Method and plant for the heat treatment of sulfidic ores using annular fluidized

A fluidized bed, sulfide technology, used in fluidized bed furnaces, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of mass transfer and heat transfer moderation, low degree of fluidization, and insufficient residence time for complete reaction. and other problems to achieve the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

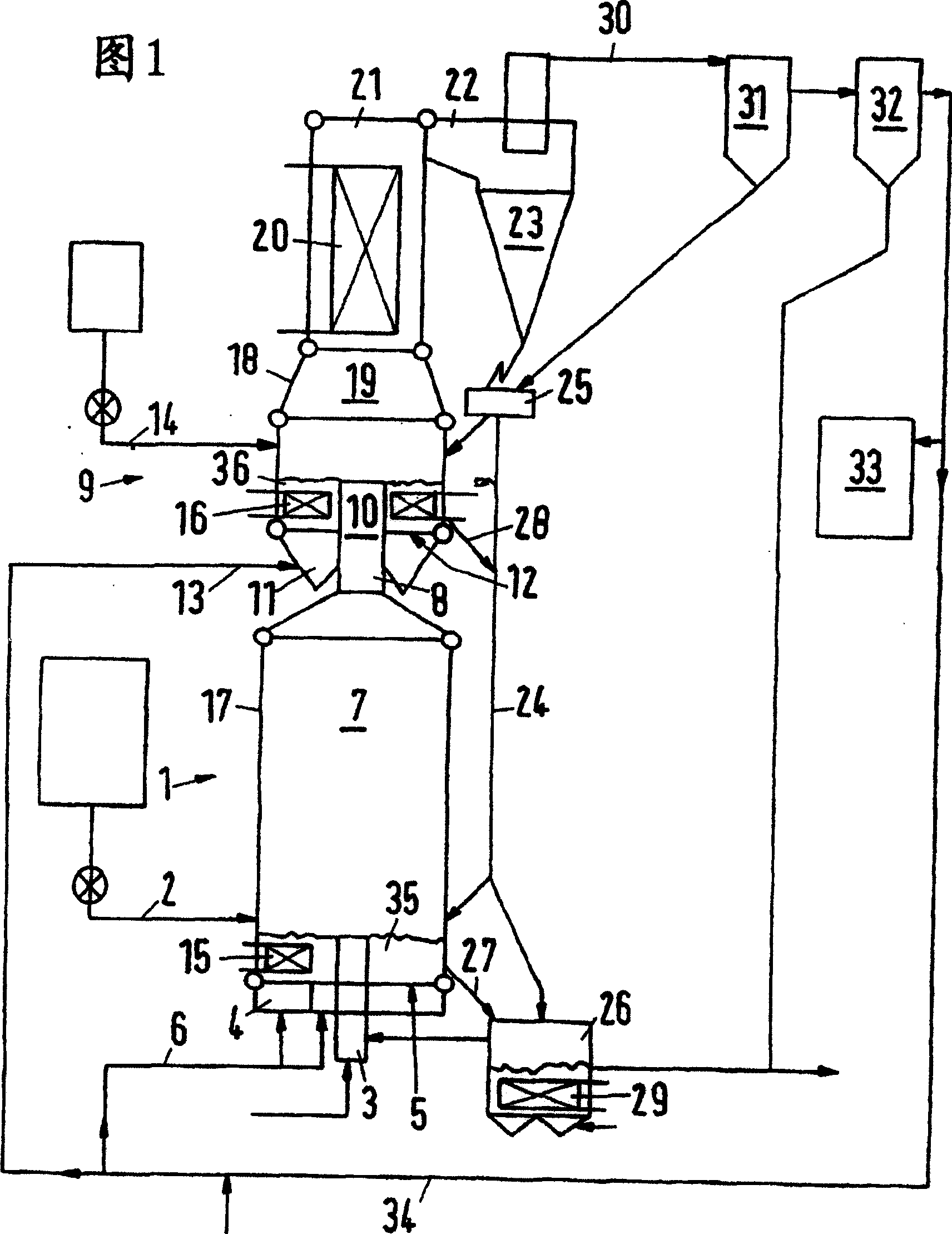

[0054] Embodiment 1 (roasting gold ore)

[0055] In a device corresponding to that shown in the accompanying drawing, 1200 kg / h of gold ore with a gold content of about 5 ppm (i.e. 5 g / t) is supplied to reactor 1 in a continuous operation mode, the gold ore is ground, dried and classified to a maximum The particle fraction is 50 μm and contains:

[0056] 1.05wt% organic carbon

[0057] 19.3 wt% CaCO 3

[0058] 12.44wt% Al 2 o 3

[0059] 2.75wt% FeS 2

[0060] 64.46wt% inert substances (such as SiO 2 )

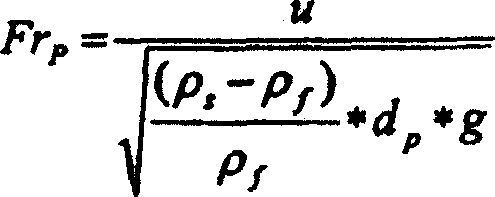

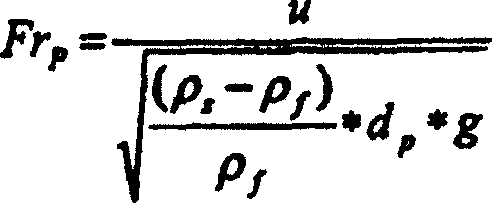

[0061] The diameter of the upper part of the reactor 1 is 800 mm. Alternatively, a temperature of 2500Nm at 520°C 3 / h Air is introduced into the reactor 1 via the central tube 3 and via the line 6 as fluidizing gas. In this case, the particle Froude number in the central tube 3 is 3.95-6.25, the particle Froude number in the mixing chamber 7 is 0.84-1.32, and the particle Froude number in the annular fluidized bed 35 is 0.32 -0.52.

[0062] The residence time of ...

Embodiment 2

[0063] Embodiment 2 (roasting sphalerite)

[0064] In the device corresponding to the attached figure, the capacity of 42t / h sphalerite at a temperature of about 25°C is about 200m 3The silo is fed to the reactor 1 through the pipe 2, and then fed into the annular fluidized bed 35 through the metering device. At the same time, the temperature is 47 ℃, the pressure is about 1.2bar about 16600Nm 3 / h air is introduced into the annular fluidized bed through pipeline 6, and the air contains:

[0065] 77.1vol%N

[0066] 20.4vol%O 2

[0067] 2.5vol%H 2 o

[0068] About 60200Nm 3 / h air and another 3000Nm discharged from the fluidized bed cooler 26 at a temperature of 150°C 3 / h waste cooler air enters reactor 1 through central tube 3, so that the total amount of air passing through central tube 3 is about 63200Nm 3 / h. Air has a temperature of 35°C and a pressure of about 1.07 bar, and contains:

[0069] 77.1vol%N

[0070] 20.4vol%O 2

[0071] 2.5vol%H 2 O.

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com