Patents

Literature

45results about How to "Energy utilization is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

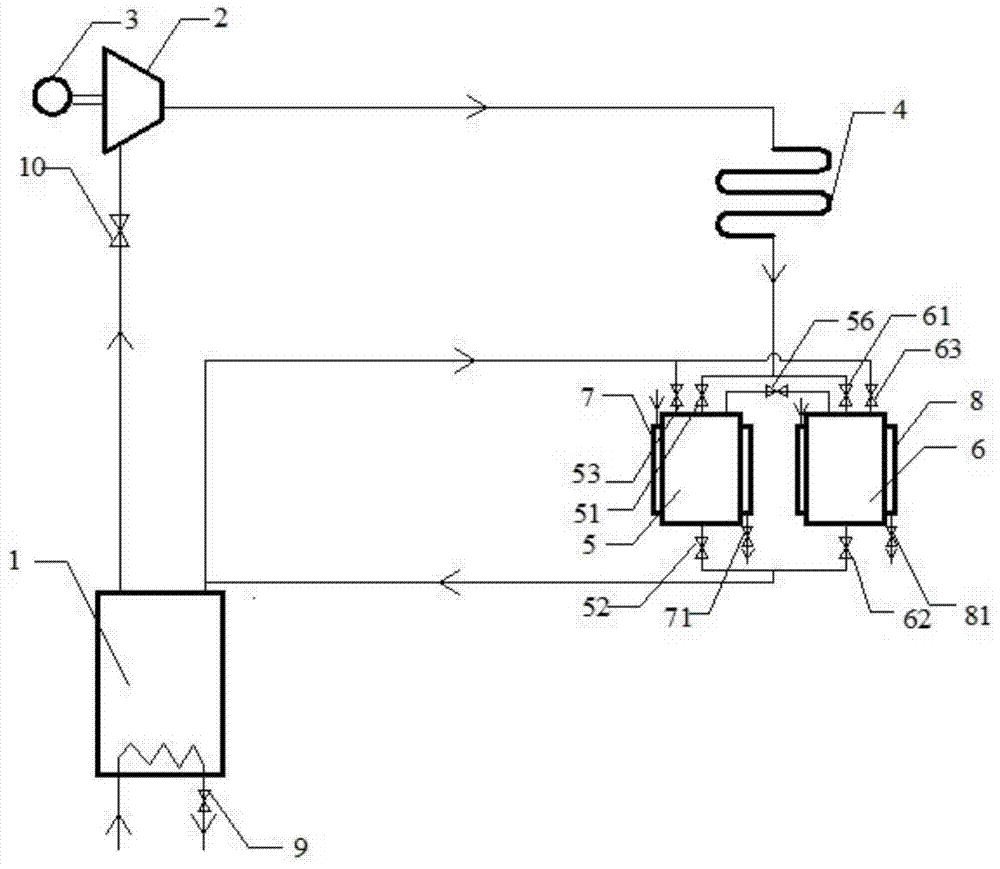

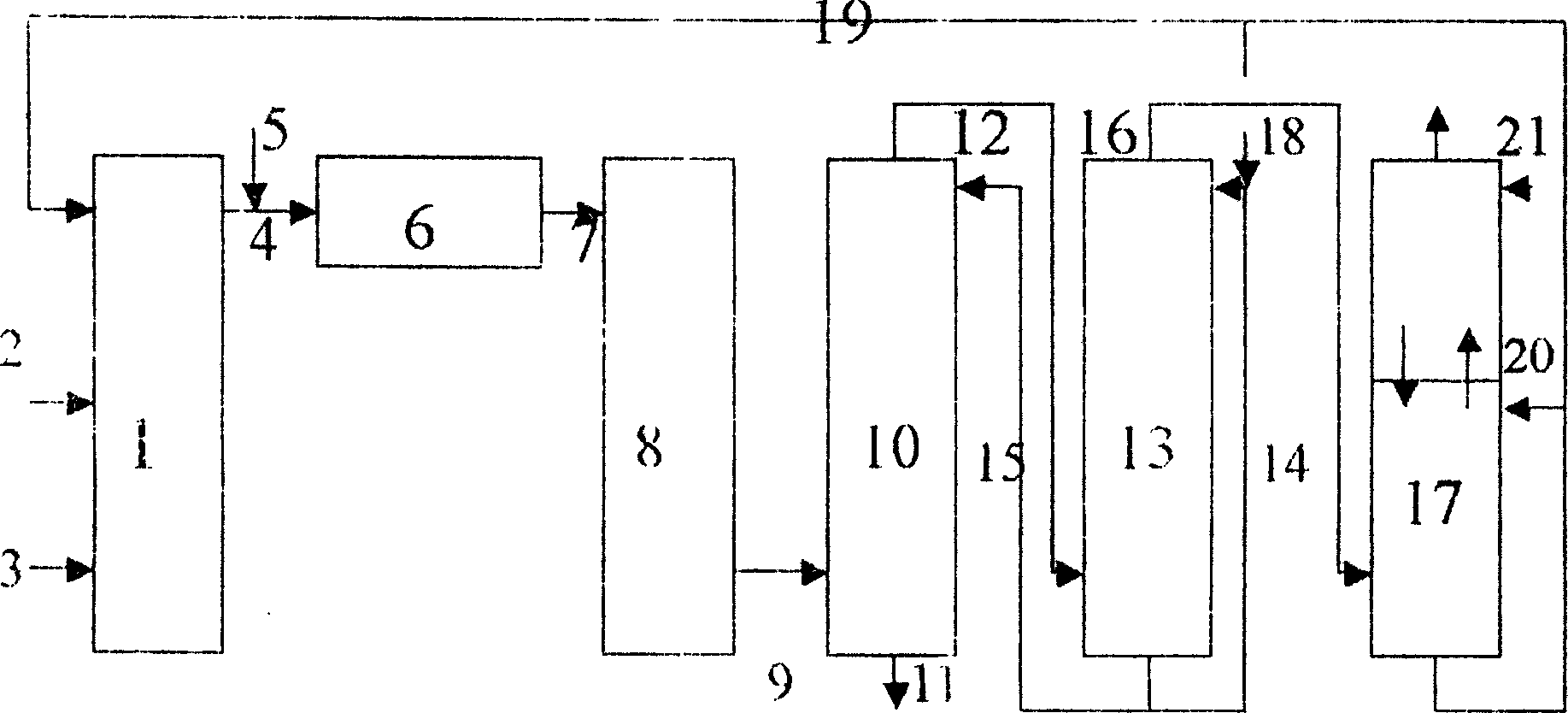

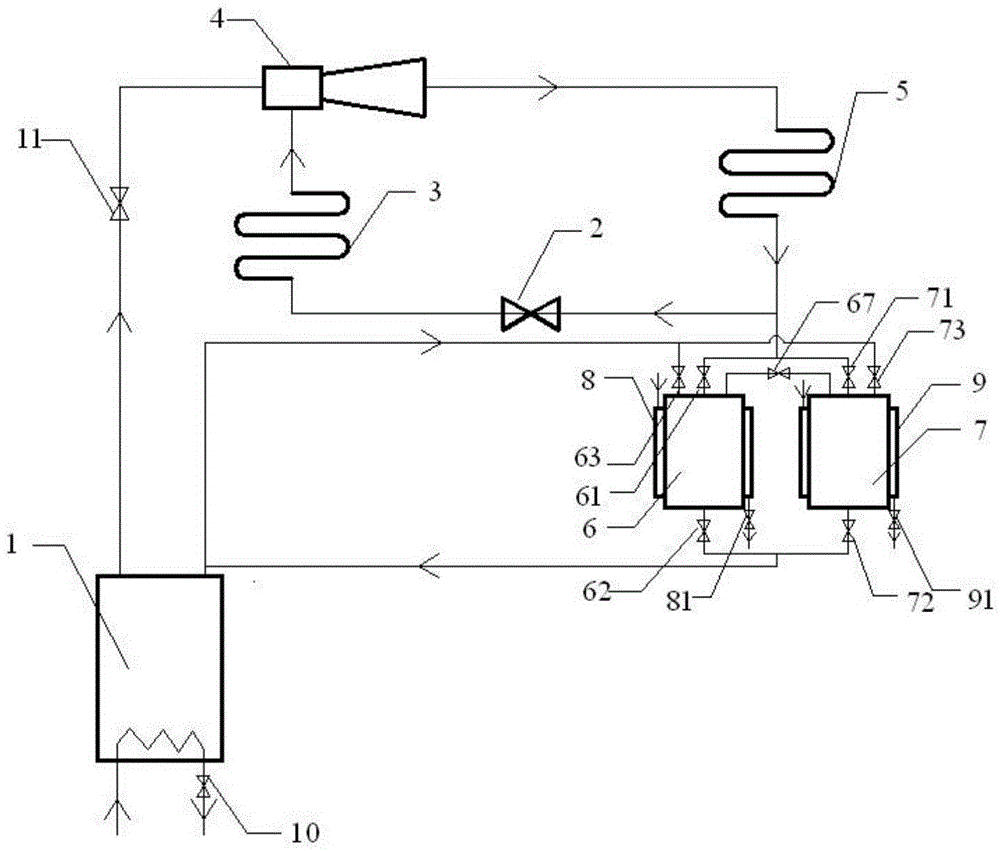

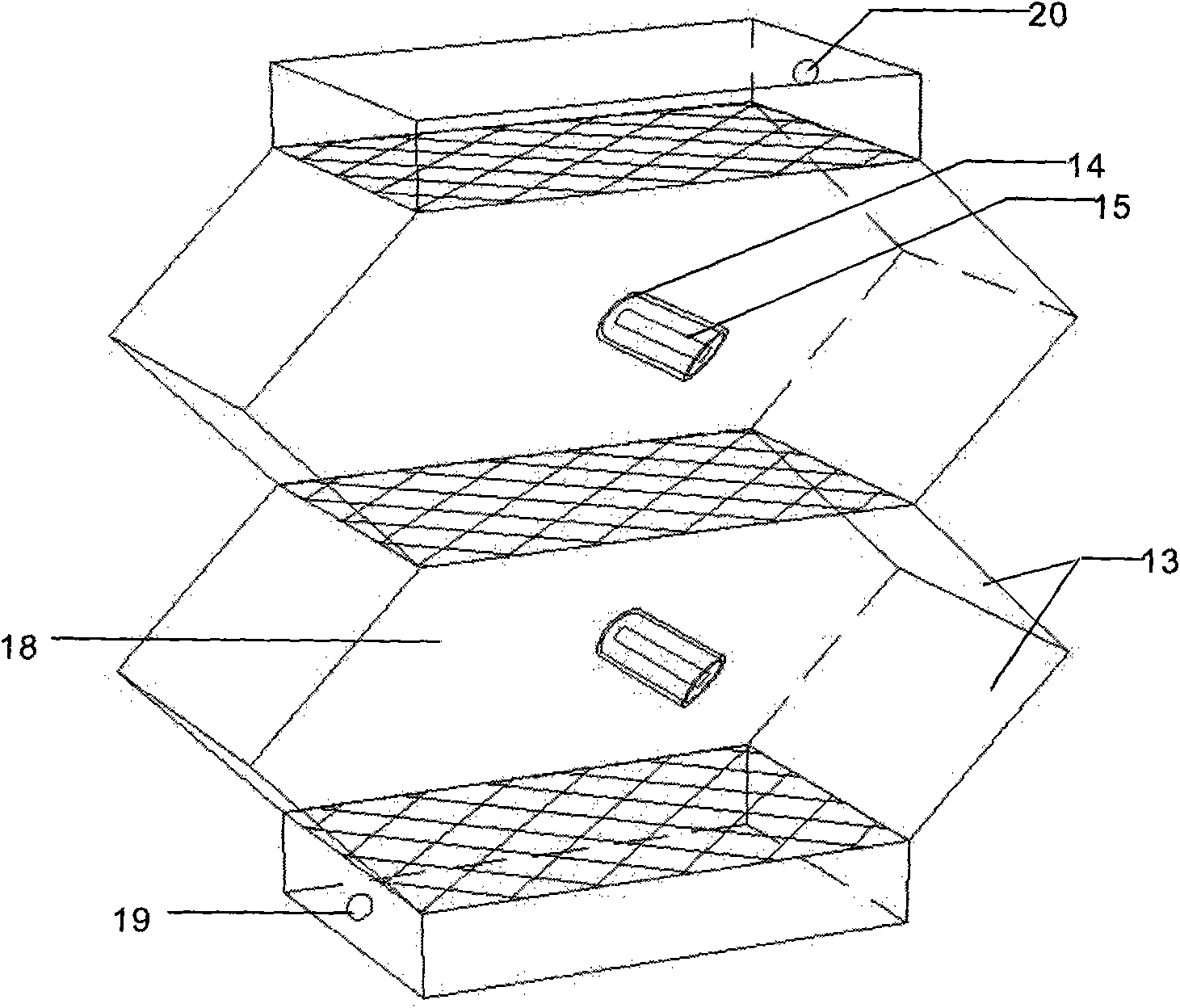

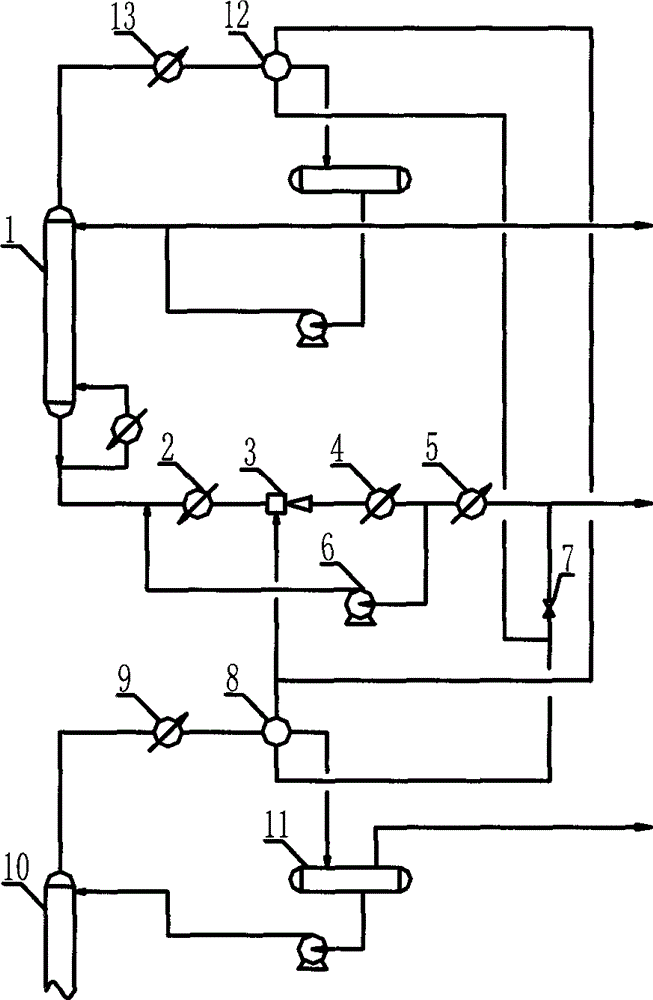

Non-pump type organic Rankine cycle method and device for power generation

InactiveCN104121046AReduce heat loadFew moving partsFeed water supplySteam engine plantsOrganic Rankine cycleEngineering

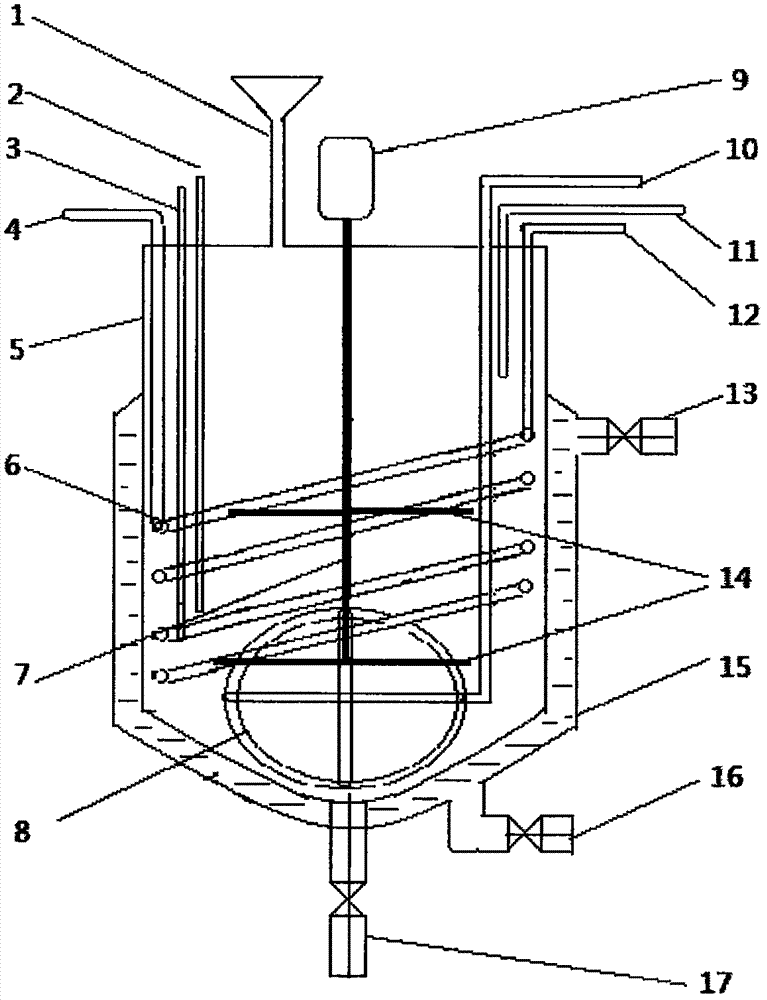

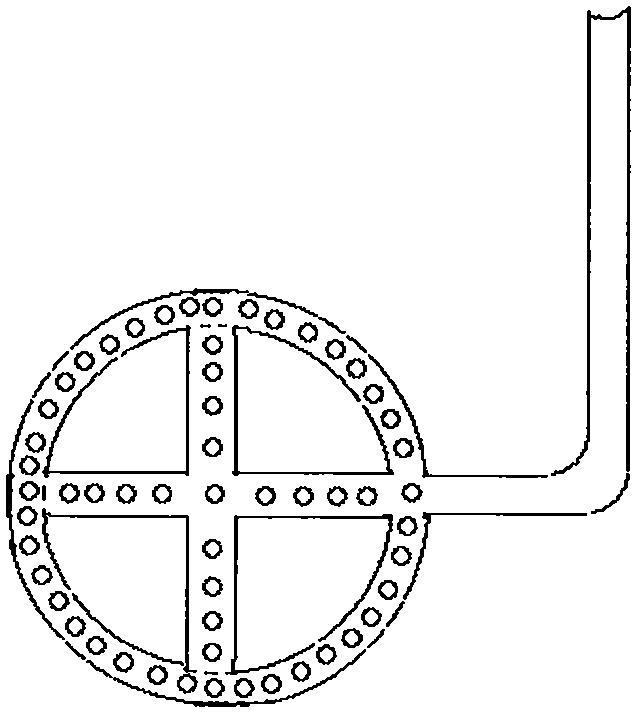

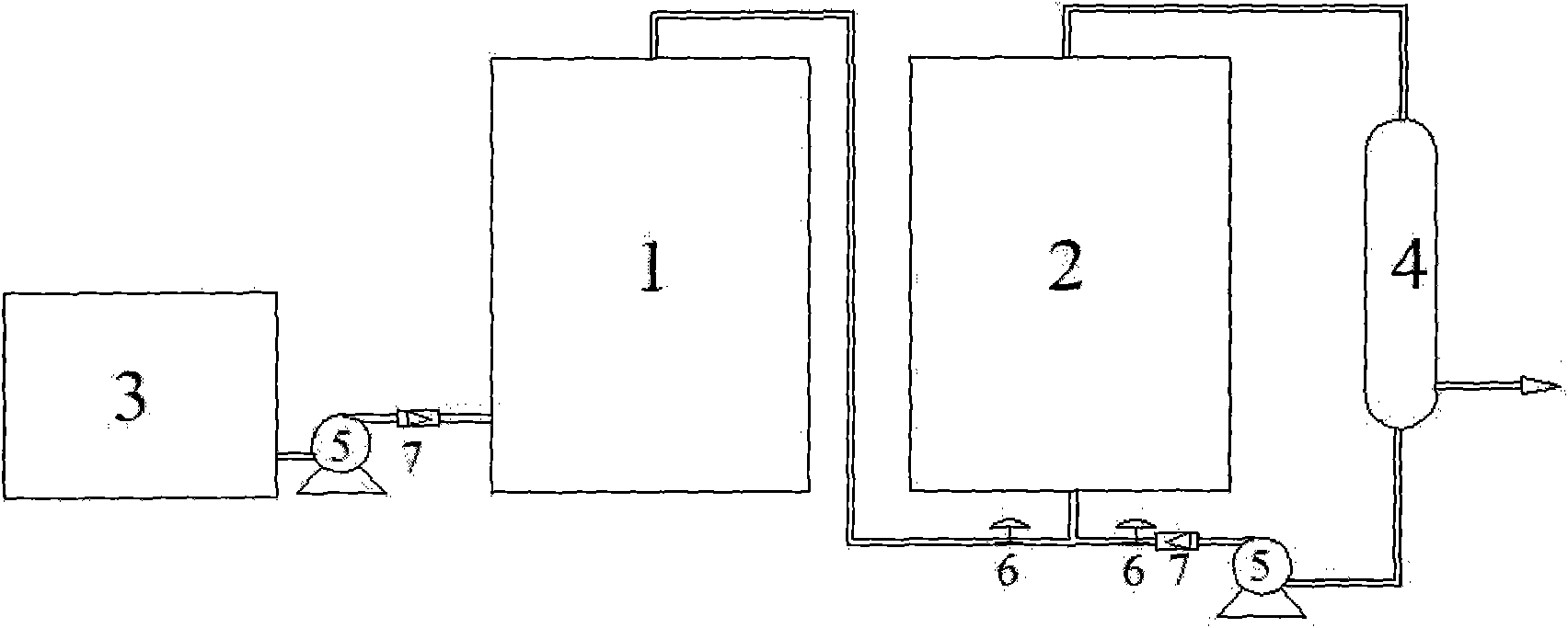

The invention discloses a non-pump type organic Rankine cycle method and device for power generation. High-temperature high-pressure working medium steam which is generated by a boiler is used for pressurizing liquid working media and conveying the liquid working media, then liquid working media to be conveyed in a next cycle are pre-pressurized, and energy of the high-temperature high-pressure working medium steam is sufficiently used for improving power generation efficiency of a system. The device comprises the boiler, an expansion machine, a generator, a condenser and a liquid storing device. The liquid storing device comprises two or more liquid storing tanks which are connected in parallel and matched. Each liquid storing tank is respectively communicated with the boiler, the condenser and the other matched liquid storing tank through control valves. The boiler is sequentially connected with the expansion machine, the generator, the condenser and the liquid storing device in series to form a loop, and the steam in the expansion machine expands and does work to drive the generator to generate power. According to the device, non-pump cycle of the system is achieved, the number of moving parts is reduced, and moving performance is more stable and reliable. Energy using of the system is more economical and reasonable, thermal loads of cooling water are reduced, and net power generation efficiency is greatly improved.

