Patents

Literature

171results about How to "Avoid local high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of light-colored polyisocyanate curing agent

ActiveCN103881050AIncreased contact areaUniform on a microscopic scalePolyurea/polyurethane coatingsAlcoholLiquid state

The invention relates to a preparation method of a light-colored polyisocyanate curing agent. The preparation method comprises the following steps: (a) purifying a raw material-trimethylolpropane to obtain trimethylolpropane with the carbonyl compound content lower than 0.1wt%; (b) reacting trimethylolpropane with the carbonyl compound content lower than 0.1wt% or a mixture of trimethylolpropane with the carbonyl compound content lower than 0.1wt% and micromolecular dihydric alcohol with excess diisocyanate in a reactor with a conical liquid distribution plate to obtain a liquid-state prepolymer reaction solution containing excess diisocyanate; and (c) removing monomers from the prepolymer reaction solution obtained in the step (b) by adopting a two-stage film evaporator, and diluting by a solvent to obtain the curing agent with the diisocyanate monomer content lower than 0.5wt%. The color number of the diisocyanate curing agent prepared based on the method can be lower than 20Hazen.

Owner:WANHUA CHEM GUANGDONG

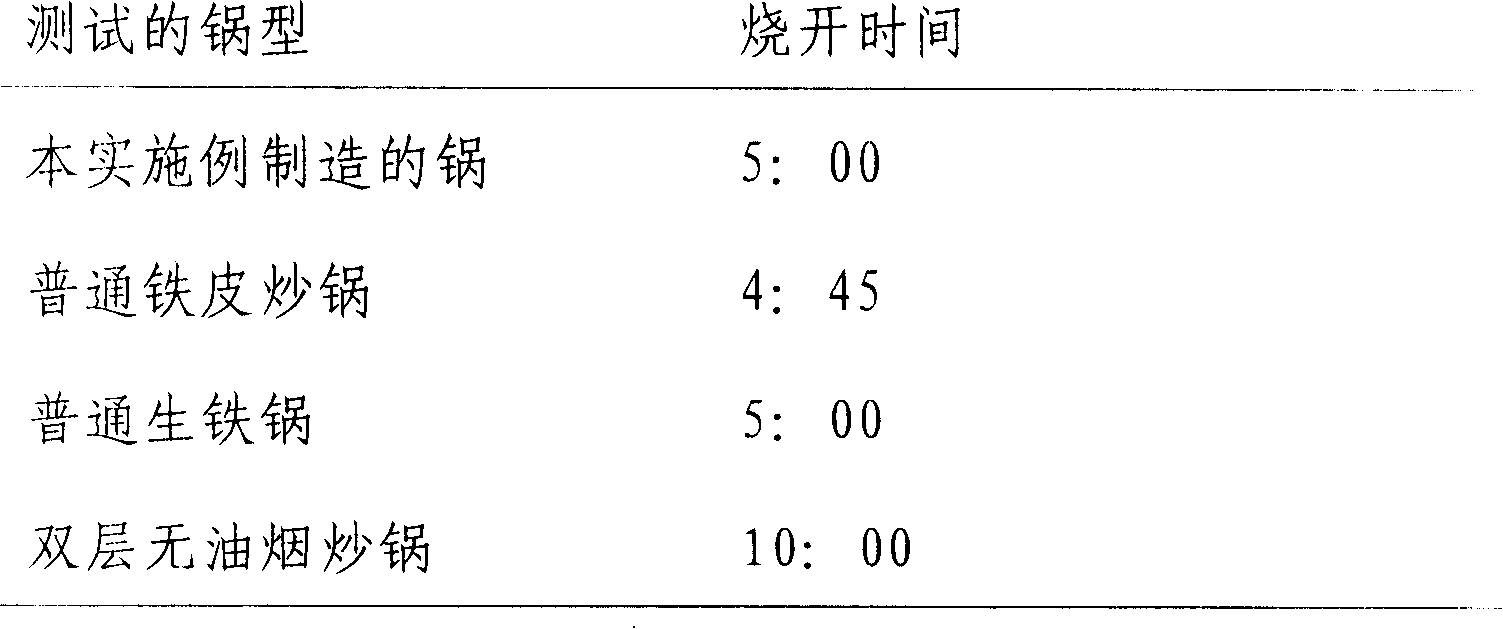

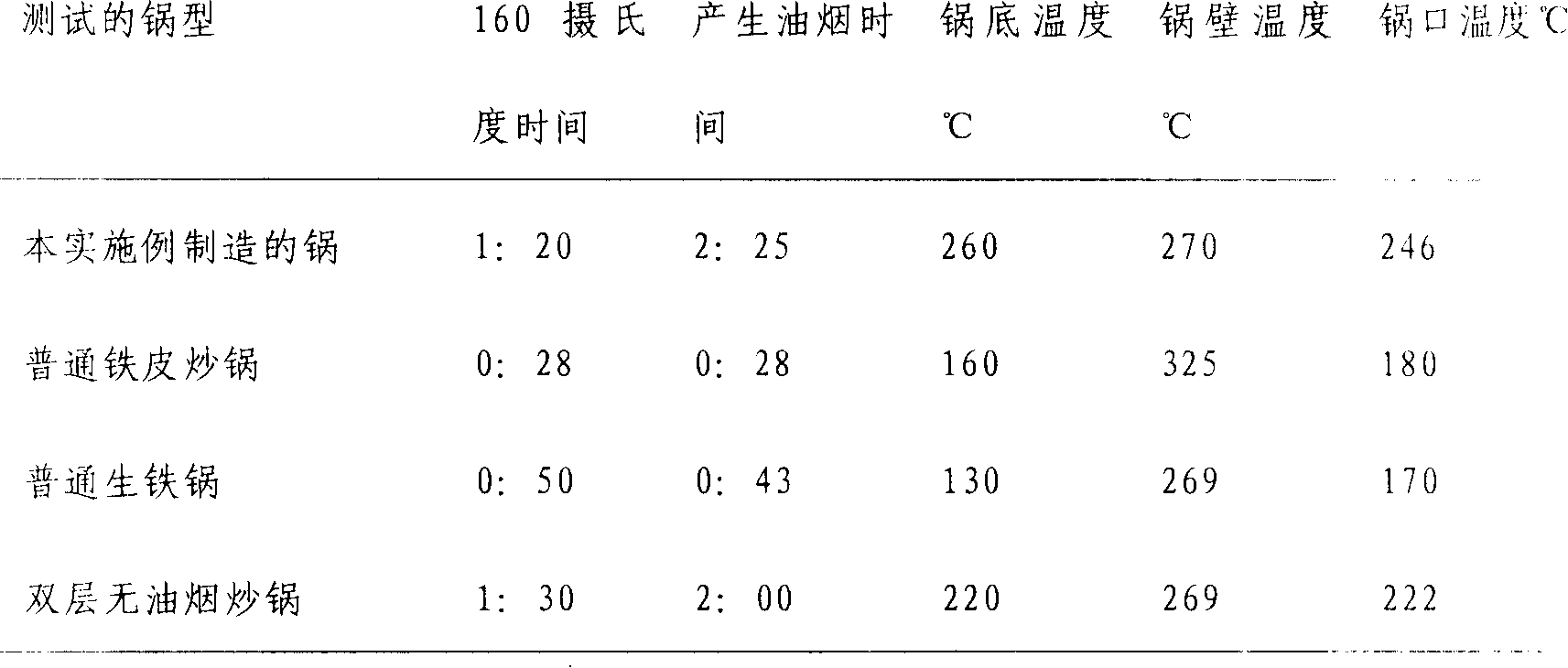

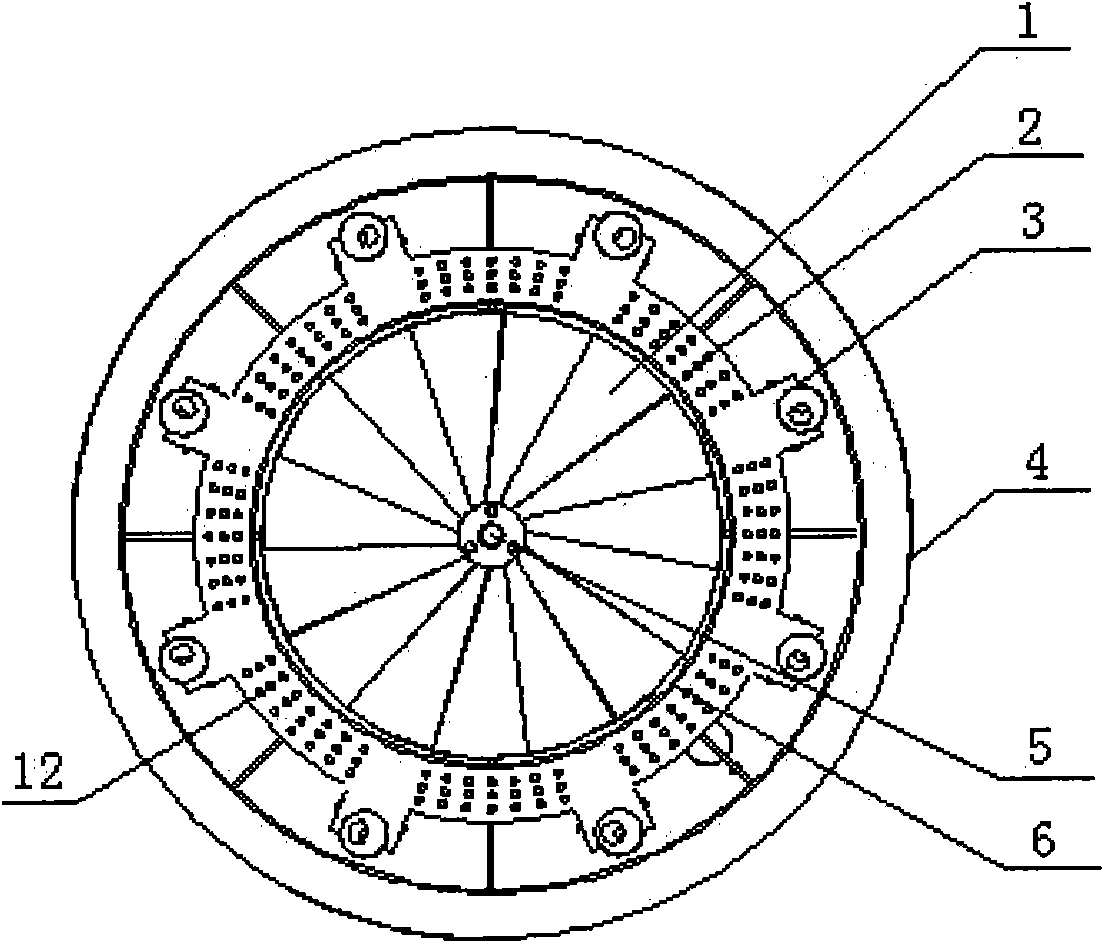

Zisha ware ceramal non-cooking fume non-stick pan and preparation method thereof

InactiveCN101190097AGood non-stickAvoid direct contactCooking-vessel materialsHardnessWear resistance

The invention relates to a purple clay pottery alloy non-stick cookware without oil smoke and a preparation method thereof. The purple clay pottery alloy non-stick cookware without oil smoke comprises a cookware body and a cookware handle, wherein, the cookware body takes aluminium alloy as a substrate, the outer surface of the substrate of the cookware body is provided with a pottery crystal layer, and the inner surface of the substrate is provided with a purple clay pottery layer. The purple clay pottery alloy non-stick cookware without oil smoke of the invention consists of the non-stick purple clay pottery layer, the substrate of the cookware body and the pottery crystal layer, so the cookware is heated uniformly and does not generate partial high temperature when in use, thus generating no oil smoke when cooking dishes; in addition, the purple clay pottery layer avoids the direct contact between food and the aluminium alloy substrate, and improves surface hardness considerably, thus leading the cookware body to have more wear resistance and adhesion resistance, resist high temperature and be safe and non-toxic to the human body.

