Patents

Literature

204results about How to "Precise control of reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of light-colored polyisocyanate curing agent

ActiveCN103881050AIncreased contact areaUniform on a microscopic scalePolyurea/polyurethane coatingsAlcoholLiquid state

The invention relates to a preparation method of a light-colored polyisocyanate curing agent. The preparation method comprises the following steps: (a) purifying a raw material-trimethylolpropane to obtain trimethylolpropane with the carbonyl compound content lower than 0.1wt%; (b) reacting trimethylolpropane with the carbonyl compound content lower than 0.1wt% or a mixture of trimethylolpropane with the carbonyl compound content lower than 0.1wt% and micromolecular dihydric alcohol with excess diisocyanate in a reactor with a conical liquid distribution plate to obtain a liquid-state prepolymer reaction solution containing excess diisocyanate; and (c) removing monomers from the prepolymer reaction solution obtained in the step (b) by adopting a two-stage film evaporator, and diluting by a solvent to obtain the curing agent with the diisocyanate monomer content lower than 0.5wt%. The color number of the diisocyanate curing agent prepared based on the method can be lower than 20Hazen.

Owner:WANHUA CHEM GUANGDONG

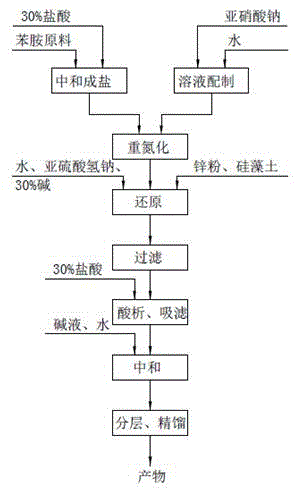

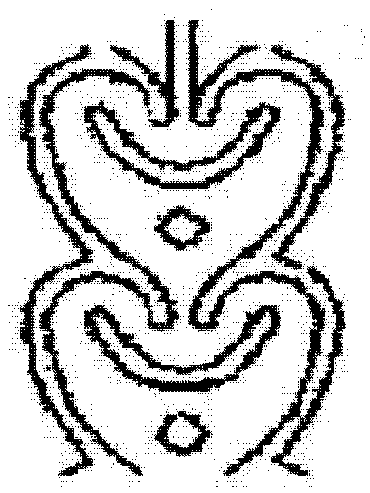

Method for preparing hydrazinobenzene in continuous micro-channel reactor

InactiveCN106316879AHigh mixing mass transfer effectImprove thermal conductivityHydrazine preparationToxic gasContinuous flow

The invention relates to a method for preparing highly pure hydrazinobenzene by using continuous flow micro-channel reactor. The method concretely comprises the following steps: preparing aniline hydrochloride from hydrochloric acid and aniline, respectively pumping the aniline hydrochloride and a sodium nitrite solution into the micro-channel reactor by two metering pumps to obtain a diazo salt solution, reducing the obtained reaction solution, carrying out acid separation on the reduced solution, filtering the obtained solution, neutralizing the filtered solution, and distilling the neutralized solution to obtain the highly pure hydrazinobenzene. The diazotization process is a strong exothermic reaction, and the generated diazo salt easily decomposes after standing at a high temperature for a long time, and generates toxic gases which pollute environment and even blast. The mixing effect of the heart-shaped micro-channel reactor is far better than the mass transfer effect generated by stirring, so the aniline conversion rate can reach 99%, the mixing mass transfer effect is good, and heat conduction is fast to avoid local overheating phenomenon; and the reaction can be carried out at constant temperature conditions, so the temperature runaway blast danger of general reactors is eliminated, and the safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing epoxidized fatty acid methyl esters in continuous flow microchannel reactor

The invention relates to a method for preparing epoxidized fatty acid methyl esters by using a microchannel reactor. The method comprises the following specific steps of: preparing catalyst formic acid and concentrated hydrochloric acid in a certain proportion; pumping fatty acid methyl ester, a formic acid catalyst, and hydrogen peroxide into the microchannel reactor by using three metering pumps; and washing reaction products, separating and drying to obtain the final product epoxidized fatty acid methyl esters. The whole process is an exothermic reaction process, and peroxyformic acid and epoxidized fatty acid methyl esters are synthesized simultaneously. When the epoxidized fatty acid methyl esters are produced by the method, the temperature of the reaction process can be controlled effectively, high safety can be guaranteed, a module is good in mixing effect, and a product obtained through reaction is high in quality; and the continuous flow reaction is performed, the process is continuous, and high production efficiency is achieved.

Owner:CHANGZHOU UNIV

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225AExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

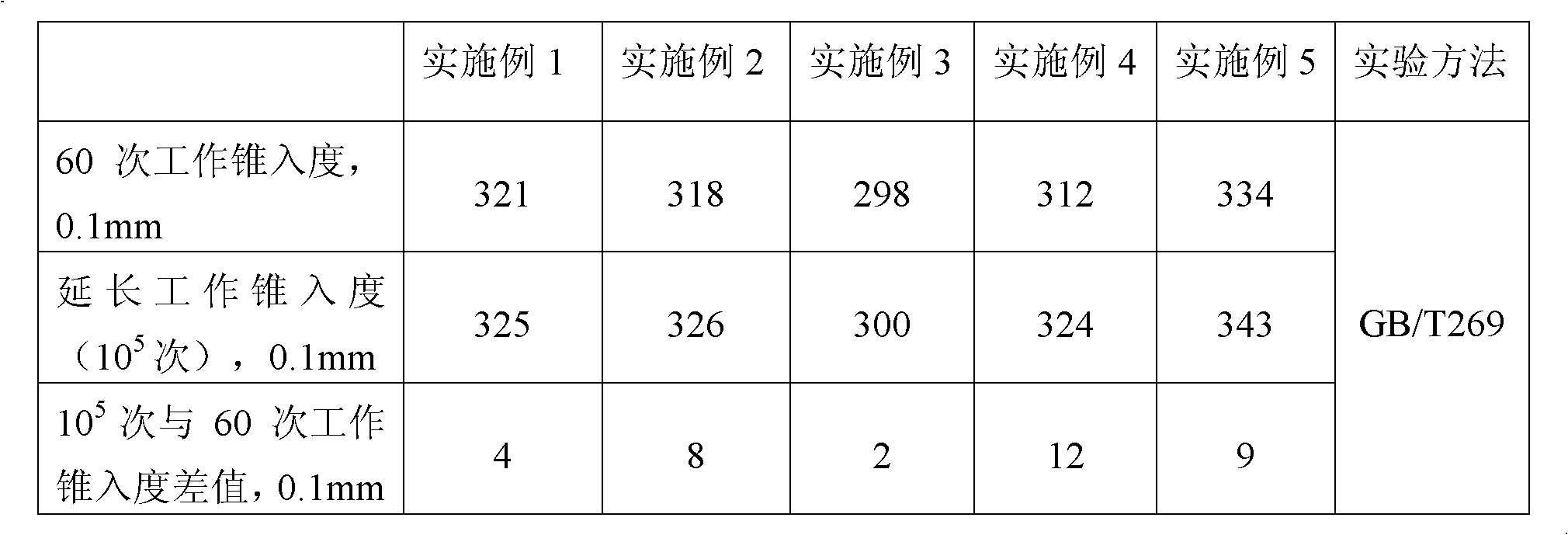

Polyurea-based lubricating grease with high mechanical stability and preparation method thereof

The invention belongs to the field of polyurea-based lubricating grease, and in particular provides polyurea-based lubricating grease with high mechanical stability and a preparation method thereof. The polyurea-based lubricating grease consists of the following components in percentage by weight: 70 to 90 percent of base oil and 10 to 30 percent of polyurea-based lubricating grease thickening agent, wherein the polyurea-based lubricating grease thickening agent is prepared by mixing diisocyanate and organic amine and directly thickening the base oil; isocyanate ions and amine ions have the same molar content; and the organic amine consists of fatty amine, naphthene amine and aromatic amine in the molar ratio of (2-4):(1-2):5. The polyurea-based lubricating grease has high mechanical stability and long service life.