Owner:ZHEJIANG UNIV

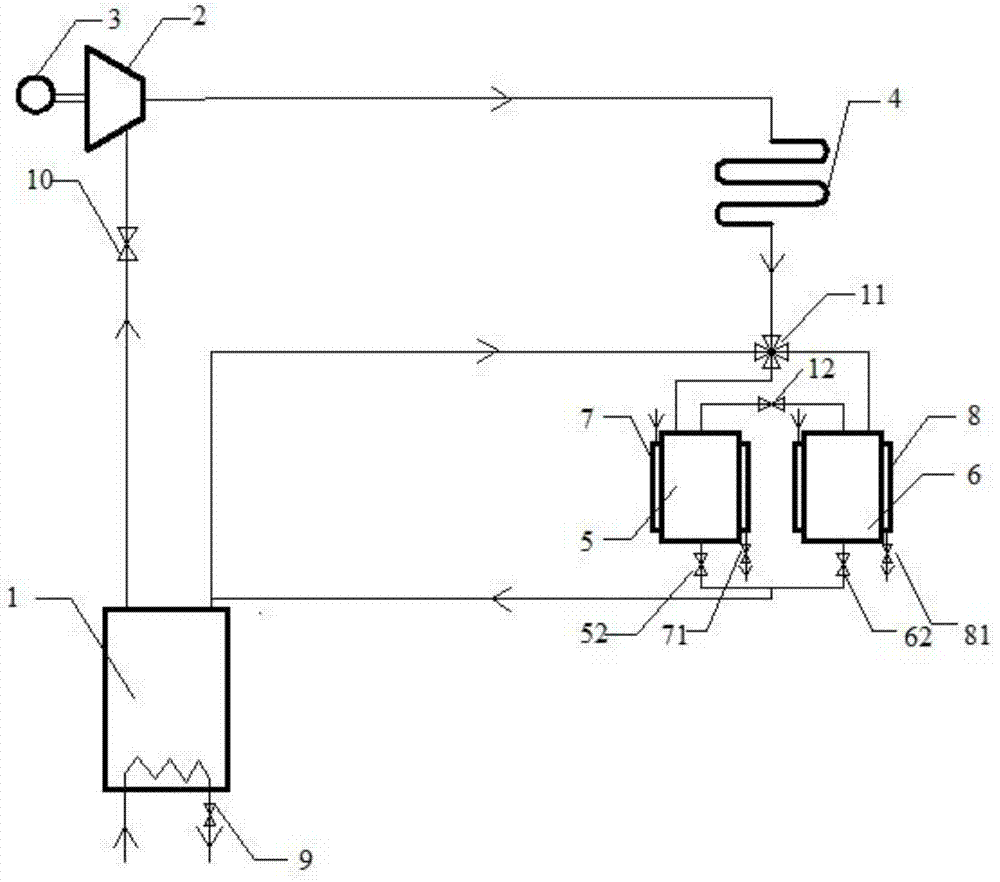

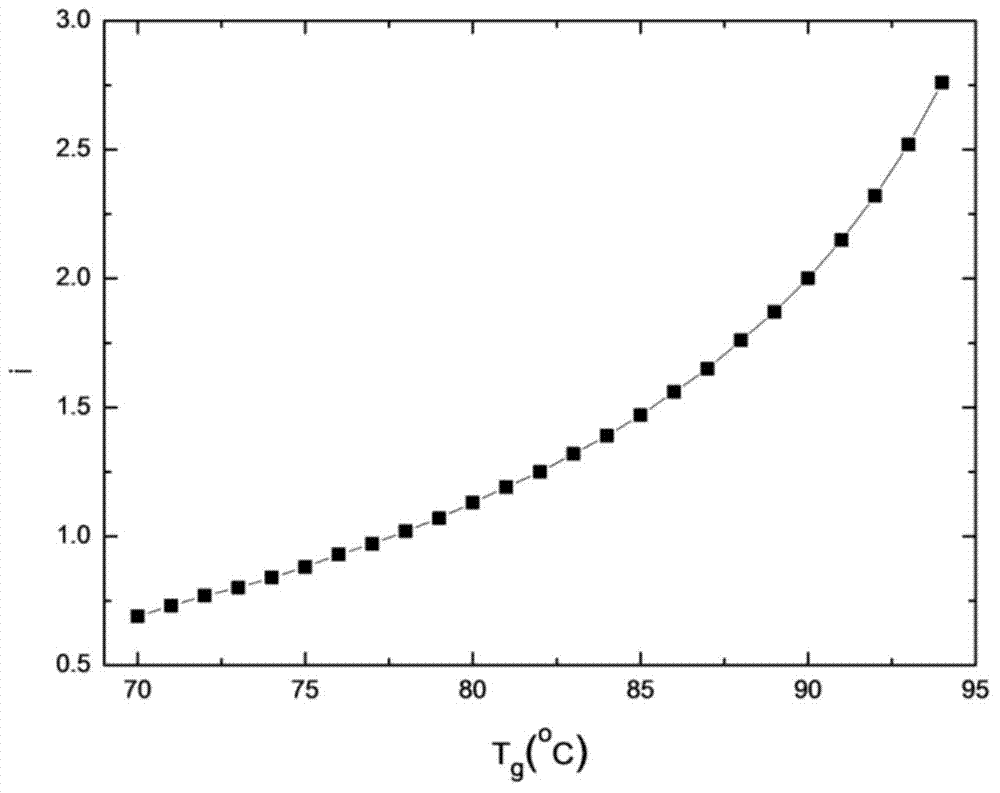

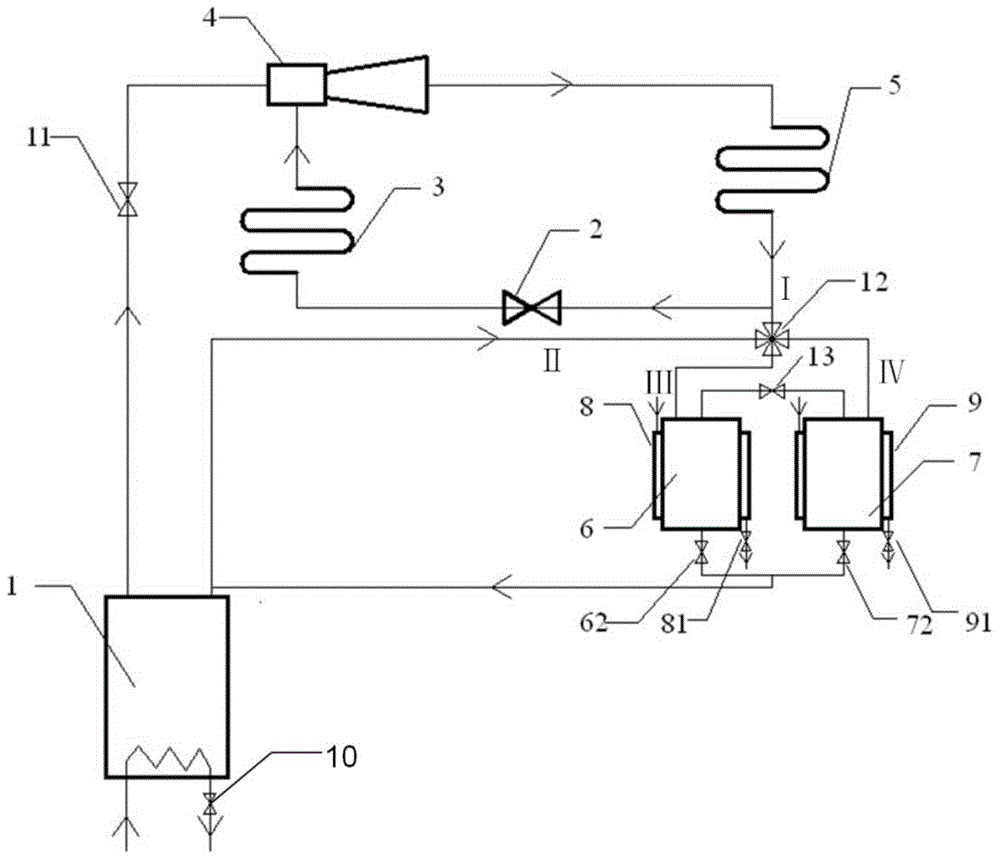

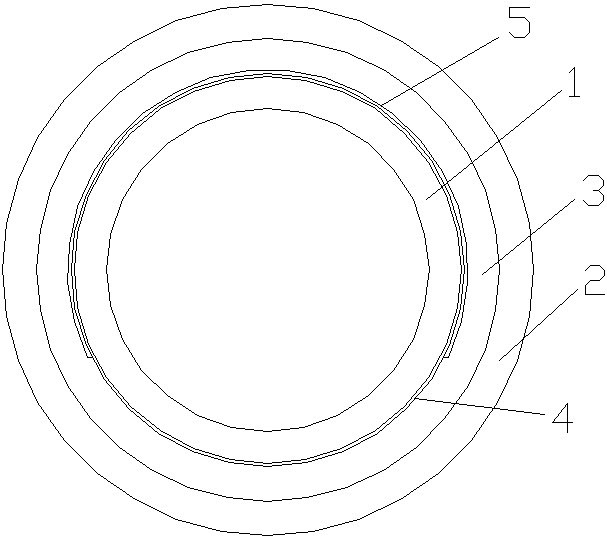

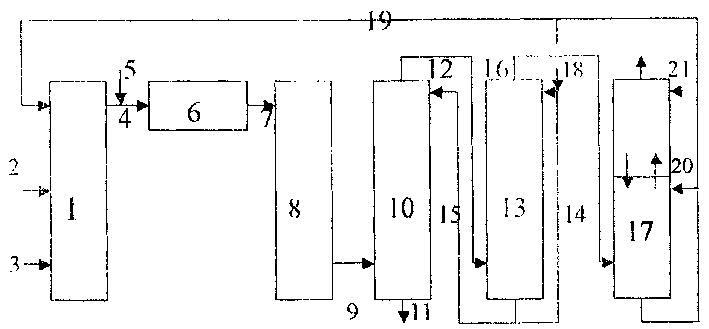

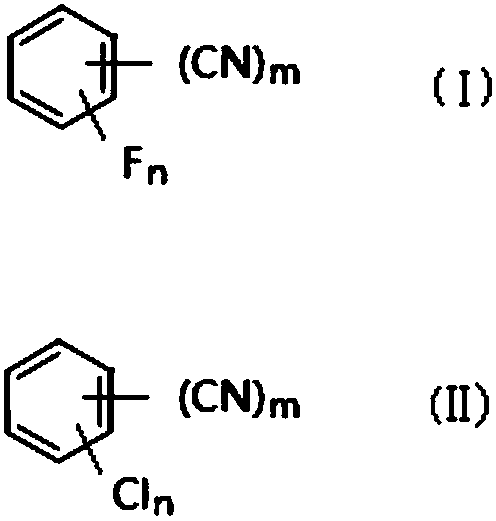

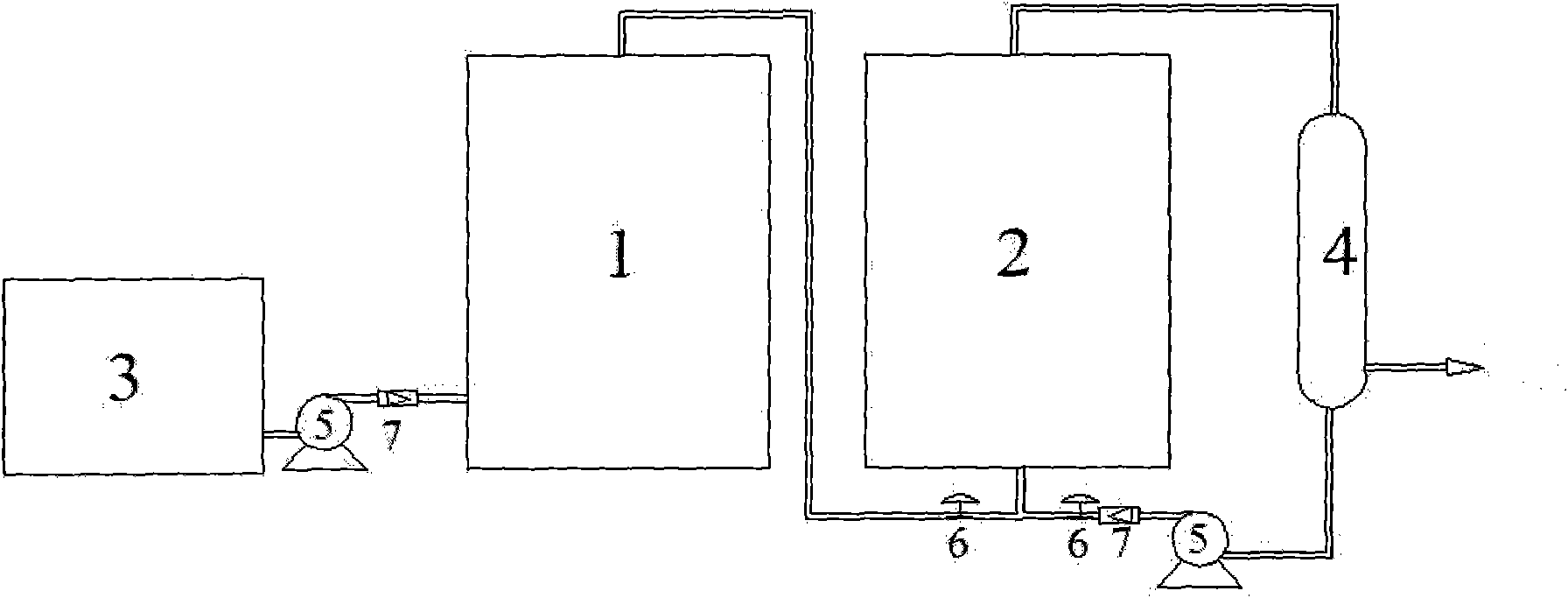

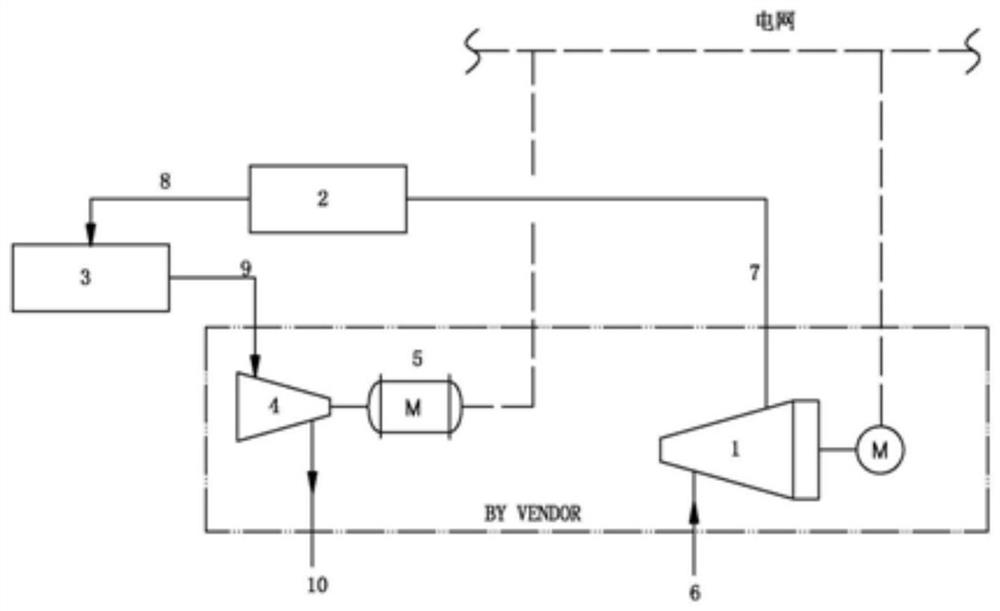

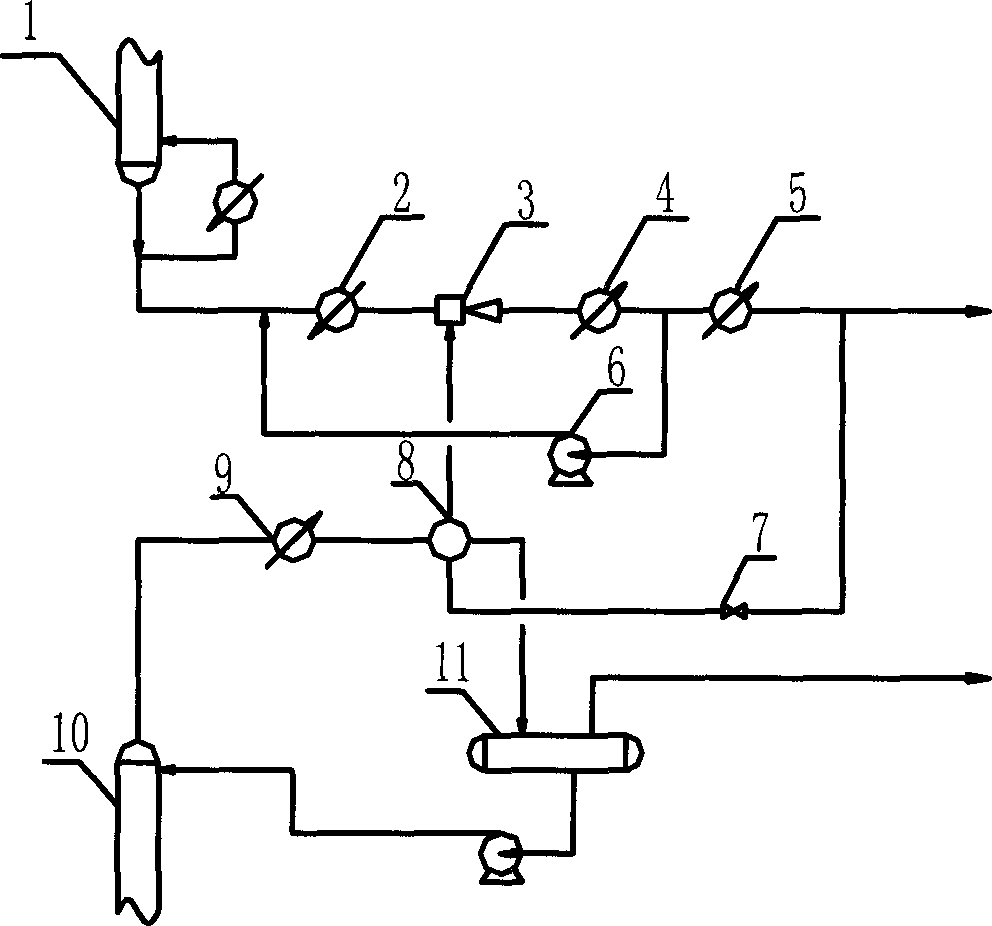

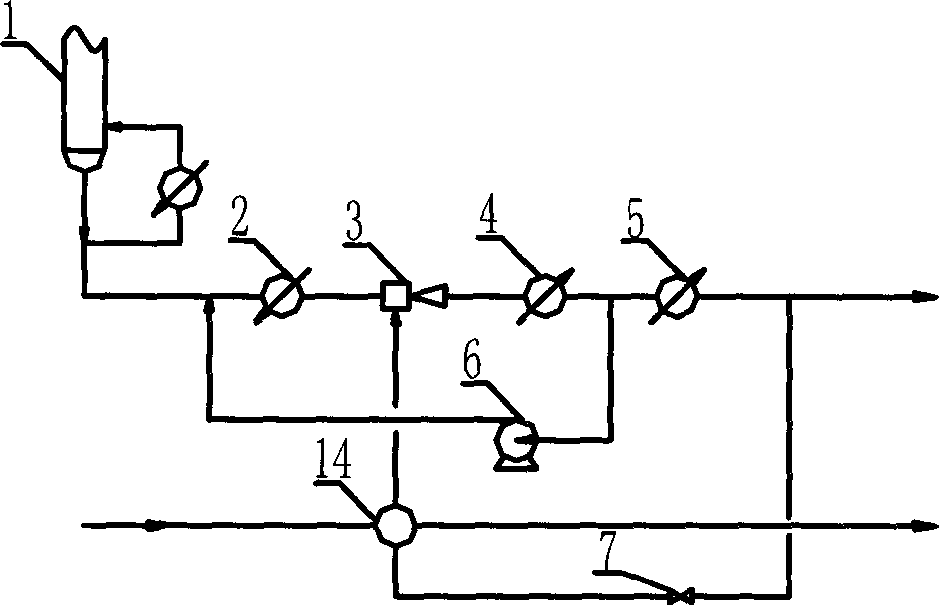

Pump-free type thermal spray refrigerating cycle method and device

InactiveCN104132486ARealize deliveryTake advantage ofMechanical apparatusFluid circulation arrangementWorking fluidLiquid storage tank

The invention discloses a pump-free type thermal spray refrigerating cycle method and device. After working fluids are pressurized and conveyed through high-temperature high-pressure refrigerant steam generated by a generator, working fluids to be conveyed in next circulation are pressurized in advance, energy of the high-temperature high-pressure refrigerant steam is fully used, and the COP of a system is improved. The device comprises the generator, a throttling element, an evaporator, an ejector, a condenser and a liquid storage device. The liquid storage device comprises at least two matched liquid storage tanks in parallel connection, each liquid storage tank is communicated with the generator, the condenser and other matched liquid storage tanks through a control valve, the ejector is sequentially connected with the condenser, the throttling element and the evaporator in series to form a loop, and the condenser is sequentially connected with the liquid storage device and the generator in series to form a loop. By means of the device, energy utilization of the system is more economical and reasonable, the thermal load of cooling water is reduced, pump-free circulating of the system is achieved, the number of moving parts is reduced, and operation performance is more stable and reliable.

Owner:ZHEJIANG UNIV

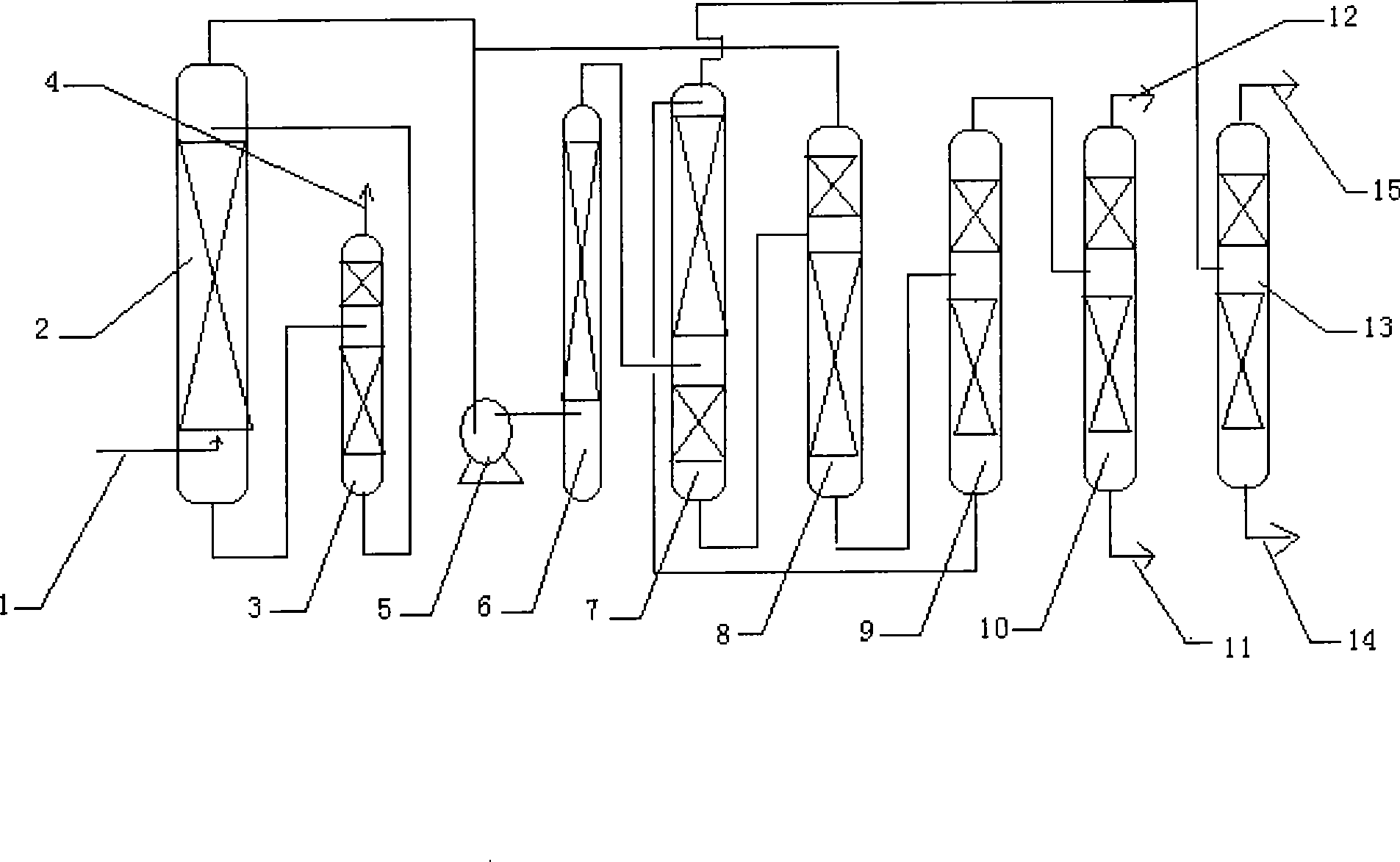

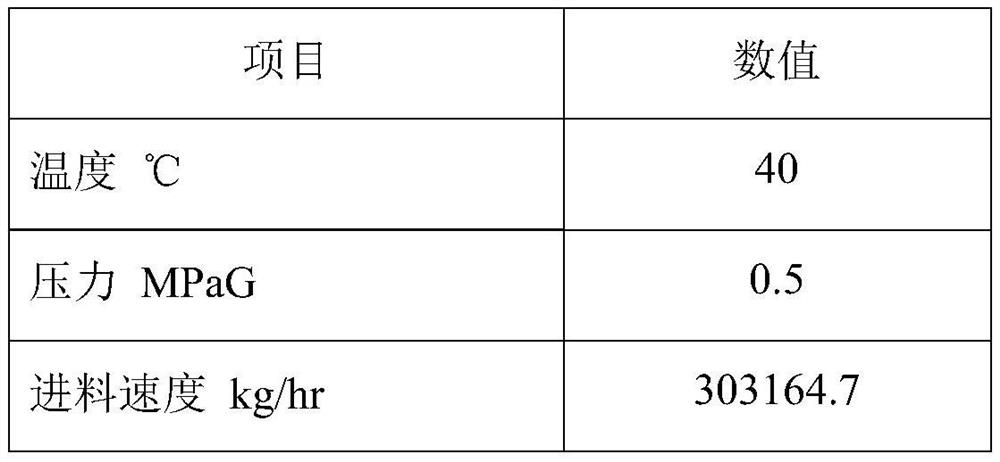

Fractionation process for cracking gas from oxidation pyrolysis of gaseous hydrocarbon

InactiveCN101486625ANo dischargeReasonable workmanshipDistillation purification/separationHydrocarbonsDesorptionFractionation