Owner:胡金高

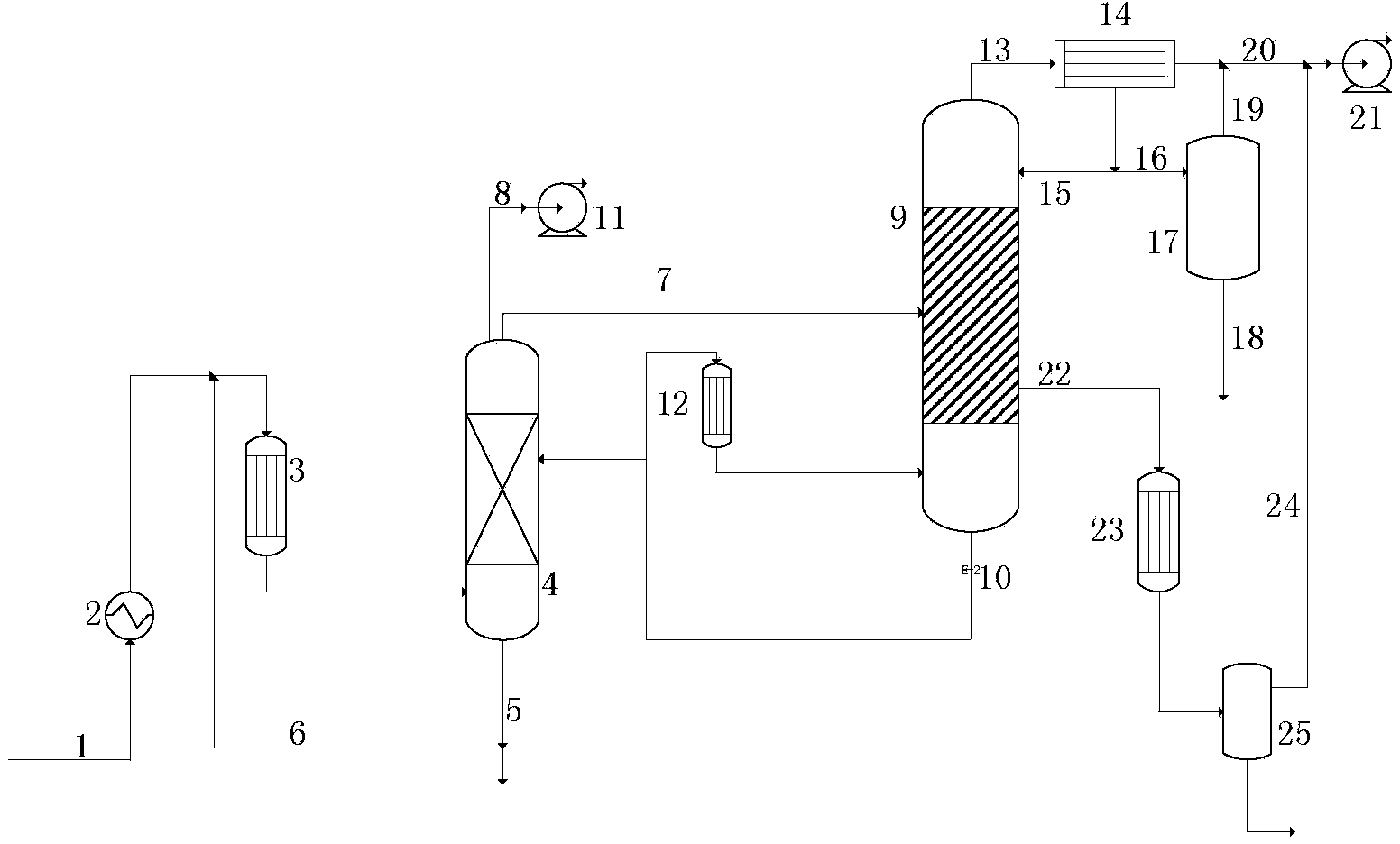

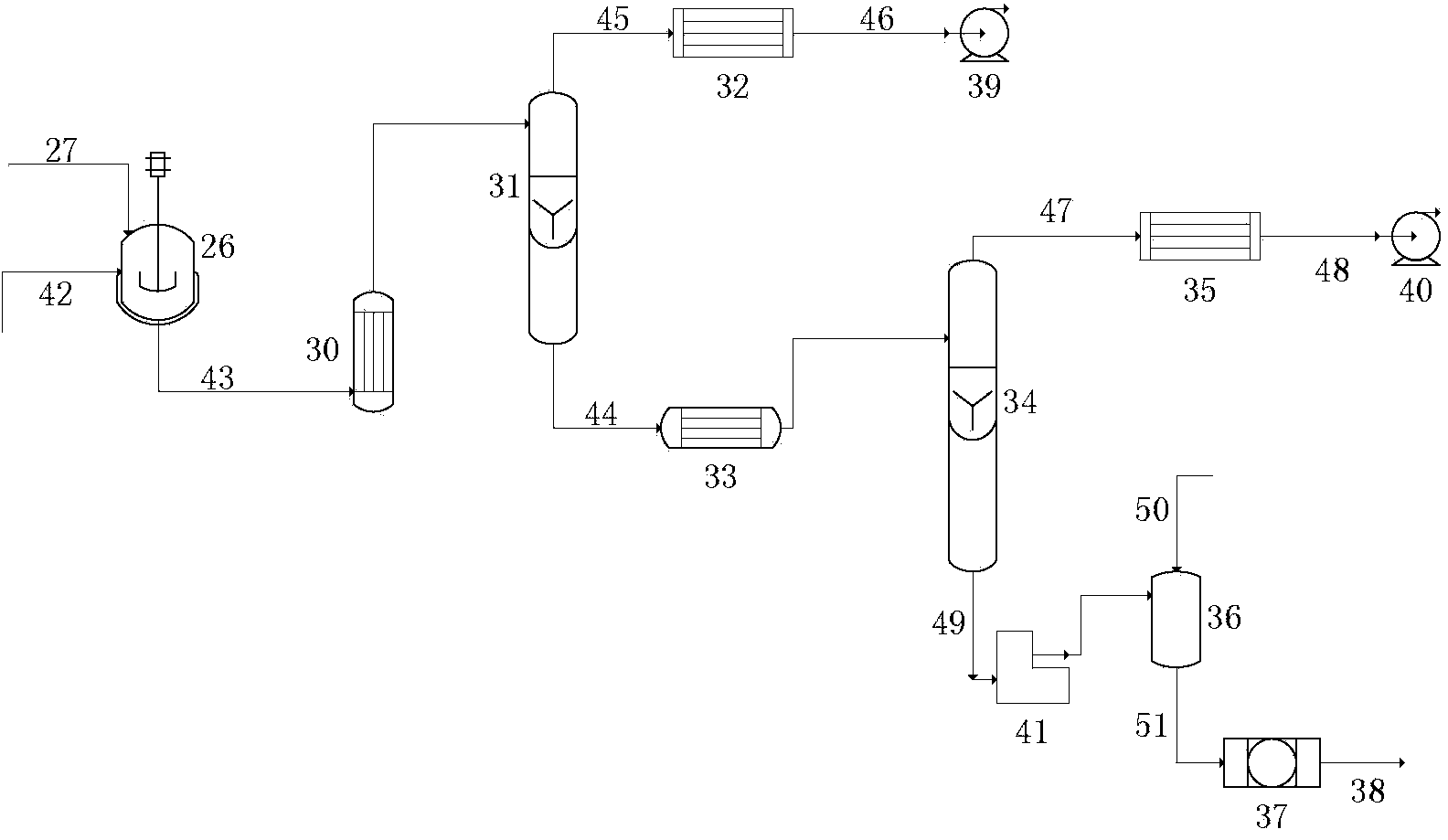

Automatic continuous production process for producing diesel oil with waste oil through catalytic cracking method

InactiveCN102585896AGuaranteed uniformitySolve the problem of not being able to feedTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionWaste oilFuel oil

The invention relates to the technical field of waste oil comprehensive utilization and fuel oil processing, particularly to an automatic continuous production process for producing diesel oil with waste oil through a catalytic cracking method. The production process comprises the following process steps: 1, the waste oil is pretreated; 2, the pretreated waste oil is subjected to hot cracking and catalytic cracking, so as to obtain crude oil, wherein the catalytic cracking comprises liquid-phase catalysis and gas-phase catalysis; 3, the crude oil is fractionated; and 4, the finished product is obtained through refining and filtering. The invention has the advantages that gelatine, asphaltene, sulfide, oxide, unsaturated hydrocarbon and the like can be well removed, so that the finished oil is clear and transparent, has a pure smell, and cannot deteriorate after being stored for a long time; viscosity and pipeline blockage are avoided in the production process, the production process is simple, the conditions are easy to control, the investment is low, the results are quick, the efficiency is high, the use is simple, and the operation is convenient.

Owner:HANGZHOU LVHUI ENERGY TECH

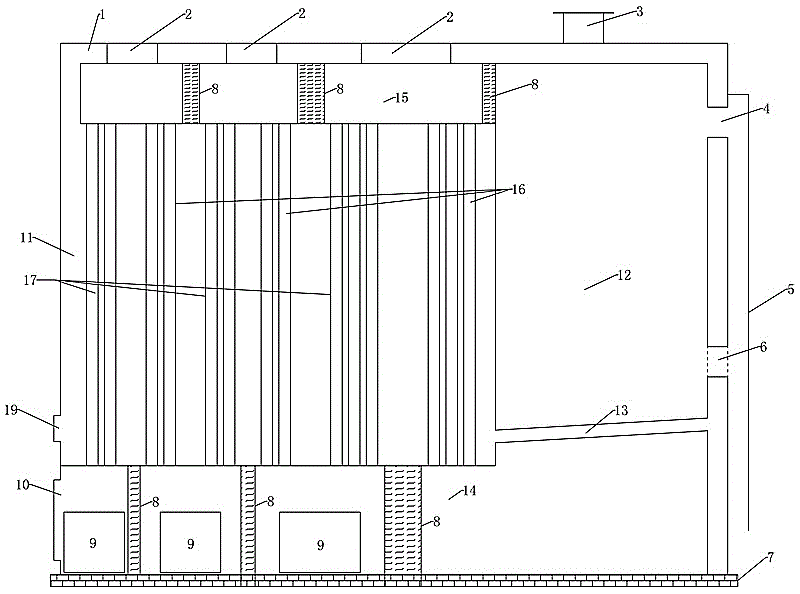

Low-NOx combustor with internal reflux of flue gas and homogeneous combustion and gas configuration method thereof

