Utilization method for waste heat and excess pressure of gas fractionation apparatus

A medium-pressure, waste heat technology, applied in fractional distillation, distillation purification/separation, organic chemistry, etc., can solve the problems of increased operating costs, low separation efficiency of deethanizer tower, reduced propylene yield and economic benefits of gas separation device, etc. , to achieve the effects of optimizing utilization, improving operational stability, and optimizing energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

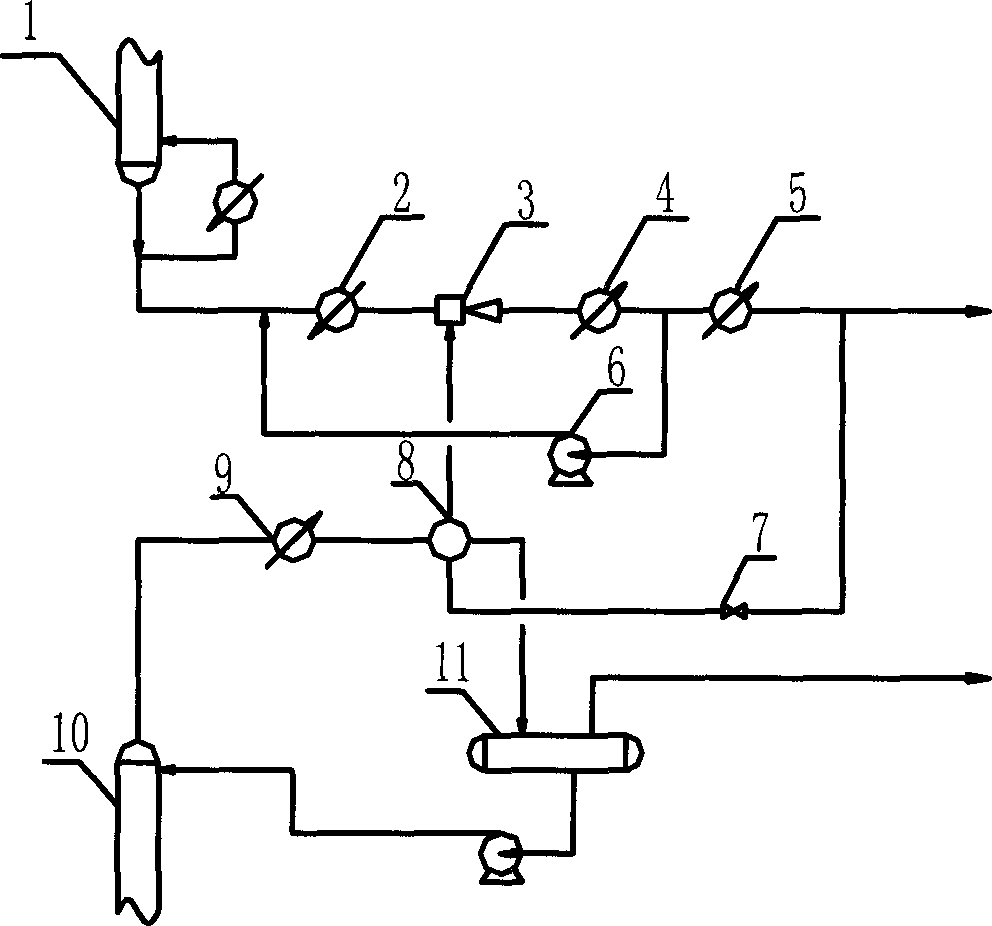

Embodiment 1

[0055] The 300kt / a gas separation device of the refining and chemical enterprise is adopted, the maximum ambient temperature is 35°C, the boundary pressure of the propane fraction from the bottom product of the propylene tower to the tank area is not lower than 1.2MPa (table), and the operating pressure of the bottom of the propylene tower is 2.1MPa (table), the temperature position of introducing low-temperature waste heat is 95 ℃.

[0056] Before the cold source is introduced, the propylene content in the dry gas at the top of the deethanizer is controlled at 55 mol%, but in order to ensure the quality index of the propylene product during operation, the propylene content in the dry gas is as high as 60 mol%. According to the method of the present invention, the top of the deethanizer is condensed and cooled to 38-42° C. by using the deethanizer top condenser, and then the cold source generated by the steam injection refrigeration cycle system is introduced. It is sent to th...