The invention provides a fractionation technique for the cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene. The cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene first goes through an oil washing tower to remove higher alkyne, C3 hydrocarbon and carbon black, and is pressurized to 0.4MPa to 1.5MPa through a compressor and deoiled through an activated carbon adsorption tower, thus dissolving acetylene and a few other indissoluble components through an absorbed solvent in the adsorption tower; the rest gases go in an ethylene separation tower to recycle concentrated ethylene products and tail gas is taken as synthesis gas; after the solvent dissolving acetylene and a few other indissoluble components enters a flashing tower to remove the indissoluble components, crude acetylene gas is obtained through the separation of an acetylene desorption tower; the indissoluble components are cycled before returning to the compressor and pure acetylene products are obtained after the crude acetylene gas is refined in a carbon dioxide tower; the wash oil saturated with higher alkyne, C3 hydrocarbon and carbon black goes back to normal pressure, flows to a wash oil purifying tower and higher alkyne and C3 hydrocarbon are obtained at the top of the tower and return to serve as gaseous hydrocarbon raw material.

Owner:SHANDONG UNIV OF SCI & TECH

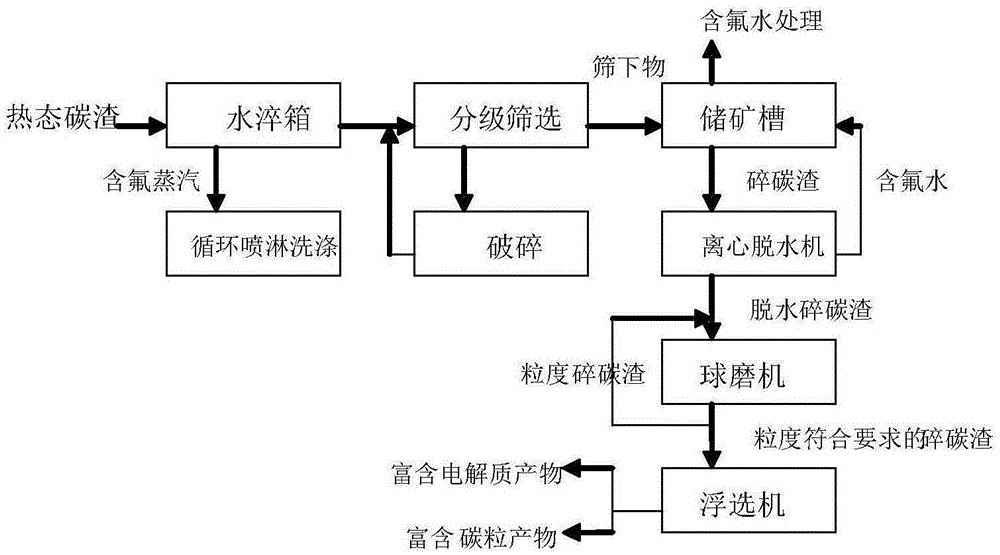

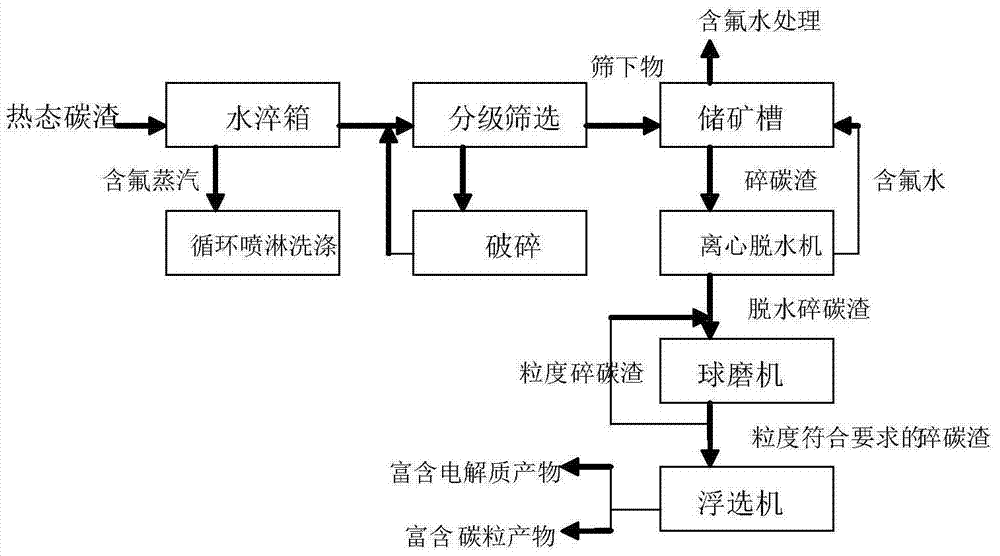

Water quenching and separating treatment method for anode carbon slime in aluminum electrolysis

ActiveCN105239097AReduce pollutionSimplified coarse crushingSolid waste disposalElectrolysisCarbon product

The invention discloses a water quenching and separating treatment method for anode carbon slime in aluminum electrolysis, and belongs to the technical field of aluminum electrolysis. The water quenching and separating treatment method comprises the steps of carrying out water quenching on the thermal-state carbon slime, classifying and sorting the water-quenched carbon slime, dehydrating the water-quenched carbon slime through a centrifugal dehydrator, carrying out wet grinding on the carbon slime and sorting the carbon slime through a flotation machine, finally carbon-rich products and electrolyte-rich products are obtained, the carbon-rich products can be used for producing carbon products, and the electrolyte-rich products can be purified and then used in the aluminum electrolysis process. According to the invention, the coarse crushing step and the fine crushing step can be simplified, and therefore the procedures are simplified, dust pollution in the crushing steps and the ore grinding step is greatly reduced, and the energy can be utilized more reasonably. The water quenching and separating treatment method can be effectively combined with the existing wet grinding technology, the existing flotation technology and the existing fluorine-containing water treatment technology.