Owner:长沙众城石油化工股份有限公司

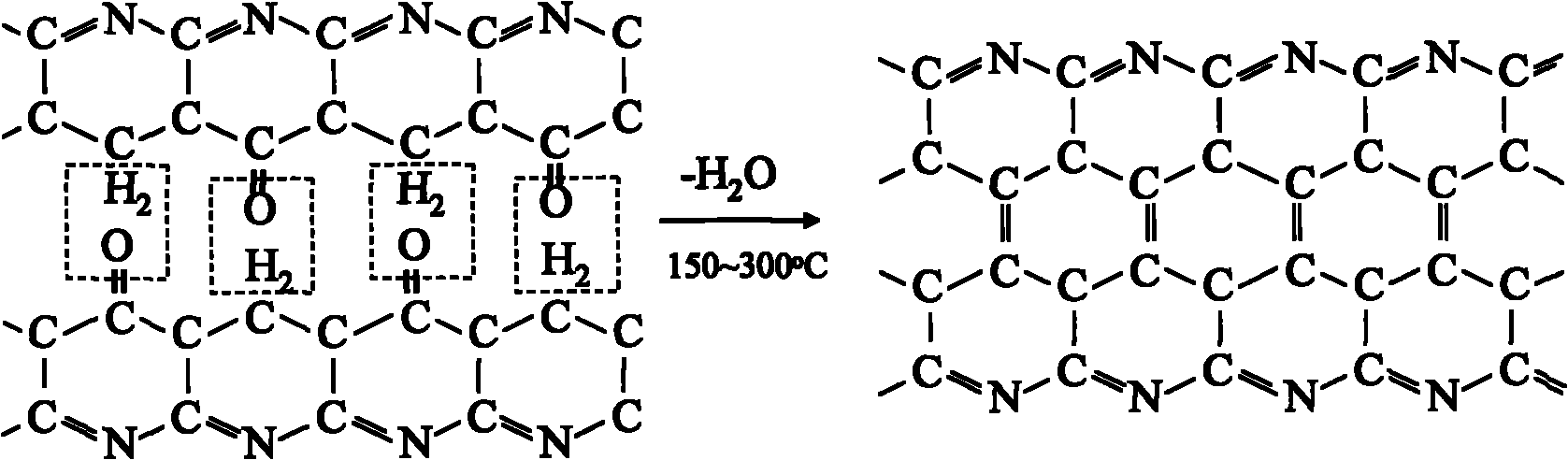

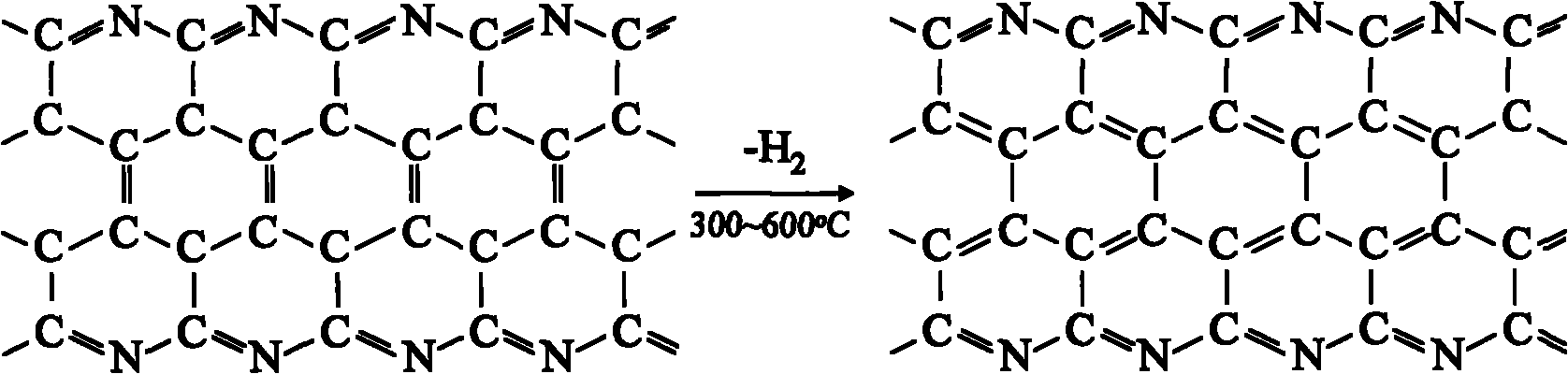

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

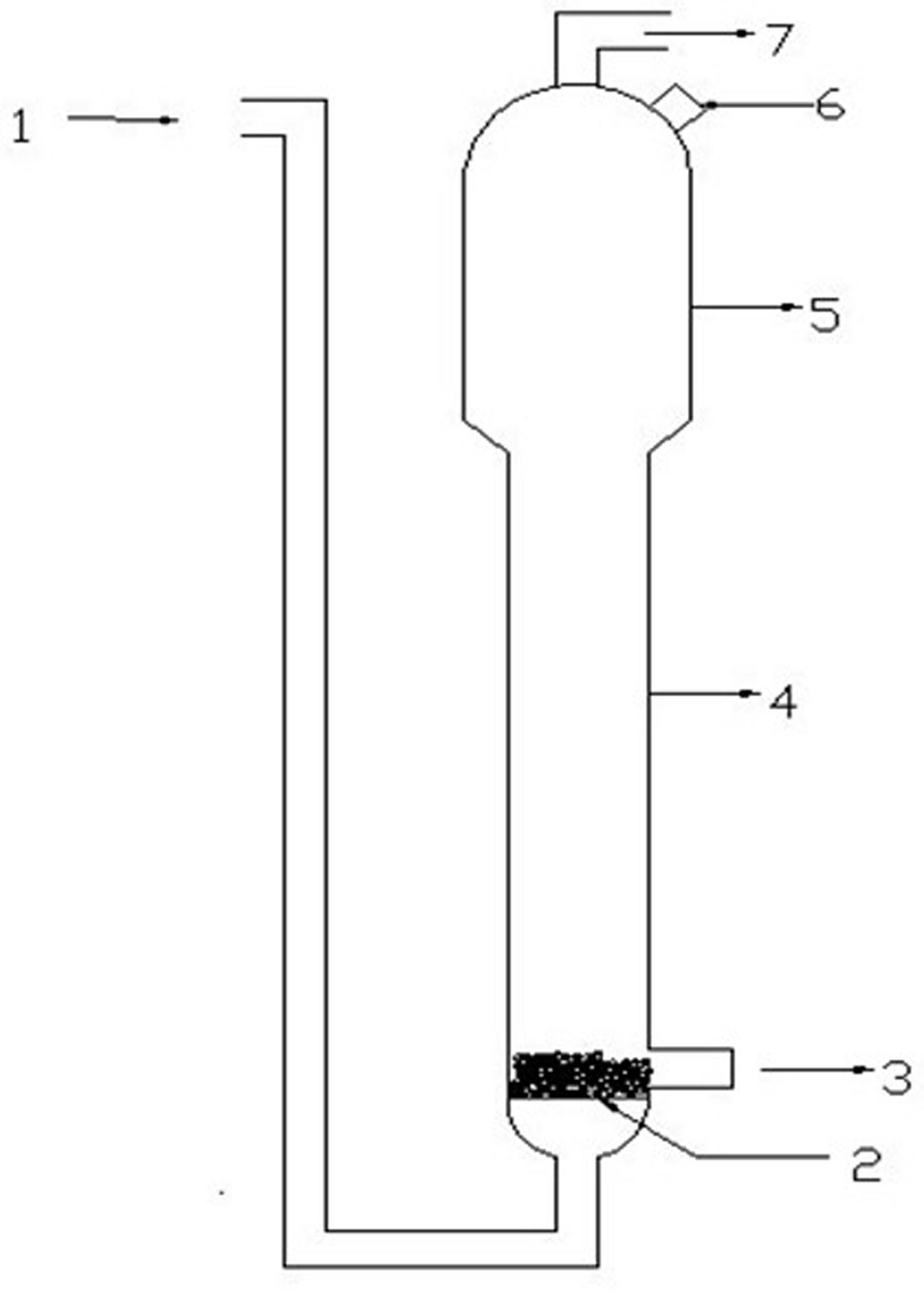

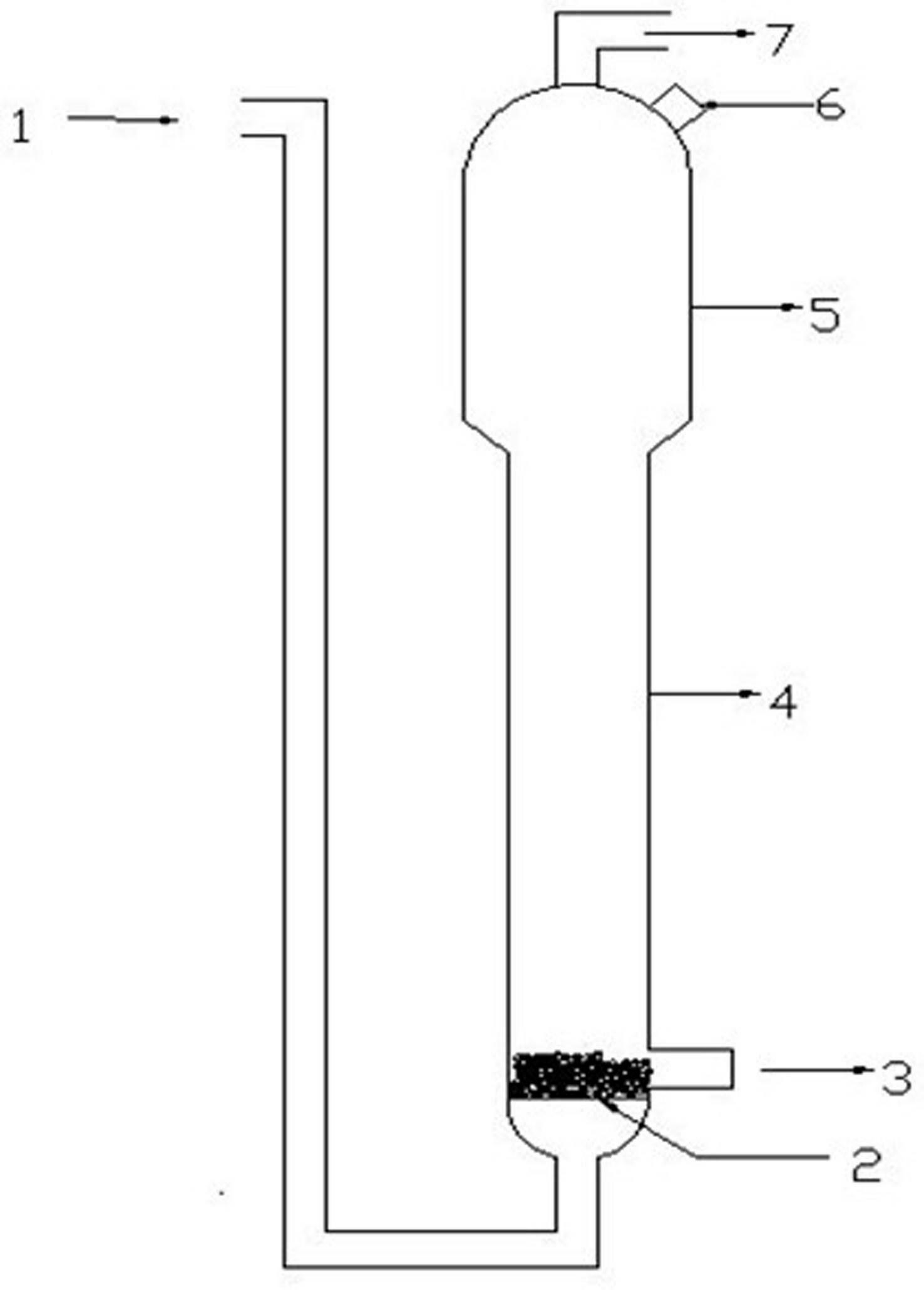

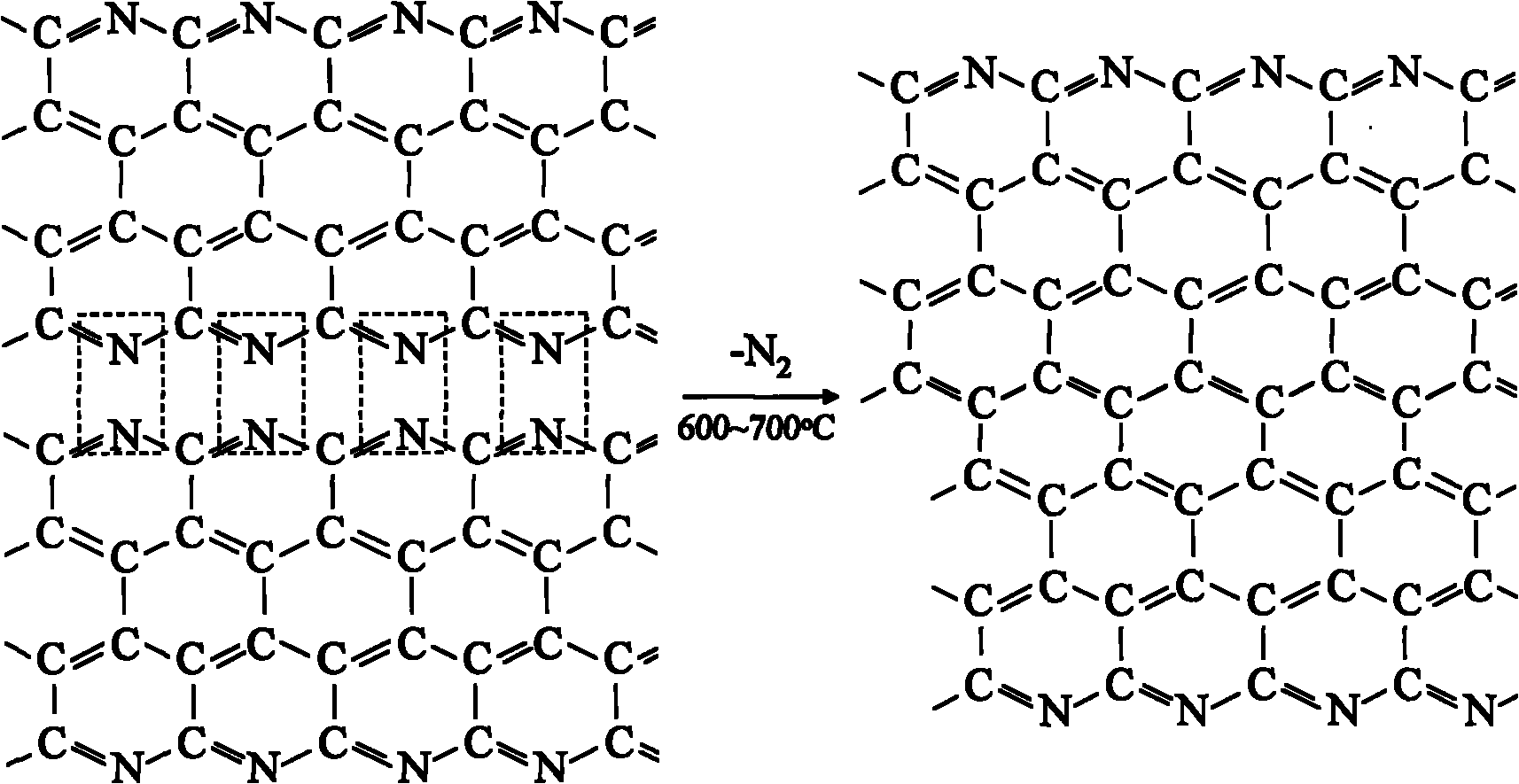

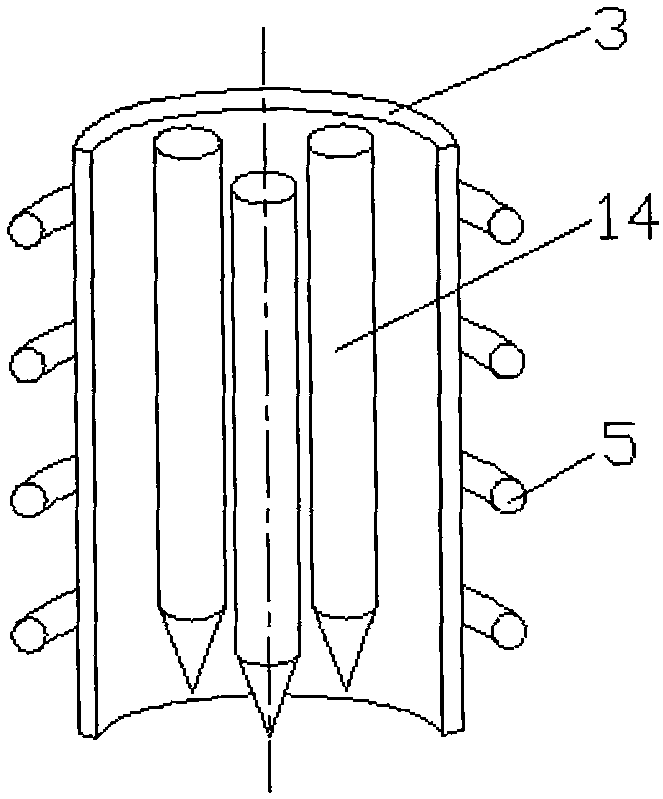

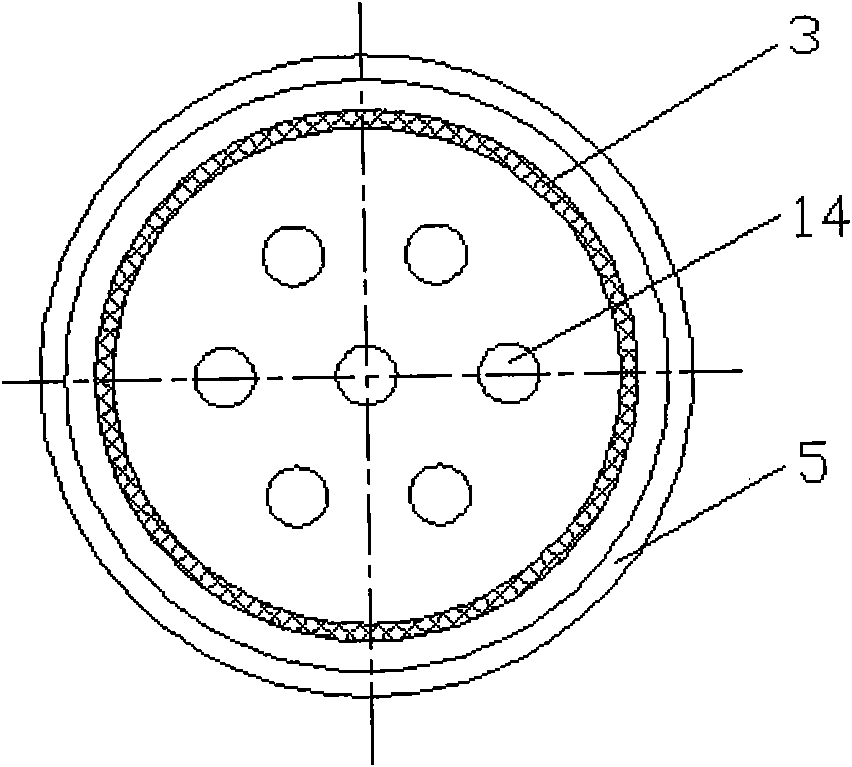

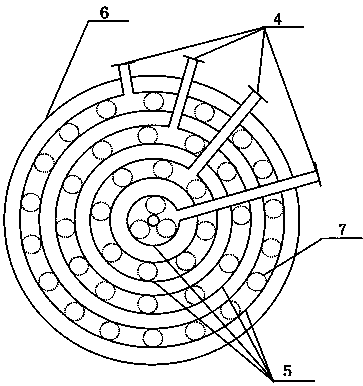

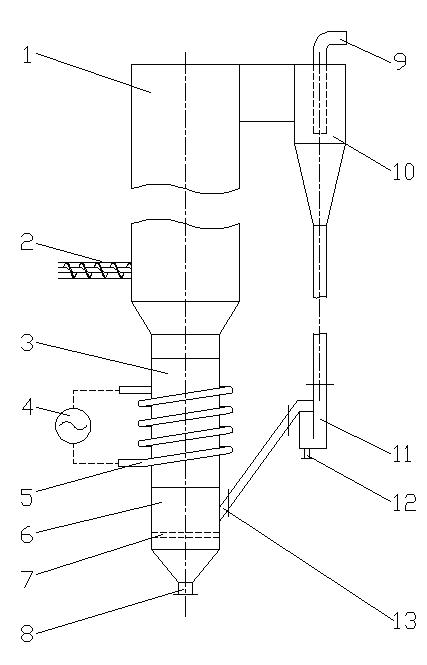

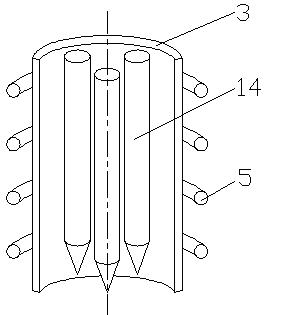

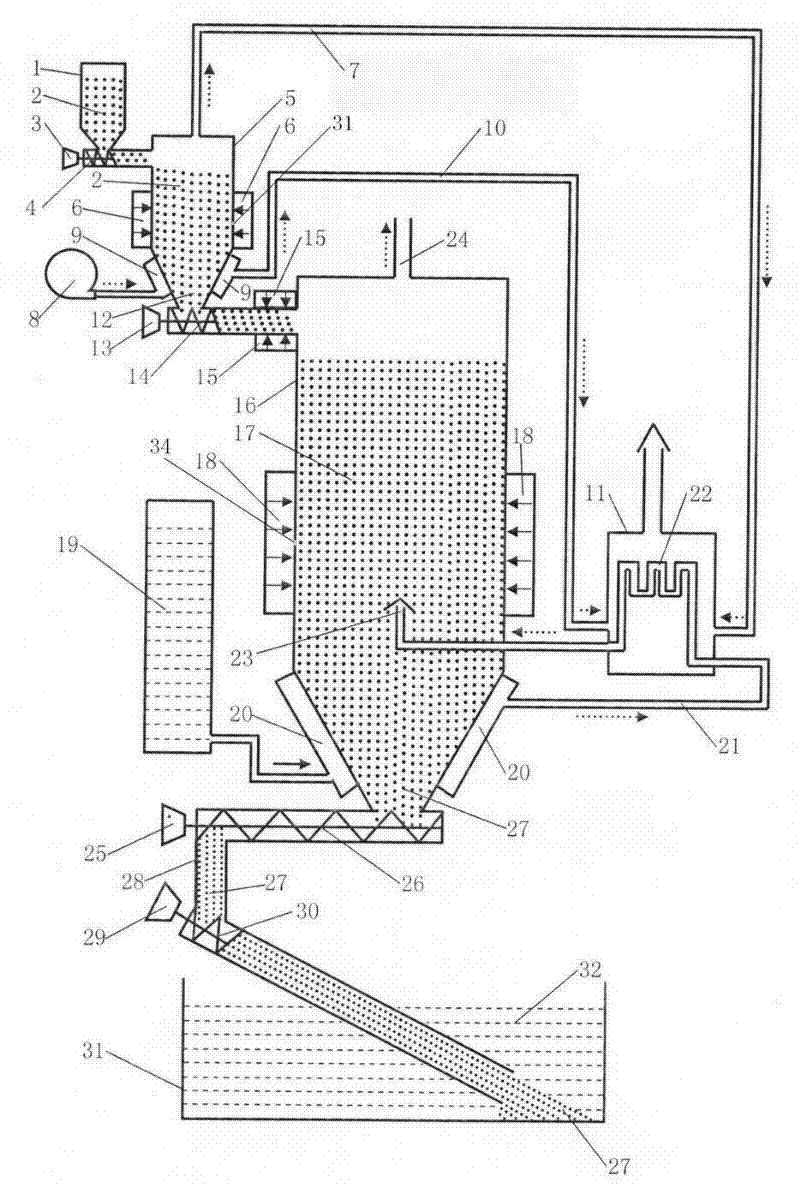

Biomass gasifying hydrogen making reactor based on induction heating

ActiveCN101857197AImprove heating uniformityFast heatingEnergy inputHydrogen productionWater vaporCyclonic spray scrubber

The invention relates to the field of renewable energy source, in particular to a biomass hydrogen making reactor based on induction heating and circulating fluidized bed technology. The reactor is characterized in that one side of an upper casing of the reactor is connected with a cyclone dust remover, the other side is connected with a biomass inlet, and the bottom is sleeved with a cylindrical lining; induction heating pieces are hung in the cylindrical lining; an electric induction coil is wound at the outer part of the cylindrical lining, and both ends of the electric induction coil are led out and connected with an induction heating power supply; the bottom of the cylindrical lining is sleeved with a lower casing; a wind distributing plate is arranged in the lower casing; a high-temperature water vapor inlet is arranged at the bottom of the cylindrical lining; a material return device is connected with the bottom of the cyclone dust remover and a material return opening; and the bottom of the material return device is provided with a material return vapor inlet. The electric induction coil is a hollow copper pipe which is wound on the cylindrical lining, and the induction heating pieces are a plurality of cylinders. The invention has the advantages of uniform heating, energy saving, environment protection, continuous running, simple structure and the like, and can be used for preparing hydrogen-enriched synthetic gas by utilizing biomasses of straws, rice hulls, sawdust and the like.

Owner:WUXI SHENKANG MECHANICAL EQUIP

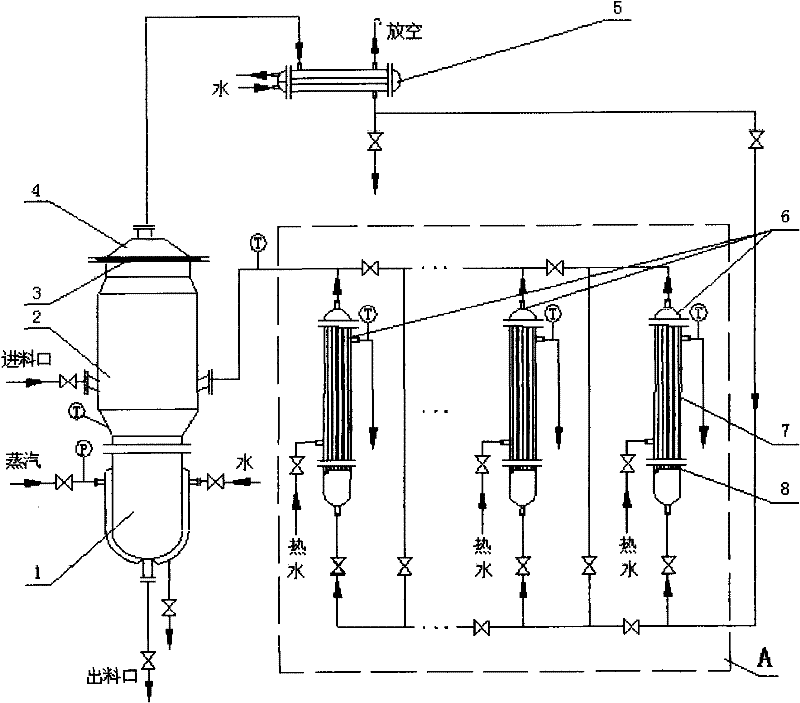

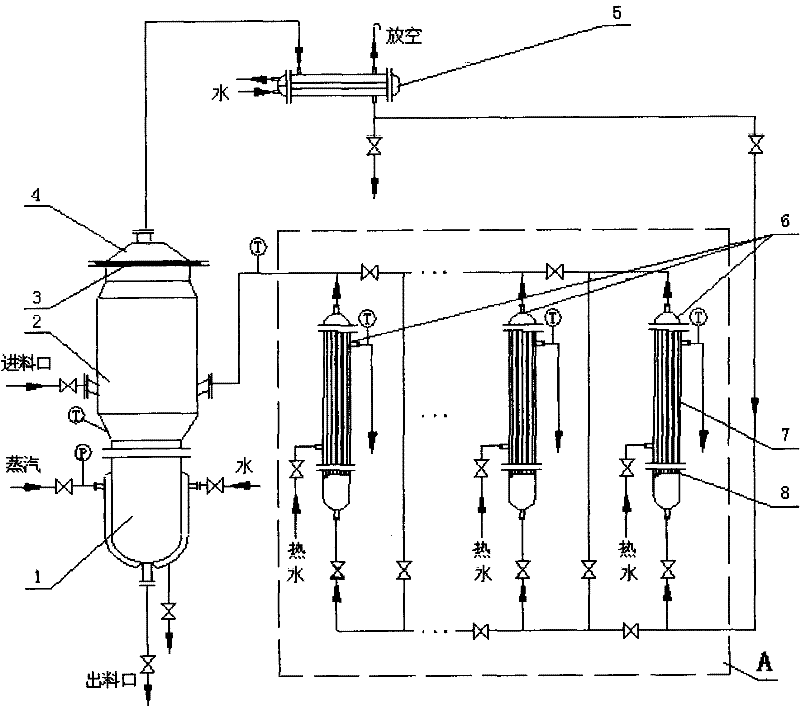

Reaction device for synthesizing levo terpineol

InactiveCN102229524AHigh selectivityLess side effectsPreparation by hydroxy group additionSide reactionLower yield

The invention provides a reaction device for synthesizing levo terpineol and relates to a reaction device with pipe type fixed bed reactors for synthesizing the levo terpineol. The reaction device mainly comprises an evaporation kettle, a condenser and 2 to 10 pipe type fixed bed reactors connected in parallel or in series. The reaction device pushes raw materials to circularly flow between the evaporation kettle and the pipe type fixed bed reactors through evaporation natural circulation, adopts evaporation and reaction separation to contribute to precisely controlling the contact time and the reaction temperature of the raw materials and a catalyst, improving selectivity of the reaction, reducing side reactions and increasing yield, is provided with an evaporation chamber and a demister on a heating kettle to contribute to separating the raw materials from the products, reducing the levo terpineol generated by the reaction and entrained to the pipe type fixed bed reactors and improving reaction efficiency, and adopts the pipe type fixed bed reactors to contribute to reducing abrasion of catalyst granules, avoiding inactivation and prolonging service life. The reaction device effectively solves the problems of low reaction selectivity, many side reactions and low yield in the conventional synthesized levo terpineol. By the reaction device, the synthetic reaction of the levo terpineol can be performed under the best process condition; and the yield can reach over 65 percent.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