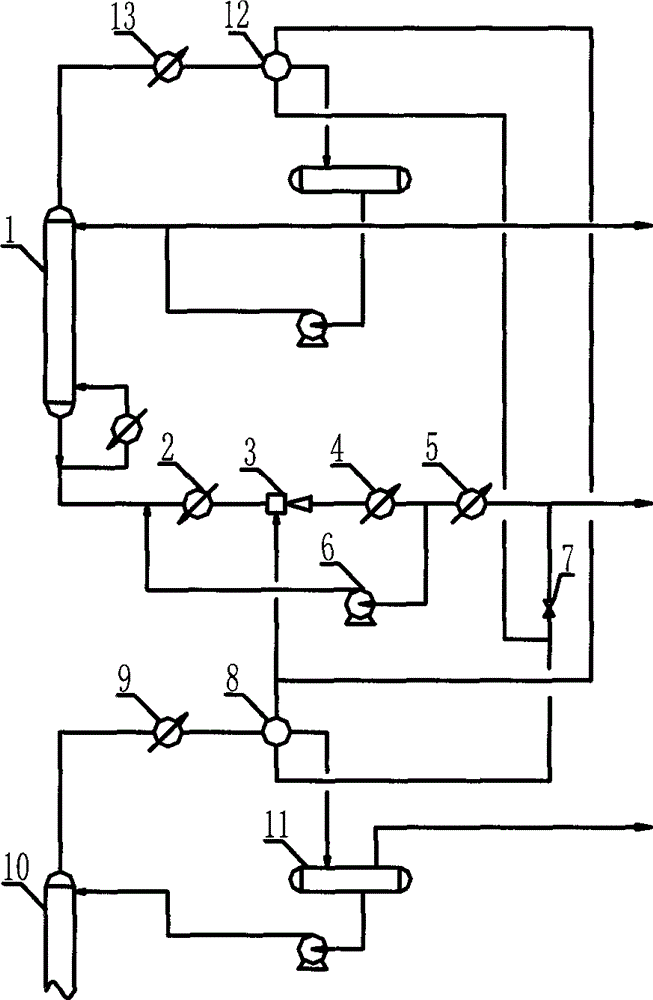

Embodiment 2

[0059]The 300kt / a gas separation device of the refining and chemical enterprise is adopted, the maximum ambient temperature is 35°C, the boundary pressure of the propane fraction from the bottom product of the propylene tower to the tank area is not lower than 1.2MPa (table), and the operating pressure of the bottom of the propylene tower is 2.1MPa (table), the temperature position of introducing low-temperature waste heat is 100 ℃.

[0060] Before the cold source is introduced, the propylene content in the dry gas at the top of the deethanizer is controlled at 55 mol%, but in order to ensure the quality index of the propylene product during operation, the propylene content in the dry gas is as high as 60 mol%. According to the method of the present invention, the top of the deethanizer is condensed and cooled to 38-42° C. by using the deethanizer top condenser, and then the cold source generated by the steam injection refrigeration cycle system is introduced. It is sent to th...

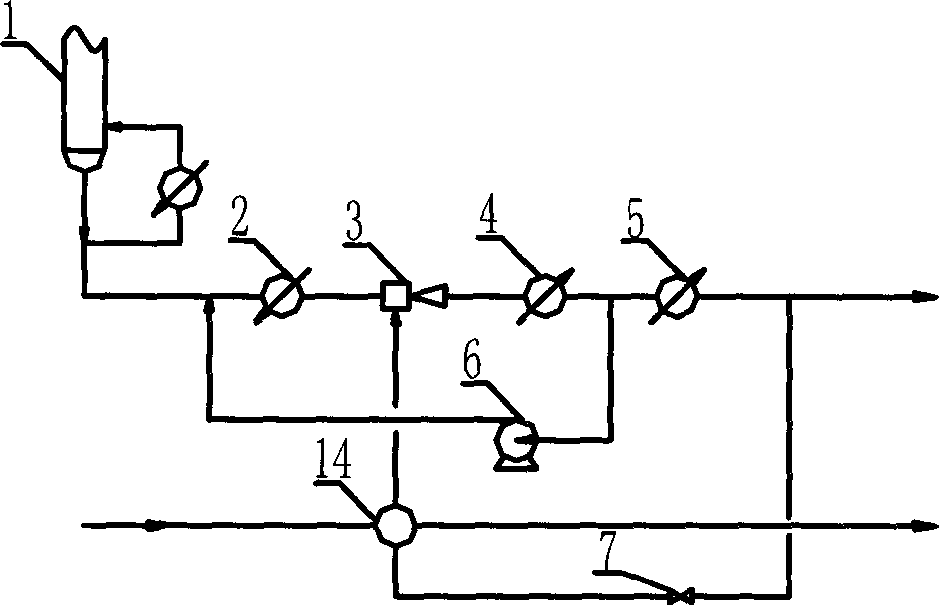

Embodiment 3

[0064] The 300kt / a gas separation device of the refining and chemical enterprise is adopted, the maximum ambient temperature is 35°C, the boundary pressure of the propane fraction from the bottom product of the propylene tower to the tank area is not lower than 1.2MPa (table), and the operating pressure of the bottom of the propylene tower is 2.1MPa (Table), the temperature position of introducing low temperature waste heat is 120 ℃.

[0065] Exchange heat between the cold source generated by the steam injection refrigeration cycle system and the refrigerant water to obtain 7-12°C chilled water, and then send the chilled water to the parts that require cooling.

[0066] According to the principle of energy "temperature matching and cascade utilization", the cold source generated by the steam injection refrigeration cycle system can partially replace the circulating cooling water according to the needs, and the refrigerant is circulated in a saturated liquid phase, so that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com