Method for preparing nano calcium carbonate by microreaction

A technology of nano-calcium carbonate and micro-reaction, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable continuous production, large equipment investment, complex reactor design, etc., to overcome uneven concentration distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

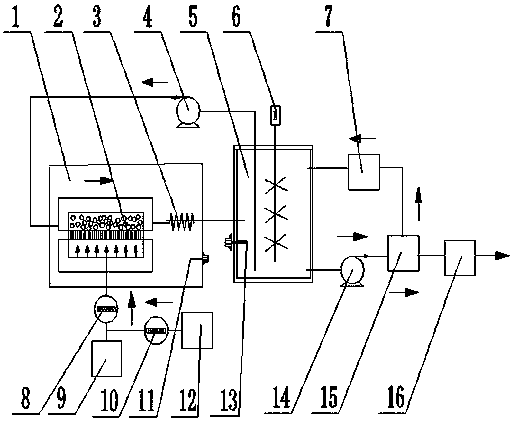

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0031] A preparation device for preparing nano-calcium carbonate by microreaction, such as figure 1 As shown, it consists of a constant temperature water tank 1, a microreactor 2, a temperature controller 3, an advection pump 4, a mixing tank 5, an agitator 6, a filtrate regenerator 7, a mixed gas flowmeter 8, a nitrogen storage tank 9, and a carbon dioxide flowmeter 10. A temperature sensor 11, a carbon dioxide storage tank 12, a pH value measuring instrument 13, a feeding pump 14, a washing filter 15, a dryer 16 and corresponding connecting pipes.

[0032] A method for preparing nano-calcium carbonate by micro-reaction, using figure 1 The preparation process shown:

[0033] (1) The reaction system is CO with a volume fraction of 30% 2 -N 2 Mixed gas and mass percent concentration of 15% to 35% Ca(OH) 2 The suspension reacts in the microreactor 2;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com