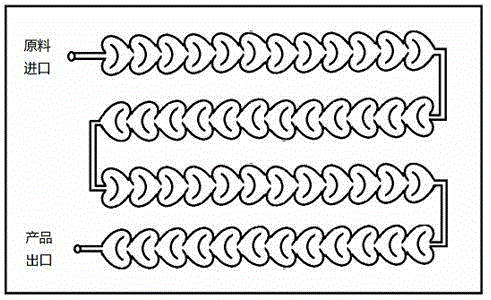

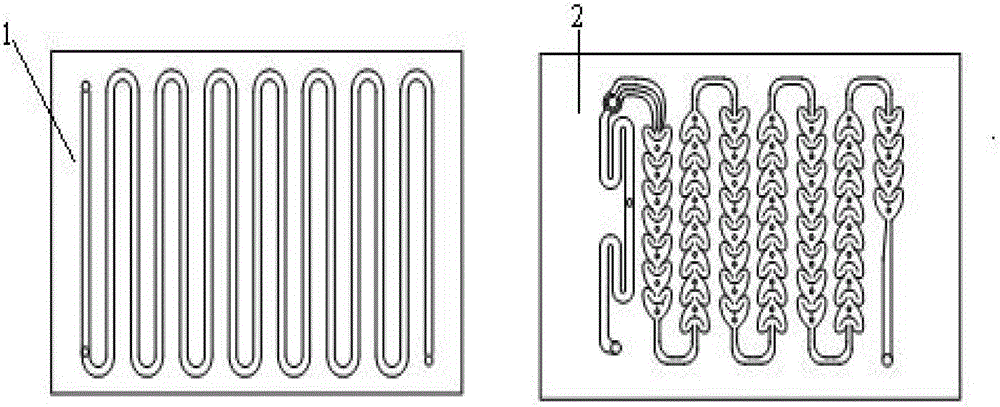

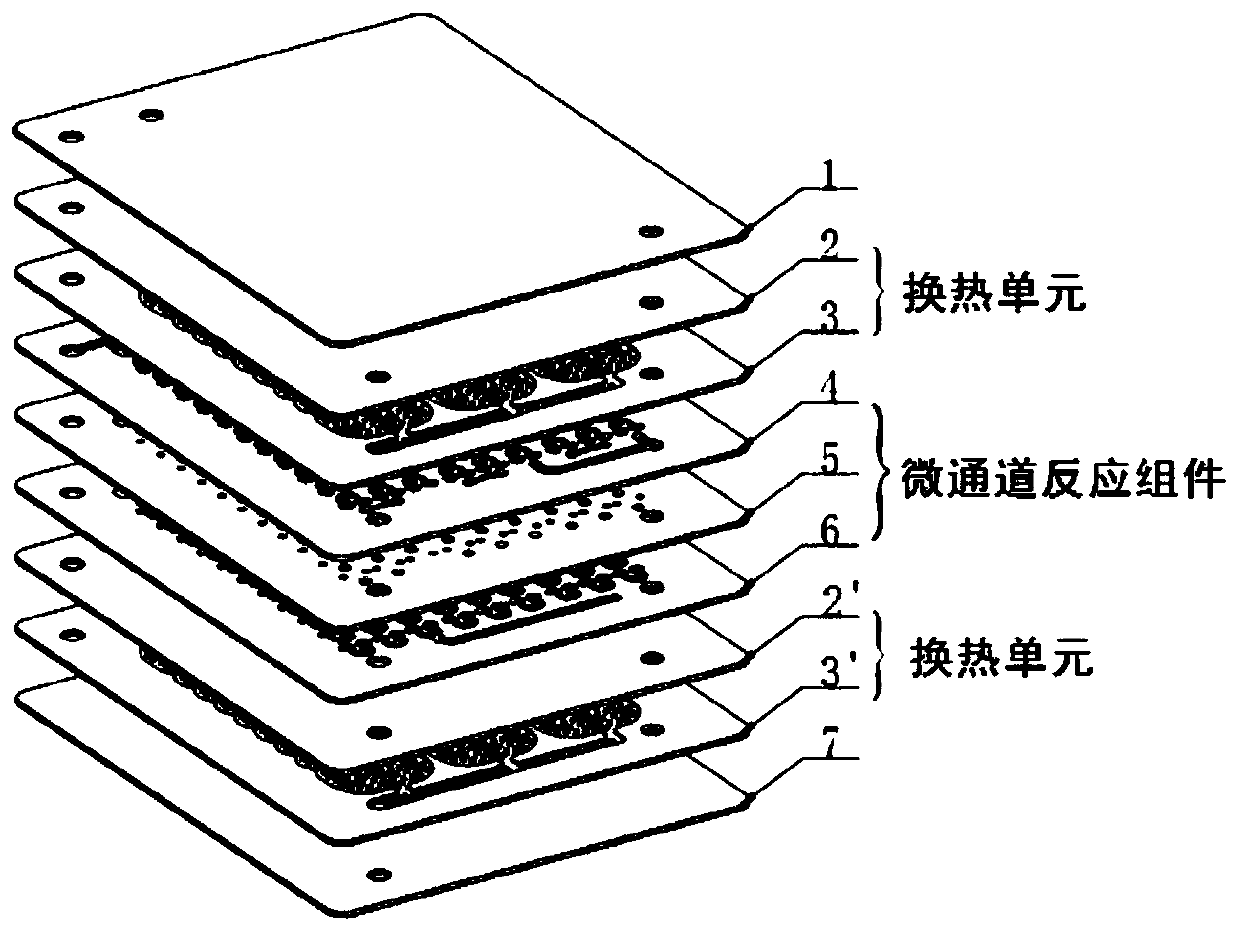

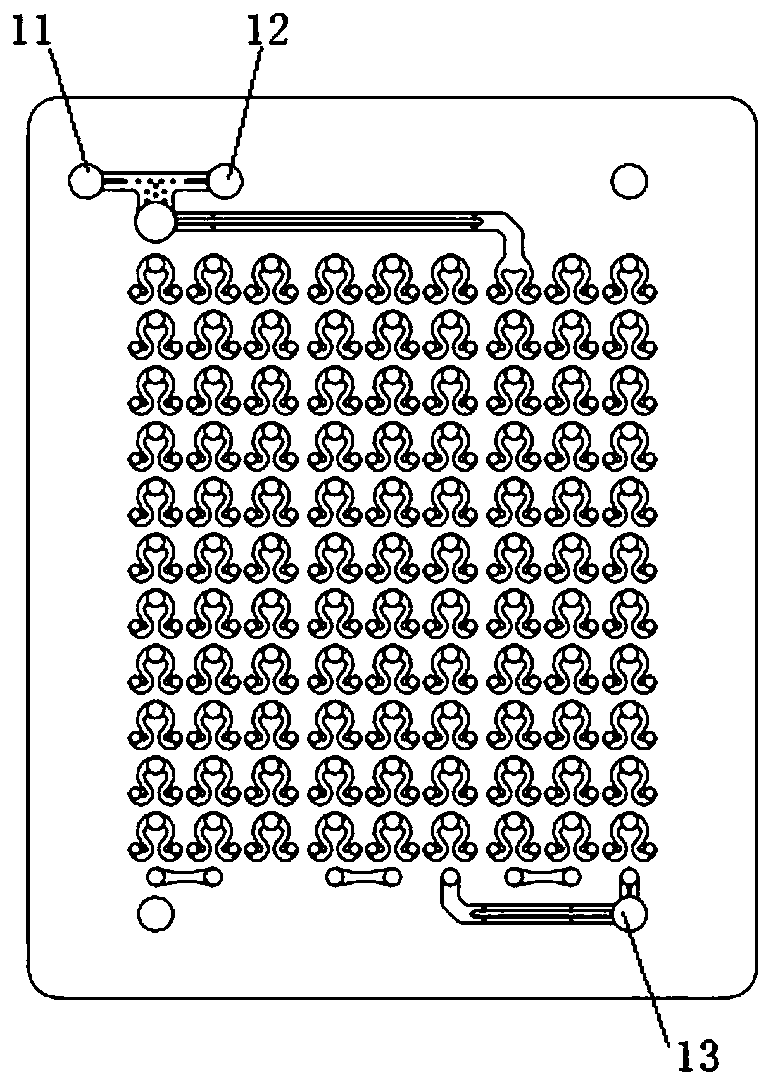

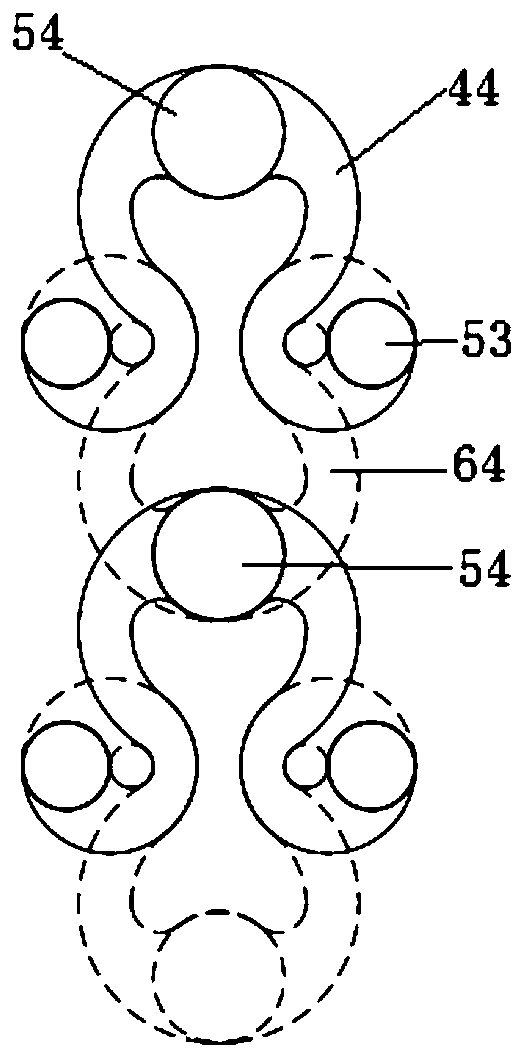

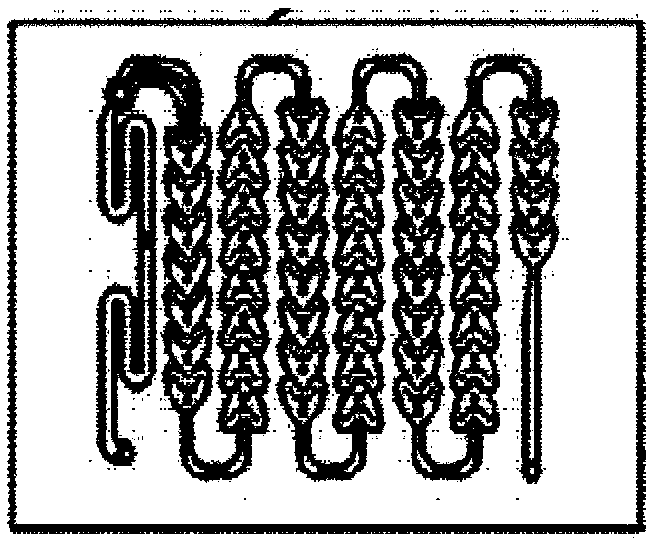

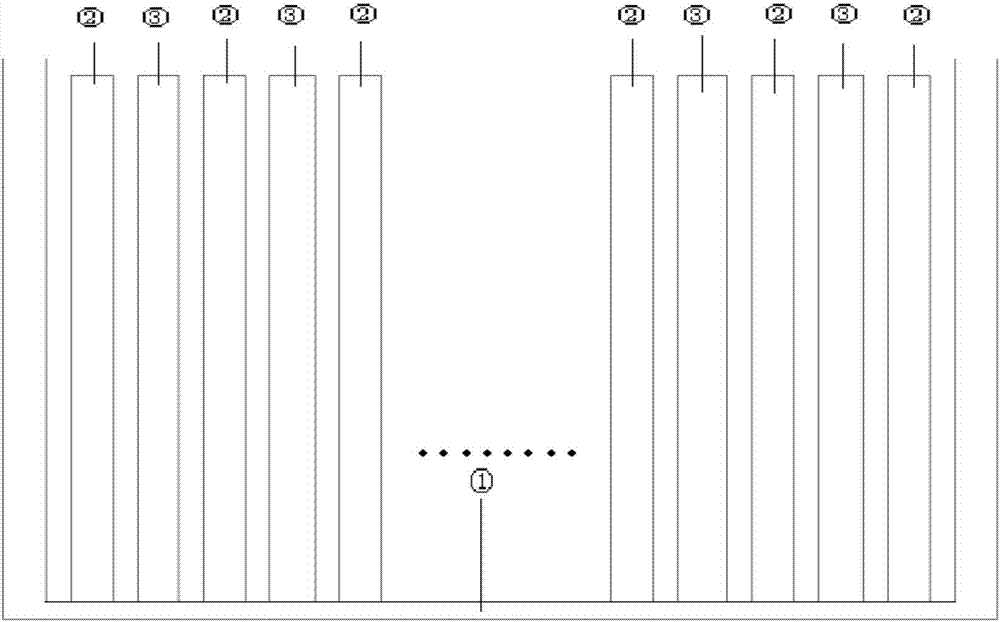

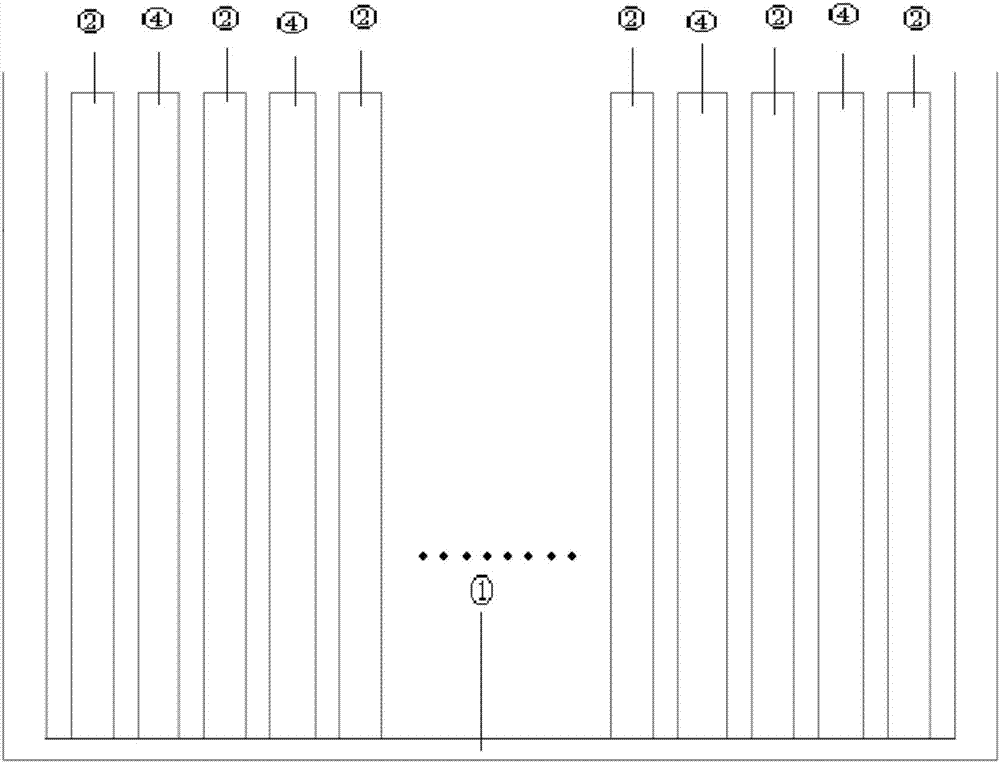

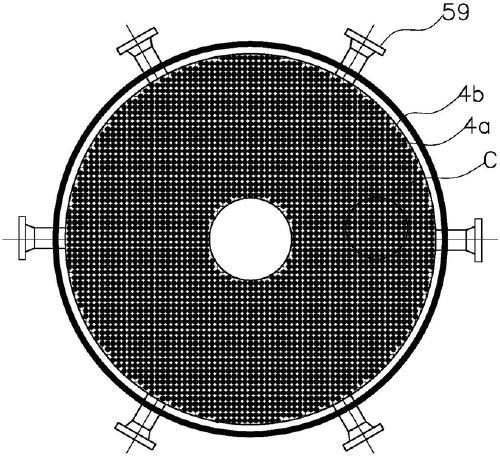

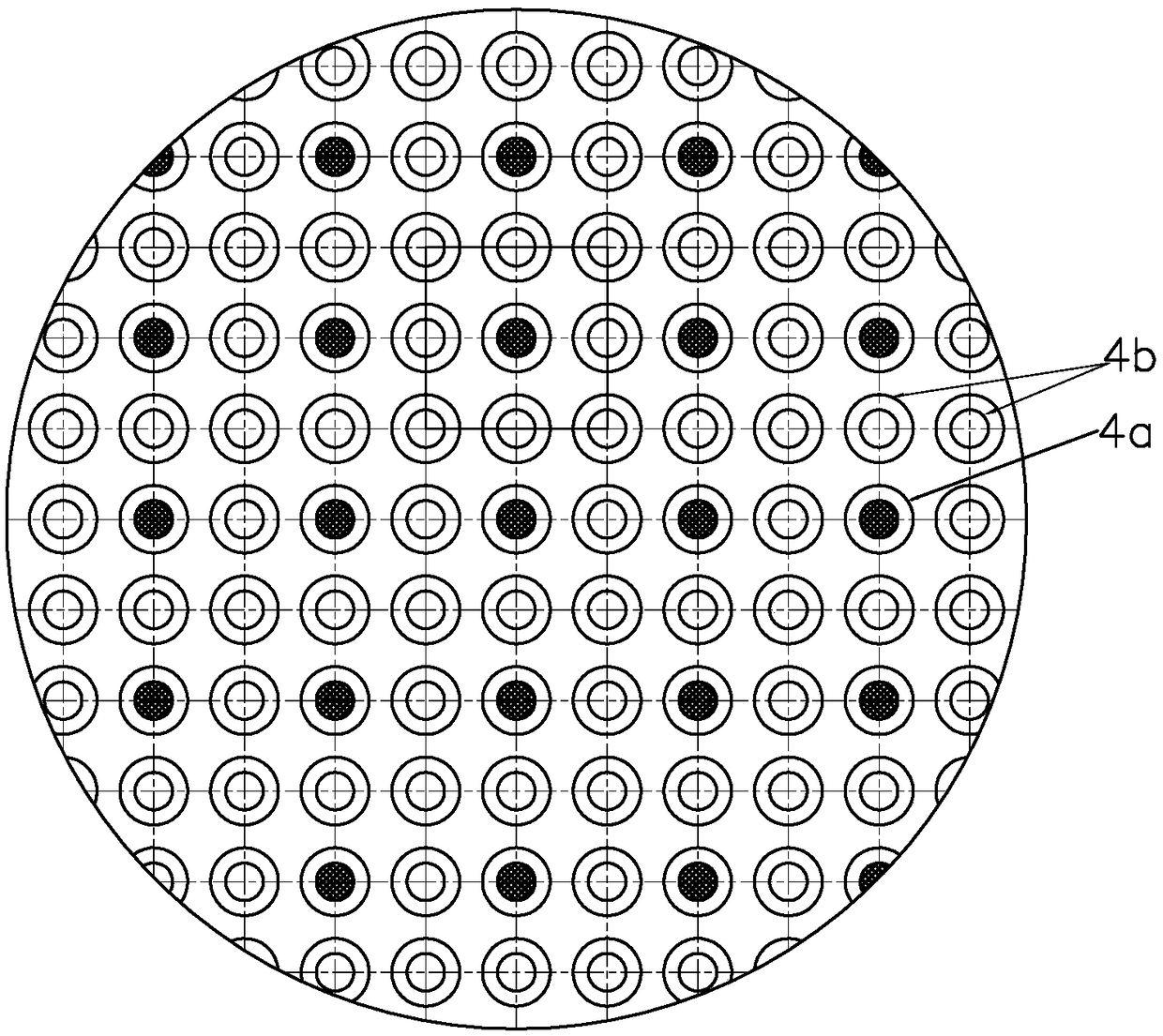

Micro-channel reaction assembly and micro-channel reactor

ActiveCN109847666AEffectively intensifies mixingEffectively intensifies the mixing effectChemical/physical/physico-chemical processesChemical industryHeat transfer efficiency

The invention relates to the technical field of reaction equipment in the fields of chemical industry, pharmacy and the like, in particular to a micro-channel reaction assembly and a micro-channel reactor. The micro-channel reaction assembly comprises: branch channels which are arranged in a first layer and are used for dividing a reaction medium; a confluence channel which is arranged in the second layer and is used for confluence of the reaction medium; communicating flow channels which are arranged between the first layer and the second layer and are communicated with the branch channel andthe convergence channel. The reaction medium is divided through the branch channels and flows to the convergence channel on the second reaction plate in series through the communicating flow channelson the communicating separation plate for confluence, and sequentially reciprocates for a plurality of cycles for a reaction on the reaction medium, so that the mixing among the media can be effectively intensified. The micro-channel reaction assembly can be compatible with reactions of granular solids with a certain diameter, so that the heat transfer efficiency is higher, the mixing effect between fluids is effectively intensified, the reaction time is shortened, and the product yield is increased.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

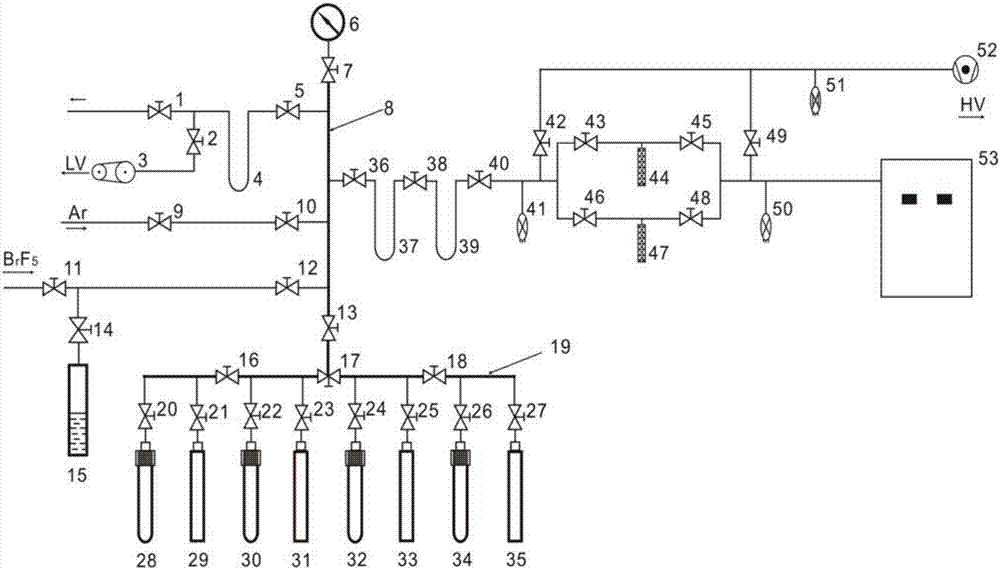

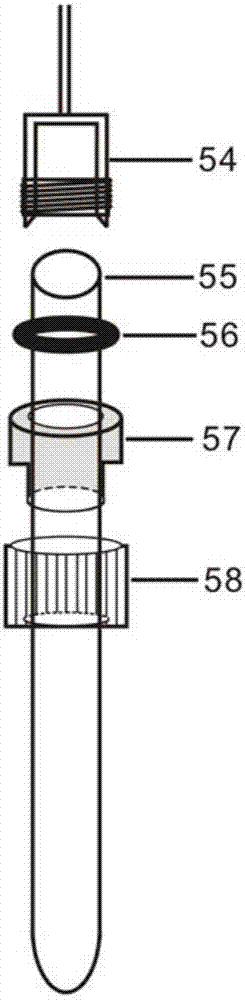

System and method for analyzing oxygen isotope composition in water of oxygen-free mineral inclusion

PendingCN107422024AIncrease vacuumGuaranteed vacuumPreparing sample for investigationMaterial analysis by electric/magnetic meansCooking & bakingMass spectrometry measurement

The invention belongs to the field of measurement of isotope composition in water of mineral inclusions and particularly discloses a system and a method for analyzing oxygen isotope composition in water of an oxygen-free mineral inclusion. One end of an inclusion burst extraction / purification separation / extract conversion system of the system is connected with a product collection and measurement system, and the other end of the inclusion burst extraction / purification separation / extract conversion system is connected with a waste treatment system. The method comprises steps as follows: sampling of a mineral sample; baking and vacuum degassing; bursting, extraction and purification of the mineral inclusion; conversion of the water in the mineral inclusion; collection and mass spectrometric measurement of a converted product; waste treatment of a reaction product. The problems that water extraction of the mineral inclusion is not thorough, impurity ingredient separation is not complete, oxygen isotope fractionation is easily caused in the conversion process and the like are solved, and the analysis and test accuracy and the analysis and test efficiency are improved.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

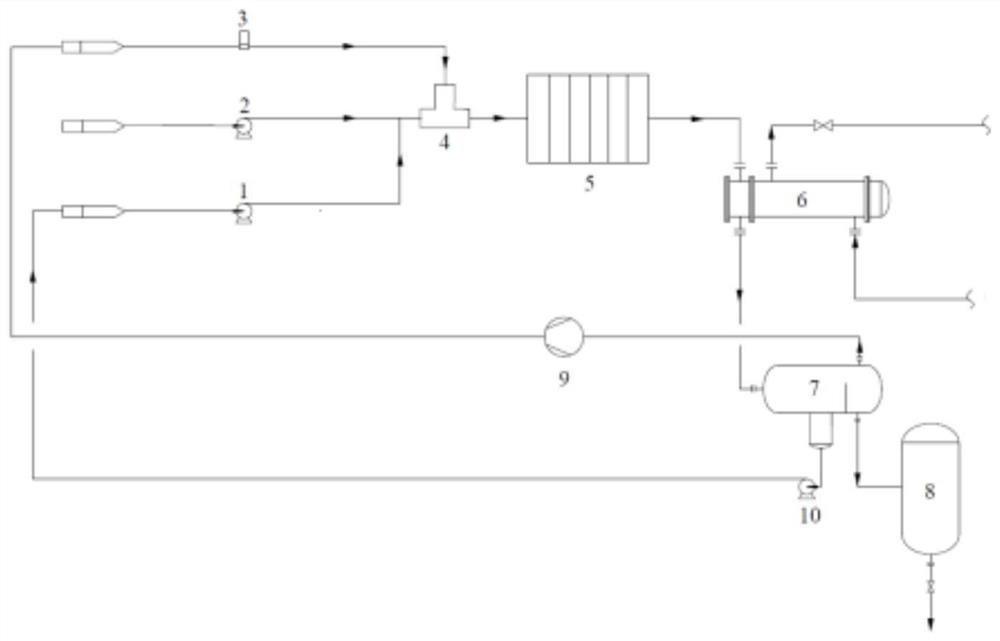

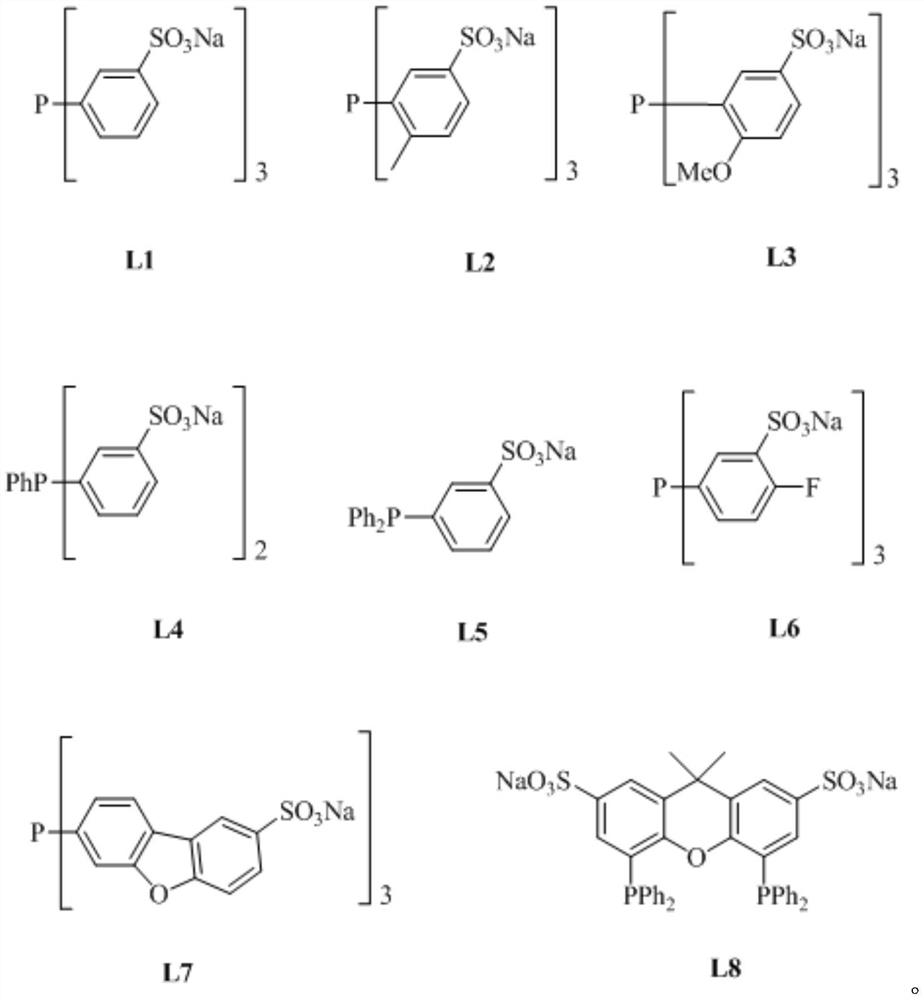

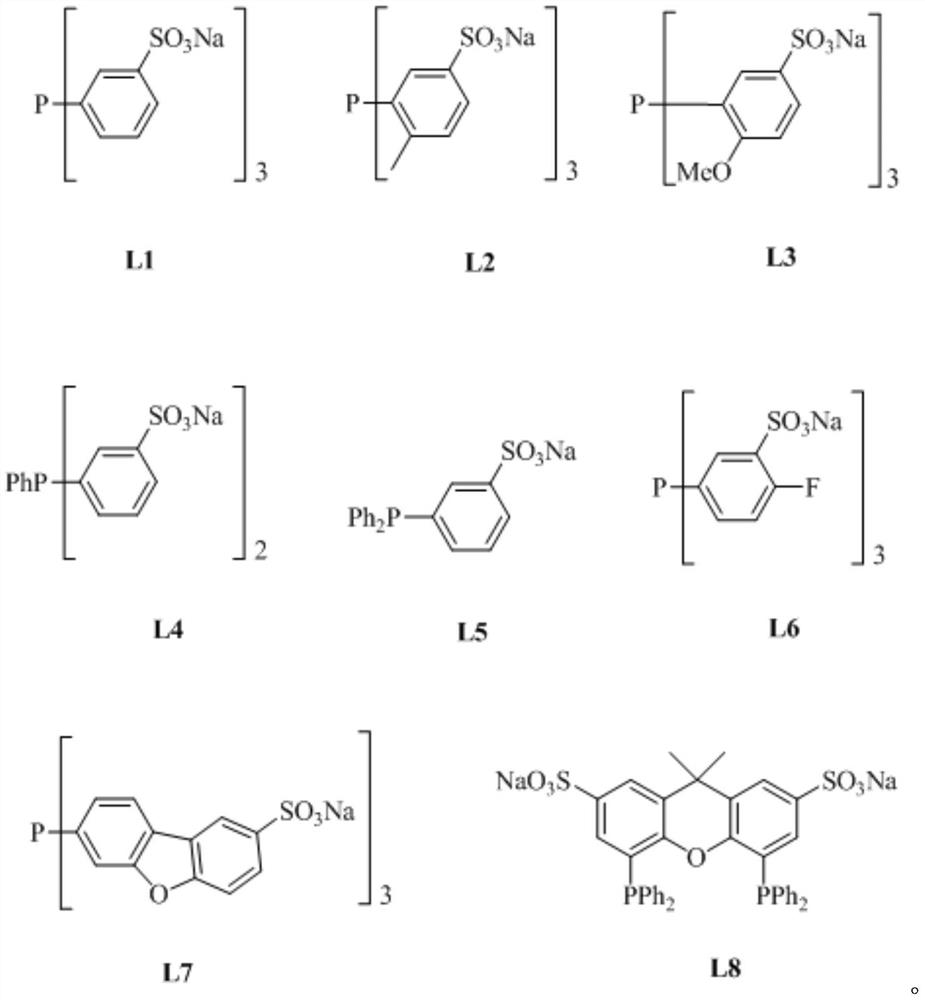

Method for synthesizing high-carbon aldehyde by using microchannel reaction device

PendingCN113372206AEasy to separateFully contactedPreparation by carbon monoxide reactionPtru catalystAlkene

The invention discloses a method for synthesizing high-carbon aldehyde by a microchannel reaction device. The method is characterized by comprising the following steps: dissolving a rhodium catalyst and a water-soluble organic phosphine ligand in water to prepare a catalyst solution; simultaneously pumping high-carbon olefin, synthesis gas and a catalyst solution into a micro-channel mixer, and mixing; then feeding the mixed solution into a micro-channel reactor, and carrying out a reaction; and cooling the obtained reaction product, feeding into a three-phase separation tank, and separating to obtain an oil phase, namely the high-carbon aldehyde. According to the invention, a water-oil two-phase hydroformylation method is adopted, a water-phase catalyst and an oil-phase product are easy to separate, and the defects that the catalyst is difficult to separate in homogeneous catalysis, the catalyst is easy to inactivate in the separation process and the like are overcome; and the micro-channel continuous flow reaction device can realize continuous circulation of a catalyst solution and synthesis gas, and realizes zero discharge of gas and liquid.