Owner:北京森泉伟业科技有限公司

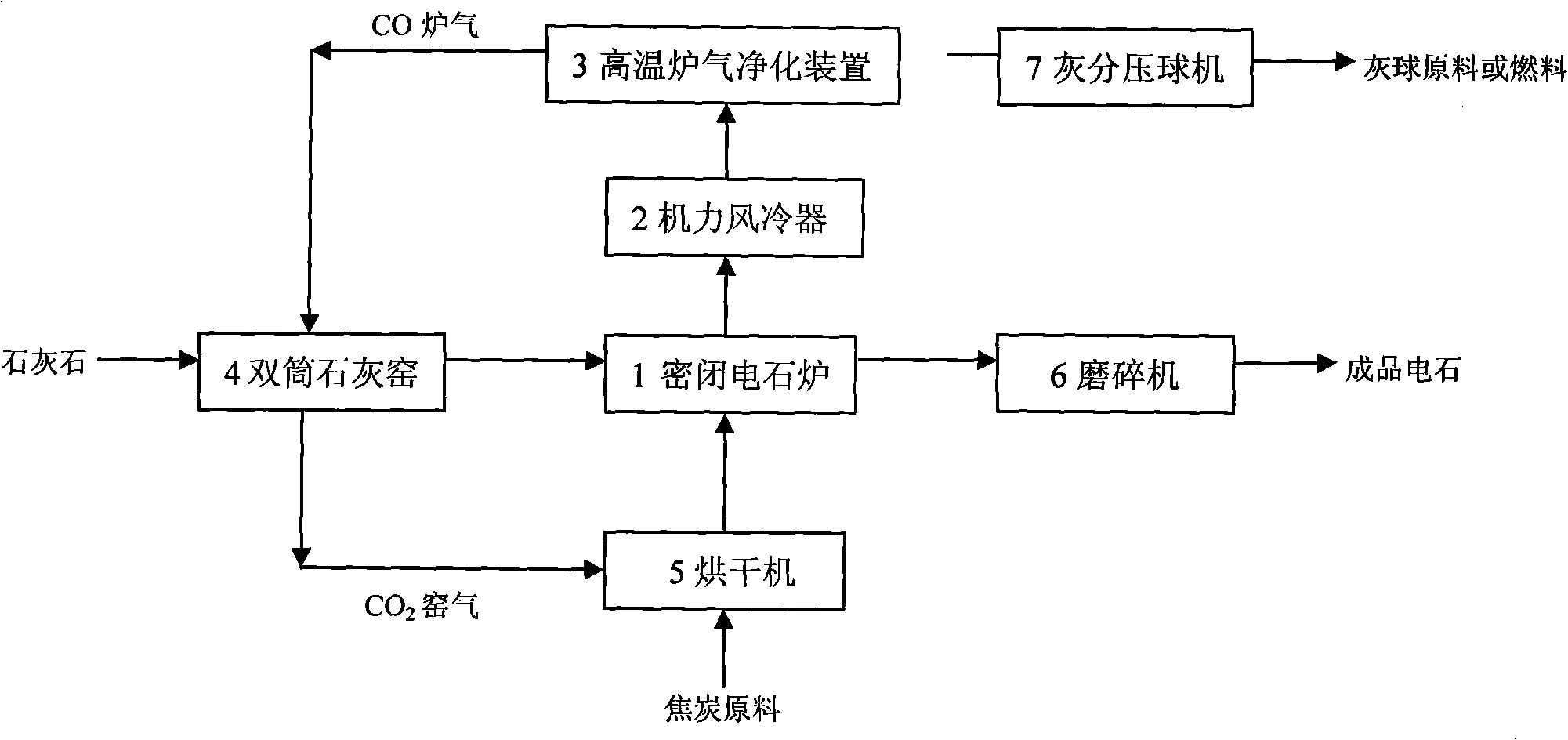

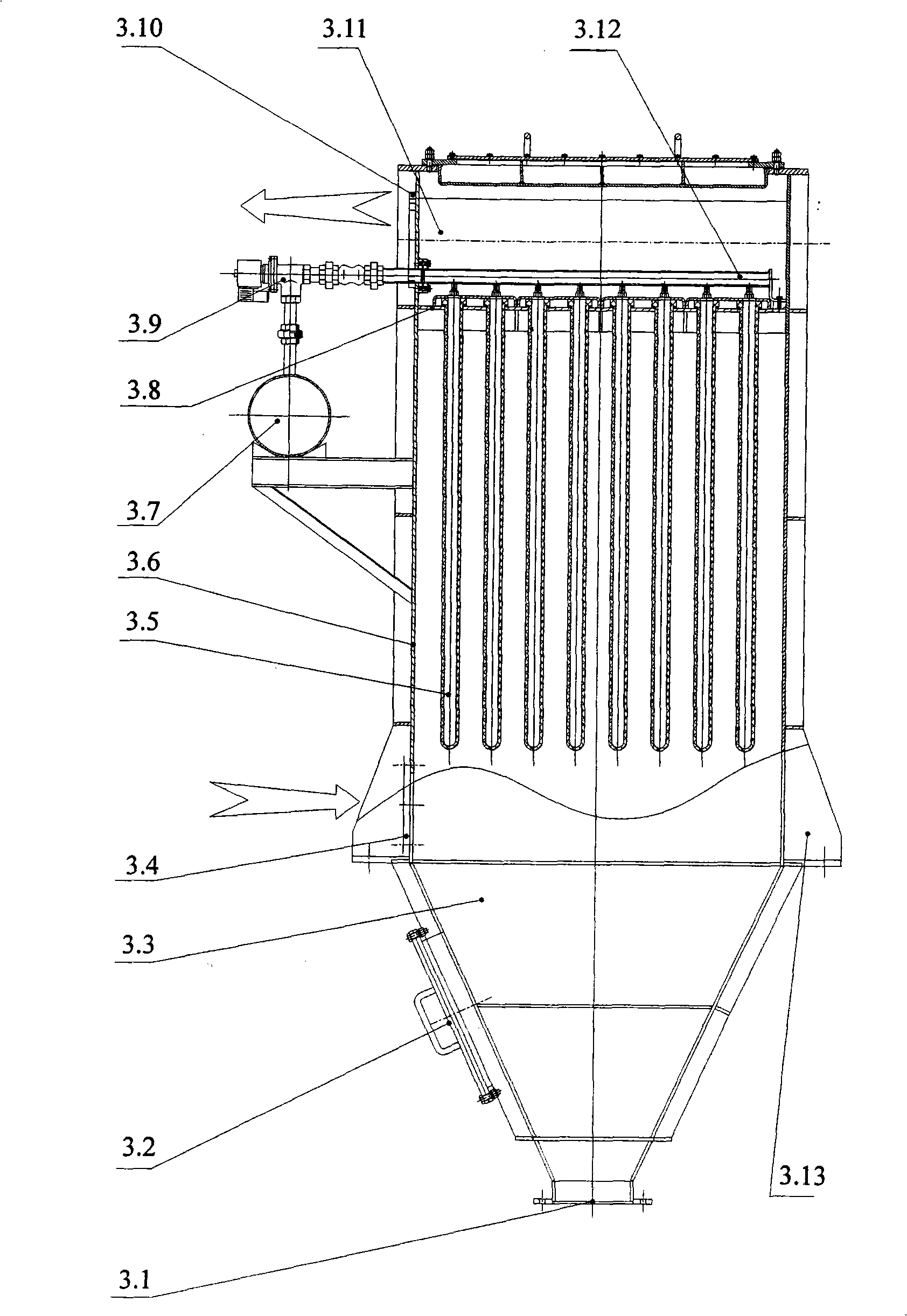

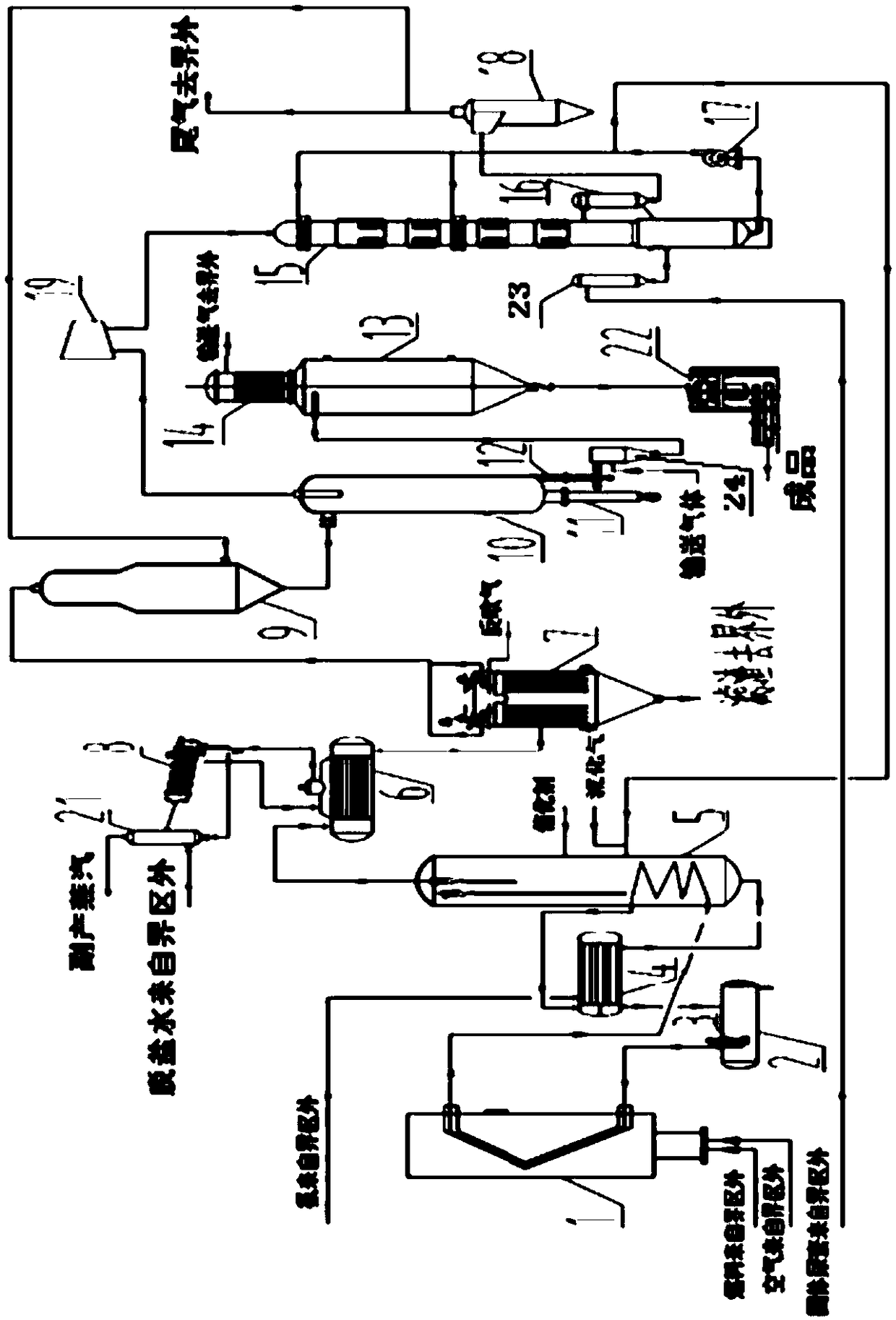

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

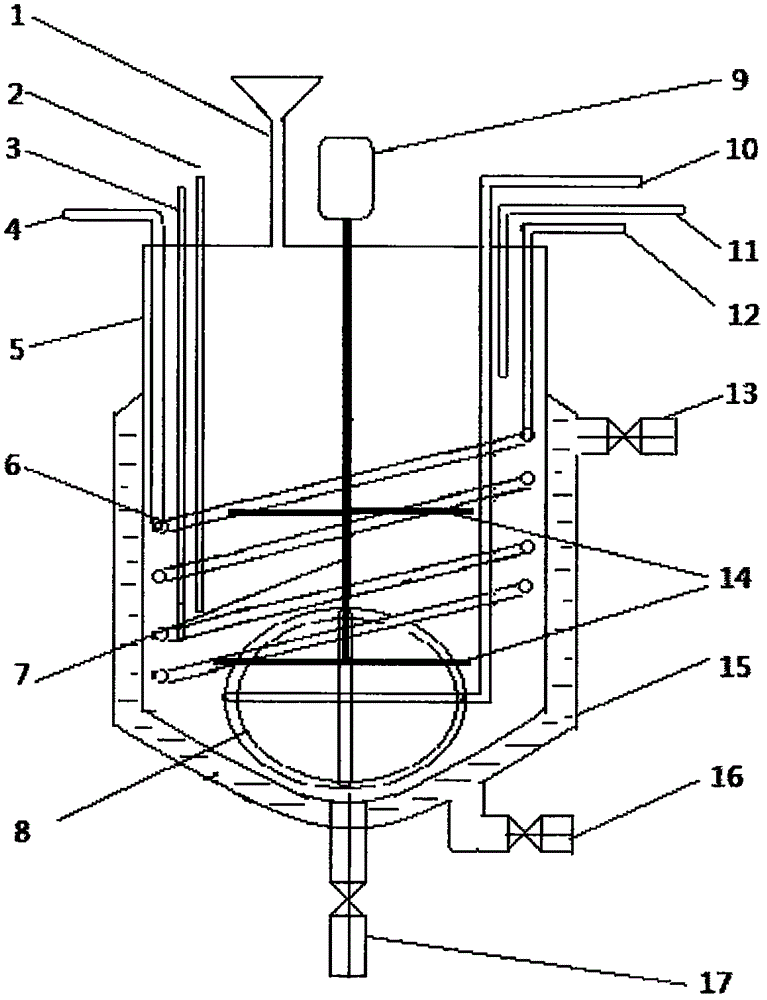

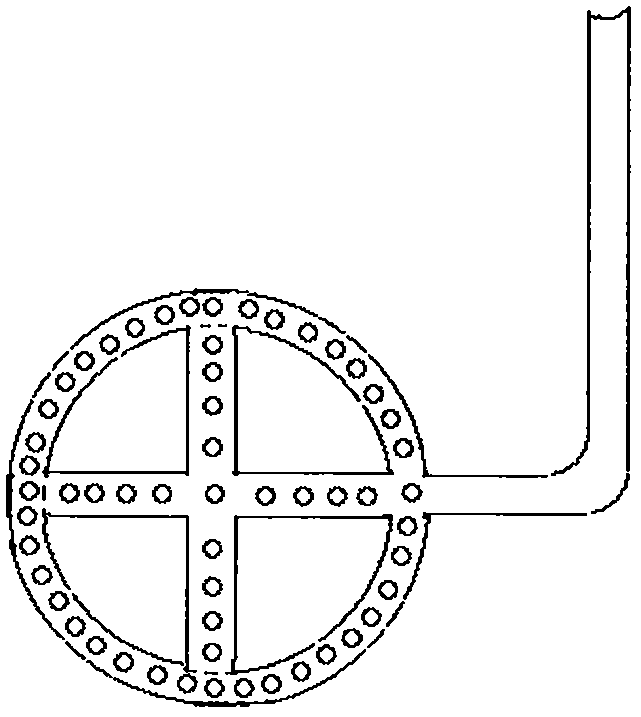

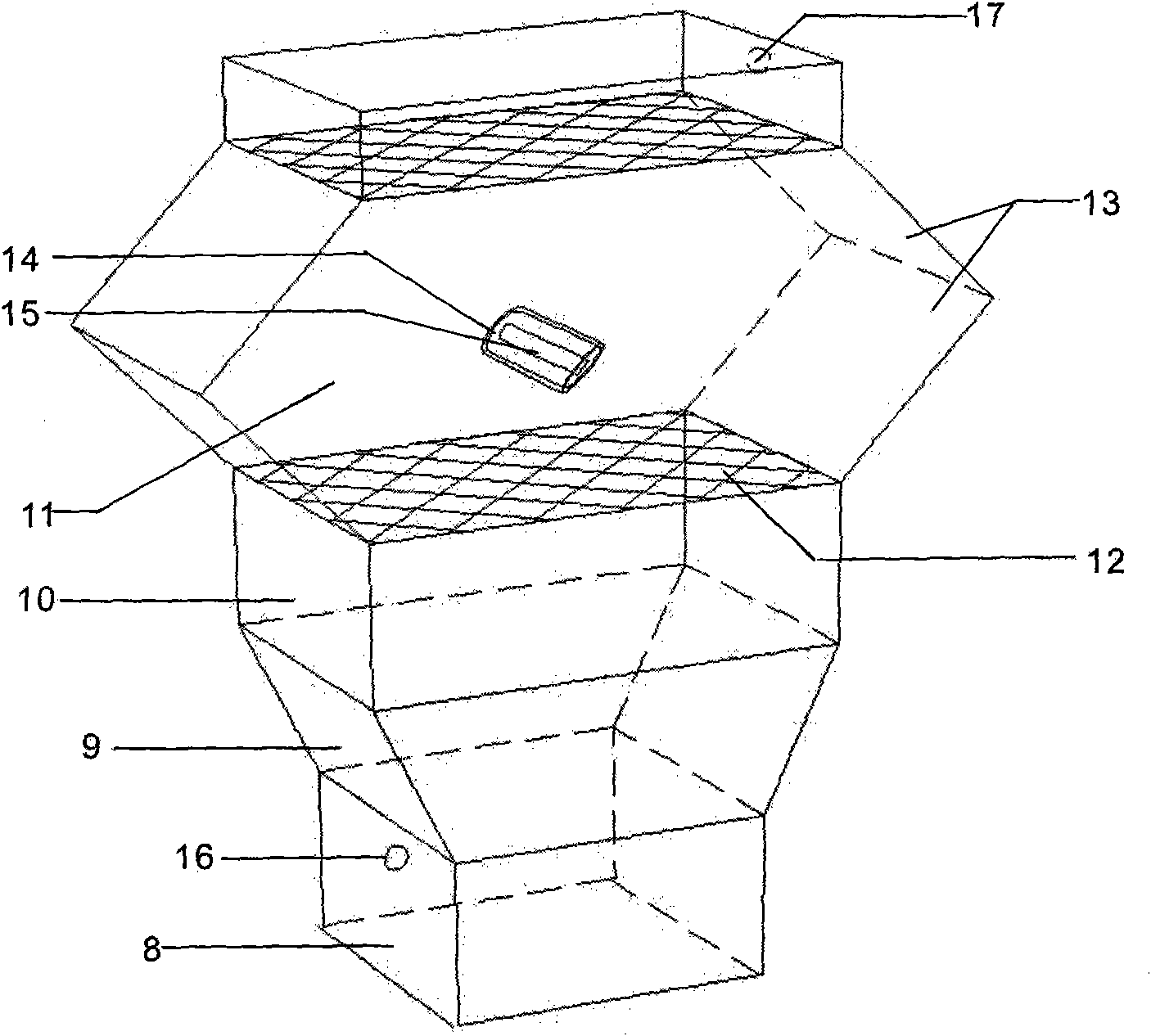

Carbonization and activation integration device and method for producing nano calcium carbonate

InactiveCN105836781ASimple structureEnergy utilization is reasonableCalcium/strontium/barium carbonatesNanotechnologyCarbonizationSlurry

The invention relates to a carbonization and activation integration device and method for producing nano calcium carbonate. The carbonization and activation integration device comprises parts such as a heat conduction oil jacket, a refrigerating coil pipe, an acidometer, a thermocouple, a gas distributor, a variable-frequency speed regulation stirrer and a carbon dioxide buffer tank. The method comprises the steps: pumping calcium hydroxide refining plasma with mass percentage of 6 to 15 percent into the carbonization and activation integration device, stirring, cooling, introducing carbon dioxide-air mixed gas of a variable concentration, performing the carbonization at 10 to 50 DEG C, ending the carbonization when pH is lowered to 6 to 7, opening the jacket to heat by virtue of the heat conduction oil, increasing the stirring rotation speed, adding additives equivalent to 1 to 5 percent of a dry matrix amount of the calcium hydroxide, controlling the activation temperature at 60 to 90 DEG C, activating and modifying for 20 to 40 minutes, stopping heating and stirring, and ending the activation modification; and moving the carbonized and activated slurry out of the integration device, press filtering, dehydrating, and sufficiently drying at 110 to 130 DEG C to obtain a nano calcium carbonate product of different crystal forms.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

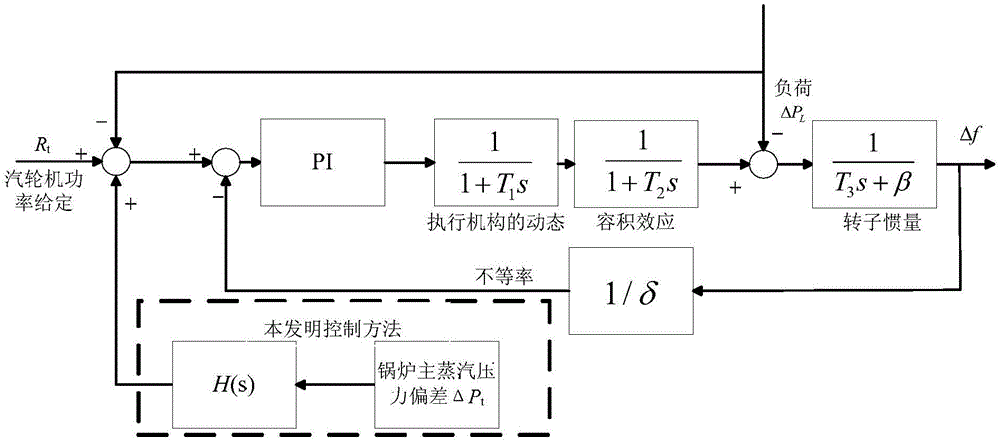

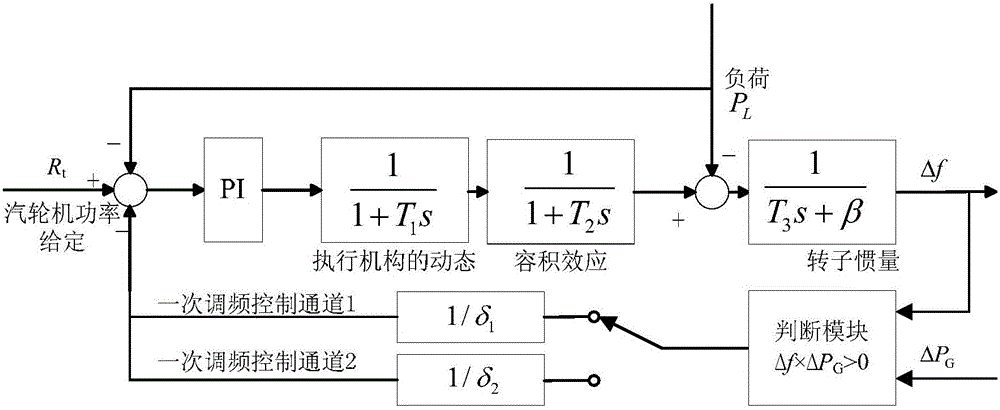

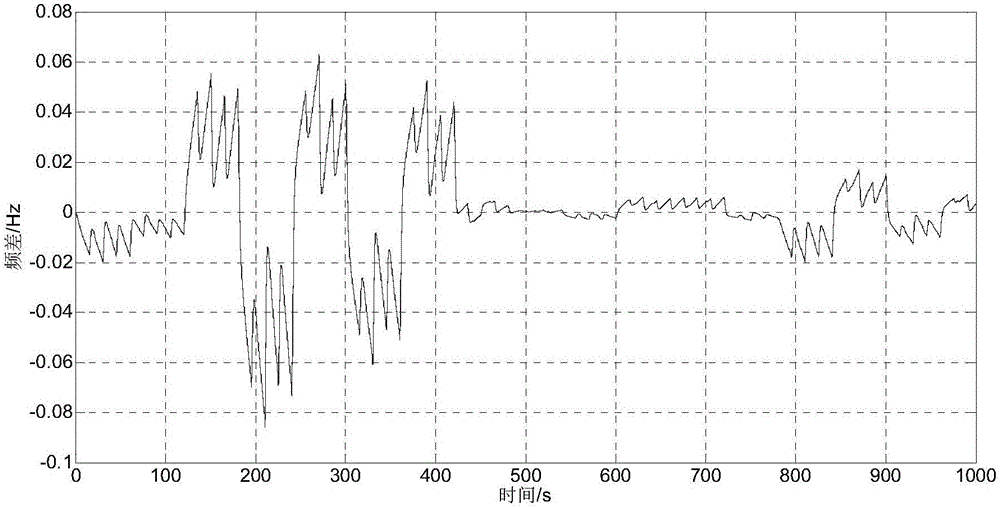

Once-through boiler, steam turbine and power grid coordinated control method for primary frequency modulation analysis

InactiveCN106780103AExtend your lifeEnergy utilization is reasonableForecastingPower gridEngineering

The invention relates to a once-through boiler, steam turbine and power grid coordinated control method for primary frequency modulation analysis. The invention aims to solve a problem that characteristics of the boiler are not considered in the prior art so that great resistance is brought to participation of a high-capacity high-parameter thermal power generation unit in primary frequency modulation and safe and stable running of an electric power system is not facilitated. The method comprises the steps of firstly, performing once-through boiler energy state analysis so as to determine the once-through boiler energy state; secondly, performing power grid energy state analysis so as to determine the power grid energy state; and thirdly, determining a grid source energy coordinated control strategy according to the once-through boiler energy state determined in the step one and the power grid energy state determined in the step two. The once-through boiler, steam turbine and power grid coordinated control method enables the thermal power generation unit to not only sufficiently participate in frequency modulation, but also be operate safely and efficiently under the premise of meeting a requirement of safe running of a power grid. The once-through boiler, steam turbine and power grid coordinated control method is applied to the field of primary frequency modulation analysis.