ActiveCN102012025AReduce generationAvoid local high temperatureGaseous fuel burnerIndustrial gasCombustor

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

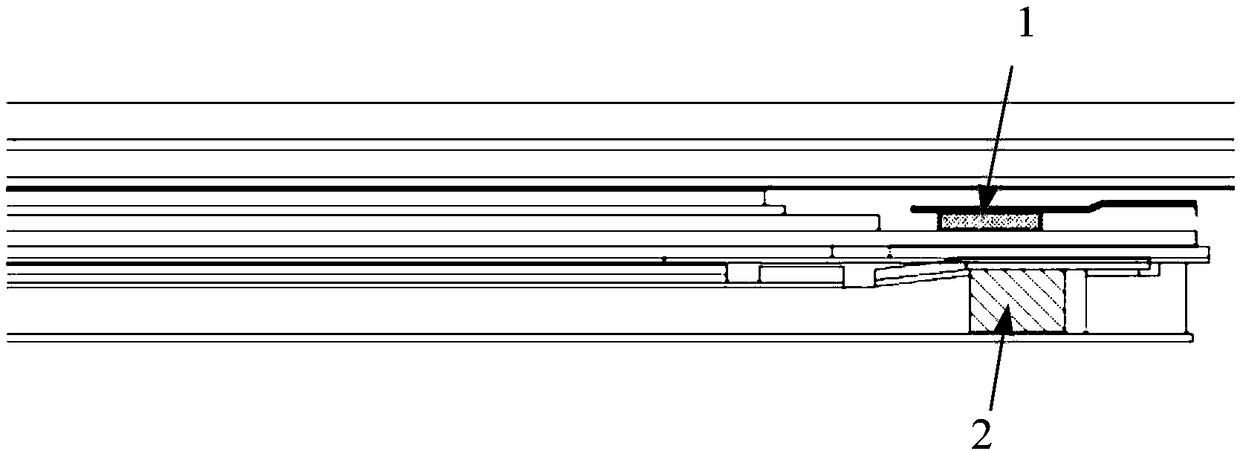

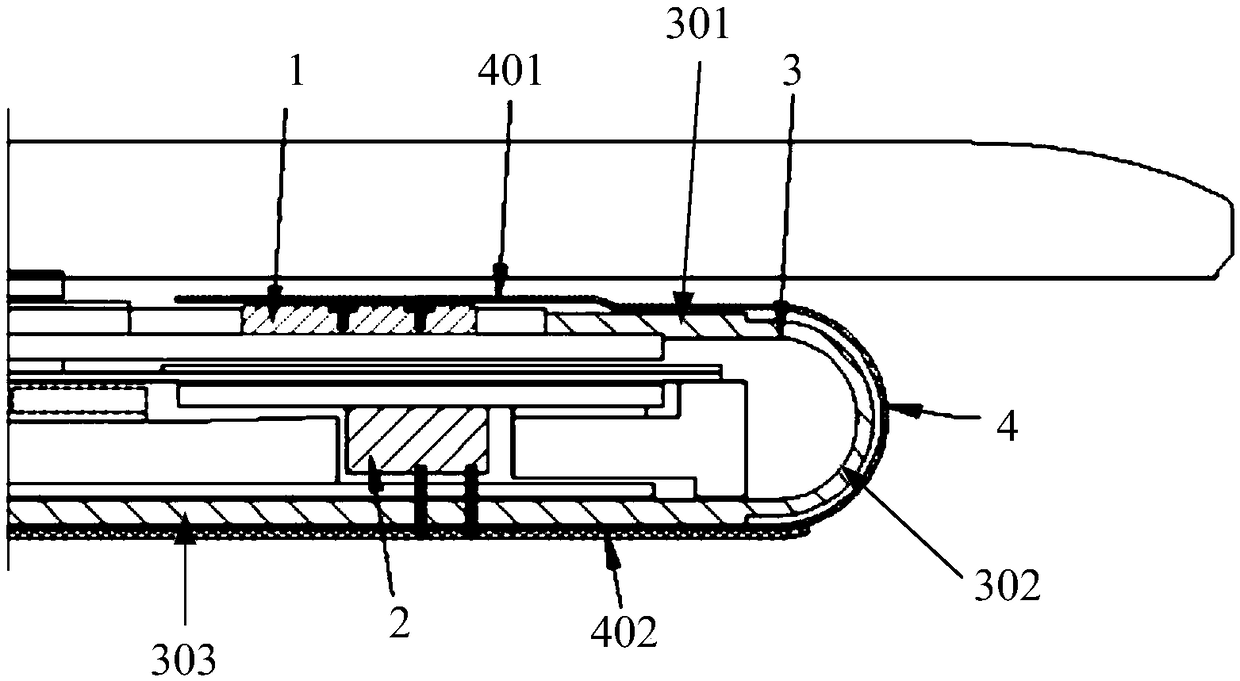

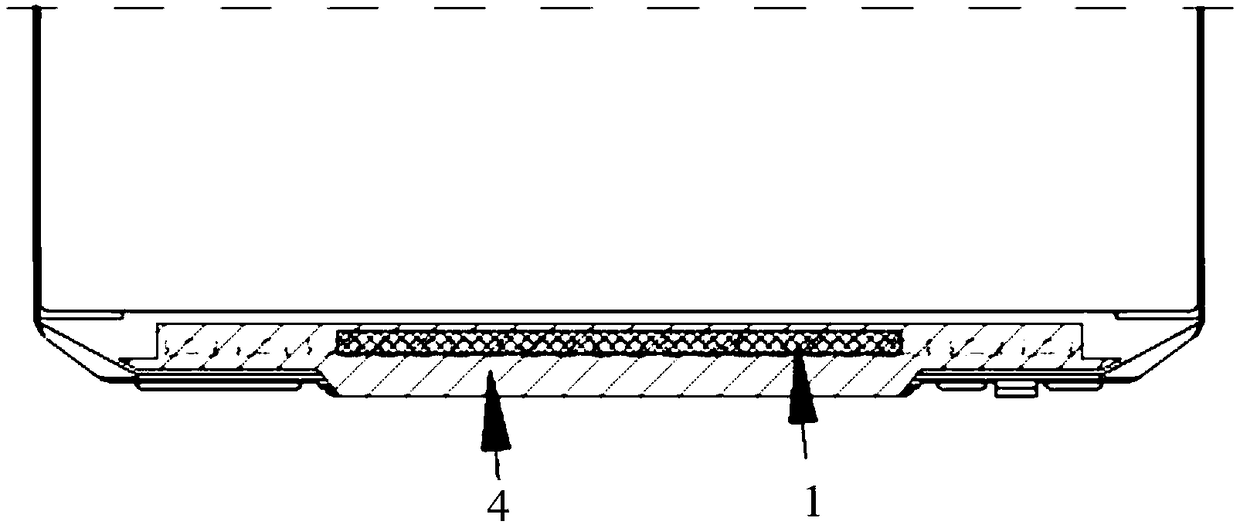

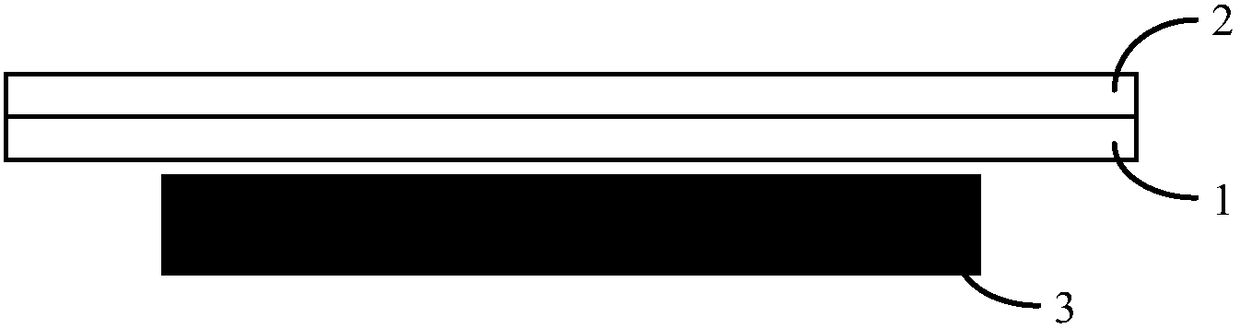

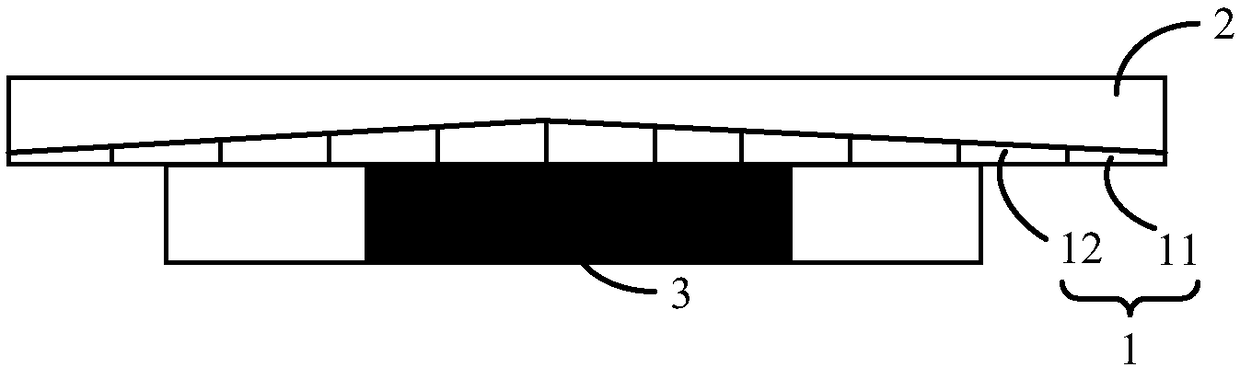

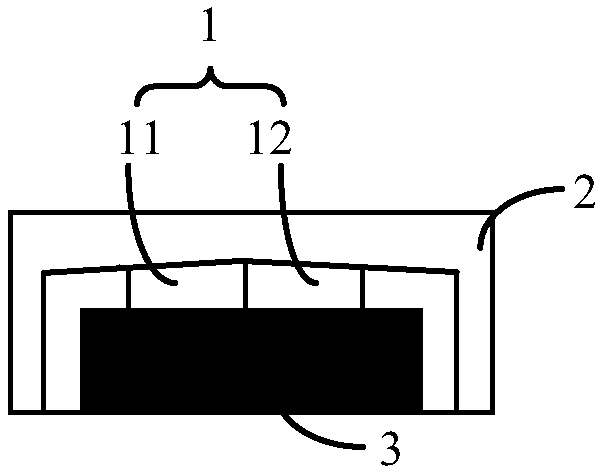

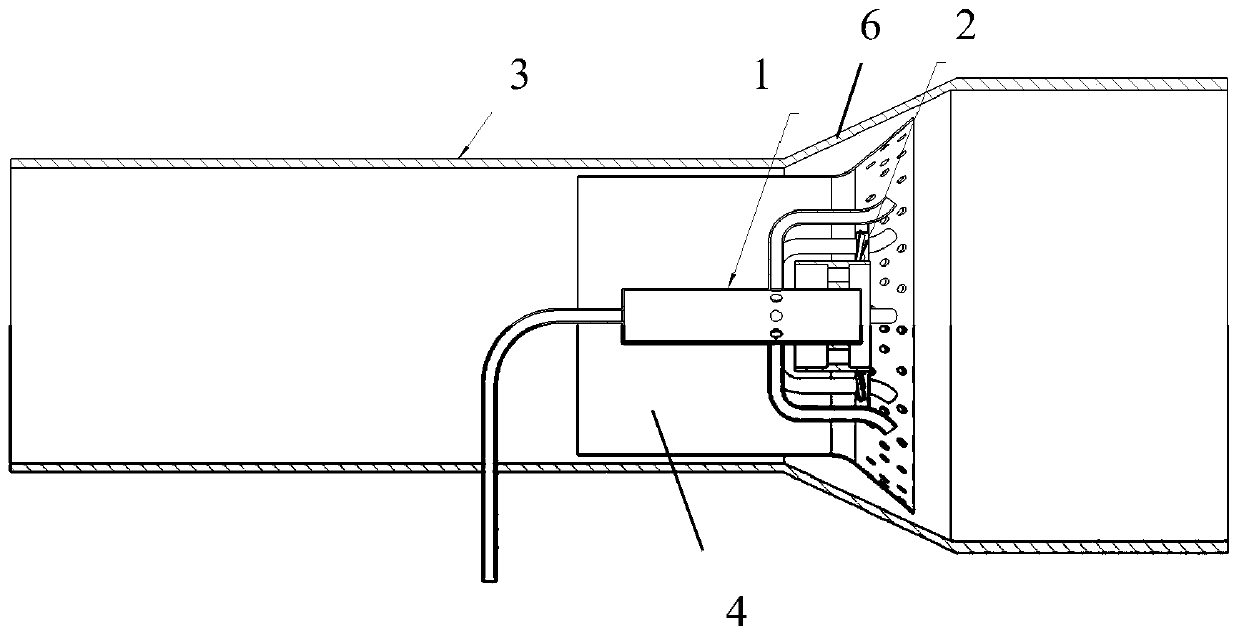

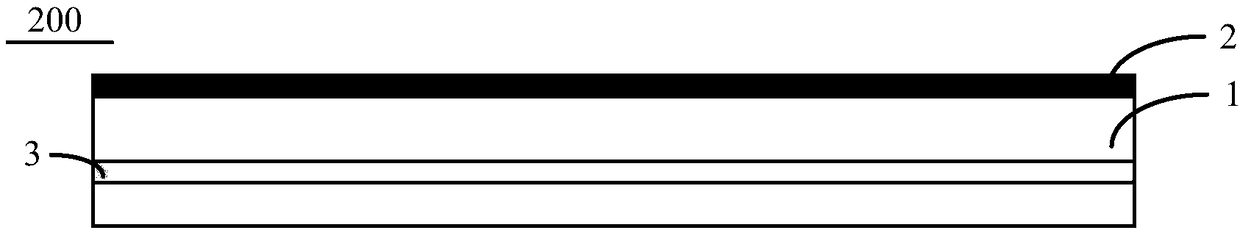

Backlight display screen and mobile terminal

ActiveCN108986681AAvoid local high temperatureIncrease cooling areaCooling/ventilation/heating modificationsIdentification meansElectricityFlexible circuits

An embodiment of the invention provides a backlight display screen and a mobile terminal. The backlight display screen comprises a driving integrated circuit, a backlight source, a flexible circuit board and a heat dissipation membrane; the backlight source is arranged under the driving integrated circuit; the flexible circuit board is electrically connected with the driving integrated circuit, the flexible circuit board is bent into a U shape and includes a first part laid on one side of the backlight source toward the driving integrated circuit, a second part bent into an arc and a third part laid on the side of the backlight source away from the driving integrated circuit, and the second part is arranged between the first part and the third part; the heat dissipation membrane comprisesa first heat dissipation part which is affixed to the side of the driving integrated circuit away from the backlight source and a second heat dissipation part which is affixed to the external surfaceof the flexible circuit board. By the arrangement, the heat dissipation membrane is fitted on the side of the backlight source of the driving integrated circuit and the outer surface of the flexible circuit board, the heat dissipation area is enlarged, and heat dissipation efficiency is improved.

