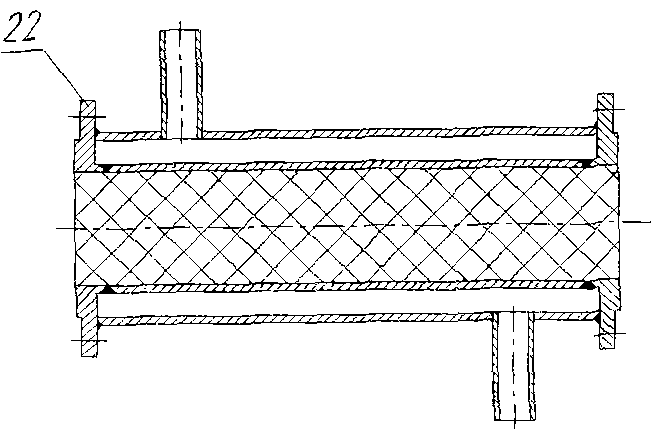

[0030] Example 3: As described in Example 1, when the porosity of the filler is changed to 95% of the press-formed wire mesh filler and the rotating bed speed is adjusted to 800 rpm, other conditions remain unchanged, and the average droplet size of 1.03 can be obtained. μm emulsion, where 90% of the particle size distribution is in the range of 0.4~3.9μm. Image 6 (c) Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com