Owner:上海簇睿低碳能源技术有限公司 +1

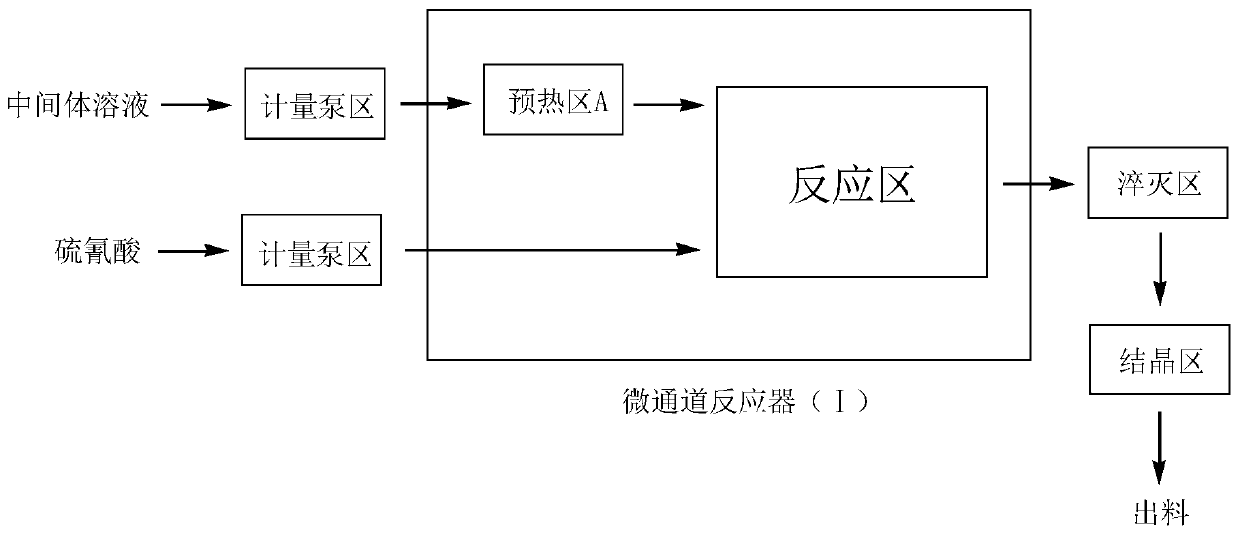

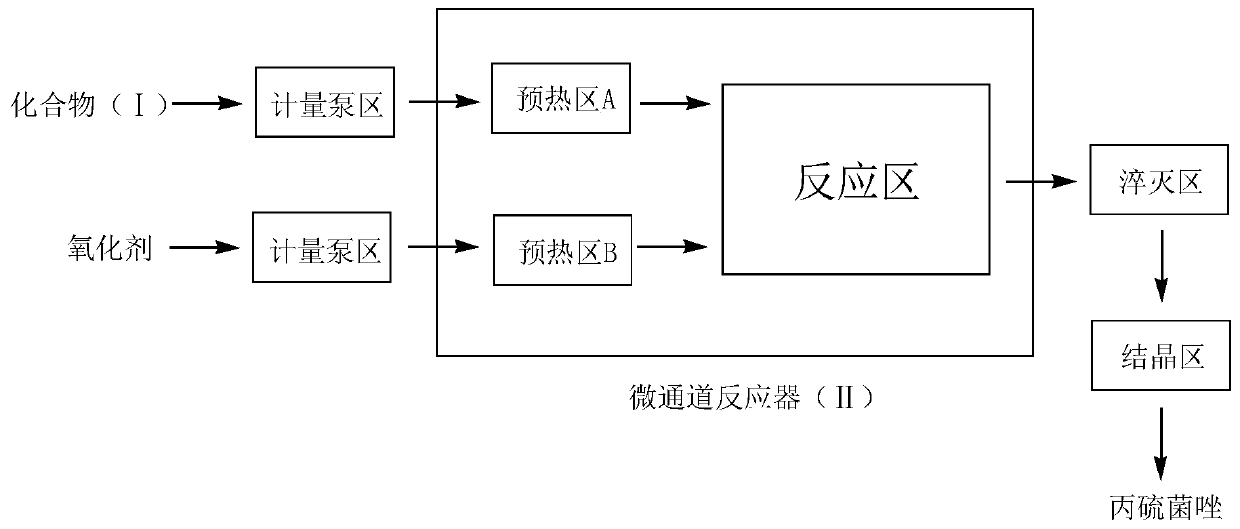

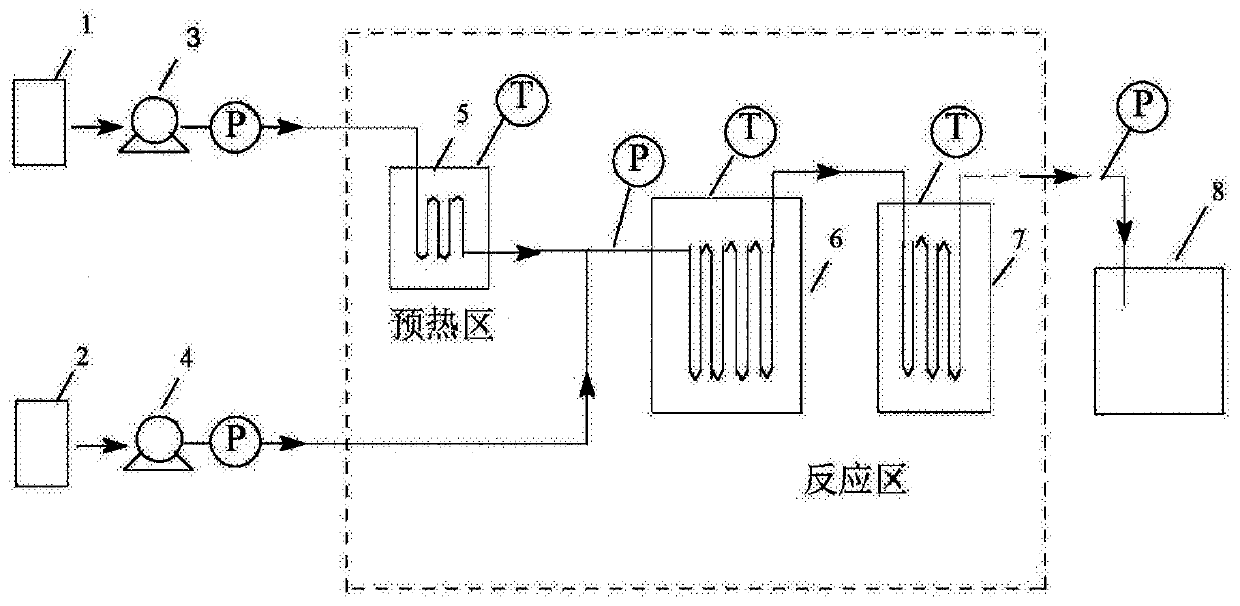

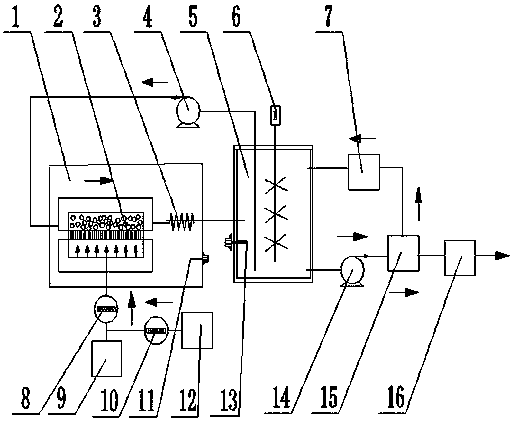

Method for continuously producing prothioconazole by utilizing micro-channel reactor and micro-channel system

ActiveCN110218197APrevent self-aggregationReduce generationOrganic chemistryChemical/physical/physico-chemical microreactorsOrganic synthesisReaction temperature

The invention relates to a method for continuously producing prothioconazole by utilizing a micro-channel reactor and a micro-channel system and belongs to the technical field of organic synthesis processes. The method comprises the following steps: taking 2-(1-chloro-cyclopropyl)-1-(2-chlorphenyl)-3-hydrazino-propyl-2-ol as a raw material, carrying out a cyclization and oxidization two-step reaction in the micro-channel reactor so as to continuously complete a preparation process of prothioconazole, introducing the material into the micro-channel reactor by a metering pump, performing preheating, mixed reaction and quenching crystallization separation so as to obtain the product prothioconazole. According to the method, mass transfer and heat transfer in the reaction process can be enhanced, the reaction temperature and reaction time are accurately controlled, side reactions and a reactant auto-polymerization phenomenon caused by material enrichment in the cyclization process are avoided, and conditions that the side reactions are increased due to 'temperature runaway' and reactive oxygen species overflow in the oxidization process and the like are also avoided. The reaction timeis finally reduced, the atom utilization ratio is improved, the reaction conversion rate is greatly improved, and production of solid wastes and side reactions is reduced.

Owner:RUICHENG COUNTY SIPULUNDI BIOLOGICAL ENG CO LTD

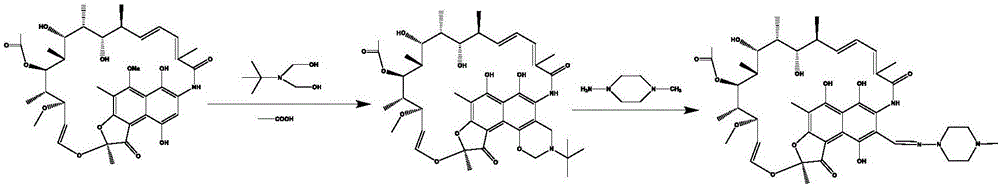

Method for preparing nano calcium carbonate by microreaction

InactiveCN108033475AOvercoming uneven concentration distributionSmall particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologyChemistryCarbon dioxide

The invention provides a method for preparing nano calcium carbonate by microreaction. A device for preparing the nano calcium carbonate by the microreaction mainly comprises a thermostatic water bath, a micro reactor, a temperature controller, a constant-flux pump, a mixing tank, a stirrer, a filtrate regenerator, a mixed gas flowmeter, a nitrogen storage tank, a carbon dioxide flowmeter, a carbon dioxide storage tank, a pH value measuring instrument, a material conveying pump, a water washing filter, a dryer and corresponding connecting pipelines. By adopting a calcium carbonate microreaction carbonization process, reaction time can be greatly shortened, the yield of a nano calcium carbonate product is improved, distribution range of particle size is narrow, the quality of a product is stable, industrial production can be realized, as well as a simple process and low energy consumption are realized.

Owner:UNIV OF JINAN

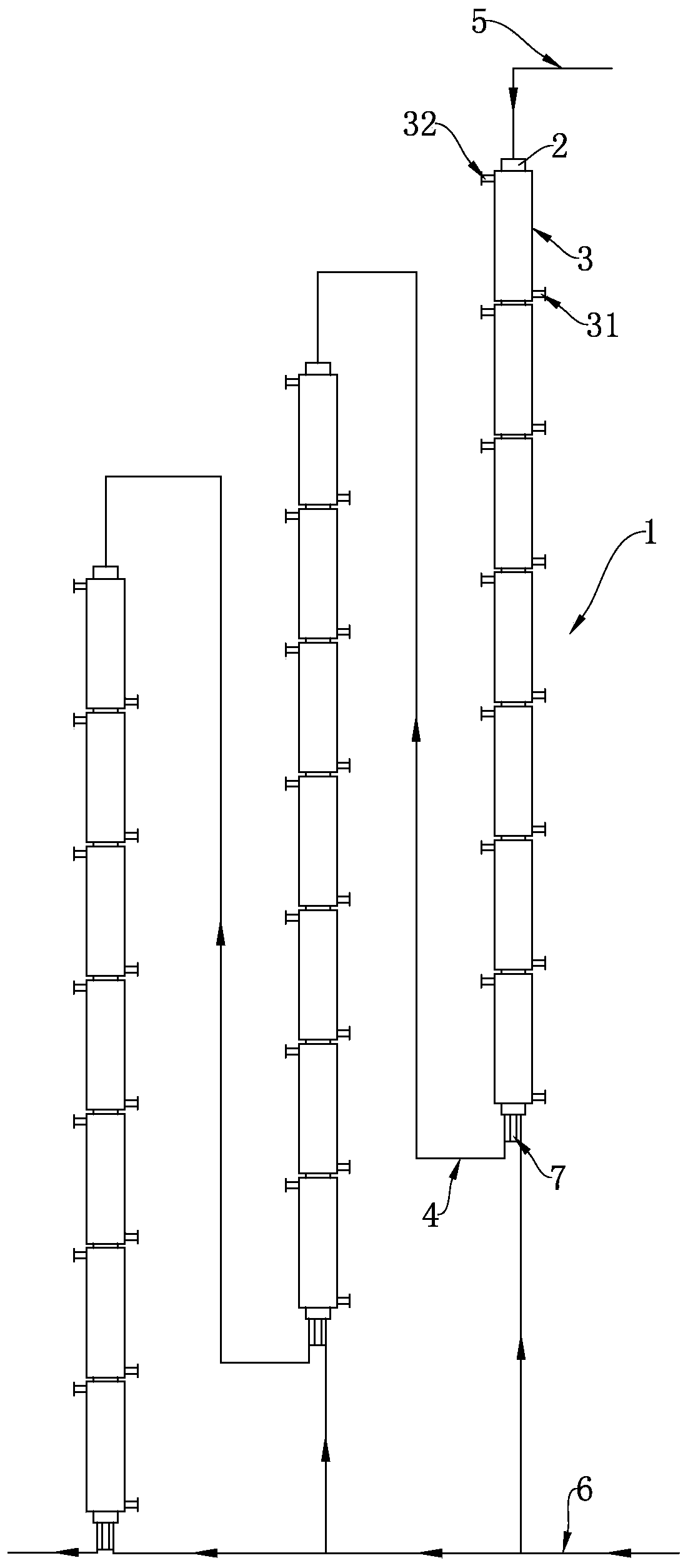

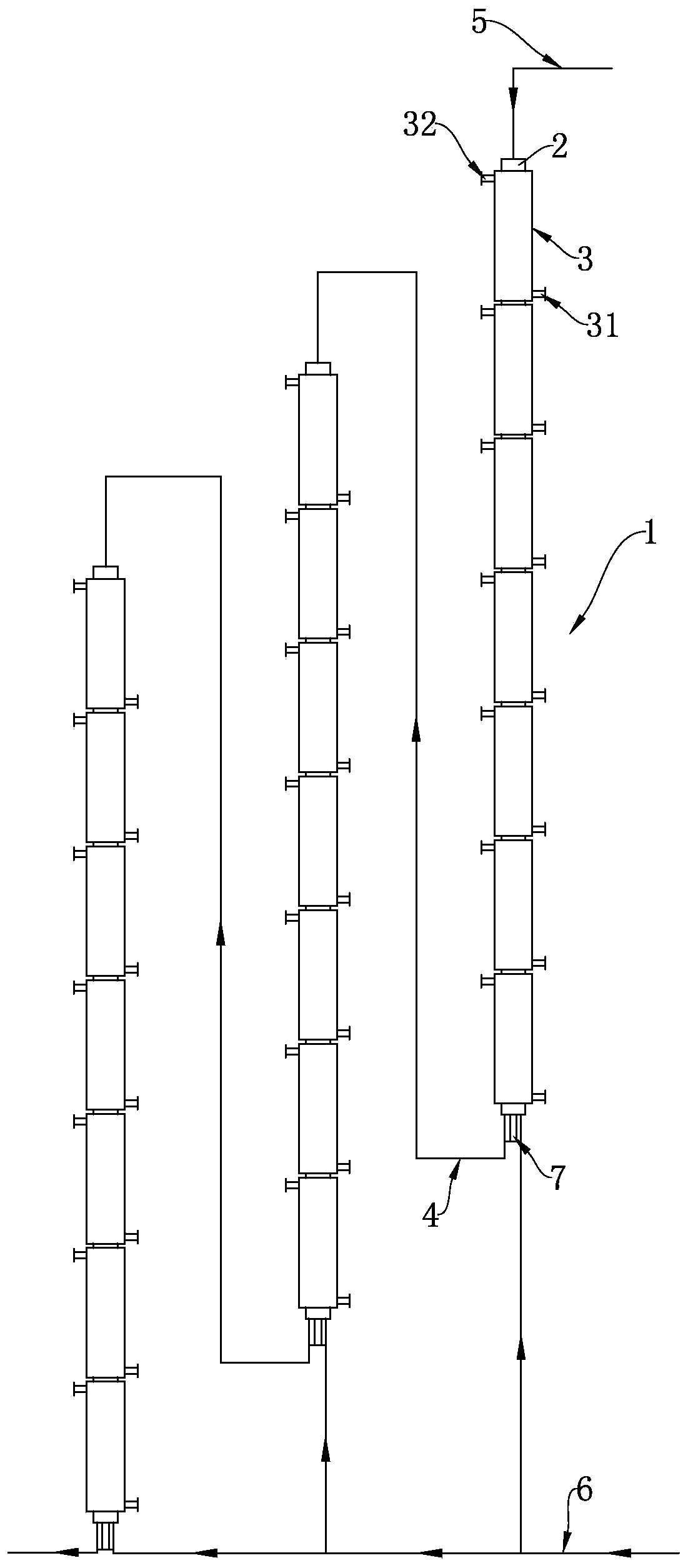

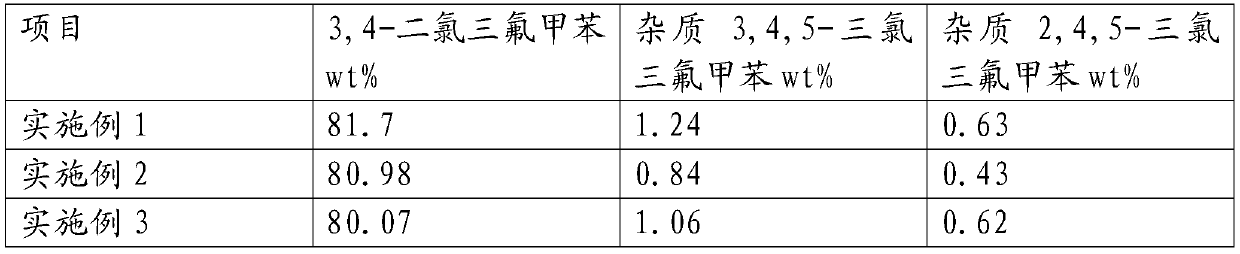

Continuous production method and continuous production equipment for 3, 4-dichloro-trifluorotoluene

ActiveCN109970507AAvoid heatingRealize continuous productionChemical/physical/physico-chemical stationary reactorsHalogenated hydrocarbon preparationHeight differenceToluene

The invention discloses a continuous production method and continuous production equipment for 3, 4-dichloro-trifluorotoluene. The production method comprises the steps that, chlorine and p-chloro-trifluorotoluene are used as raw materials for multi-stage continuous reaction, and the p-chloro-trifluorotoluene enters from the top of a first-stage tubular reactor; the chlorine enters from the bottomof a tubular reactor of each stage for countercurrent reaction; materials in the tubular reactor of each stage overflow from the bottom of the tubular reactor into a tubular reactor of next stage forcontinuous countercurrent reaction with the chlorine entering from the bottom of the tubular reactor; and the multi-stage continuous reaction adopts a step-by-step gradient cooling reaction mode. Theproduction equipment comprises multi-stage tubular reactors which are connected in series, wherein the multi-stage tubular reactors connected in series are arranged in a ladder shape with certain height differences; and an overflow pipeline is arranged between the bottom of an upper-stage tubular reactor and the top of a lower-stage tubular reactor. According to the production method and production equipment, continuous production can be achieved, moreover, reaction energy consumption is reduced, the reaction effect is good, reaction with less byproduct, and the product yield is high.