Owner:VIVO MOBILE COMM CO LTD

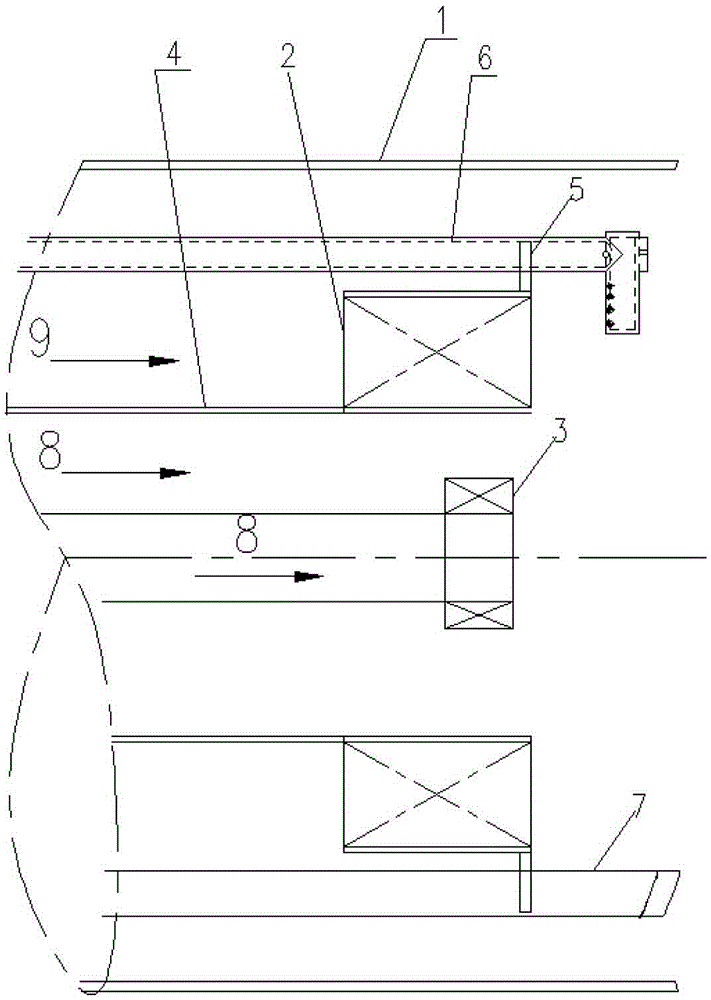

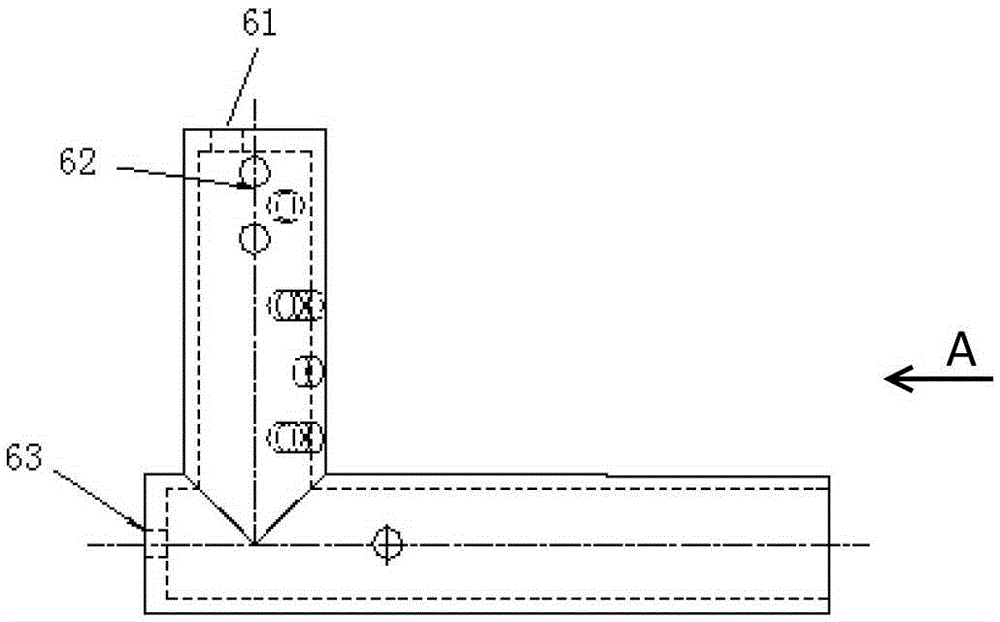

Low-emission gas combustion furnace and combustion air preparation method thereof

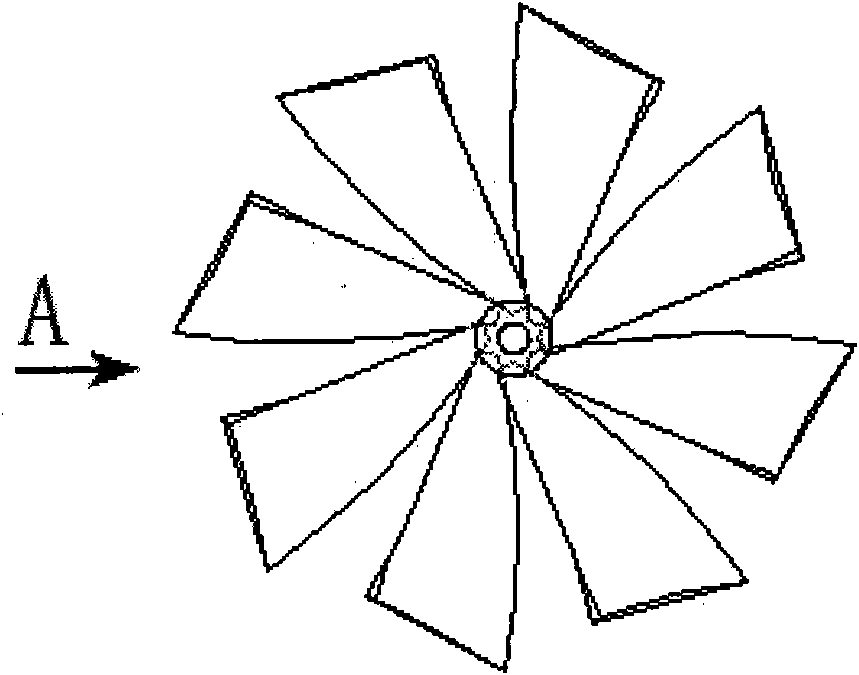

ActiveCN105351925AHomogeneous mixed combustionAvoid it happening againGaseous fuel burnerCycloneEngineering