Owner:HARBIN INST OF TECH

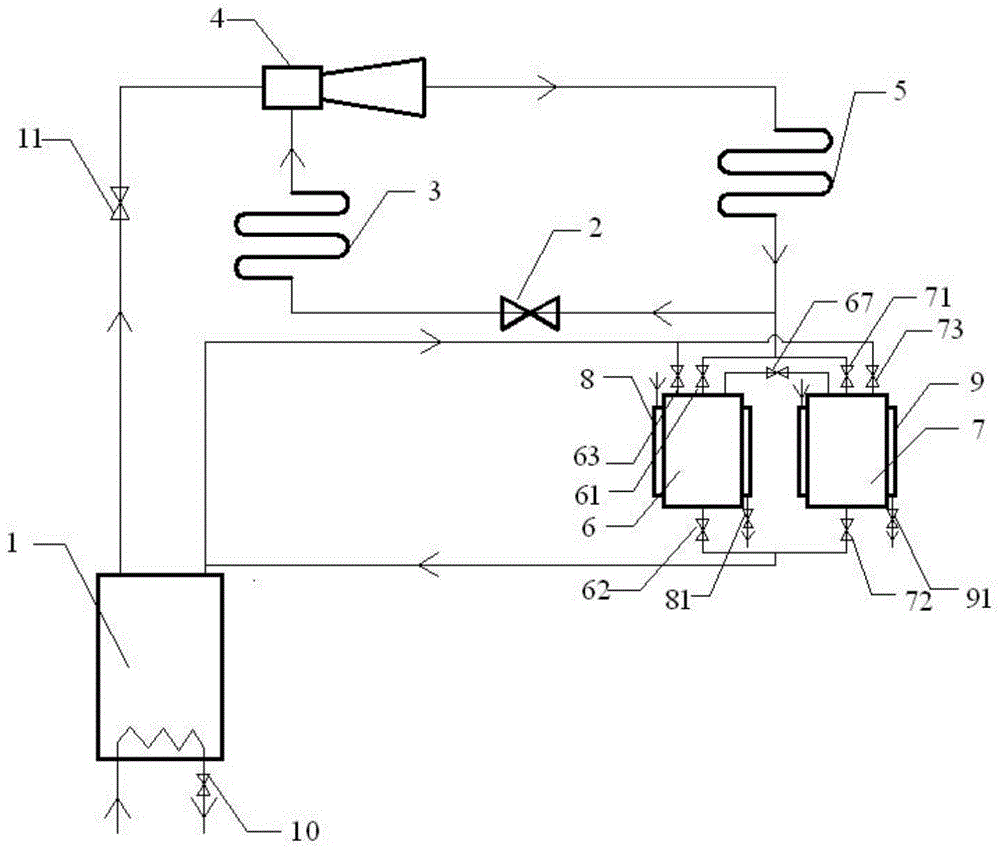

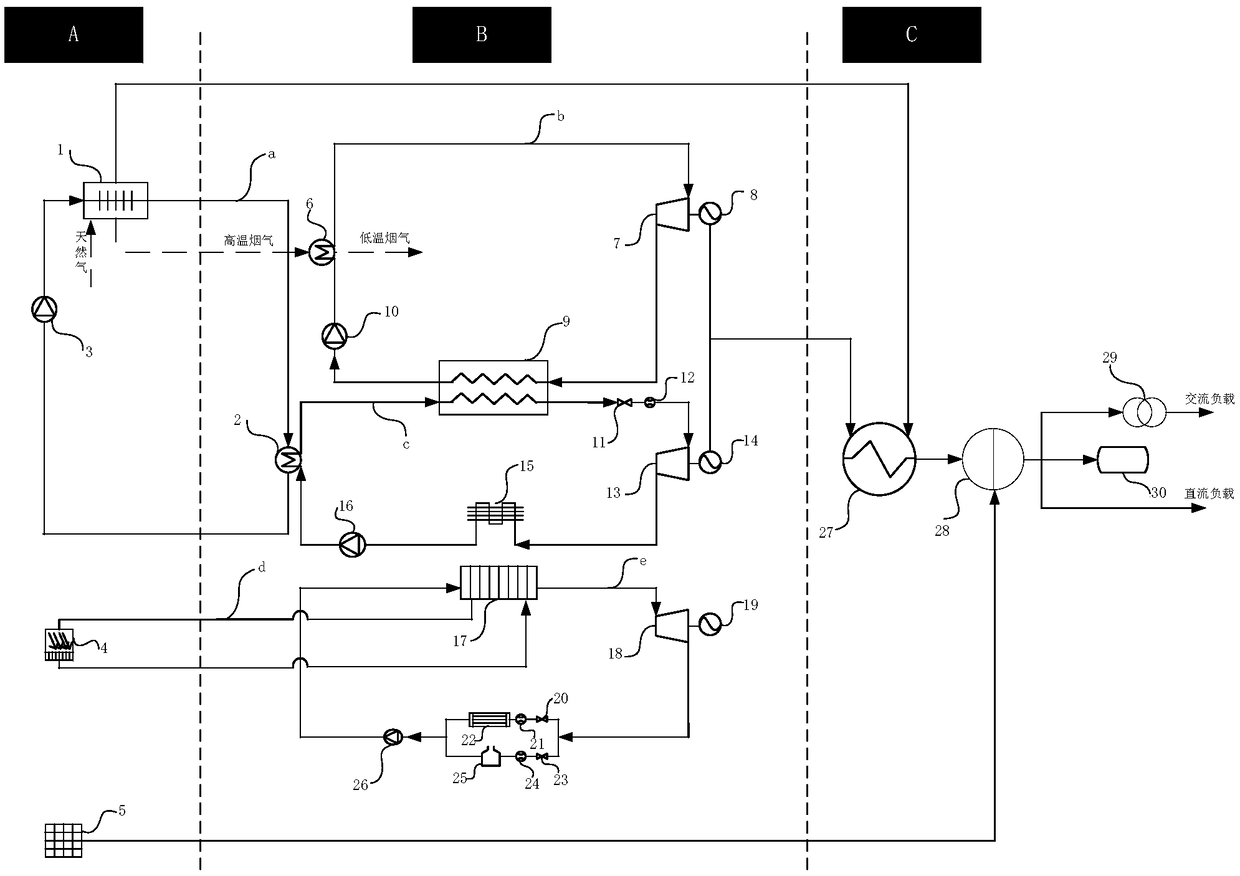

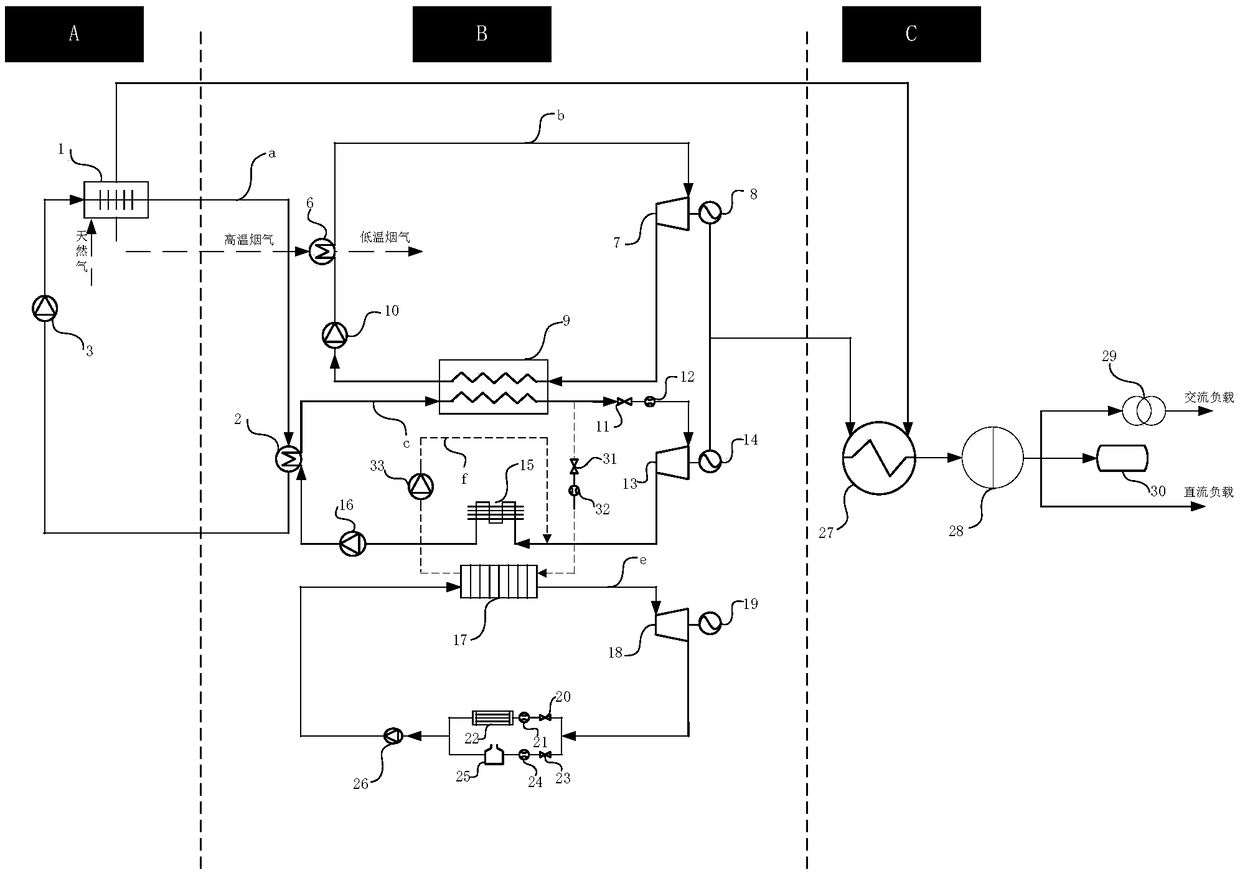

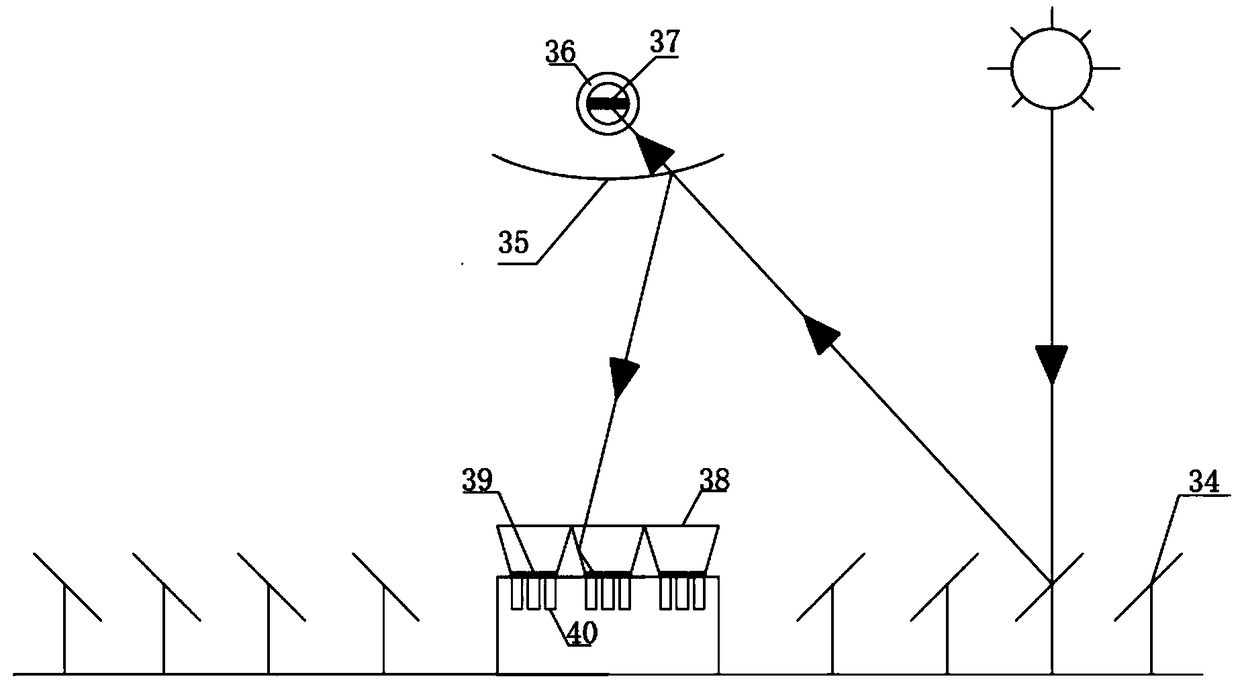

Distributive cold and hot electricity continuous supply system based on condensed and frequency divided photovoltaic photothermal and double-combined Rankine cycle technology

ActiveCN108625913AReduce dosageEmission reductionInternal combustion piston enginesLighting and heating apparatusNew energyInternal combustion engine

The invention discloses a distributive cold and hot electricity continuous supply system based on condensed and frequency divided photovoltaic photothermal and double-combined Rankine cycle technology. The system comprises a cylinder jacket water afterheat recovery subsystem, a double-combined Rankine cycle afterheat recovery and power generation subsystem, a condensed and frequency divided photovoltaic photothermal device, a heat pump circular heat supply / cold supply subsystem, an AC / DC inverter, a controller, a DC / AC inverter and an accumulator; natural gas is used for combustion in an internal combustion engine to generate electric power; high-temperature smoke afterheat and high-temperature cylinder jacket water afterheat generated by the internal combustion engine are recovered for power generation; and one part of sunlight is used for photovoltaic cell power generation through condensation and frequency division technologies. The system is high in energy utilization efficiency, reasonable in energy utilization mode and not limited by regions, weathers and the time change, can realize individual energy outputting according to user demands when realizing stable energy outputting, is compact in structure and easy to realize modular installation, realizes combination of new energy and traditional energy, and achieves the advantages of energy conservation, emission reduction and environmental protection.

Owner:JIANGSU UNIV

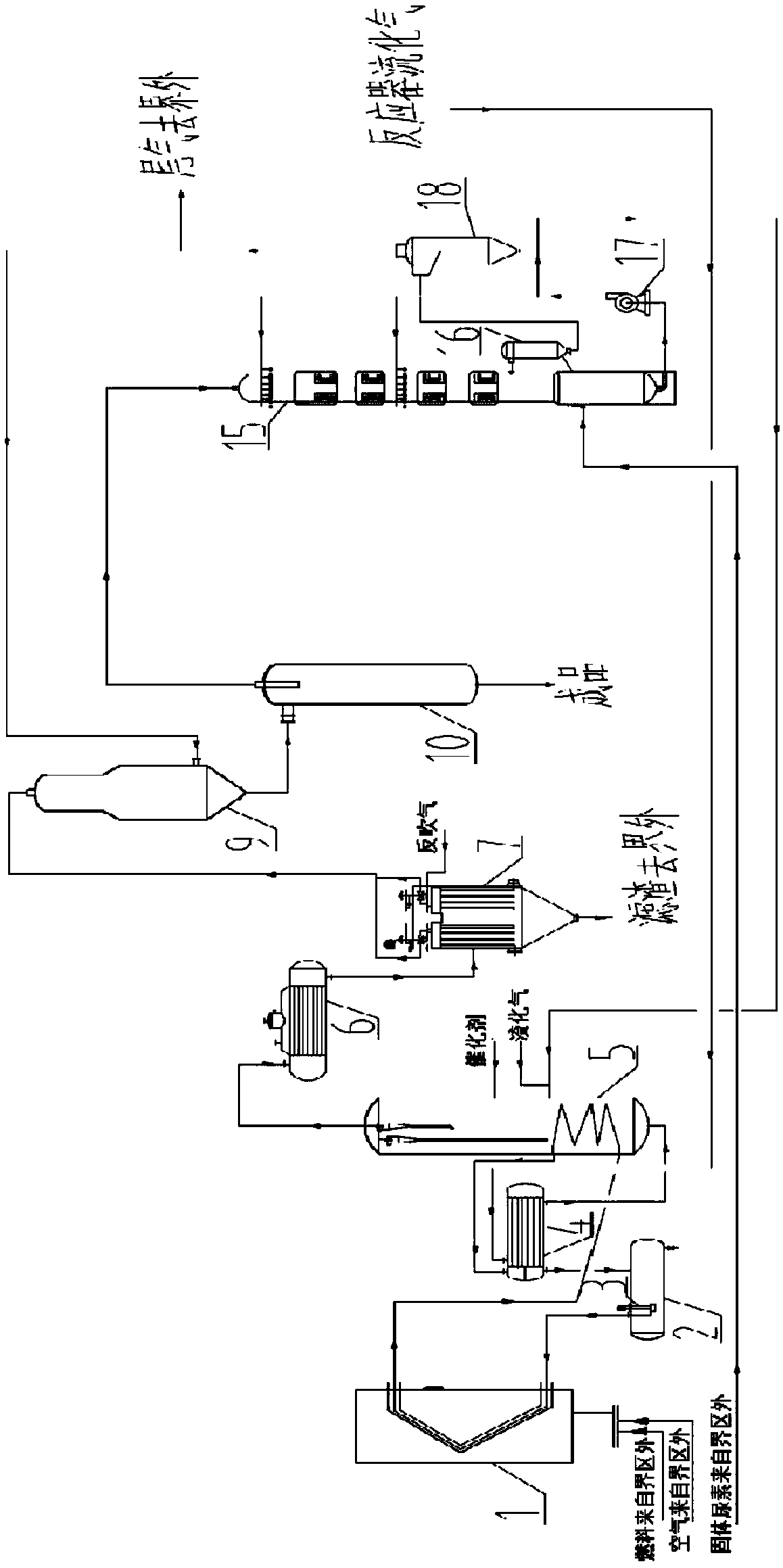

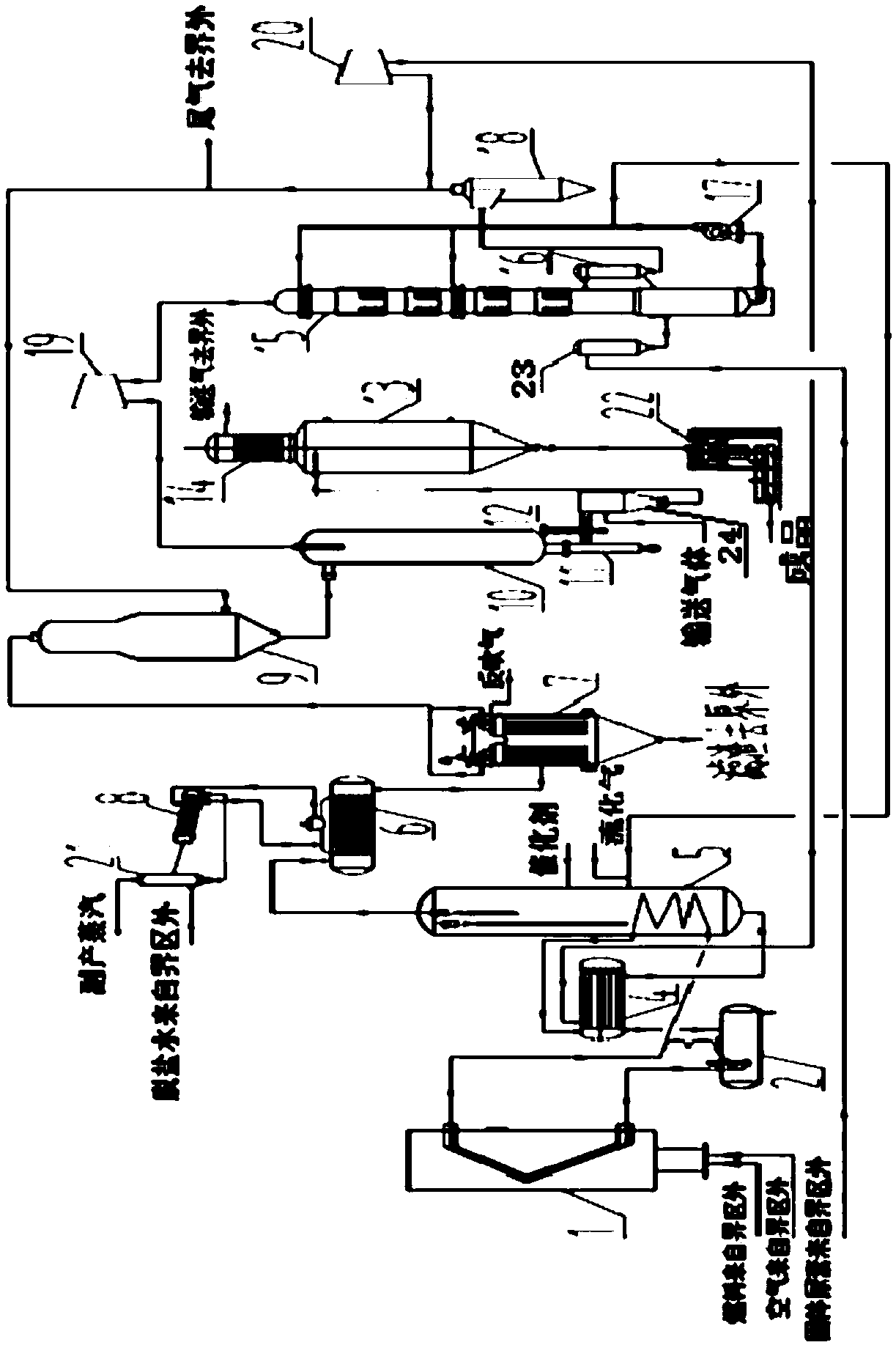

System and method for producing melamine

ActiveCN109053615AReduce dosageReduce energy consumptionOrganic chemistryVapor–liquid separatorFluidized bed