Owner:SHANDONG DOCRIS CHEM +1

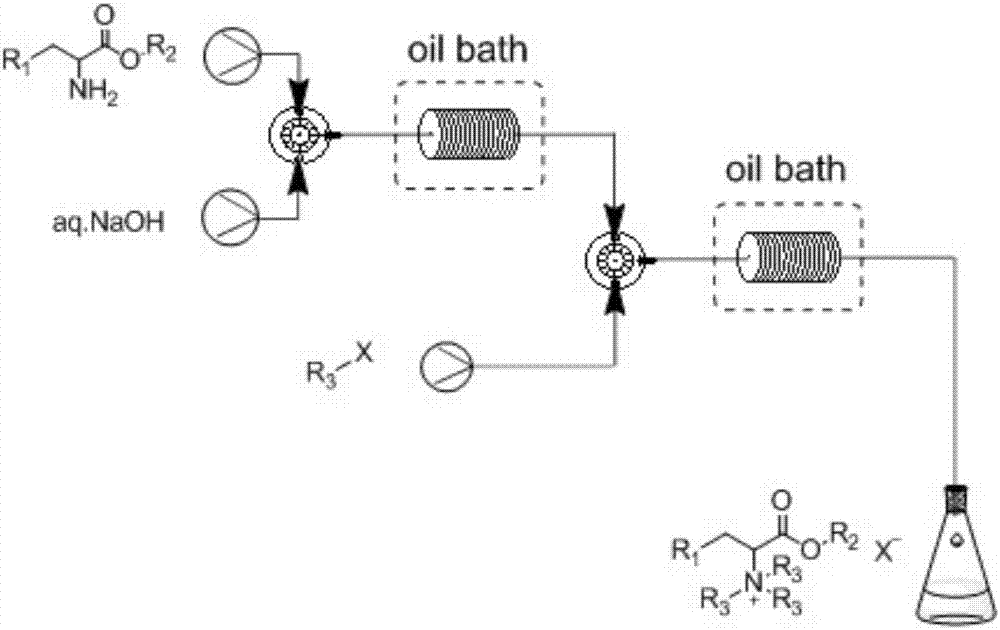

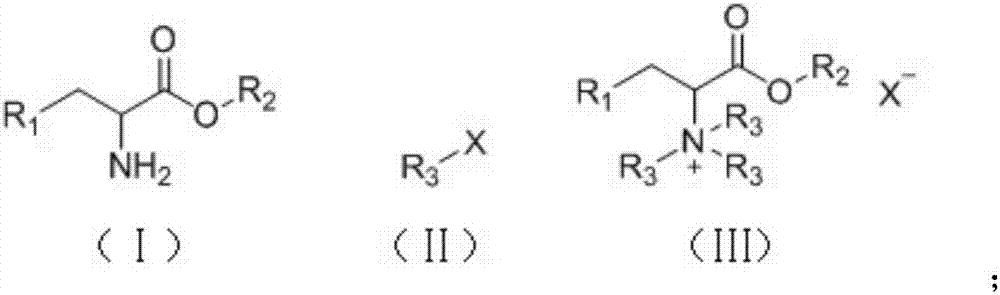

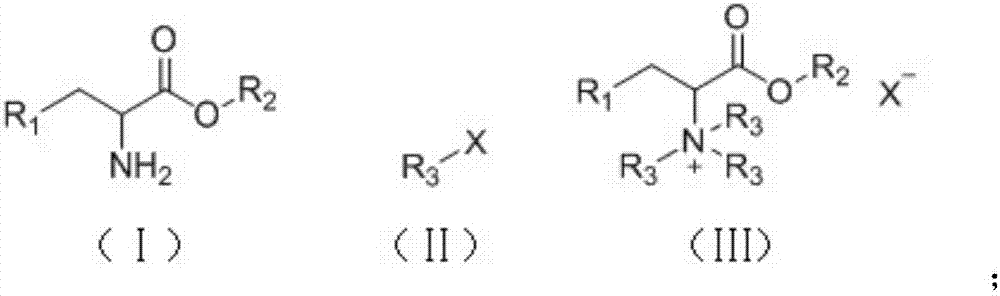

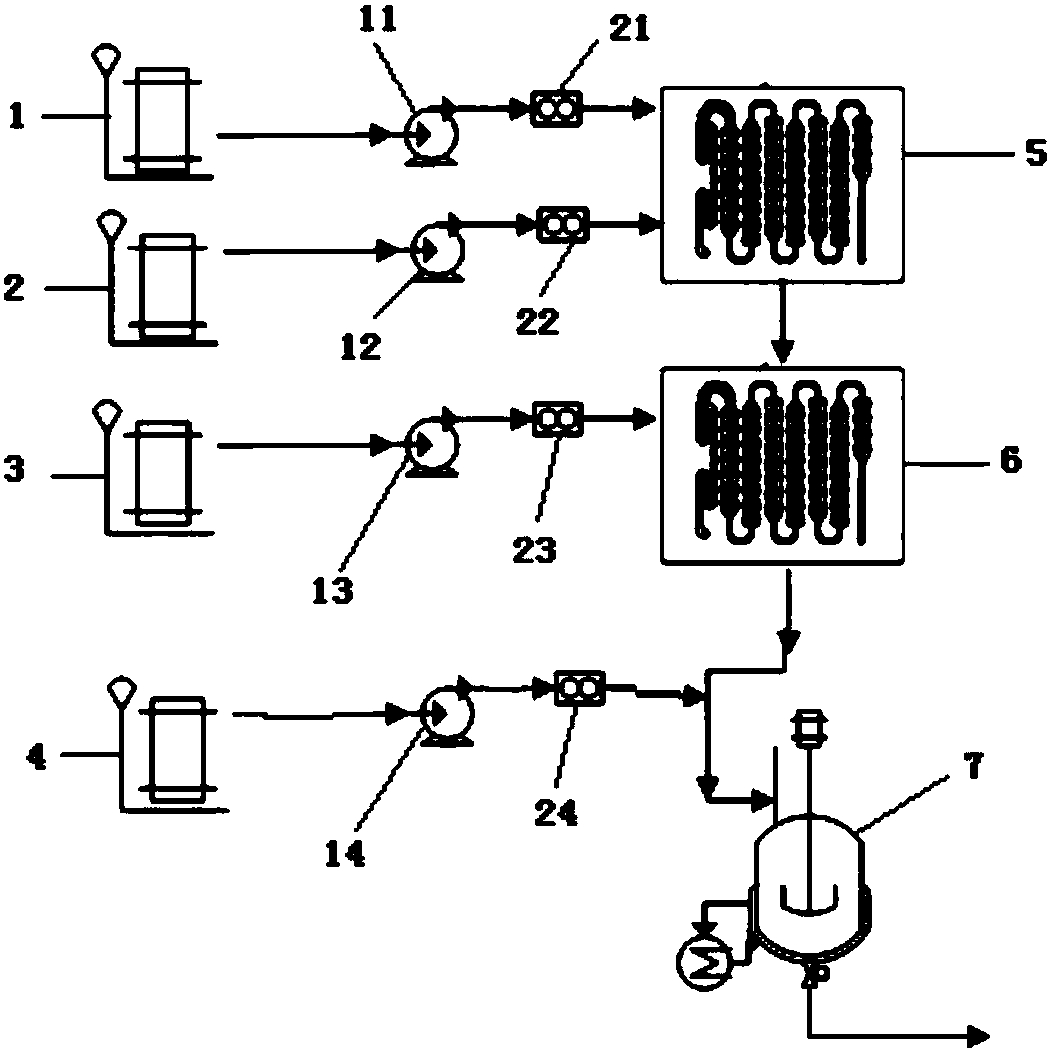

Method of continuously synthesizing quaternary ammonium salt by using microreaction device

InactiveCN107445851AImprove qualityThe process is simple and convenientBiocideOrganic compound preparationMicroreactorQuaternary ammonium cation

The invention discloses a method of continuously synthesizing quaternary ammonium salt by using a microreaction device. An amino acid derivative and halohydrocarbon as reactants, and sodium hydroxide as an acid-binding agent for a reaction are pumped into a microreactor for the reaction in a thrice feeding manner. An obtained product is a quaternary ammonium salt compound derived from amino acid. Compared with the prior art, the method is high in automation degree; a material ratio and a reaction temperature of the reactants are controlled accurately; the reaction time is short; the equipment and energy loss is low; the method is easy and simple to operate; and the required manpower and material resources are greatly reduced. At the same time, when the method is used for the reaction, a catalyst, various complicated instruments and a dangerous reagent are not required to be used; reaction conditions can be met only by heating; in addition, the problem of local heat release in a reaction process is solved; the uniform and stable temperature is achieved; and the high-quality product can be obtained efficiently.

Owner:NANJING UNIV OF TECH

Method for preparing fluorinating reagent and fluoride continuously by microchannel reactor

InactiveCN109776365AIncrease profitPrevent overflowOrganic compound preparationChemical/physical/physico-chemical processesReaction temperatureSolvent

The invention discloses a method for preparing a fluorinating reagent and fluoride continuously by a microchannel reactor. The method comprises the following steps: introducing a mixed solution of amine and a solvent as well as fluorine-containing olefin into the microchannel reactor separately, performing reaction at the reaction temperature of subzero 20 to 30 DEG C for 30 to 180 seconds to prepare the fluorinating reagent, introducing the fluorinating reagent and a compound A into the microchannel reactor, performing mixing, heating and reaction to obtain a compound B, and performing hydrolysis reaction on the reaction liquid of the compound B to obtain a compound C. The method is simple to operate and safe to use, the use amount of the materials is greatly reduced, the process is environmentally-friendly and continuous, and the risk of high pressure and high temperature is avoided, so that high-yield continuous production of the fluorinating agent or fluoride is feasible. The comprehensive yield of the fluoride reaches 90 to 95 percent, basic quantitative reaction of the fluorinating reagent is realized and industrialized production is facilitated.

Owner:JIANGSU HANSYN PHARMA

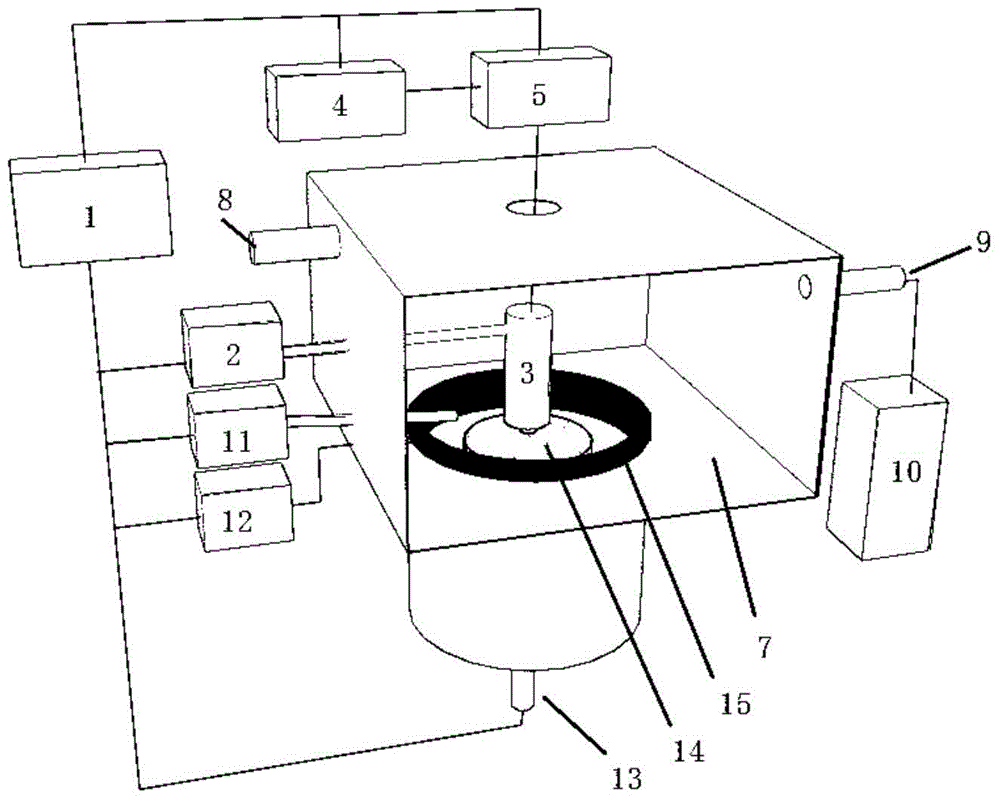

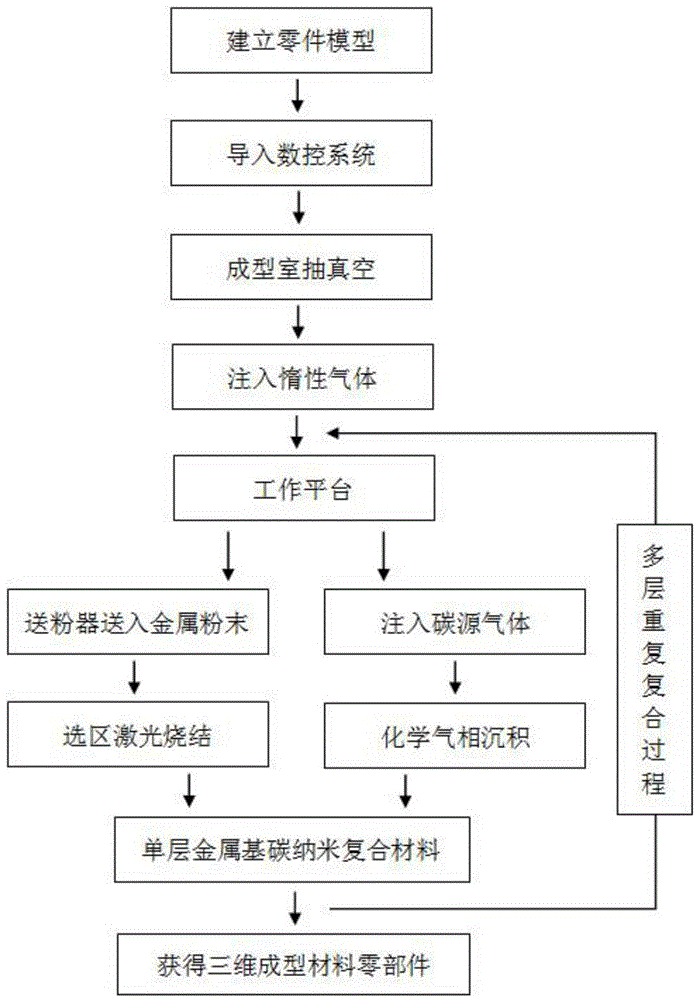

Laser preparation device and method of metal matrix carbon nanometer composite material

The invention discloses a laser preparation device and method of a metal matrix carbon nanometer composite material. According to the device and method, a numerical control system is adopted for centralized control, a powder feeder controls metal powder to be laid on a substrate through a computer instruction, area selecting sintering is performed on the metal powder through laser beams according to computer graphic data, meanwhile, carbon source gas is introduced, thermolysis is performed in a high-temperature area controlled by a temperature compensating device, various carbon nanostructure materials are generated through catalysis and combined with a metal matrix in the sintering process in real time, and the metal matrix carbon nanometer composite material can be formed. According to the device and method, a powder paving device, a laser, a temperature adjuster and the like are used for centralized control through the numerical control system, and the device and method have the advantages of being high in instantaneity, high in processing speed and the like. The manufactured metal matrix carbon nanometer composite material is high in efficiency and accuracy and good in performance.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Method for preparing nitro compound from aromatic hydrocarbon compound through isothermic tubular reaction

ActiveCN108238944AEasy to controlHigh heat transfer efficiencyChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesNitro compoundHeat transfer efficiency

The invention belongs to the technical field of organic chemistry and particularly relates to a method for preparing a nitro compound from an aromatic hydrocarbon compound through isothermic tubular reaction. The method is characterized by comprising the following steps: adequately mixing two phases, namely a nitration raw material and mixed acid by virtue of a static mixer in a tubular reactor soas to realize simultaneous flow, reaction and heat exchange in a shell of the tubular reactor, and carrying out nitration separation, alkali washing, washing and refining, so as to obtain the nitro compound, wherein row tubes which can be controlled in different regions are arranged in the tubular reactor and are used for removing reaction heat. The method for preparing the nitro compound has thebeneficial effects that the flow is simple, the continuous production is realized, the reaction process is easy to control, the heat transfer efficiency is high, the situation that byproducts are increased due to the overheat in the reaction can be effectively avoided, the energy consumption and the raw material consumption are low, and the production process is safe and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

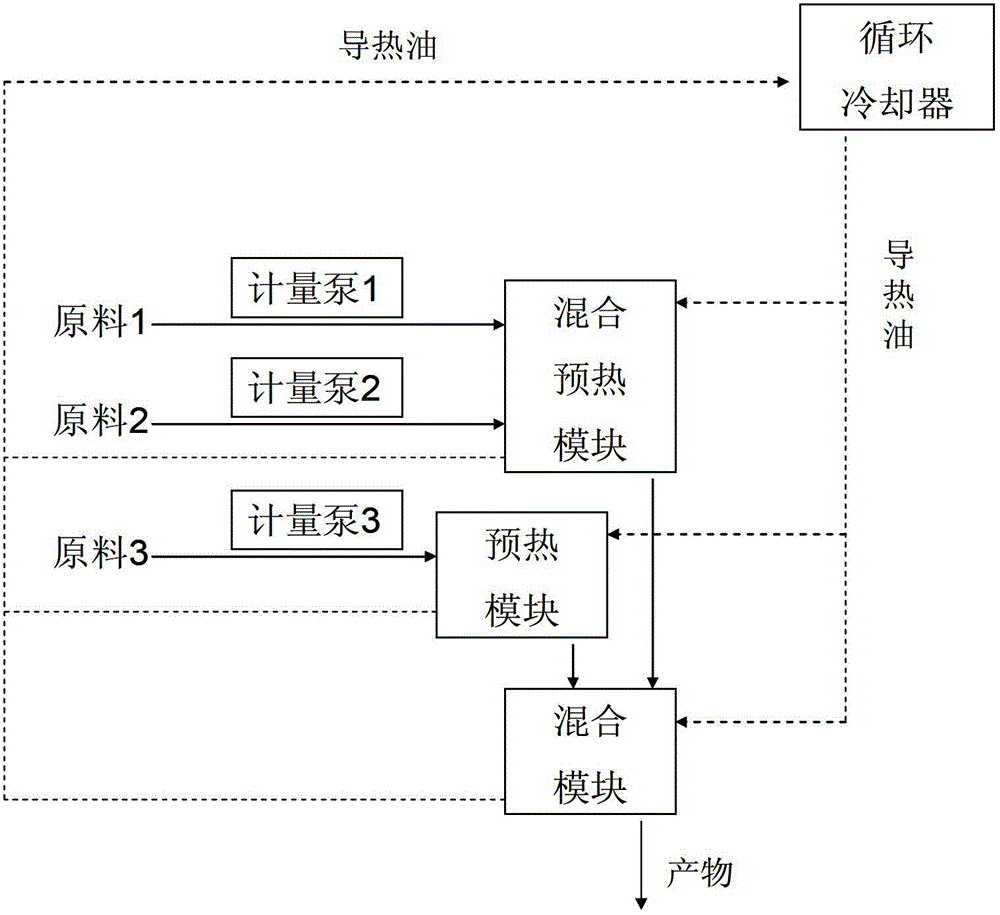

Hydrogenation process for silicon tetrachloride and process for preparing high-purity silicon from trichlorosilane

InactiveCN107162003AImprove securityWell mixedSiliconHalogenated silanesHydrogenation processSilicon tetrachloride

The invention provides a hydrogenation process for silicon tetrachloride and a process for preparing high-purity silicon from trichlorosilane. The process for preparing high-purity silicon from trichlorosilane comprises the following steps: (1) introducing trichlorosilane gas and hydrogen into a micro-channel mixing and heating device for heating and mixing so as to obtain a heated gas mixture; (2) conveying the heated gas mixture into a micro-channel reactor, heating the gas mixture and carrying out a reaction in the presence of a catalyst so as to obtain a reacted mixture; and (3) cooling the reacted mixture and carrying out solid-gas separation so as to obtain high-purity silicon and a cooled gas mixture, and separating and recycling each component in the cooled gas mixture. The invention also discloses a hydrogenation process for silicon tetrachloride. Compared with the prior art, the hydrogenation process for silicon tetrachloride and the process for preparing high-purity silicon from trichlorosilane in the invention have the beneficial effects that the conversion rates of silicon tetrachloride and trichlorosilane can reach 50% or above; and through combination of the processes with micro-chemical technology, the conversion rates are increased, security of the production processes is improved, and energy consumption is reduced.

Owner:于志远

Preparation method of perfluoroalkane

ActiveCN103288587APrecisely control the feeding ratioPrecise control of reaction temperatureHalogenated hydrocarbon active ingredientsRespiratory disorderAlkanePhysical chemistry

The invention provides a method for preparing perfluoroalkane. The method comprises the following steps of: filling a filler in a reactor, fluorating by using a fluorating agent, keeping the temperature inside the reactor between 100 to 300 DEG C, adding reaction materials in a vaporizer to vaporize, controlling the temperature inside the vaporizer between 130 to 150 DEG C, wherein the reaction materials comprise C5-C16 alkanes and one or more of partial fluorides of the C5-C16 alkanes, continuously bringing reaction material vapor in the reactor by using an inert gas, continuously feeding the fluorating agent in the reactor to react with the reaction material vapor continuously fed in the reactor, and separating and purifying to obtain the perfluoroalkane. The method provided by the invention is suitable for large-scale continuous productions; the reaction conditions are easily controlled; the yield is high; the by-products are less; the reaction production is easily separated and purified; no three wastes are discharged during the production process. With the adoption of the method, perfluorooctane with the purity being greater than or equal to 98% can be prepared and can act as a production material of lung cavity ventilation aerating liquid and a preparation for ophthalmologic operations.