The invention provides a low-emission gas combustion furnace and a combustion air preparation method thereof and relates to the technical field of combustion equipment. The technical purpose of NOx emission reduction is achieved. A first cyclone, a middle barrel and a second cyclone are sequentially and coaxially arranged in a throat of the gas combustion furnace in a sleeving manner from outside to inside. Multiple flame stabilizing boards are symmetrically arranged between the outer ring of the first cyclone and the inner wall of the throat. Multiple L-shaped gas guns and inclined-port gas guns which are arranged between the flame stabilizing boards are fixedly distributed around the axis of the throat at equal diameter. Forward spray holes, radial spray holes, return spray holes and multiple side spray holes are formed in the L-shaped gas guns. Multiple inclined spray holes are formed in the inclined-port gas guns. All the gas spray directions incline outwards in a scattered manner without mutual interference. Combustion air enters the throat through a center combustion air channel in the middle barrel and a second combustion air channel outside the middle barrel, and the combustion air entering the throat from the second combustion air channel accounts for 80% to 95% of the total amount of the combustion air. By the adoption of the gas combustion furnace, the NOx emission is low.

Owner:SHANGHAI WISEBOND TECH

Structure design of mobile terminal

InactiveCN1878452ALow costImprove temperature uniformityCooling/ventilation/heating modificationsGraphiteEngineering

The invention relates to a structure design of mobile terminal. Wherein, the relative high-temperature area of circuit board is arranged with heat emitter, to emit the heat of said area through the frame of mobile terminal; or the relative high-temperature area and relative low-temperature area are mounted with heat emitters, to transmit the heat of high-temperature area to the low-temperature area; the heat emitter is made from carbon (graphite), with high thermal conductivity and low density. The invention has low cost, small volume, better temperature uniformity and the application for avoiding partly high temperature of element and frame.