The invention belongs to the technical field of melamine preparation, and relates to a system and a method for producing melamine. The system comprises a fluidized bed reactor, wherein mixed gas generated by the fluidized bed reactor goes into a hot gas cooler, a hot gas filter, a crystallizer, a catcher, a urea scrubber, a gas-liquid separator and a demister successively; the demister is connected with the crystallizer; a molten salt bath is successively connected with a molten salt furnace and the fluidized bed reactor to provide a heat transfer medium; a carrier gas preheater is connected with the fluidized bed reactor and the molten salt bath; molten salt enters the molten salt furnace, the fluidized bed reactor and the carrier gas preheater successively from the molten salt bath and then returns to the molten salt bath; granular urea outside a boundary area enters the lower part of the urea scrubber; part of molten urea flowing from the bottom of the urea scrubber partly enters the upper and middle parts of the urea scrubber through a circulating pump and the rest enters the fluidized bed reactor. The urea is added in a granule form of during the production of melamine, and reduces the energy consumption of the molten urea with less environmental pollution.

Owner:郗运柱

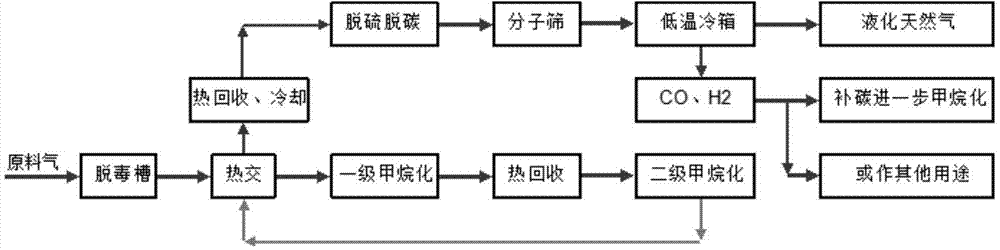

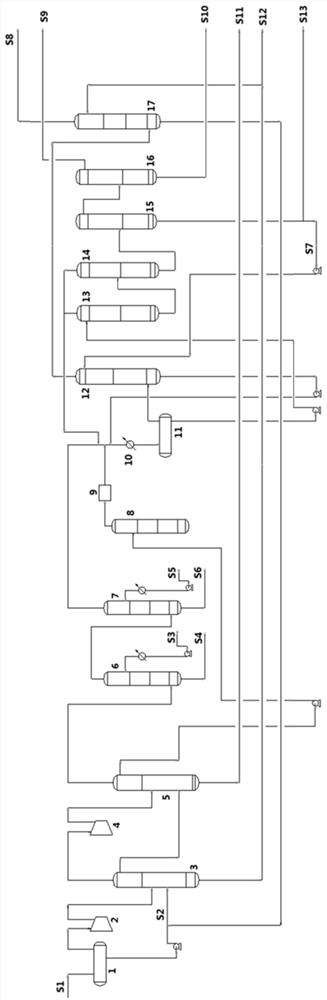

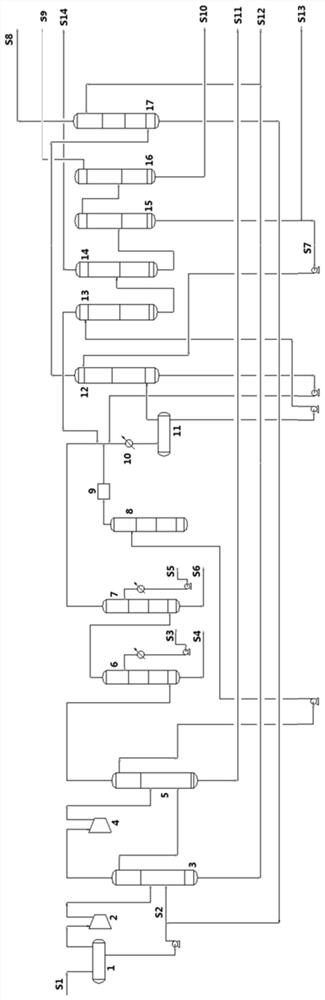

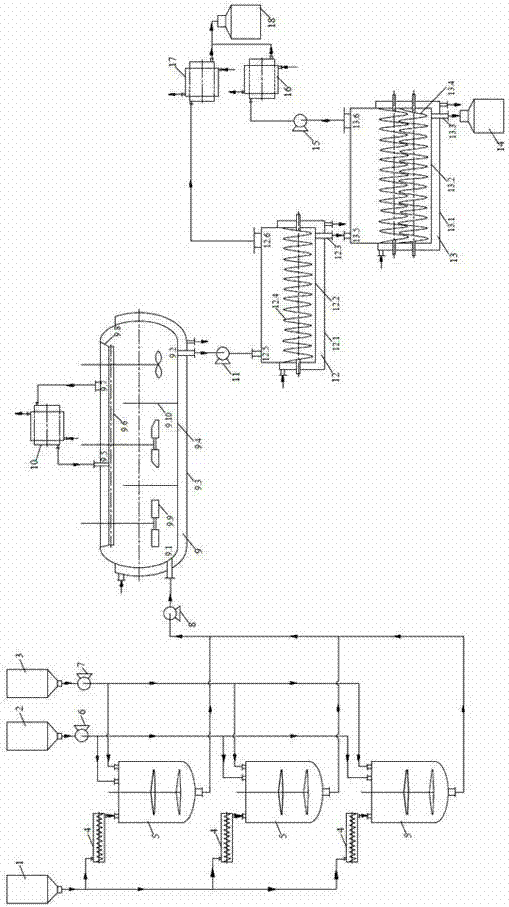

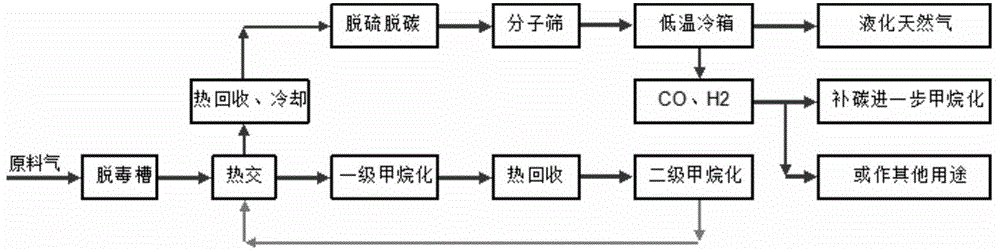

Production technology of natural gas or liquefied natural gas

The invention provides a technology for preparing natural gas or liquefied natural gas from Lurgi and coke oven gas mixture. The technology comprises at least a first-stage multifunctional catalytic reaction, and parts of sulfur-tolerant shift conversion and sulfur-tolerant methanation reactions and an organic sulfur hydrogenation conversion reaction are carried out in the multifunctional reaction; a gas from a multifunctional reactor undergoes heat exchange and high pressure superheated steam recovery, undergoes selective oxidation to remove hydrogen sulfide, undergoes transformation adsorption to remove carbon dioxide, and enters a sulfur-intolerant methanation reactor (heat insulation or isothermal reaction) to undergo a CO methanation reaction, and a gas from the outlet of the sulfur-intolerant methanation reactor is finished natural gas or is sent o a low temperature cold box to liquefy methanol in order to form liquefied natural gas, wherein the CO content is smaller than 0.1%, the CO2 content is smaller than 0.5%, and the CH4 content is greater than 97%.

Owner:青岛联信催化材料有限公司

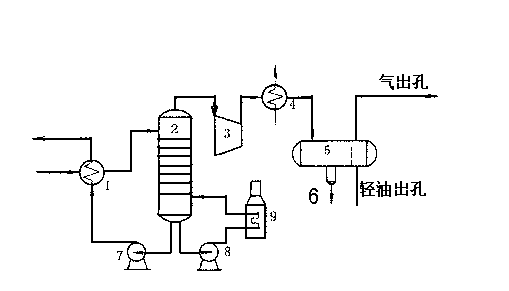

Crude oil stripping stabilization device

InactiveCN102851057ASimple processSimple operation and managementHydrocarbon distillationResource savingProcess engineering

The invention relates to the crude oil separation field, and especially relates to a crude oil stripping stabilization device. The crude oil stripping stabilization device mainly comprises a heat exchanger, a stabilization tower, a compressor, a condenser, a three-phase separator, a tower bottom oil pump, a reboiling oil pump and a heating furnace, wherein the heat exchanger is connected with the stabilization tower, the top of the stabilization tower is connected with the compressor, the compressor is connected with the three-phase separator through the condenser, the separator is provided with a water outlet, a light oil outlet and a gas outlet, and the bottom of the stabilization tower is connected with the heat exchanger through the tower bottom oil pump. The crude oil stripping stabilization device has the advantages of simple crude oil stripping stabilization process flow, easy operation management, reasonable energy utilization, low device investment and operation cost, resource saving, and production efficiency improvement.

Owner:NANTONG TIANHUA HERUI TECH VENTURES

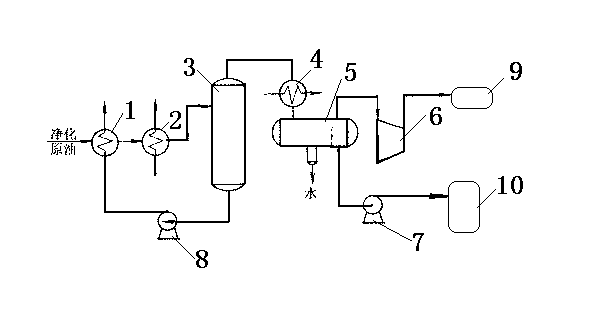

Heating, flashing and separating device

InactiveCN102876351ASimple processSimple operation and managementHydrocarbon distillationFractionating columnProcess engineering

The invention relates to the field of crude oil separation, in particular to a heating, flashing and separating device. The heating, flashing and separating device mainly comprises a heat exchanger, a heater, a stabilizer, a condenser, a condensate separator, an oil pump, a secondary cylinder and a fractionating column, wherein the heat exchanger is connected with the heater; the heater is connected with the stabilizer; the oil pump is arranged between the stabilizer and the heat exchanger; the stabilizer is connected with the condensate separator through the condenser; and the condensate separator is respectively connected with a water outlet, the secondary cylinder and the fractionating column. The invention has the advantages that a process flow of heating, flashing and separating crude oil is simple and easy to operate and manage, energy is utilized reasonably, device investment and operating cost are low, resources are saved, and the production efficiency is improved.

Owner:NANTONG TIANHUA HERUI TECH VENTURES

Combination preparation method for anhydrous magnesium chloride and potassium sulphate

ActiveCN101121536AStrongly corrosiveEasy to operateMagnesium chloridesAlkali metal sulfites/sulfatesOleumSulfate

The present invention provides a combined preparation method of a waterless magnesium chloride and a potassium sulfate and meanwhile produces a hydrochloride. The technic proposal is that a hexahydrated magnesium chloride (MgCl2 question mark 6H2O) is dehydrated to a dihydrated magnesium chloride. A hydrogen chloride dry gas is dried and dehydrated to a waterless magnesium chloride in a fluidized bed. The second step is that after a heat transfer, a dehydrated hydrogen chloride tail gas enters into a drying tower of a concentrated sulfuric acid and an oleum and the tail gas is dehydrated. The dried hydrogen chloride is recycled. After absorbing the water, a dilute sulfuric acid enters into a sulfate production device to absorb a sulfur trioxide again and becomes the concentrated sulfuric acid. The redundant dilute sulfuric acid enters into a Mannheim device to produce a potassium sulfate and the produced hydrogen chloride produces the hydrochloride after being cleansed. The technology producing the waterless magnesium chloride, provided by the present invention, has the advantages of low cost, good quality, high purity quotient, low energy consumption and little environmental pollution.

Owner:HANGZHOU HI TECH FINE CHEM

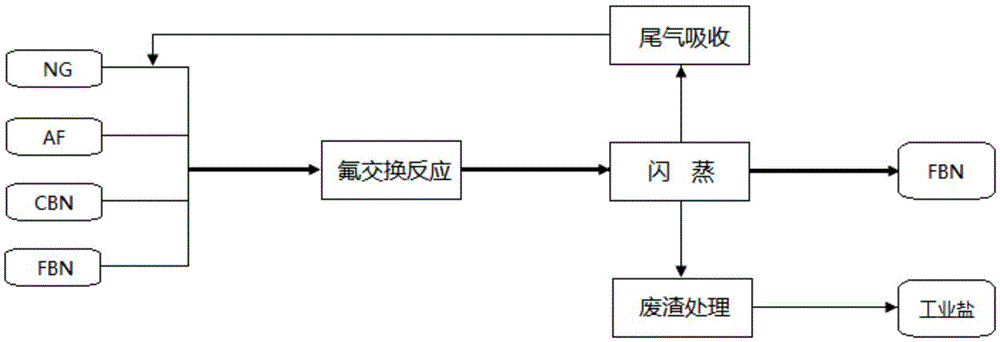

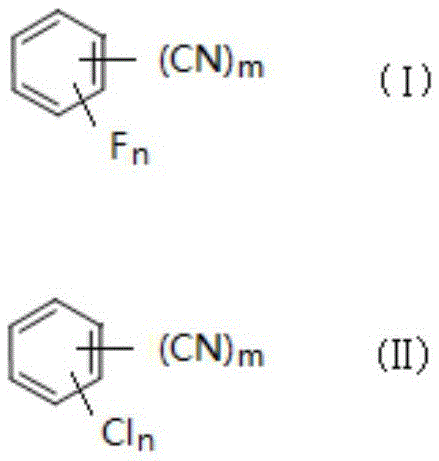

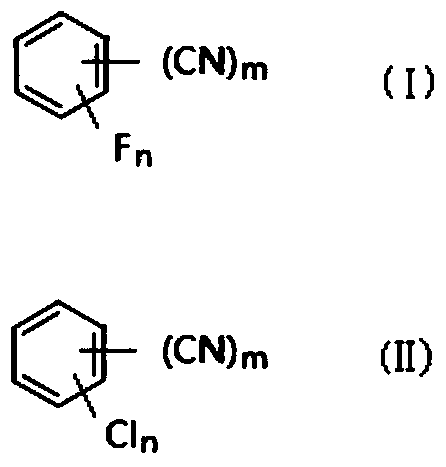

Fluorobenzonitrile compound preparation method

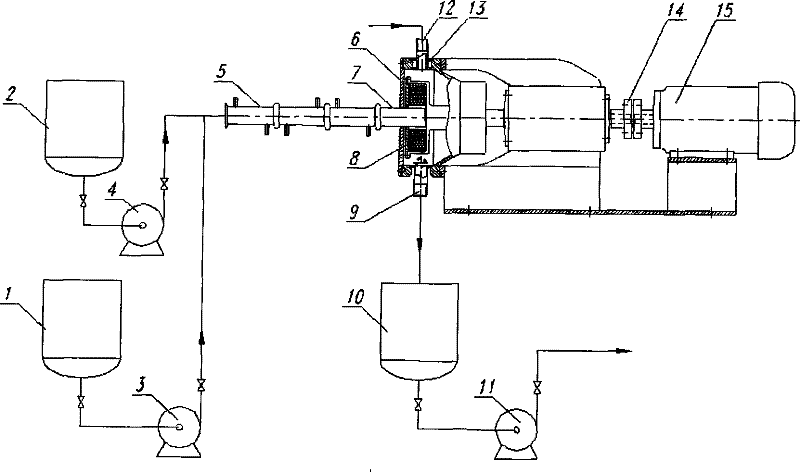

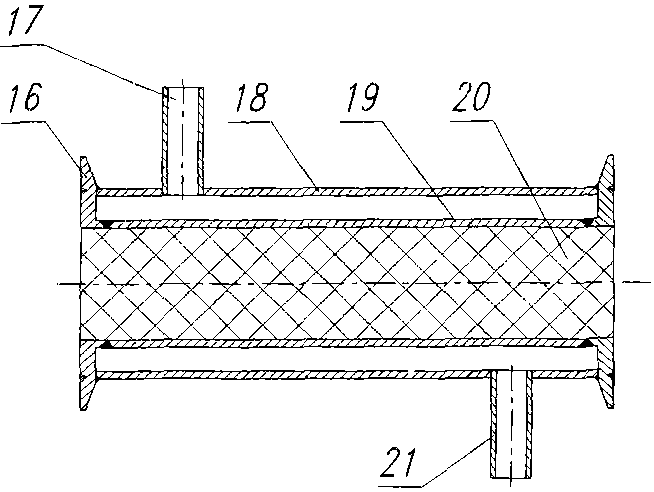

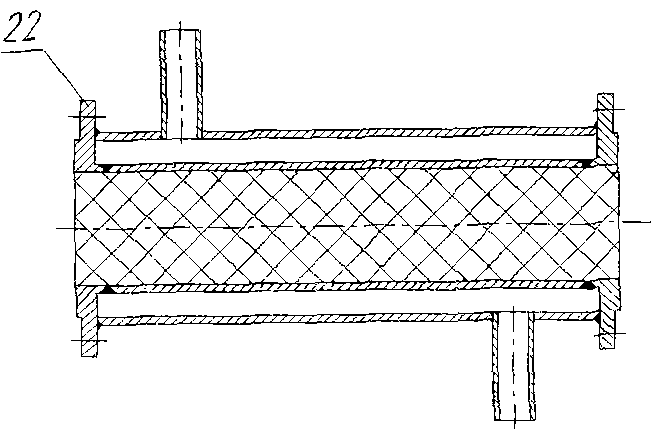

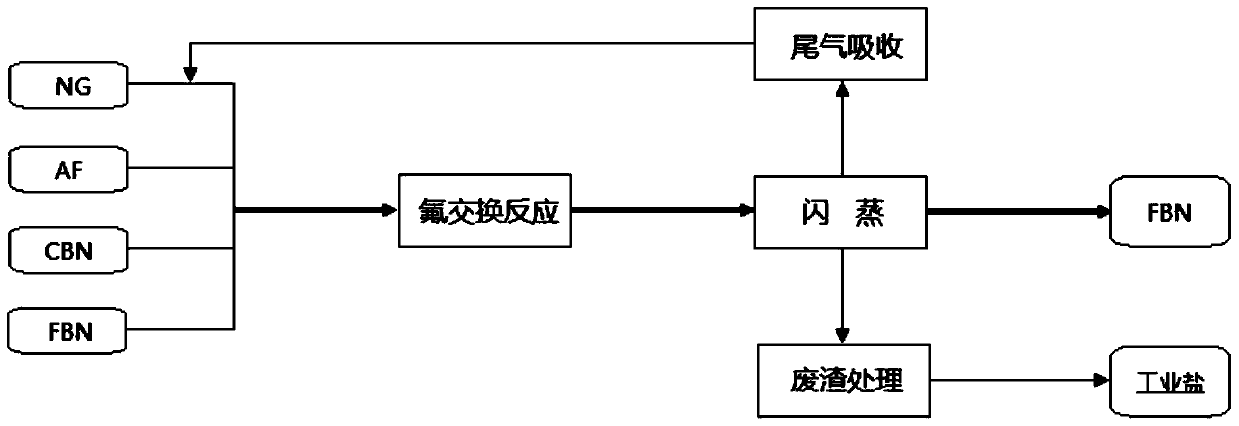

ActiveCN105523962AComplex processHigh energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationHigh pressureSolvent

The present invention provides a fluorobenzonitrile compound preparation method, fluorobenzonitrile compounds are as shown in the general formula (I), an objective product can be prepared from a general-formula-(II)-shown chlorobenzonitrile compound as a raw material by reacting with an anhydrous fluoride in the presence of an inert gas under high temperature high pressure reaction conditions and flashing a reaction product, wherein the objective product itself is used as a solvent. Due to use of the objective product itself as the solvent, a main component of the fluorine exchange reaction product only comprises the objective product, due to use of an inert gas pressurization method to improve the fluorine exchange reaction and product separation conditions, the product is separated and purified in the flashing manner, the reaction residual heat is rationally used, and the whole process is simple and feasible. The method is readily available in raw materials, simple in process, energy-saving, consumption-reducing, and more suitable for industrial scale production.

