Method and device for comprehensively utilizing oil sand and oil sludge

A technology for oil sludge and oil sand, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc., can solve the problems of complex components of oily sludge, and achieve the effect of solving adhesion and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

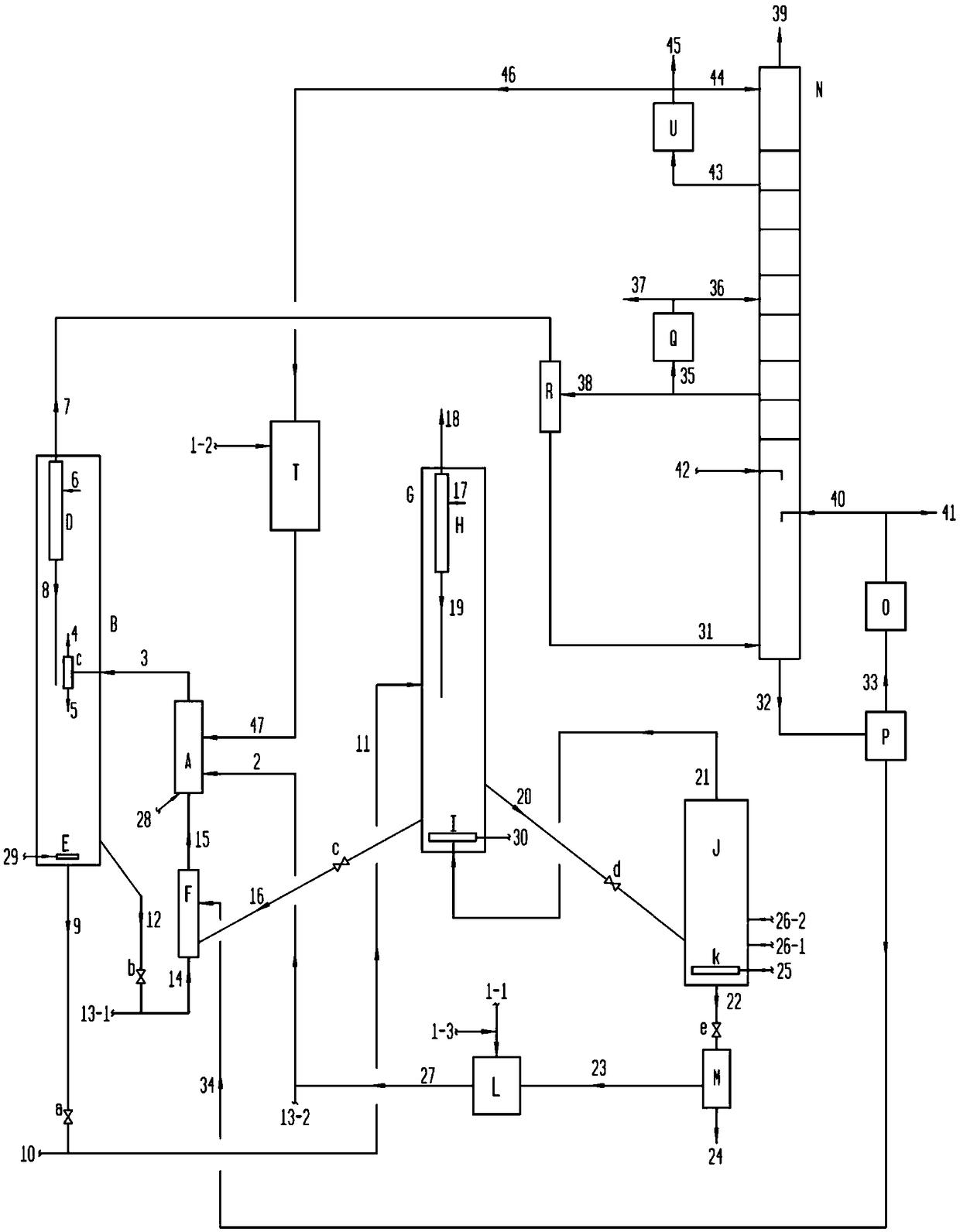

Method used

Image

Examples

Embodiment

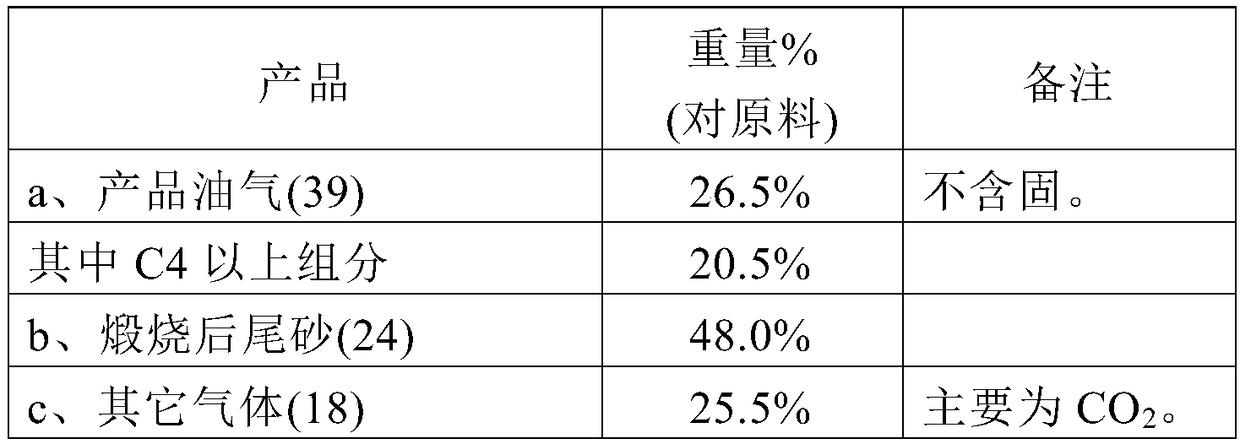

[0108] In this embodiment, the device and method of the present invention are used to process Indonesian oil sands and tank farm oil sludge.

[0109] The main properties of Indonesian Buton oil sand and oil sludge used in this device are shown in Table 1 and Table 2, respectively.

[0110] Table 1 Main properties of oil sand raw materials in Butun, Indonesia

[0111] project

unit

value

Remark

weight%

2.4

Ash

weight%

52.6

Volatile matter

weight%

44.2

Sulfur content

weight%

0.8

[0112] Oil sand raw material particle size range: particle size <20cm;

[0113] Table 2 Main Properties of Oil Sludge Raw Materials

[0114] project

unit

value

Remark

weight%

6.0

Ash

weight%

21.0

Volatile matter

weight%

73.0

Sulfur content

weight%

0.5

[0115] The ratio of oil sand to oil s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com