Owner:苏州工业园区捷仕通医疗设备有限公司

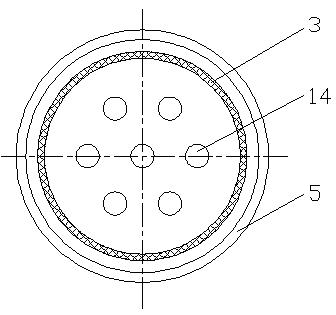

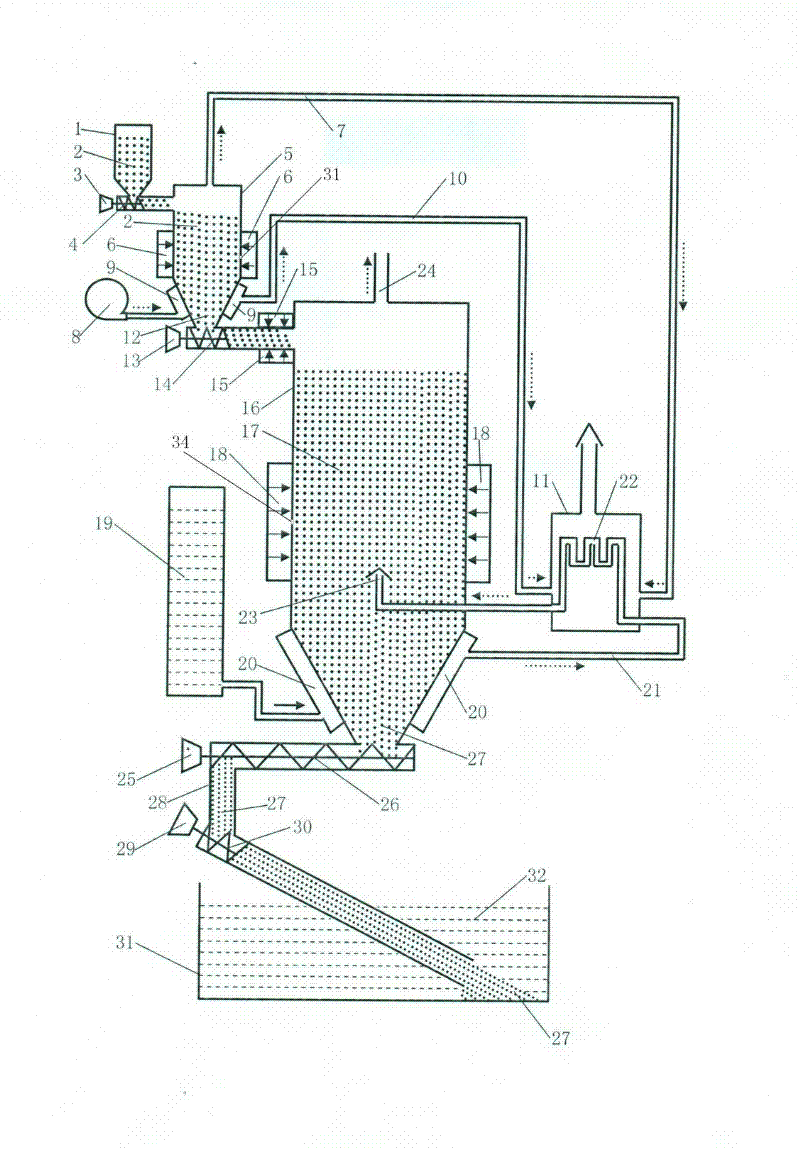

Circulating fluidized bed reactor for preparing hydrogen by gasifying biomass

InactiveCN101885472AWide adaptability of raw materialsSimple structureHydrogen productionDistributorCyclonic spray scrubber

The invention provides a circulating fluidized bed reactor for preparing hydrogen by gasifying biomass. The reactor comprises a reactor shell, a cyclone dust collector and a material returning device, wherein the reactor shell consists of a reactor upper shell, a cylindrical furnace lining and a reactor lower shell, the top part of the reactor upper shell is connected with the cyclone dust collector, the lower end of the reactor upper shell is provided with a biomass charging port, and the bottom part of reactor upper shell is muff coupled with the cylindrical furnace lining; an induction heating device is suspended in the cylindrical furnace lining, and an electric induction coil is wound outside the cylindrical furnace lining and connected with a heating power supply; the bottom part of the cylindrical furnace lining is muff coupled with the reactor lower shell, air distributors are arranged in the reactor lower shell, the bottom part of the reactor lower shell is provided with a vapor charging port, and a material returning port is arranged above the air distributors; and the bottom part of the cyclone dust collector is connected with the material returning device, the material returning device is connected with the material returning port, and the bottom part of the material returning device is provided with a material returning vapor charging port. The circulating fluidized bed reactor has the advantages of uniform heating, energy conservation and environmental protection, continuous operation, simple structure and the like, and can produce the hydrogen-enriched synthetic gas by pyrolysis of biomass materials such as stalks, rice hulls and sawdust.

Owner:ZHENJIANG DANTU TIANLONG CHEM

Method for preparing active carbon by using coke reactivity testing device

The invention relates to a method for preparing active carbon by using a coke reactivity testing device. The method comprises the following steps: adding coke powder into a potassium hydroxide solution by using the coke reactivity testing device, grinding until the grain size is 0.07-0.08mm, adding coal tar and water, and heating a crucible at a temperature raising rate of 8-12 DEG C / minute; when the temperature reaches 400-410 DEG C, introducing nitrogen, wherein the flow rate of nitrogen is 1.0-1.5L / min; when the temperature reaches 850-880 DEG C, insulating for 40-60 minutes; obtaining coarse active carbon; and crushing, washing and drying the coarse active carbon to obtain active carbon. The method for preparing active carbon provided by the invention is carried out in the coke reactivity testing device which is good in tightness. The coke reactivity testing device is capable of precisely controlling the temperature raising rate and the reaction temperature, preventing the active carbon from being oxidized in the preparation process, improving the specific surface area of the active carbon, strictly controlling the change of introducing nitrogen and preventing the coke powder from being oxidized, and moreover, the rate of an activating reaction is accelerated by virtue of the flow rate of nitrogen.