Owner:DALIAN QIKAI MEDICAL TECH

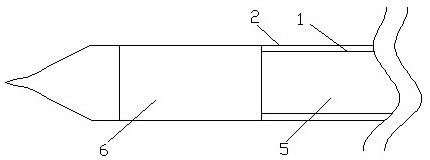

All-glass vacuum solar heat collecting tube

InactiveCN102589174AImprove absorption efficiencyAvoid coolingSolar heating energySolar heat devicesSolar waterEngineering

The invention relates to an all-glass vacuum solar heat collecting tube, which is used for solar water heater and solar heating. The all-glass vacuum solar heat collecting tube comprises an outer tube, an inner tube and a clamp. A vacuum space exists between the outer tube and the inner tube. The outer tube and the inner tube are sintered at the tail end and fixed through the clamp. The outer layer of the inner tube is coated with a metal reflection layer. The outer surface of the metal reflection layer is coated with an absorption layer. The coating area of the absorption layer is limited in a sunlight irradiating area under the operation state of the all-glass vacuum solar heat collecting tube. The invention has advantages of reasonable structural design, greatly reduced emittance and low cost.

Owner:许虎良

Method for producing low alcohol, high concentration formaldehyde

InactiveCN1208298CEnergy utilization is reasonableLow costCarbonyl compound separation/purificationRational useHigh concentration

Owner:洪海玲

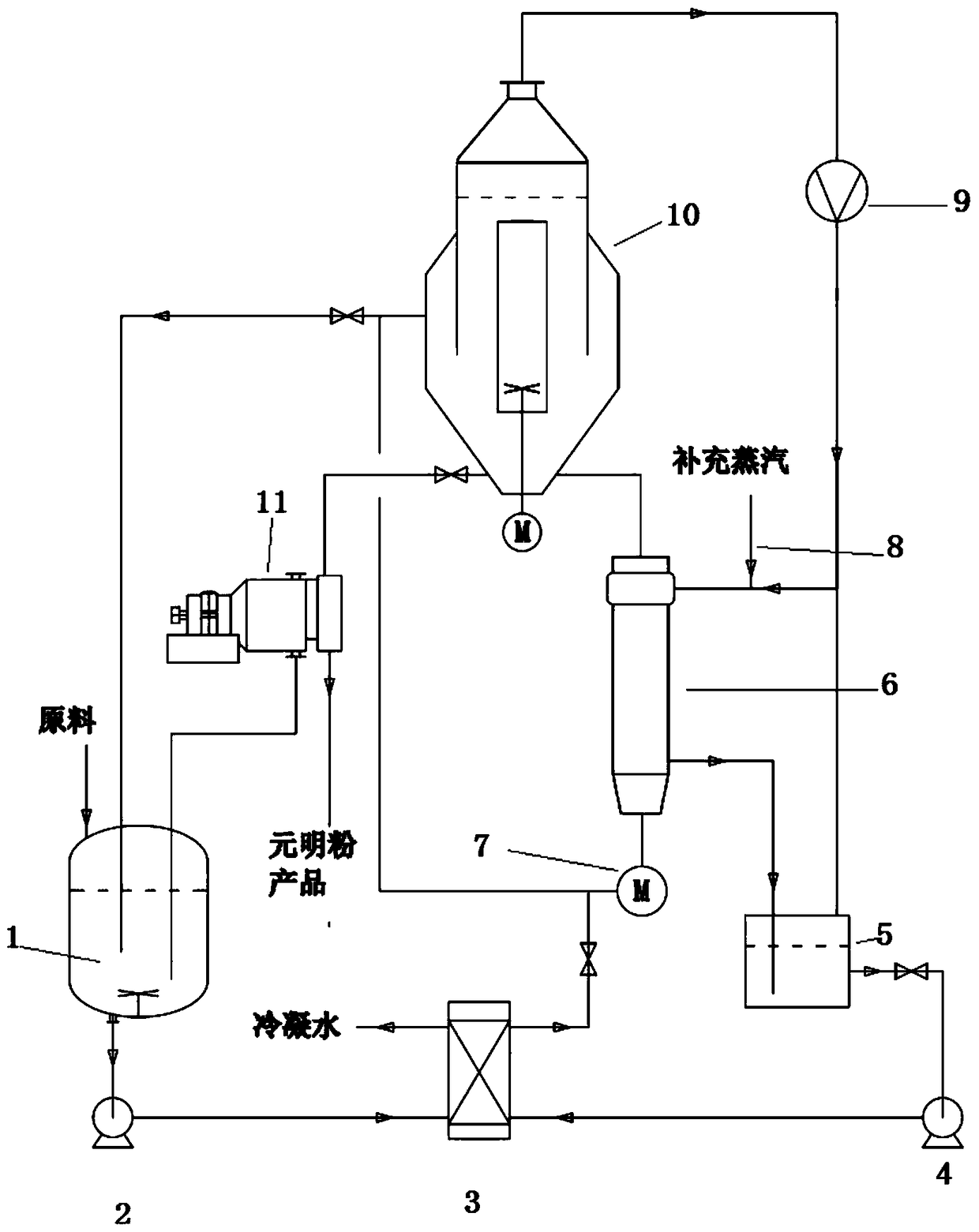

Anhydrous sodium sulfate production equipment

InactiveCN109502610AAvoid easy cloggingReduce pollutionAlkali metal sulfite/sulfate dehydrationEvaporationCondensate pump

The invention provides anhydrous sodium sulfate production equipment which comprises a nitrate dissolving tank, a feed pump, a first heat exchanger, a circulating pump, a second heat exchanger, a condensate pump, a centrifugal machine, a DTB evaporation crystallizer, an MVR (Mechanical Vapor Recompression) compressor and a steam supplementing pipeline. According to the anhydrous sodium sulfate production equipment disclosed by the invention, the nitrate dissolving energy consumption is reduced by utilizing heat of the feed liquid discharged by the DTB evaporation crystallizer and the mother liquor discharged by the centrifugal machine, the anhydrous sodium sulfate production equipment is simple in technical process, compact in equipment arrangement and reasonable in energy utilization, andmultiple advantages of saving investment, shortening the process flow, reducing the cost, comprehensively utilizing resources, protecting the environment and the like are fully achieved; moreover, the anhydrous sodium sulfate production equipment has the advantages that the product liquidity is excellent, the stock bin is difficult to block, the stored material is difficult to agglomerate, the drying energy consumption is reduced, the dust pollution is reduced, the product cost is low.

Owner:ENG TECH INST CO LTD OF CNSIC

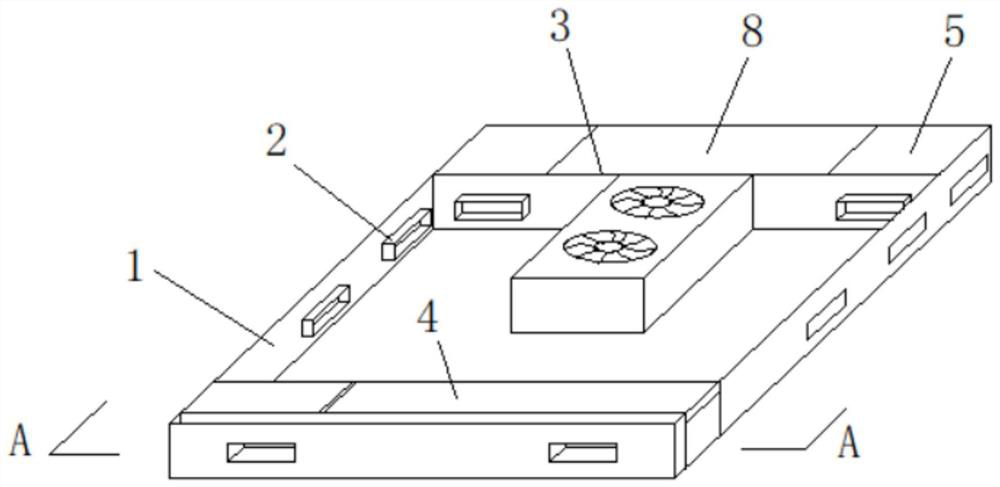

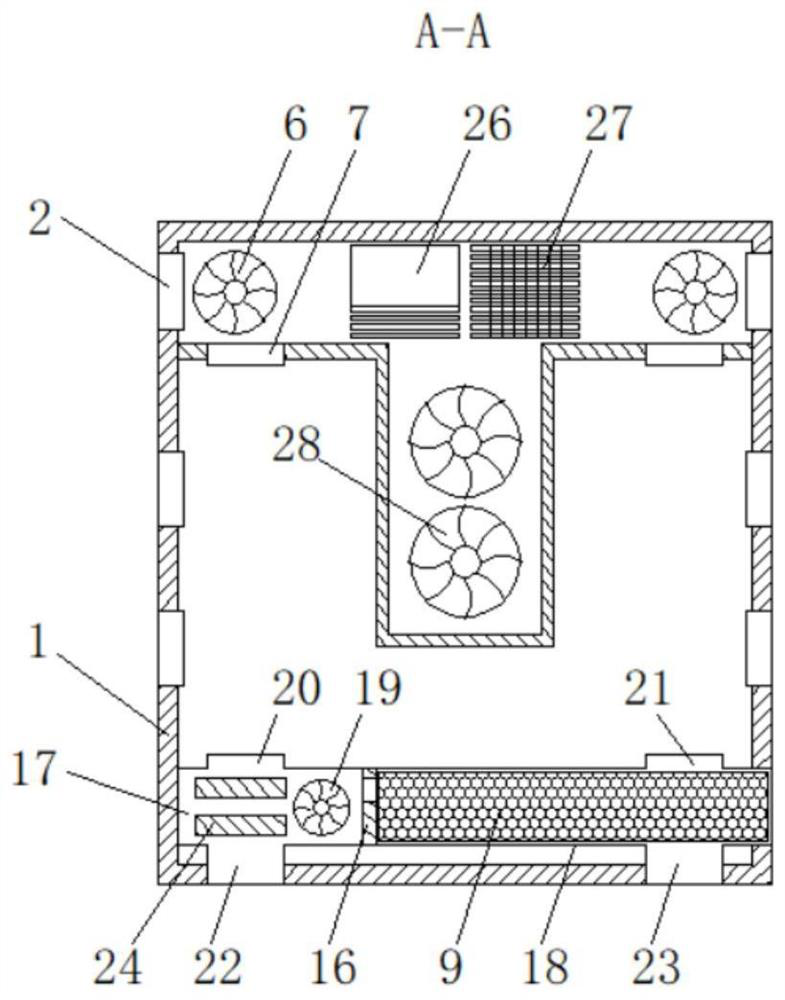

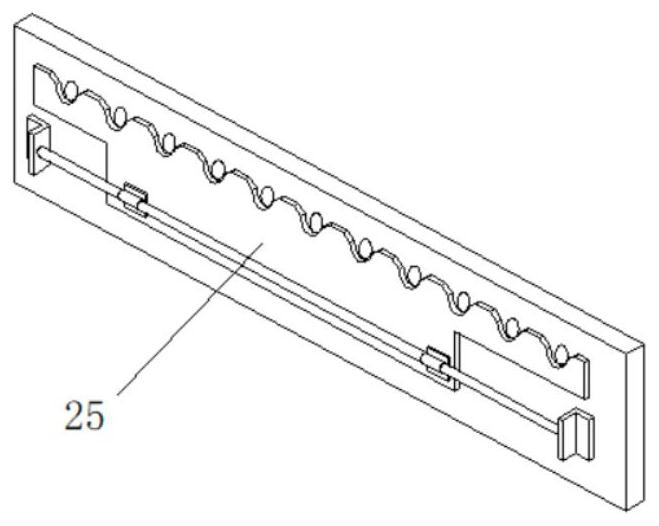

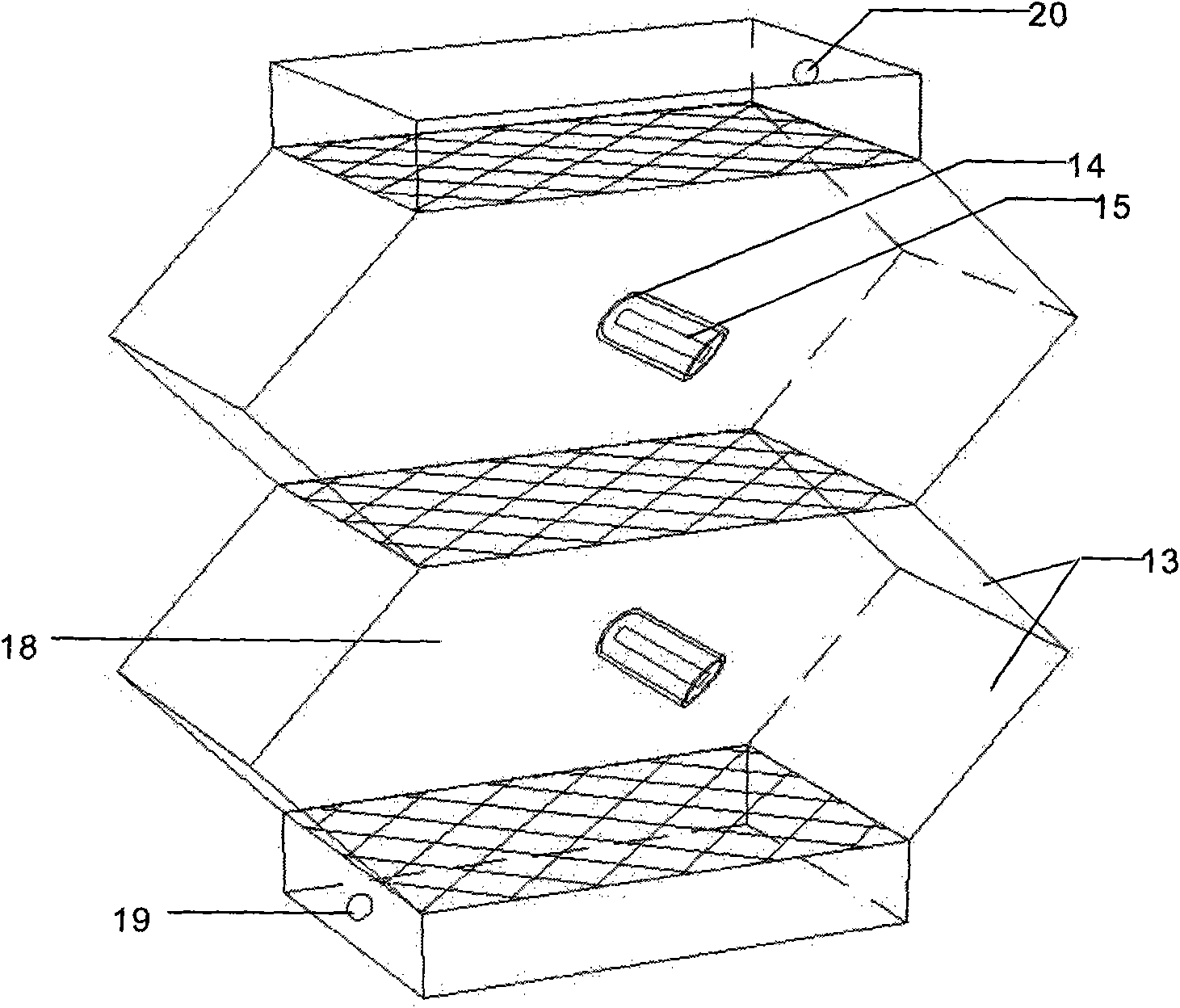

Temperature adjusting and humidity adjusting cushion capable of adjusting closed state

PendingCN112212432ASolve the problem of not keeping warmEfficient use ofMechanical apparatusStuffed mattressesEnergy conservationCushion

The invention discloses a temperature adjusting and humidity adjusting cushion capable of adjusting a closed state, belongs to the technical field of cushions, and aims at solving the problems that traditional cushions, mattresses and the like are poor in air permeability and damp and hot contact parts are generated due to poor ventilation after long-time use. At least one first air window is arranged on a cushion main body, and temperature and humidity adjustment of the cushion main body is achieved by changing the closed state of the cushion main body. According to the temperature adjustingand humidity adjusting cushion capable of adjusting the closed state, the humidity and the temperature can be balanced through internal and external circulating air, energy conservation and stabilityare achieved, and a cool and dry controllable environment is kept between the body part of a user and the cushion.