Owner:SHANDONG IRON & STEEL CO LTD

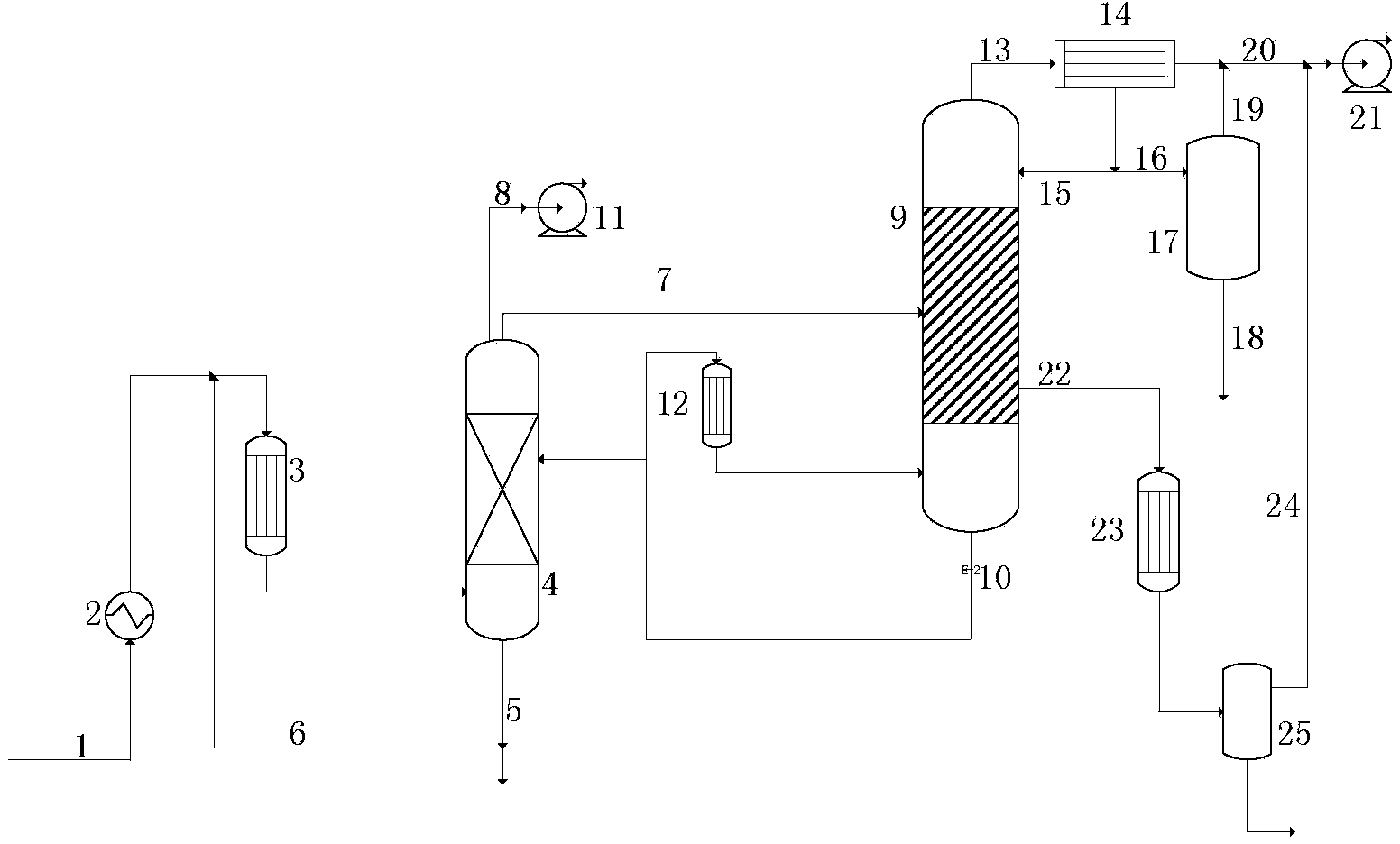

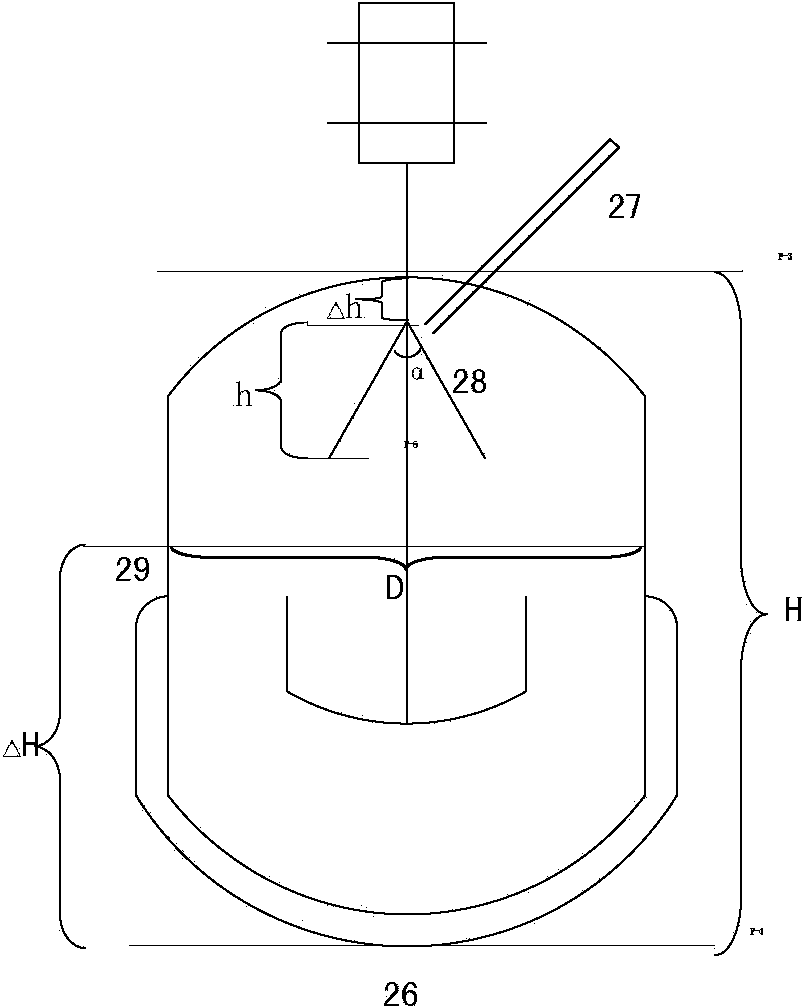

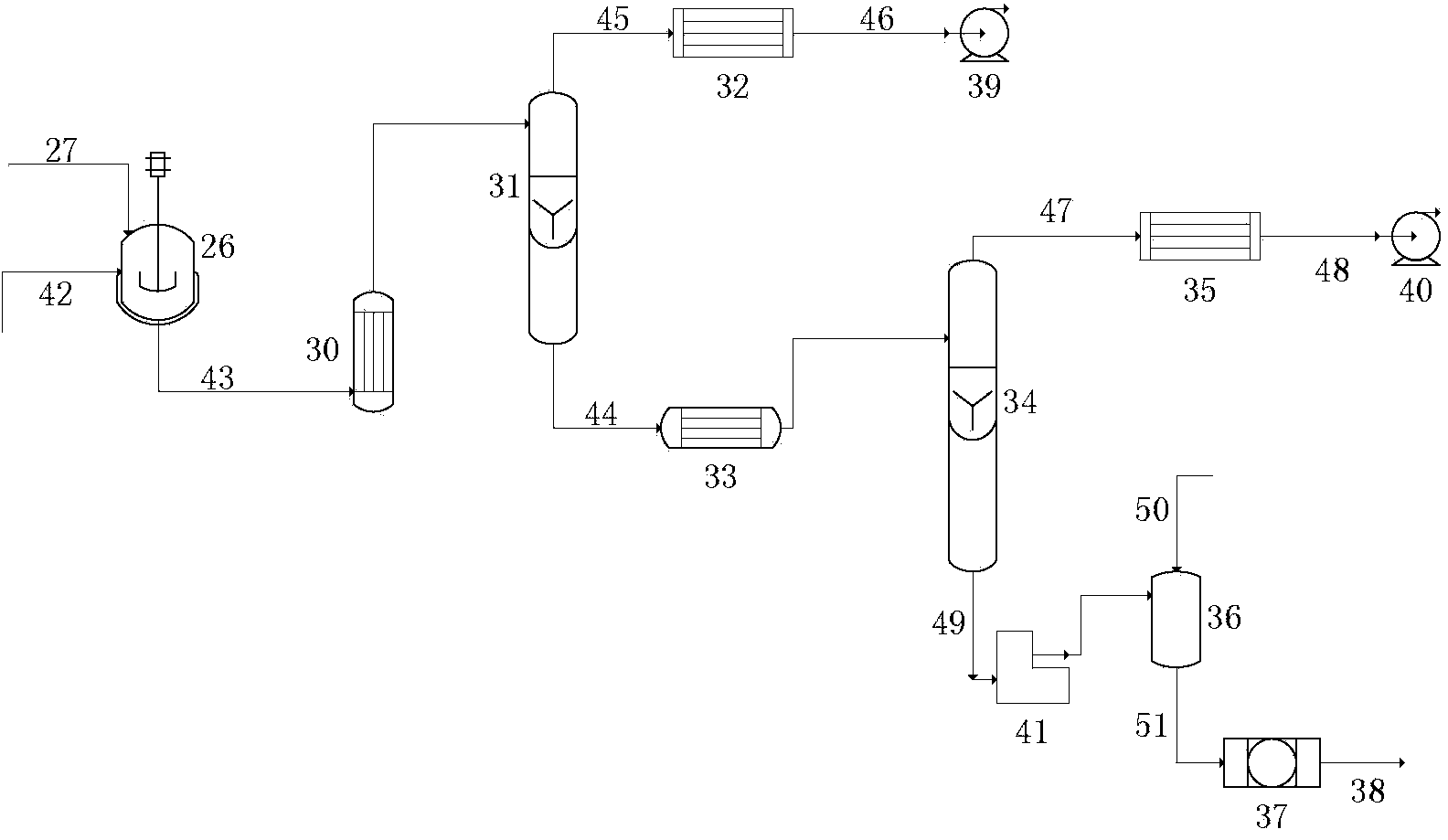

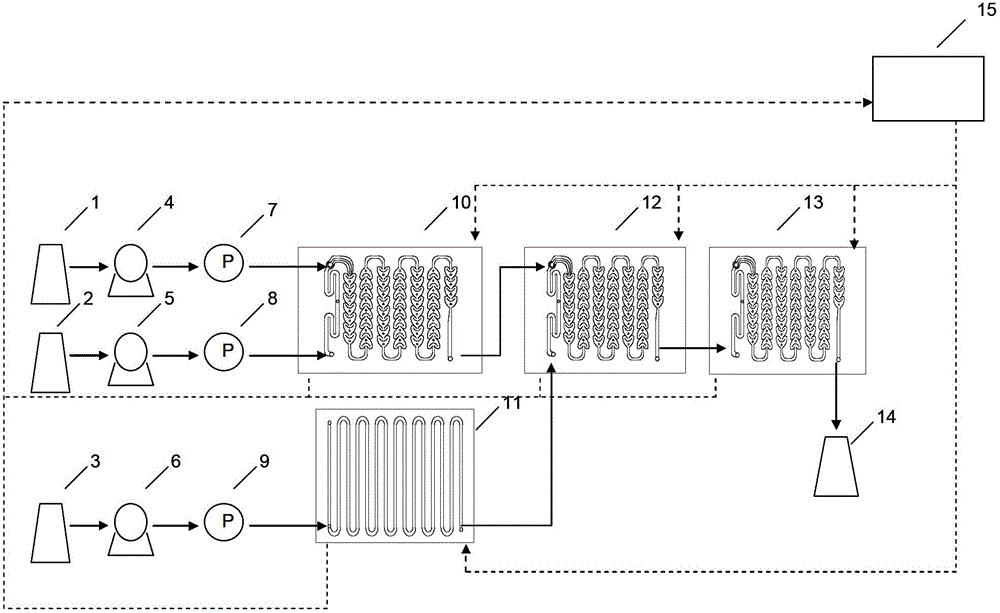

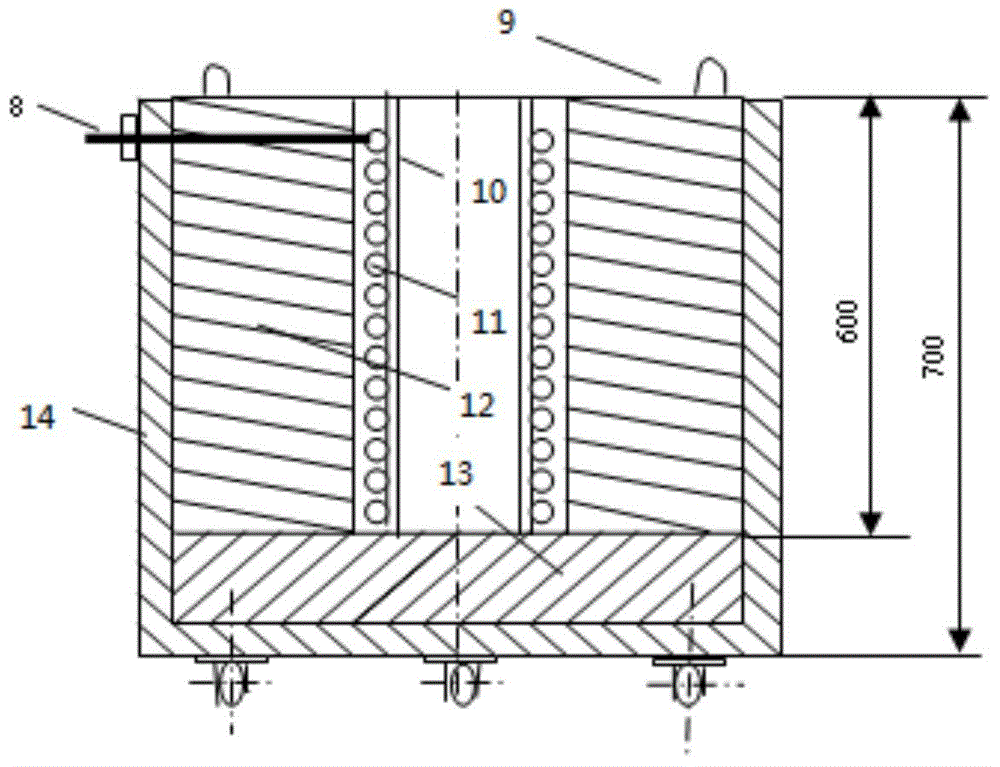

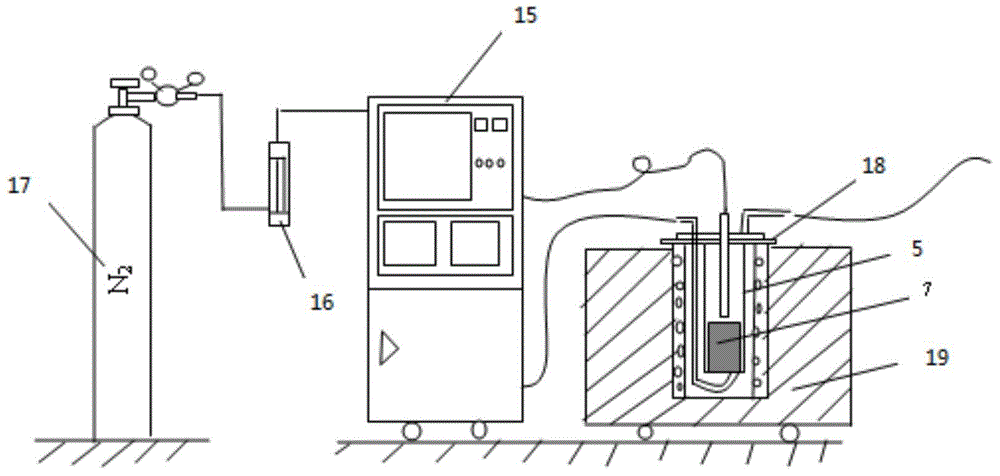

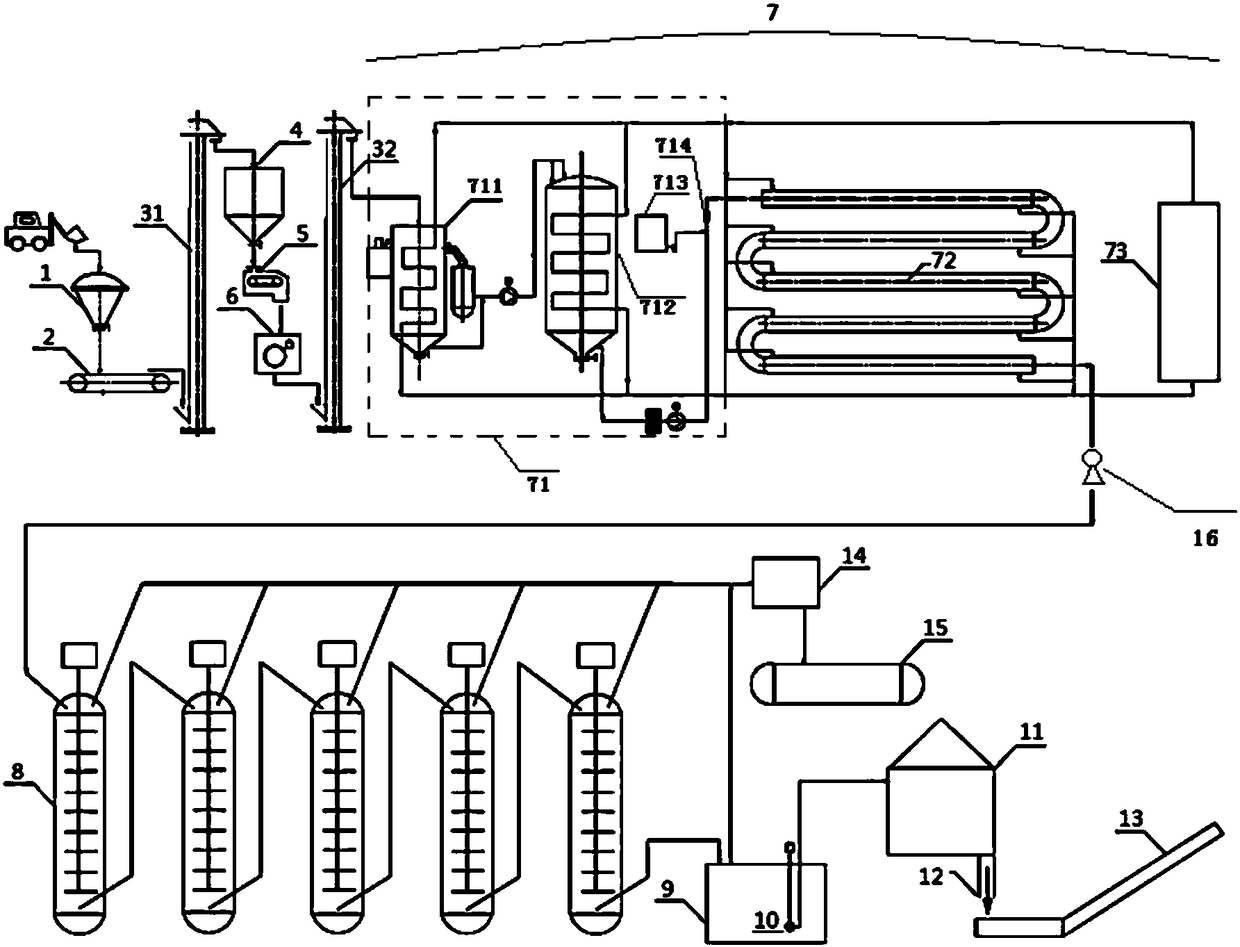

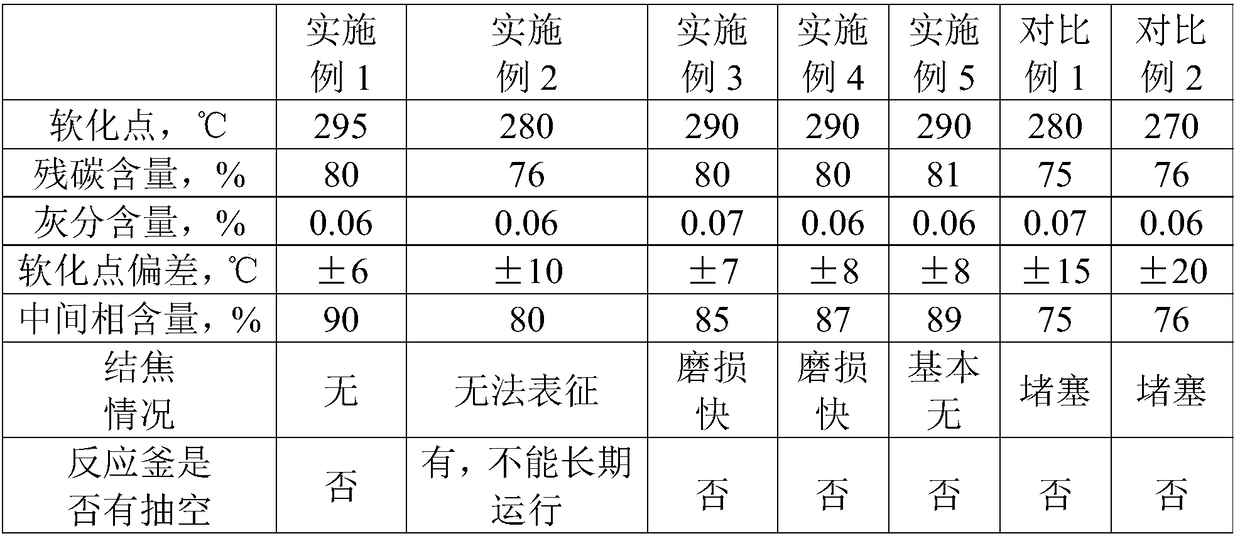

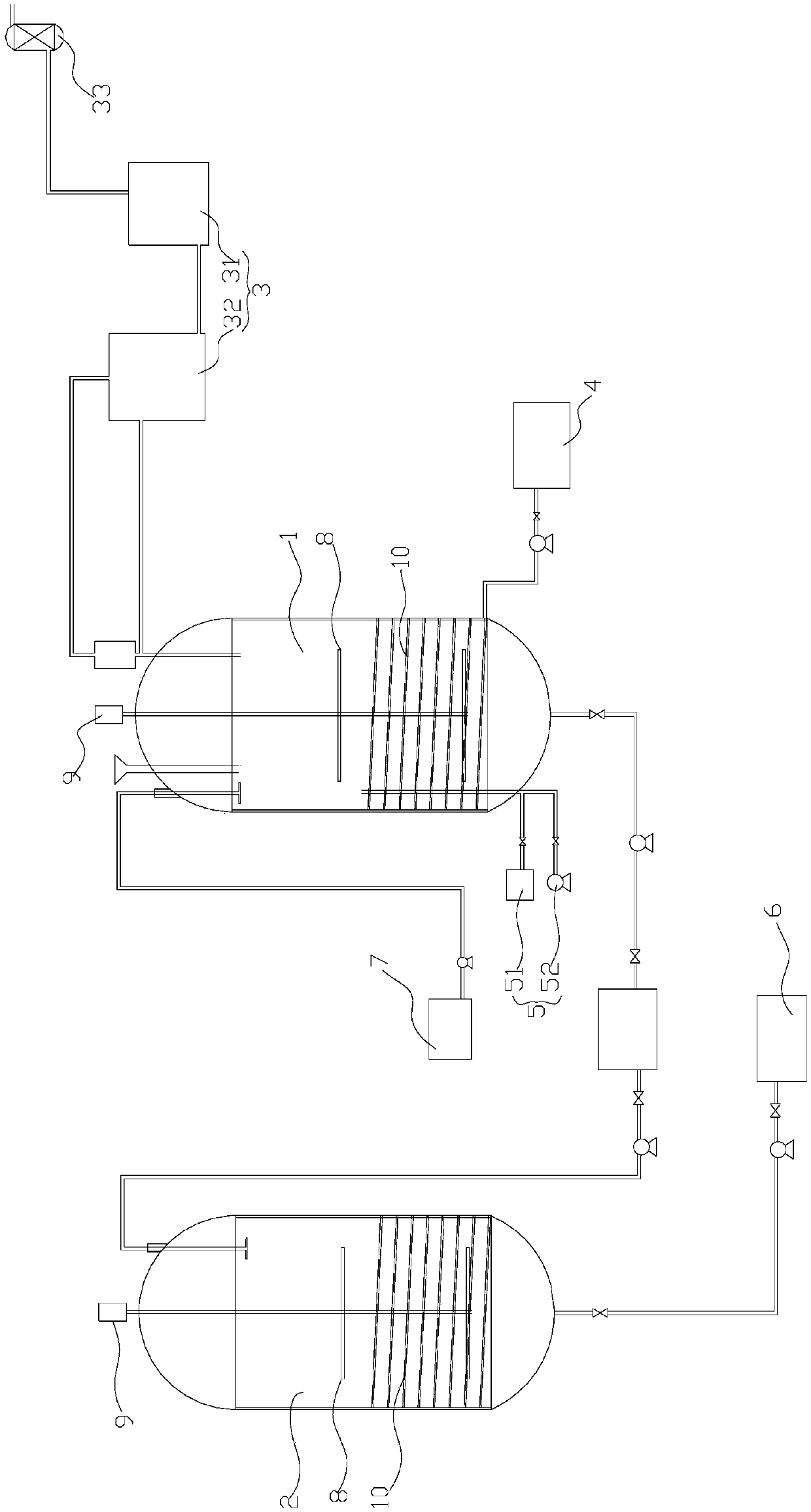

Mesophase pitch, and continuous production method and system thereof

ActiveCN108219813AShort reaction residence timeReduce in quantityWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by meltingProcess engineeringContinuous production

The invention relates to the field of mesophase pitch production, and discloses mesophase pitch, and a continuous production method and a continuous production system thereof. The system comprises a continuous heating feeding system (7) and a pitch polymerization reaction system (8) at downstream of the continuous heating feeding system (7); a discharging port of the continuous heating feeding system is connected with a feeding port of the pitch polymerization reaction system; the continuous heating feeding system comprises a pitch melting unit (71) and a pitch heating unit (72); the pitch polymerization reaction system comprises two to eight stages of reaction kettles which are connected in series and at least one stage of standby reaction kettle; the pitch heating unit comprises spaces for holding pitch and molten salt respectively. The method comprises the following steps: melting pitch; heating to a preset temperature to form pitch melt; adding the pitch melt into the pitch polymerization reaction system to perform contact reaction; heating the molten pitch through the molten salt, wherein the polymerization reaction system comprises two to eight stages of reaction kettles which are connected in series and at least one stage of standby reaction kettle. The produced mesophase pitch is high in quality controllability, uniform in softening point and high in stability; continuous production can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

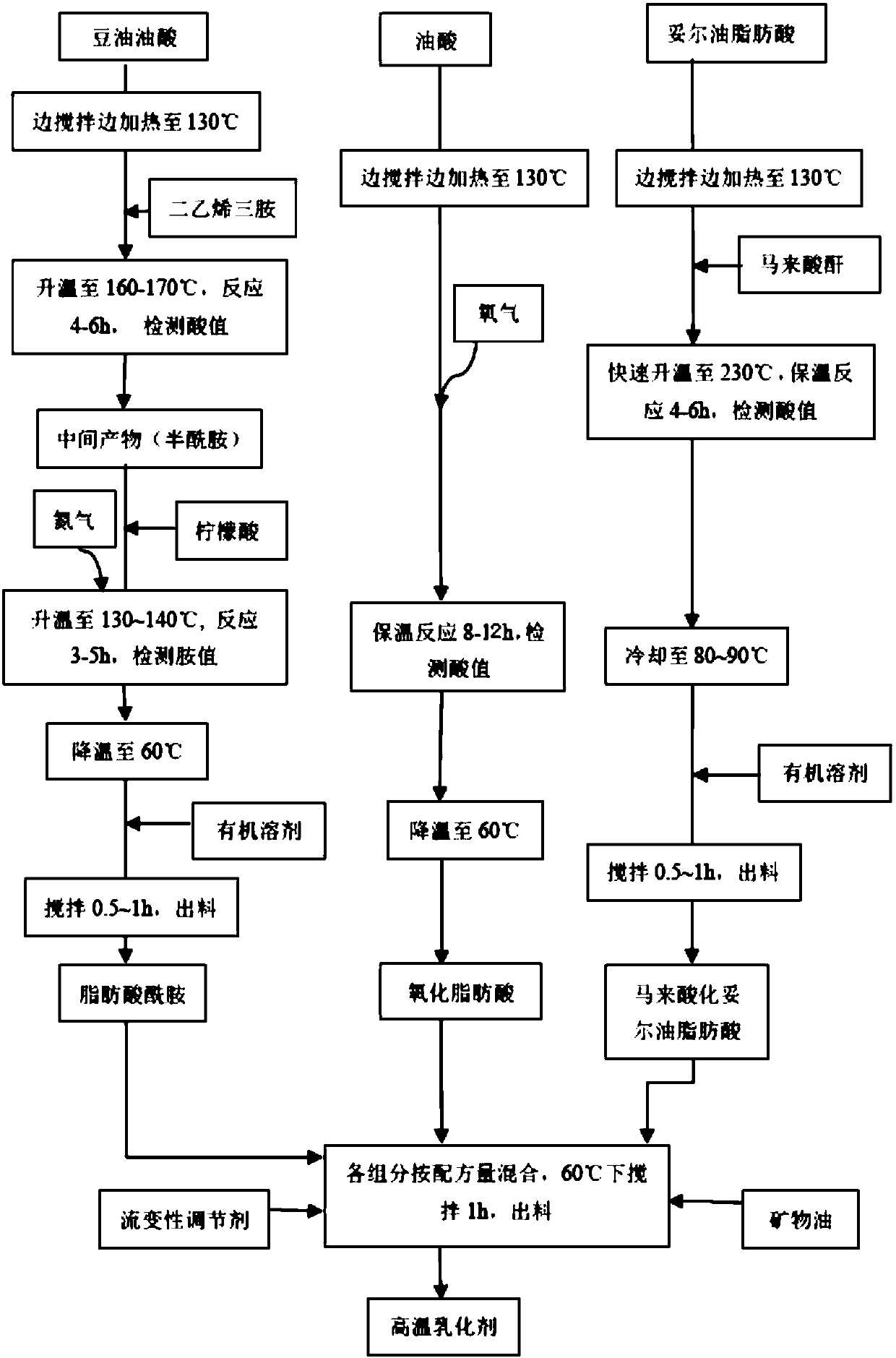

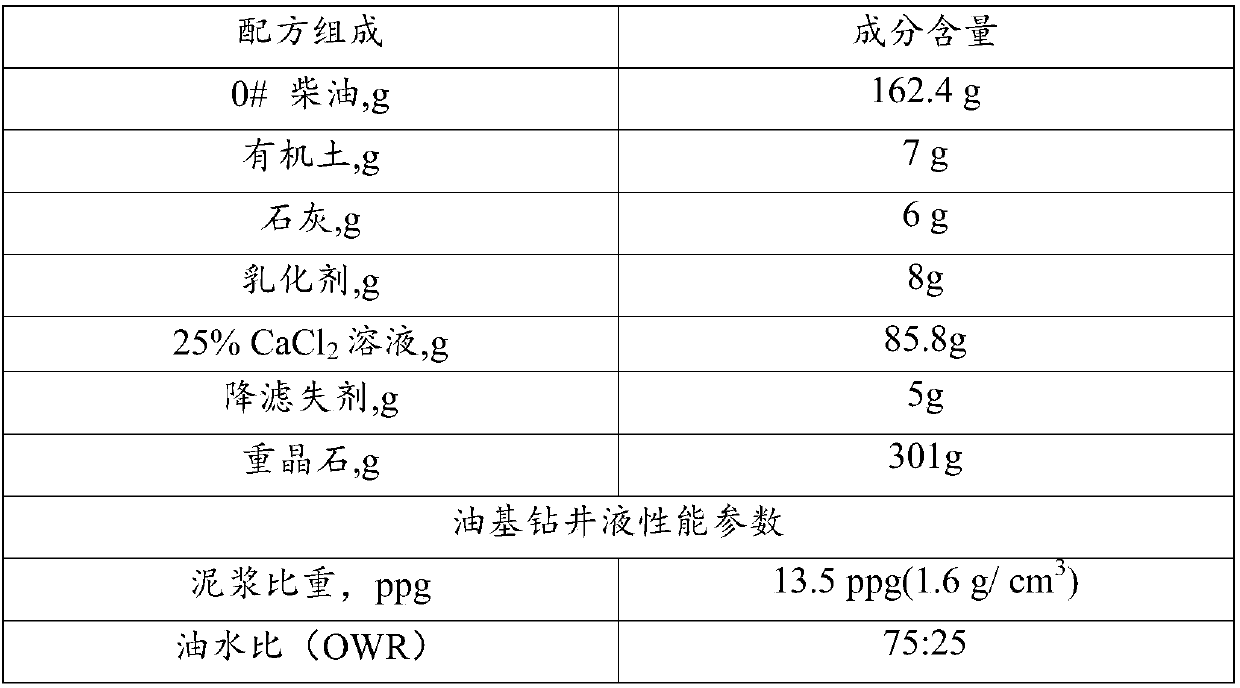

High-temperature emulsifier applied to oil-based drilling fluids and preparation method of high-temperature emulsifier

PendingCN107828391AReduce the number of additionsReduce the amount addedDrilling compositionPetroleum oilMineral oil

The invention discloses a high-temperature emulsifier applied to oil-based drilling fluids and a preparation method of the high-temperature emulsifier, and belongs to the technical field of petroleumdrilling fluids. The high-temperature emulsifier comprises, by mass, 10-45% of fatty acid amide, 30-60% of oxidized fatty acid, 10-30% of Malay acidized tall oil fatty acid, 5-20% of rheological property regulators and 10-30% of mineral oil. The total percentage of the raw materials is 100%. The preparation method includes mixing the fatty acid amide with the oxidized fatty acid, the Malay acidized tall oil fatty acid, the rheological property regulators and the mineral oil, stirring the raw materials at the temperature of 60 DEG C for 1-2 hours of reaction, and discharging the mixture to obtain the high-temperature emulsifier. The high-temperature emulsifier has the advantages of high temperature resistance, high demulsification voltage, low filter loss, capability of stabilizing a drilling fluid system, low adding amount, convenience and effectiveness in use, convenience in popularization and application, and the like. The preparation method has the advantages of simple procedure andstep, convenience in production and greatly reduced production cost.

Owner:联技精细材料(珠海)有限公司

Method for continuous industrial production of coal gas by multi-chamber microwave heating

InactiveCN102585912APrecise control of reaction temperatureEasy maintenanceCombustible gas productionWater vaporProcess engineering

The invention relates to a method for continuous industrial production of coal gas by multi-chamber microwave heating. Pyrolysis chambers and gasification chambers are separated to be independent chambers, each gasification chamber is provided and connected with at least one pyrolysis chamber, and the pyrolysis chambers and the gasification chambers produce pyrolytic coal gas and gasified coal gas; the heat energy required by reactions of the pyrolysis chambers and the gasification chambers is provided by microwave energy, and the microwave power is adjustable; a raw material pushing device used in the production process comprises a semi-coke pushing device, a coal ash delivering device, a coal ash pushing device, all adopting a spiral pushing structure; the spiral pushing devices adopt speed control by frequency variation, and controls the entire reaction progress and reaction speed; and pyrolytic coal gas is used for conducting secondary heating of water vapor, and the water vapor is reheated to a temperature higher than 600 DEG C. The method provided by the invention can realize low requirements on raw materials, simple equipment, easiness in operation, continuous production of pure coal gas, and accuracy in control of coal gas components.

Owner:王俊

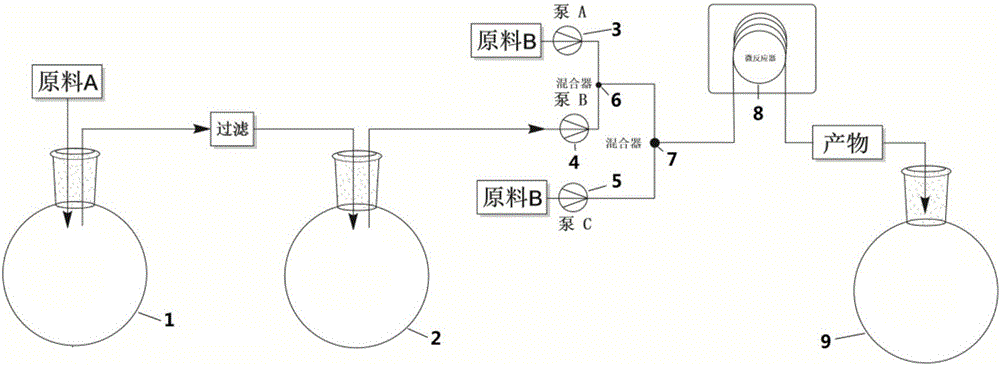

Method for preparing rifampicin by utilizing cascade reaction of kettle type reaction device and microchannel reaction device

InactiveCN106632394ASave heatLow costOrganic chemistryChemical/physical/physico-chemical microreactorsSodium saltPiperazine

The invention provides a method for preparing rifampicin by utilizing cascade reaction of a kettle type reaction device and a microchannel reaction device. In the kettle type reaction device, rifamycin S sodium salt is used as a raw material to obtain N-tedin-1,3-oxazine (5,6-C) rifamycin through reaction, and the N-tedin-1,3-oxazine (5,6-C) rifamycin reacts with 1-methyl-4-amino-piperazine in the microchannel reaction device to obtain the rifampicin. Continuous production of the rifampin is achieved, the product quality is good, the cost is low, the profit is high, and the method is green, environmentally friendly, capable of saving energy, efficient and suitable for industrial application.

Owner:NANJING UNIV OF TECH

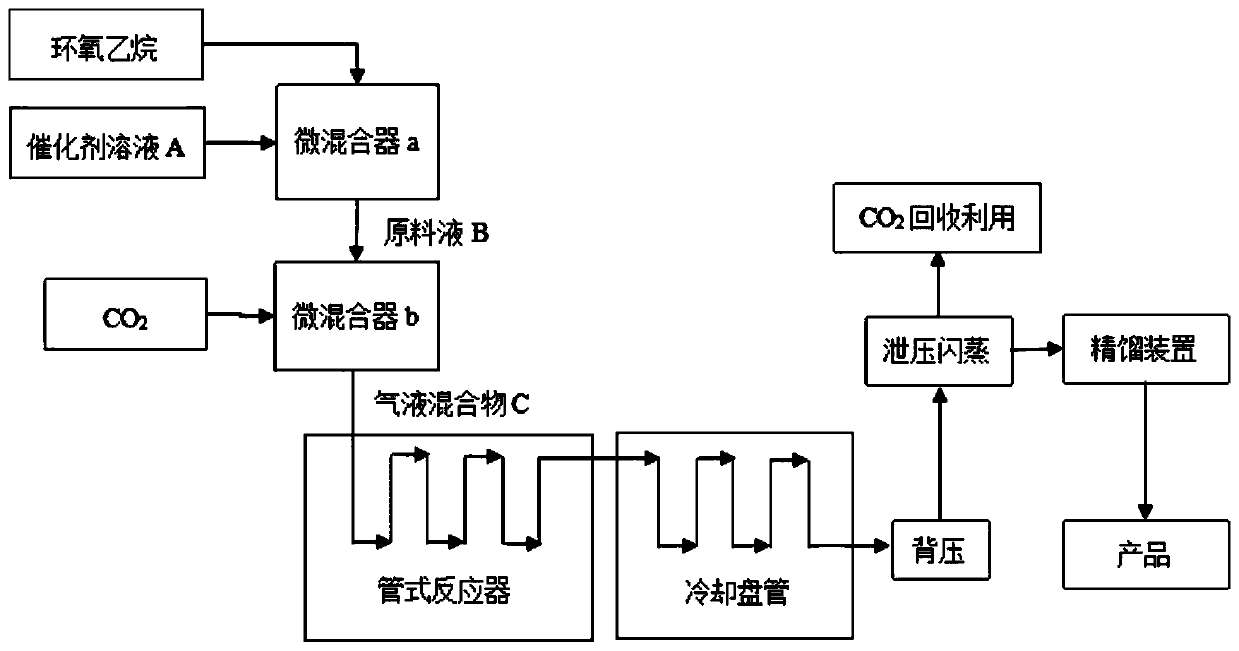

Method for continuously preparing ethylene carbonate

The invention relates to a method for continuously preparing ethylene carbonate. The method comprises the following steps: (1) mixing ethylene carbonate with a catalyst and water to obtain a catalystsolution A; (2) introducing CO2 into a reaction system, and performing back pressure regulation on the pressure of the reaction system to a required pressure by using a back pressure valve; (3) introducing the catalyst solution A and ethylene oxide into a micro-mixer, and quickly and uniformly mixing to obtain an ethylene oxide mixed solution B in which a catalyst is dissolved; (4) continuously introducing the mixed solution B and CO2 gas into a micro-mixer to obtain a gas-liquid mixture C, and enabling the gas-liquid mixture C to enter a tubular reactor for reaction; (5) introducing an obtained reaction liquid into a flash tank, and carrying out flash evaporation to separate out unreacted ethylene oxide, CO2 and water to obtain a primary product; and (6) rectifying the primary product obtained in the step (5) to obtain the product ethylene carbonate. The method is safe and efficient, and the reaction residence time is greatly shortened; the reaction efficiency is high, and the conversion rate of ethylene oxide is close to 100% in a short reaction residence time.

Owner:ZHEJIANG UNIV OF TECH

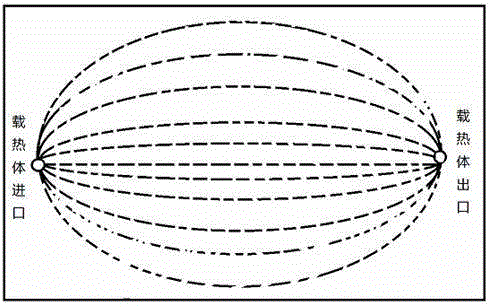

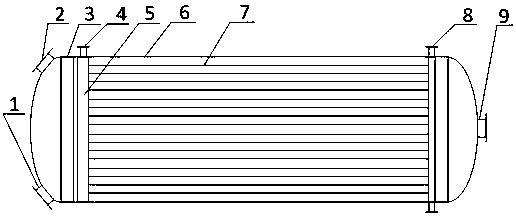

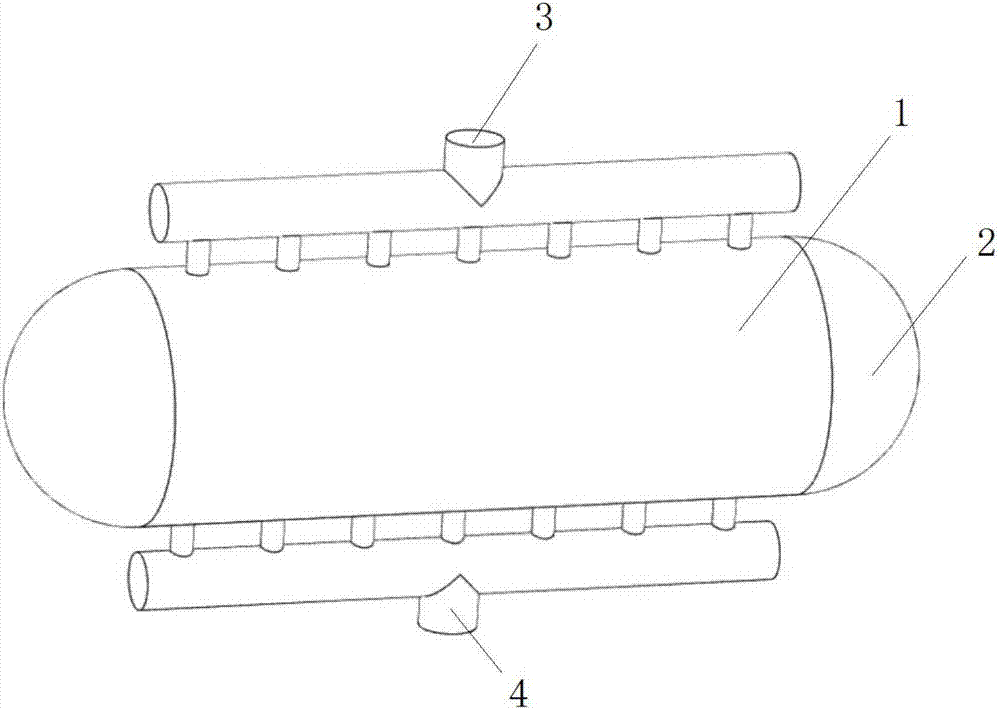

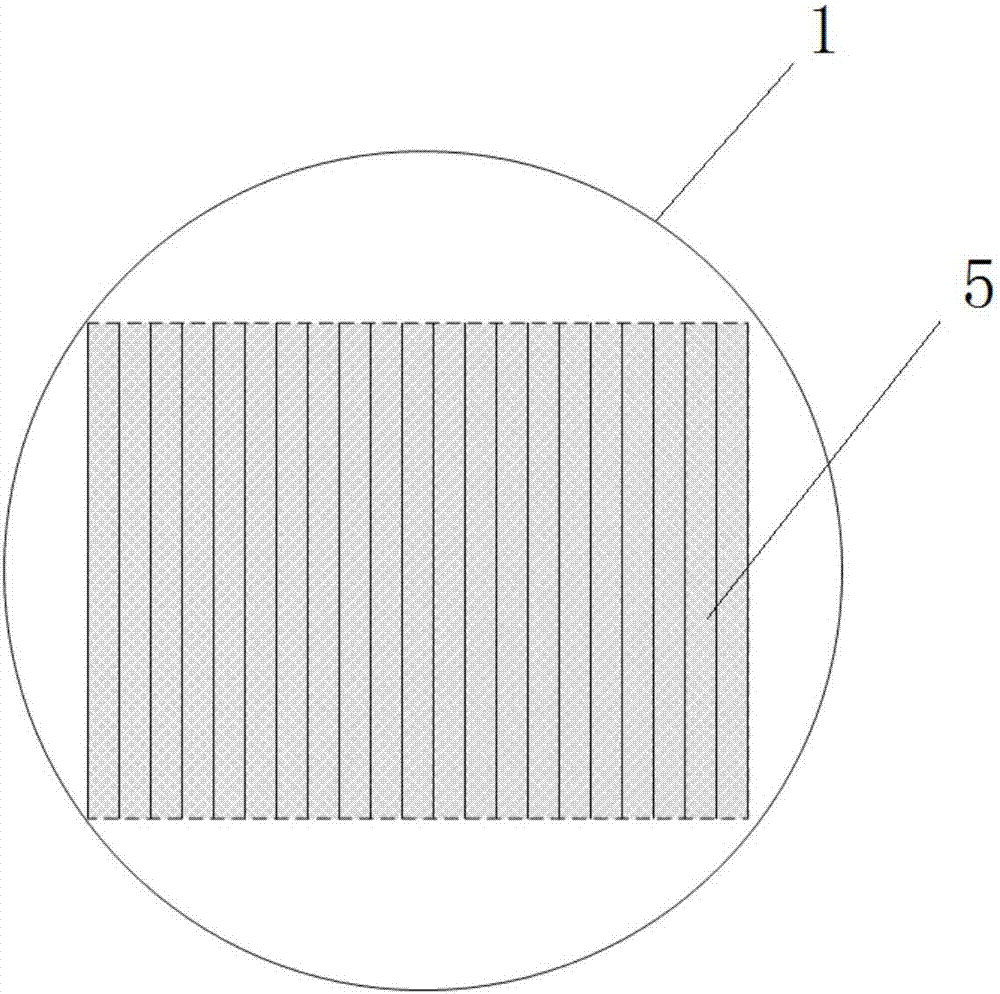

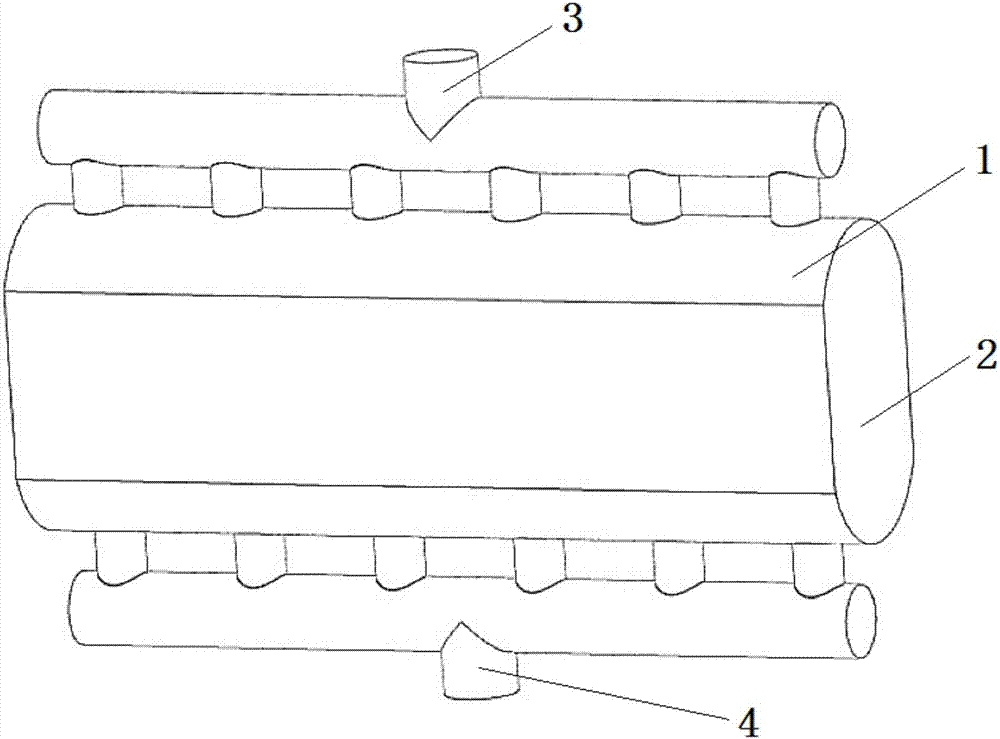

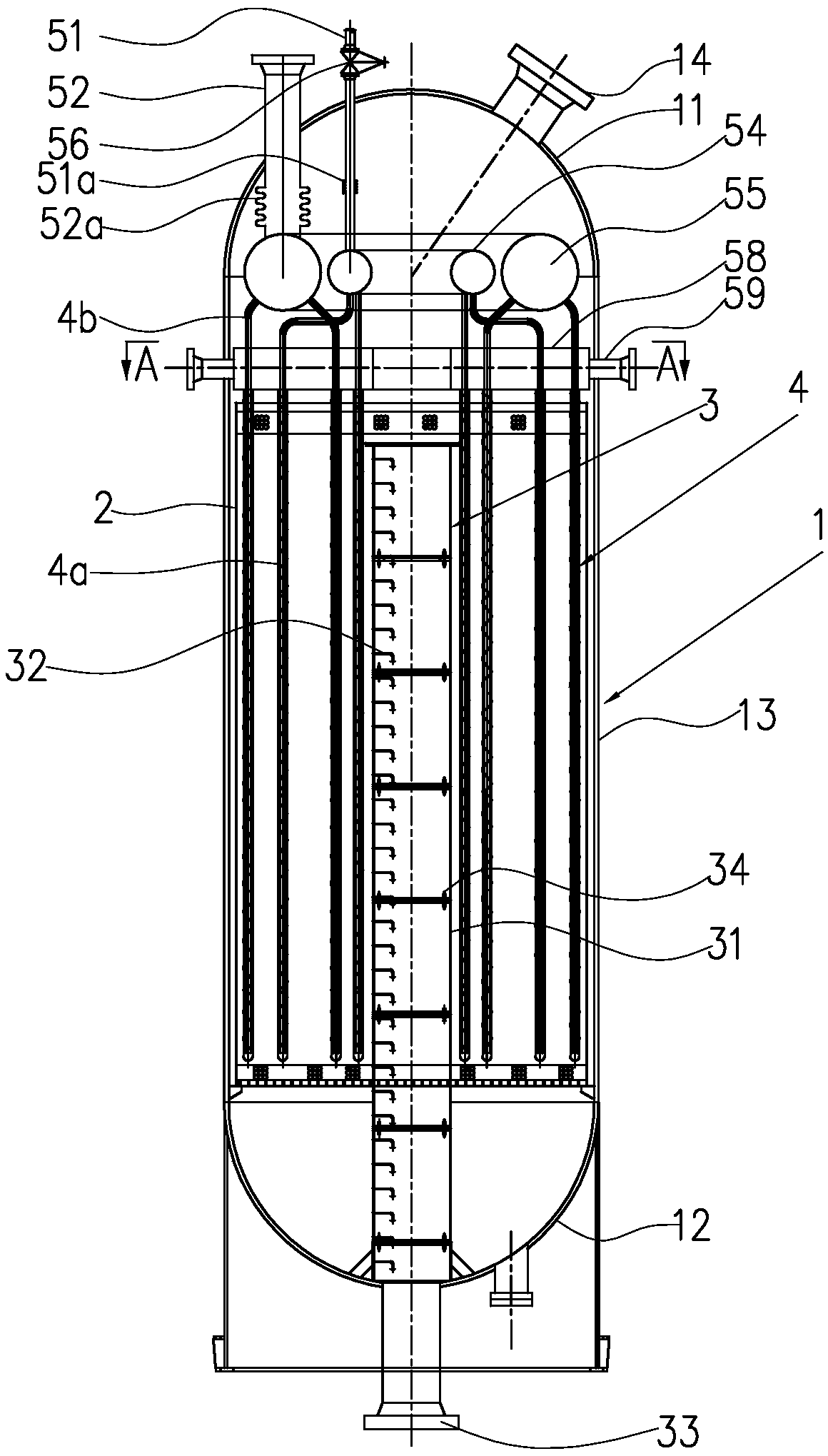

Temperature-controlled gas-liquid horizontal reactor with special distributor

PendingCN107243298AAccurate temperature controlPrecise control of reaction temperatureOrganic compound preparationCarboxylic acid esters preparationThermodynamicsPtru catalyst

The invention relates to a temperature-controlled gas-liquid horizontal reactor with a special distributor. The reactor comprises a shell body and a catalyst bed layer arranged inside the shell body, wherein the shell body is provided with a material inlet and a product outlet, a modular core assembly for heat exchange penetrates through the inside of the catalyst bed layer and consists of a plurality of plates which are arranged in parallel, and a gas distributor is arranged at the material inlet of the reactor. According to the reactor, heat exchange core assembly units penetrate through the catalyst bed layer, and the form of the modular core assembly is specifically arranged as required; cores are parallel and are adjustable in spacing, so that a reaction temperature can be accurately controlled, and the gas distribution is good; fluid is short in flow path, large in cross section and low in flow velocity, gas pressure drop is positively correlated to distance and flow velocity, the pressure drop is reduced, and the system energy consumption is lowered, so that the reactor is particularly applicable to working conditions of low operating pressure; and the horizontal reactor can realize a treatment scale, which is 3 to 5 times that of a common axial reactor, is large in treatment capacity and meets the requirements of large-scale production.

Owner:ATHCO ENG SHANGHAI CO LTD

Water-cooled reactor for methanol synthesis

ActiveCN109173936AAvoid increased wall thicknessAvoid increased drum wall thicknessOrganic compound preparationHydroxy compound preparationEngineeringMethanol

The invention relates to a water-cooled reactor for methanol synthesis. The reactor comprises a furnace body, and a catalyst frame and a synthetic gas collection tube which are arranged in the furnacebody; a plurality of heat exchange tubes are arranged in a catalyst bed, the synthetic gas collection tube is provided with a plurality of gas inlet holes communicated with the catalyst bed and the inner cavity of the synthetic gas collection tube, and the outlet of the synthetic gas collection tube is connected with a synthetic gas outlet; every heat exchange tube comprises an outer tube and aninner tube; the lower port of every outer tube is closed, the inner tube is inserted into the outer tube from the upper port of the outer tube, the lower port of the inner tube is close to the lower port of the outer tube and is communicated with the inner cavity of the outer tube, the upper port of the inner tube is connected with a boiler water pipeline, and the sidewall of every inner tube is provided with a plurality of through holes at intervals; a gap exists between the sidewall of the outer tube and the sidewall of the inner tube; and the upper ports of the outer tubes are connected with a steam collection tube.

Owner:SINOPEC NINGBO ENG +2

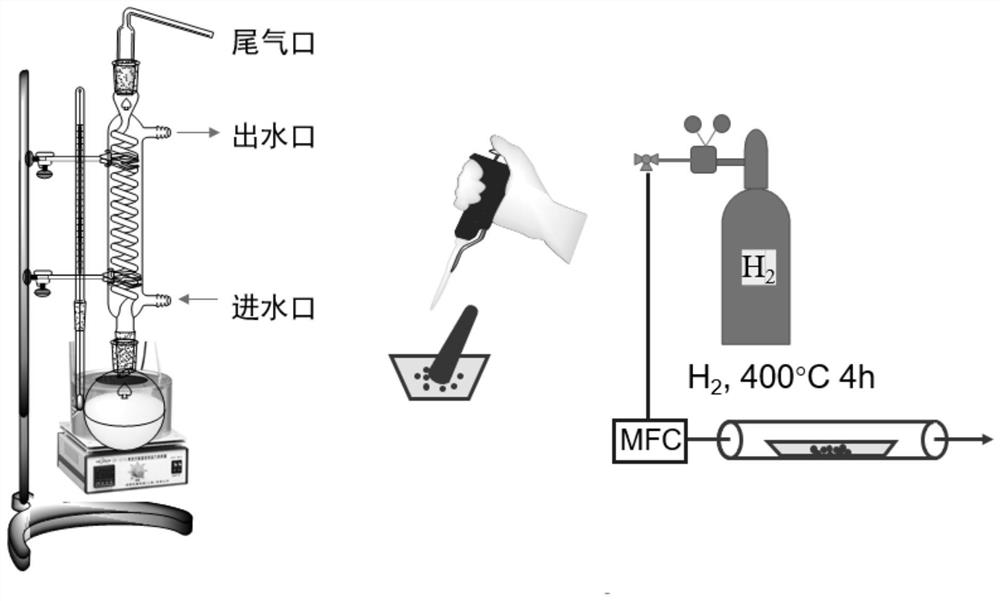

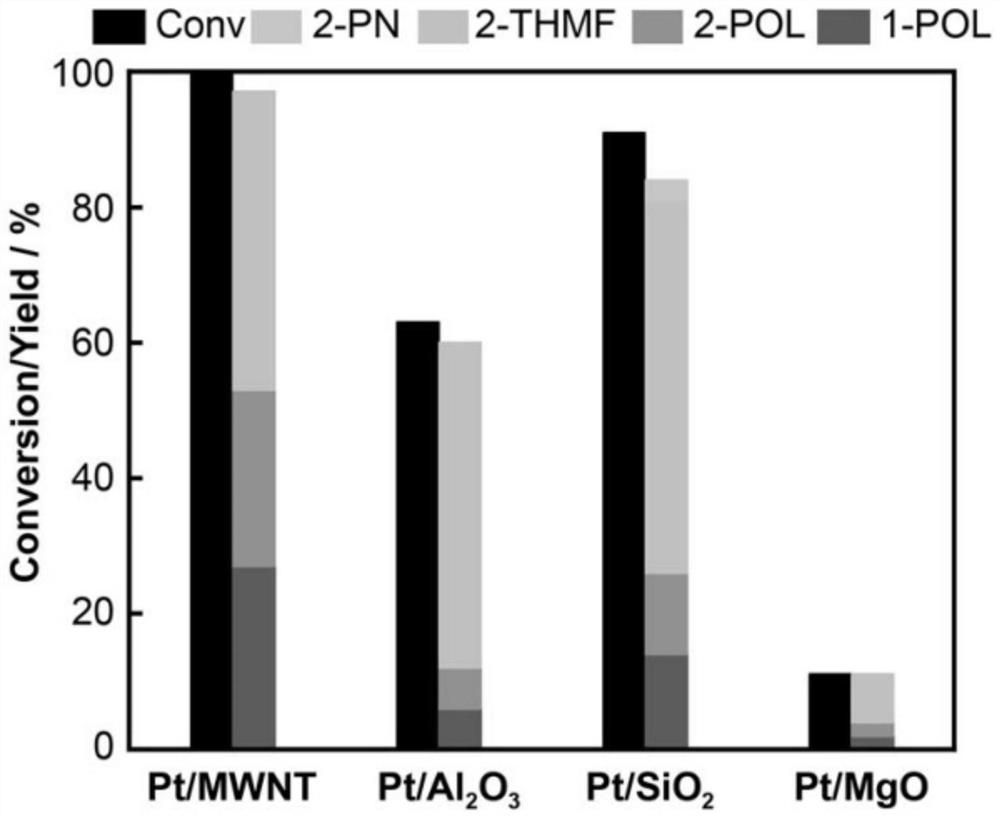

Method for preparing amyl alcohol from 2-methylfuran at room temperature by adopting supported catalyst

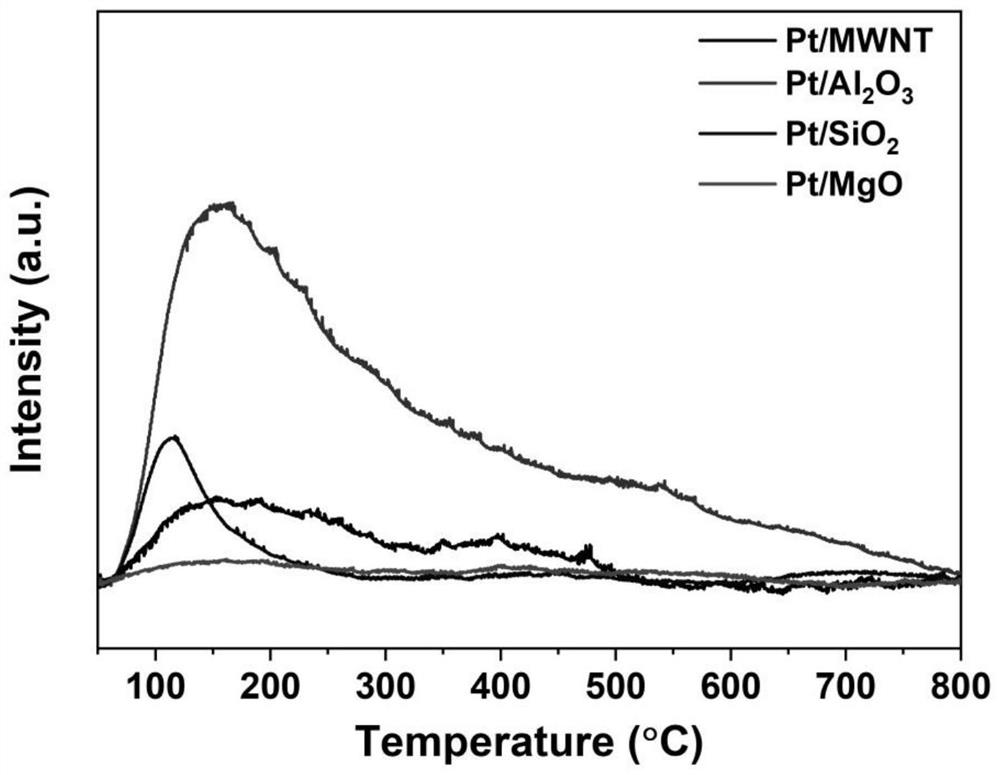

InactiveCN113754514AEasy to makeMild reaction conditionsOrganic compound preparationHydroxy compound preparationPtru catalystAmyl alcohol

The invention provides a method for preparing amyl alcohol from 2-methylfuran at room temperature by adopting a supported platinum-based catalyst. Influences of various catalyst carriers, active metals, metal loading capacity and reaction conditions (solvents, time, pressure and the like) are investigated. The acid treatment time of a 5 wt% Pt / MWNT catalyst on MWNT is 4 hours, the catalyst shows excellent activity and selectivity under the H2 pressure of 1 MPa and at the ultralow temperature of 25 DEG C, the 2-MF conversion rate is 100%, and the pentanol (POLs) yield is 53%. A brand new route is provided for synthesis of pentanol, and compared with a traditional synthesis process route, the process route is simple in preparation process, milder in reaction condition, capable of greatly reducing energy consumption and more environmentally friendly. The Pt / MWNT catalyst provided by the invention has good reusability, and shows wide potential in industrial application.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com