Owner:HARBIN ZIRAN TECH DEV CO LTD

A carbonization and activation integrated device and method for producing nano-calcium carbonate

InactiveCN105836781BSimple structureEnergy utilization is reasonableCalcium/strontium/barium carbonatesNanotechnologyCarbonizationSlurry

The invention relates to a carbonization and activation integration device and method for producing nano calcium carbonate. The carbonization and activation integration device comprises parts such as a heat conduction oil jacket, a refrigerating coil pipe, an acidometer, a thermocouple, a gas distributor, a variable-frequency speed regulation stirrer and a carbon dioxide buffer tank. The method comprises the steps: pumping calcium hydroxide refining plasma with mass percentage of 6 to 15 percent into the carbonization and activation integration device, stirring, cooling, introducing carbon dioxide-air mixed gas of a variable concentration, performing the carbonization at 10 to 50 DEG C, ending the carbonization when pH is lowered to 6 to 7, opening the jacket to heat by virtue of the heat conduction oil, increasing the stirring rotation speed, adding additives equivalent to 1 to 5 percent of a dry matrix amount of the calcium hydroxide, controlling the activation temperature at 60 to 90 DEG C, activating and modifying for 20 to 40 minutes, stopping heating and stirring, and ending the activation modification; and moving the carbonized and activated slurry out of the integration device, press filtering, dehydrating, and sufficiently drying at 110 to 130 DEG C to obtain a nano calcium carbonate product of different crystal forms.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

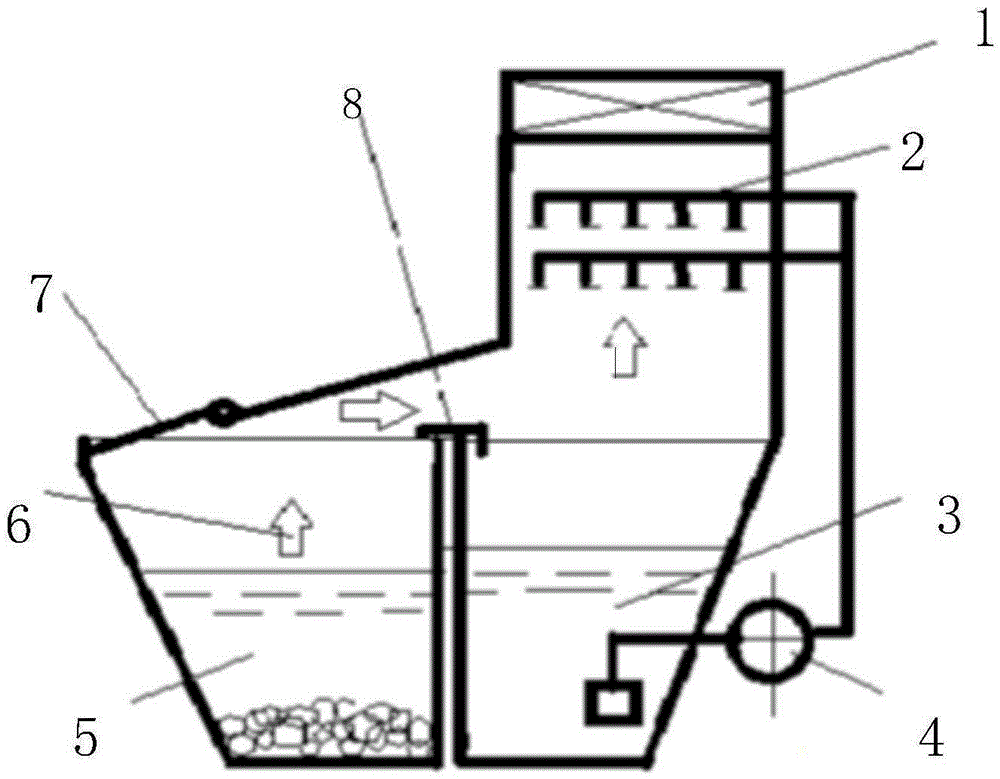

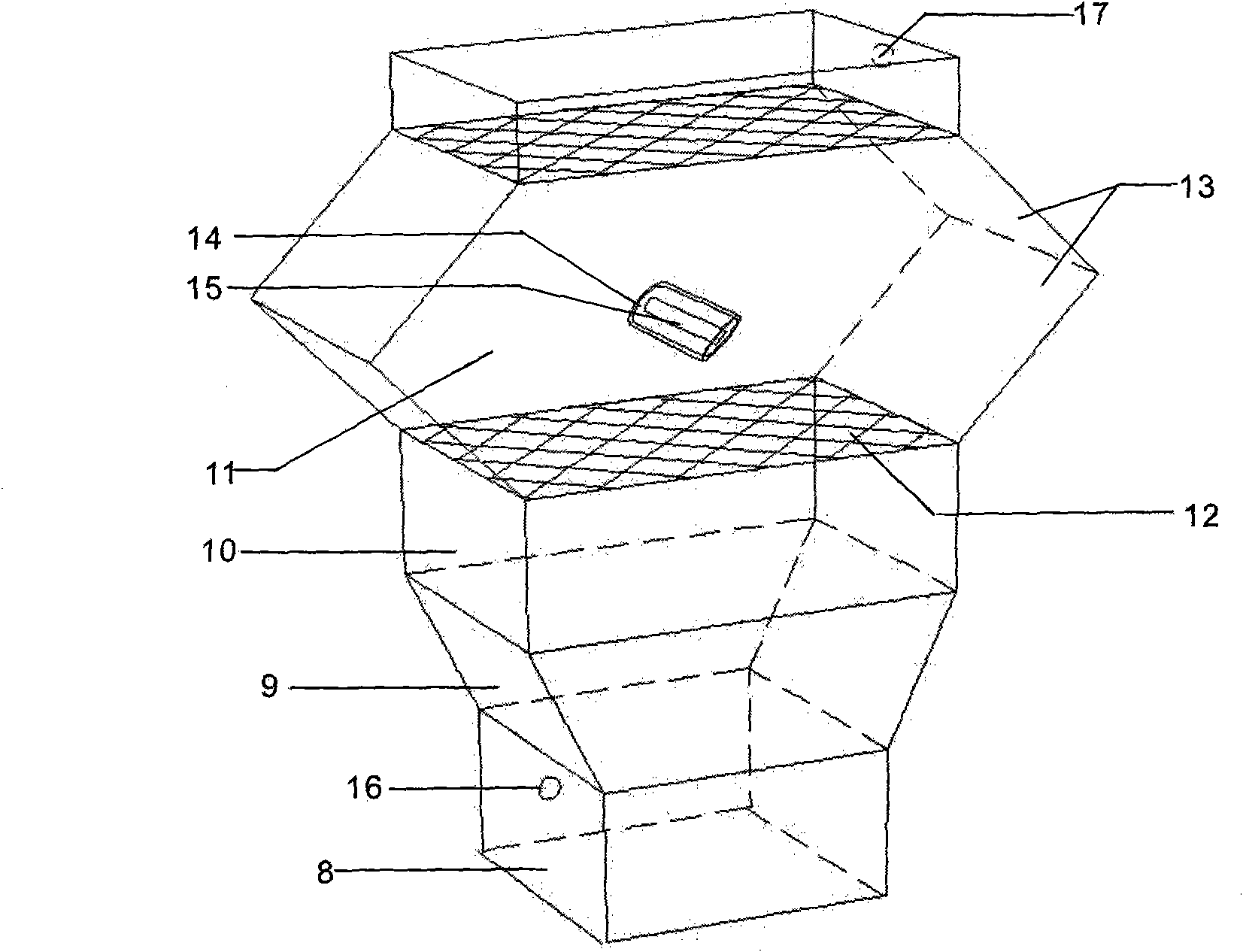

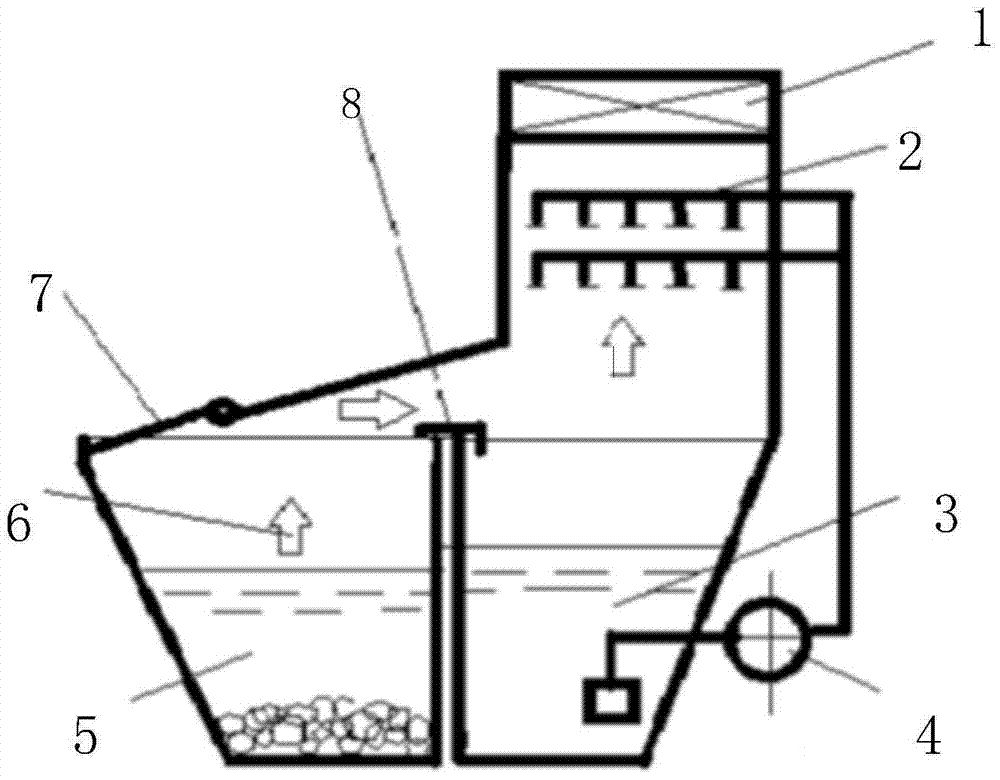

Absorption and photocatalysis integrated system for deep-treating organic waste water

ActiveCN101643250AStrong impact resistanceEnergy utilization is reasonableWater/sewage treatment by irradiationWater/sewage treatment by sorptionWater treatment systemWater storage tank

The invention discloses an absorption and photocatalysis integrated system for deep-treating organic waste water. A water outlet at the lower end of an organic waste water storage tank is connected into a water inlet at the lower end of a pretreating photocatalysis reaction system by a liquid inlet pump and a flow meter; a water outlet at the upper end of the pretreating photocatalysis reaction system is connected into a water inlet at the lower end of a deep photocatalysis reaction system by a first valve; the water inlet at the lower end of the deep photocatalysis reaction system is connected into a water outlet of another liquid inlet pump by a second valve and another flow meter; a water inlet of another liquid inlet pump is connected into a water outlet at the lower end of a purifiedwater storage tank; and the upper end of the deep photocatalysis reaction system is connected into a water inlet at the upper end of the purified water storage tank. The photocatalysis integrated device has the advantages of double-system water treatment system, simple internal structure, strong shock resistance, reasonable energy utilization and high photocatalytic oxidation efficiency, the establishment of the double-system water treatment system leads the mineralization of organic matters to be more thorough, and the operation is more convenient. The device has easy popularization, industrialization and commercialization.

Owner:江苏金秋刺绣花边有限公司

Oil-gas separation and recovery device and method thereof

ActiveCN112760129AReduce circulationReduce energy consumptionTreatment with plural serial refining stagesGasolinePetrochemical

The invention belongs to the field of petrochemical engineering, and particularly discloses an oil-gas separation and recovery device and a method thereof. According to the oil-gas separation and recovery device and the method thereof, gasoline and C4 and below components are separated in advance before light hydrocarbon separation, so that in the follow-up process, gasoline does not need to be adopted for absorbing liquefied gas components, consumption of absorbent circulation is saved, and meanwhile, the tower top material flow of a light hydrocarbon-light gasoline separation tower is desulfurized, so that the material flow does not contain H2S in the light hydrocarbon separation process, the material requirement of a light hydrocarbon separation and recovery system is reduced, the risk possibly caused by H2S leakage is reduced, and the safety of the whole process is ensured; meanwhile, the method is simple in technological process, mild in operation condition and low in energy consumption.

Owner:SINOPEC ENG +1

Preparation method of cod-liver oil emulsion

InactiveCN101574632BCompact structureSmall footprintMixer accessoriesTemperature controlCod liver oil

Owner:BEIJING UNIV OF CHEM TECH +1

Preparation method of fluorobenzonitrile compounds

ActiveCN105523962BComplex processHigh energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationHigh pressureSolvent

The present invention provides a fluorobenzonitrile compound preparation method, fluorobenzonitrile compounds are as shown in the general formula (I), an objective product can be prepared from a general-formula-(II)-shown chlorobenzonitrile compound as a raw material by reacting with an anhydrous fluoride in the presence of an inert gas under high temperature high pressure reaction conditions and flashing a reaction product, wherein the objective product itself is used as a solvent. Due to use of the objective product itself as the solvent, a main component of the fluorine exchange reaction product only comprises the objective product, due to use of an inert gas pressurization method to improve the fluorine exchange reaction and product separation conditions, the product is separated and purified in the flashing manner, the reaction residual heat is rationally used, and the whole process is simple and feasible. The method is readily available in raw materials, simple in process, energy-saving, consumption-reducing, and more suitable for industrial scale production.

Owner:DALIAN QIKAI MEDICAL TECH

A pumpless thermal injection refrigeration cycle method and device

InactiveCN104132486BReduce heat loadReduce dosageMechanical apparatusFluid circulation arrangementLiquid storage tankControl valves

The invention discloses a method and device for a pumpless thermal injection refrigeration cycle. The high-temperature and high-pressure refrigerant vapor generated by a generator is used to pressurize the liquid working medium and complete the delivery, and then carry out the liquid working medium to be transported in the next cycle. Pre-pressurization makes full use of the energy of high-temperature and high-pressure refrigerant vapor and improves the COP of the system. The device includes a generator, a throttling element, an evaporator, an ejector, a condenser, and a liquid storage device. The liquid storage device is at least two parallel matched liquid storage tanks, and each liquid storage tank is connected to the generator through a control valve. , the condenser and other matching liquid storage tanks are connected; the ejector is connected in series with the condenser, the throttling element and the evaporator to form a circuit, and the condenser is connected in series with the liquid storage device and the generator to form a circuit. The device makes the energy utilization of the system more economical and reasonable, and reduces the heat load of the cooling water; realizes the system's pump-free circulation, reduces moving parts, and has more stable and reliable operating performance.

Owner:ZHEJIANG UNIV

Continuous production system for preparing high-quality formic acid by acidifying sodium formate with polyphosphoric acid

InactiveCN102260158BIncrease productivityAchieve continuous operationPreparation from carboxylic acid saltsPhosphorus compoundsDistillationSodium phosphates

The invention discloses a continuous production system for preparing high-quality formic acid by acidifying sodium formate with polyphosphoric acid. The continuous production system is characterized in that the tops of multiple raw material premixing tanks are separately provided with three inlets, and the three inlets are separately connected with a sodium formate storage tank through respectivescrew feeders, a polyphosphoric acid storage tank through a first conveying pump and a formic acid auxiliary agent storage tank through a second conveying pump; the bottom outlets of the multiple rawmaterial premixing tanks are connected with a multi-stage acidification reaction kettle through a third conveying pump; the top of the reaction kettle is connected with a first condenser, and the bottom is connected with a normal-pressure distillation unit through a fourth conveying pump; the normal-pressure distillation unit is connected with a decompressing distillation unit; the decompressing distillation unit is connected with a formic acid product storage tank through a vacuum pump and a second condenser; the normal-pressure distillation unit is also connected with the formic acid product storage tank through a third condenser; and the bottom of the decompressing distillation unit is connected with a compound sodium phosphate salt storage tank. In the continuous production system disclosed by the invention, high-quality formic acid is prepared by acidifying sodium formate from yellow phosphorus tail gas, thereby eliminating pollution, changing waste into valuable and acquiring a useful product.

Owner:ZHEJIANG UNIV +1

Production process of liquefied natural gas

The invention provides a production process of liquefied natural gas and particularly relates to a sulfur-resistance methanation production process for producing liquefied natural gas by taking coke-oven gas as a raw material. The production process at least comprises two stages of sulfur-resistant methanation processes. The volume content of dry-basis CO in outlet gas subjected to two-stage methanation is less than or equal to 1.0 percent, and the volume content of methane is more than or equal to 48 percent; gas discharged from a second reactor is subjected to high-pressure overheat steam through a spent pit, enters a desulfuration and decarburization device to remove H2S and CO2, then enters a low-temperature cold box and is subjected to methane liquefaction by the low-temperature cold box; gases, such as H2 and little CO can be further produced into more methane or used as other purposes in a carbon replenishing manner. Compared with a non-sulfur-resistant methanation process of coke-oven gas, the production process provided by the invention has the advantages of simple flow, remarkably low equipment cost and operation cost; after project implementation, the production cost of natural gas is further reduced; a relatively energy-saving production path is created for the coal gas making industry and coke-oven gas in China.

Owner:青岛联信催化材料有限公司 +1

Absorption and photocatalysis integrated system for deep-treating organic waste water

ActiveCN101643250BStrong impact resistanceEnergy utilization is reasonableWater/sewage treatment by irradiationWater/sewage treatment by sorptionWater treatment systemWater storage tank

The invention discloses an absorption and photocatalysis integrated system for deep-treating organic waste water. A water outlet at the lower end of an organic waste water storage tank is connected into a water inlet at the lower end of a pretreating photocatalysis reaction system by a liquid inlet pump and a flow meter; a water outlet at the upper end of the pretreating photocatalysis reaction system is connected into a water inlet at the lower end of a deep photocatalysis reaction system by a first valve; the water inlet at the lower end of the deep photocatalysis reaction system is connected into a water outlet of another liquid inlet pump by a second valve and another flow meter; a water inlet of another liquid inlet pump is connected into a water outlet at the lower end of a purifiedwater storage tank; and the upper end of the deep photocatalysis reaction system is connected into a water inlet at the upper end of the purified water storage tank. The photocatalysis integrated device has the advantages of double-system water treatment system, simple internal structure, strong shock resistance, reasonable energy utilization and high photocatalytic oxidation efficiency, the establishment of the double-system water treatment system leads the mineralization of organic matters to be more thorough, and the operation is more convenient. The device has easy popularization, industrialization and commercialization.

Owner:江苏金秋刺绣花边有限公司

Oxidized tail gas energy recovery method during cyclohexanone oxidation production

InactiveCN111608805AReduce energy consumptionReduce consumptionGas turbine plantsIncinerator apparatusCyclohexanoneEnergy recovery

The invention relates to the field of oxidized tail gas energy recovery method during cyclohexanone oxidation production and provides an oxidized tail gas energy recovery method during cyclohexanone oxidation production in order to solve the problems that an existing cyclohexanone device is high in energy consumption and unreasonable in energy utilization. The method comprises the steps of conducting catalytic combustion on organic matter such as cyclohexane, cyclohexanone and cyclohexanol with the total content of 10-3000 ppm to form carbon dioxide and water; feeding treated exhaust gas intoan expansion machine; converting heat energy generated during the catalytic treatment process and the pressure of an expansion power generator unit into electric energy through one-time expansion, anddirectly emptying the exhaust gas subjected to energy recovery from an outlet of the expansion machine. According to the oxidized tail gas energy recovery method during cyclohexanone oxidation production, the device is simple in structure, stable in operation, reasonable in energy utilization and high in economic benefit, extra equipment investment is avoided, consumption of low-pressure steam isreduced, and the problems existing in the prior art are solved well.

Owner:CHINA PETROLEUM & CHEM CORP +2

A water quenching and sorting treatment method for aluminum electrolysis anode carbon slag

The invention discloses a water quenching and sorting treatment method for aluminum electrolysis anode carbon slag, which belongs to the technical field of aluminum electrolysis. The method comprises the steps of water quenching of hot charcoal slag, classification and sorting of charcoal slag in water quenching, dehydration by centrifugal dehydrator, wet grinding of charcoal slag and sorting by flotation machine, and finally obtains carbon-rich products and electrolyte-rich products, which can be After producing carbon products and further purification, they are returned to the aluminum electrolysis process for use. The invention can simplify the links of coarse crushing and fine crushing, not only simplify the process, but also greatly reduce the dust pollution in the links of crushing and grinding, and the energy utilization is more reasonable. The invention can be effectively combined with existing wet grinding, flotation and fluorine-containing water treatment technologies.

Owner:北京森泉伟业科技有限公司

Utilization method for waste heat and excess pressure of gas fractionation apparatus

ActiveCN103585777BOptimizing Energy UtilizationEnergy utilization is reasonableDistillation purification/separationFractional distillationFractionationEngineering

The invention discloses a utilization method for waste heat and excess pressure of a gas fractionation apparatus. According to the method, a material flow from the bottom of a propylene tower and a saturated solution from a working medium pump are mixed and then undergo heat exchange in a low temperature waste heat exchanger; obtained steam and low pressure injection steam are introduced into an injector; deceleration and pressurization are carried out by the injector so as to obtain medium-pressure overheated steam which enters into a circulating water condenser or an air cooler for condensation into a medium-pressure saturated solution; one part of the medium-pressure saturated solution is pressurized by the working medium pump to a pressure which is same as the pressure at the bottom of the propylene tower and is then mixed with the material flow at the bottom of the propylene tower, and an obtained mixture is sent back to the low temperature waste heat exchanger for cyclic usage; the other part of the medium-pressure saturated solution is converted into a medium-pressure supercooled liquid phase by a circulating water cooler and then divided into two paths, wherein one path of the medium-pressure supercooled liquid phase is discharged as a product from a system, and the other path of the medium-pressure supercooled liquid phase is throttled and decompressed by a thermal expansion valve so as to obtain a cold source which is used for cooling a material flow at the top of a deethanization tower, a material flow at the top of the propylene tower and refrigerant water. With the method provided by the invention, waste heat and excess pressure of the material flow at the bottom of the propylene tower are fully used, operation stability of the propylene tower is improved, and product quality is guaranteed.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com