Owner:HUAWEI TECH CO LTD

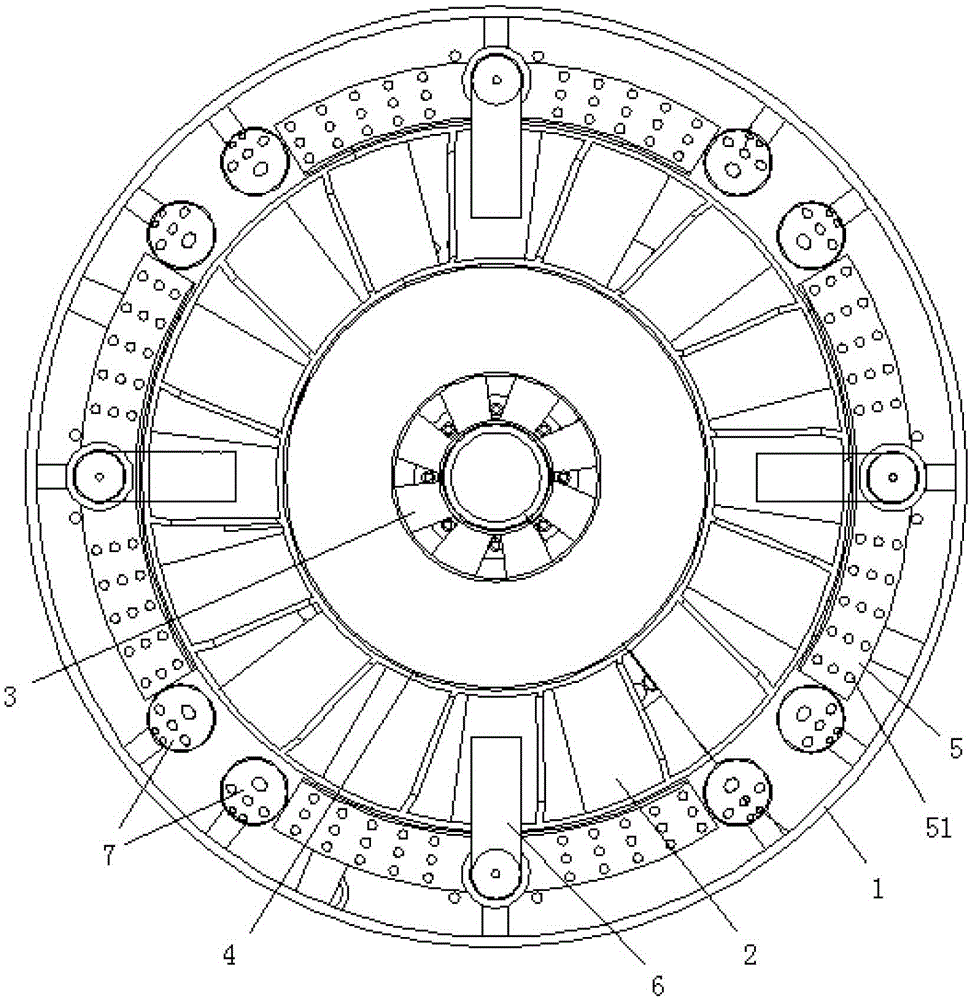

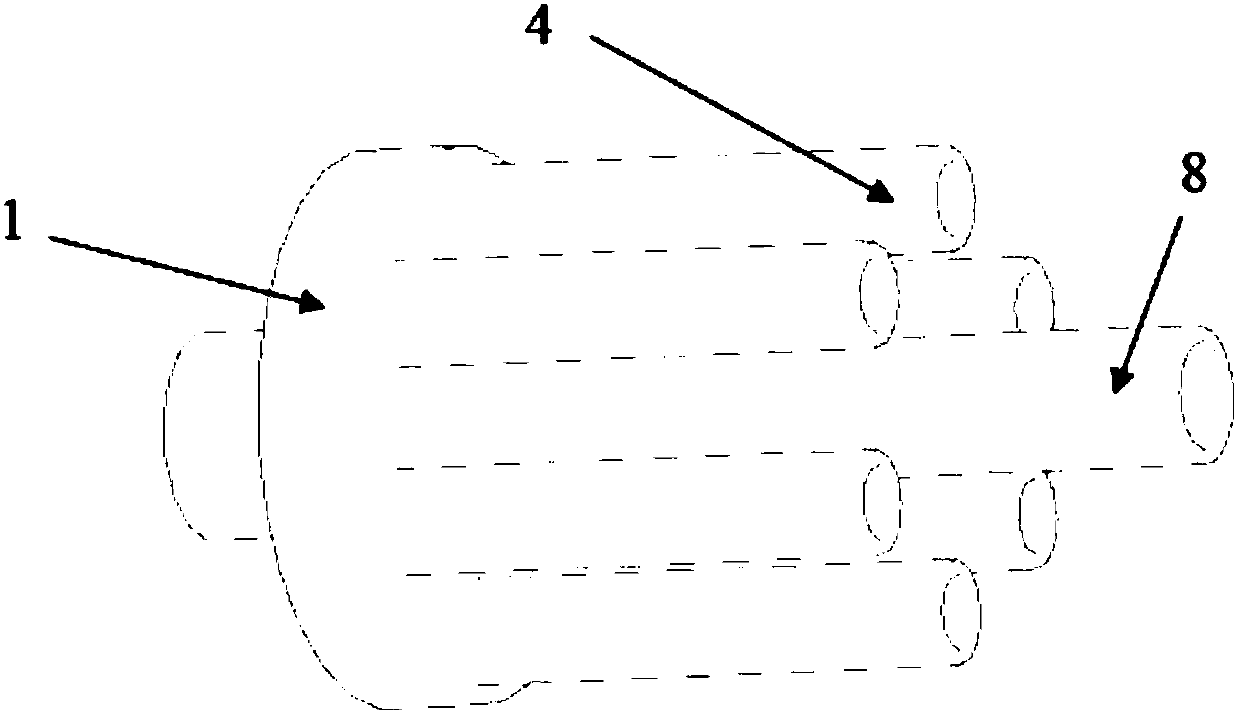

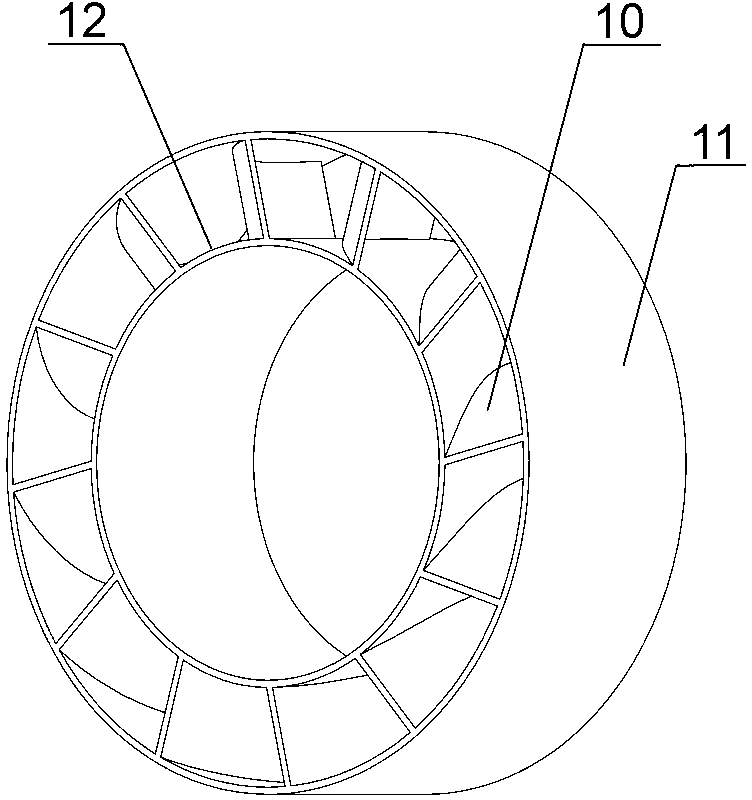

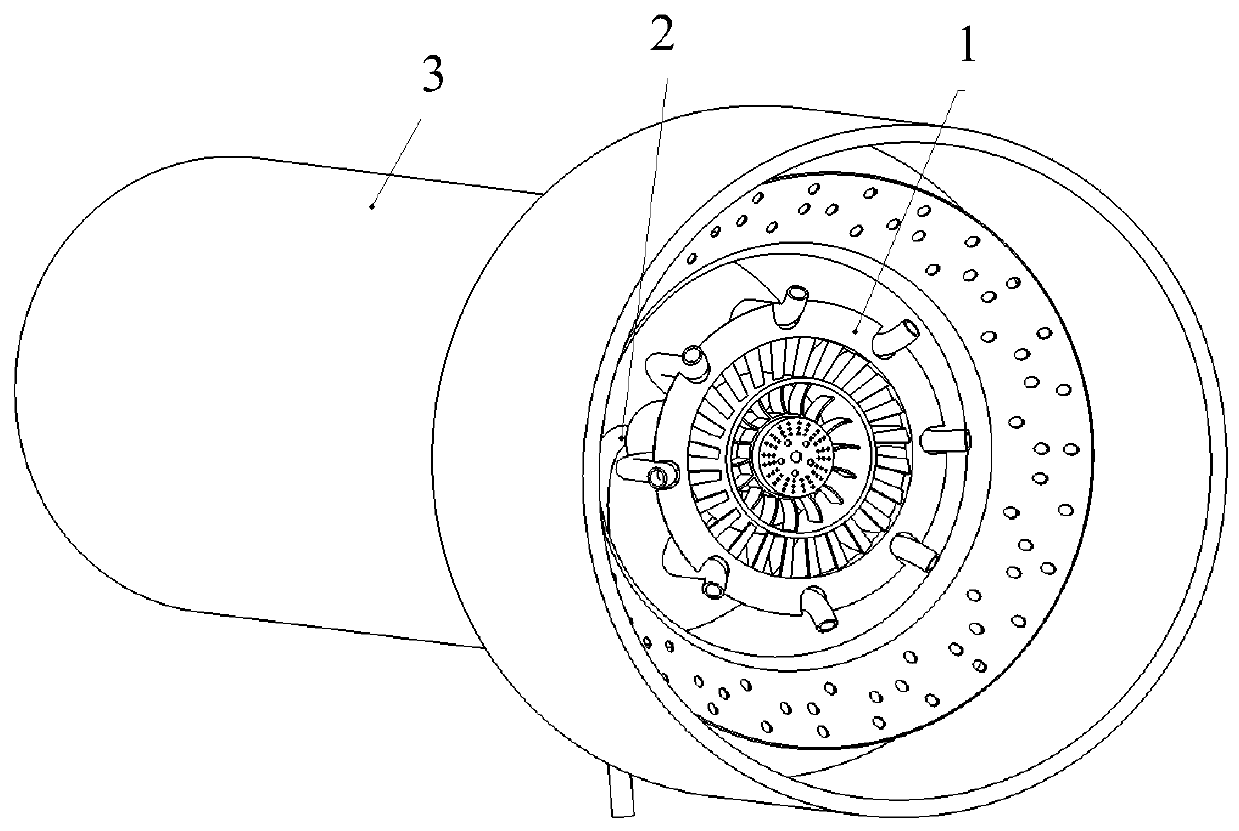

Ultralow-nitrogen gas burner

ActiveCN107559827AAchieving Circumferential GradingImprove the mixIndirect carbon-dioxide mitigationGaseous fuel burnerHearthProcess engineering

The invention relates to an ultralow-nitrogen gas burner. The ultralow-nitrogen gas burner comprises a first-stage gas header, a second-stage gas collecting ring, a furnace body, an igniter and an airflue with openings in the two ends, and the outlet of the air flue penetrates through a furnace wall of the furnace body to enter a hearth; the air flue at least comprises a central air flue, a primary air flue and a secondary air flue which are sequentially arranged from inside to outside in a sleeved mode, and the first-stage gas header and the second-stage gas collecting ring are connected with a fuel gas main pipe; the first-stage gas header is connected with a central spray gun and a plurality of first-stage gas spray guns, the first-stage gas spray guns are uniformly distributed on theperiphery of the central spray gun, and the central spray gun and the first-stage gas spray guns extend into the central air flue; the second-stage gas collecting ring is uniformly connected with a plurality of second-stage gas spray guns, and the second-stage gas spray guns extend into the secondary air flue; and the igniter is arranged in the central spray gun, and an ignition end of the igniterextends out of an outlet end of the central spray gun. According to the ultralow-nitrogen gas burner, a double-header and pipe group type supply mode is adopted, so that circumferential grading of the fuel is realized, air / gas mixing condition is improved, combustion balance is realized, and NOx generation is reduced.

Owner:XI AN JIAOTONG UNIV

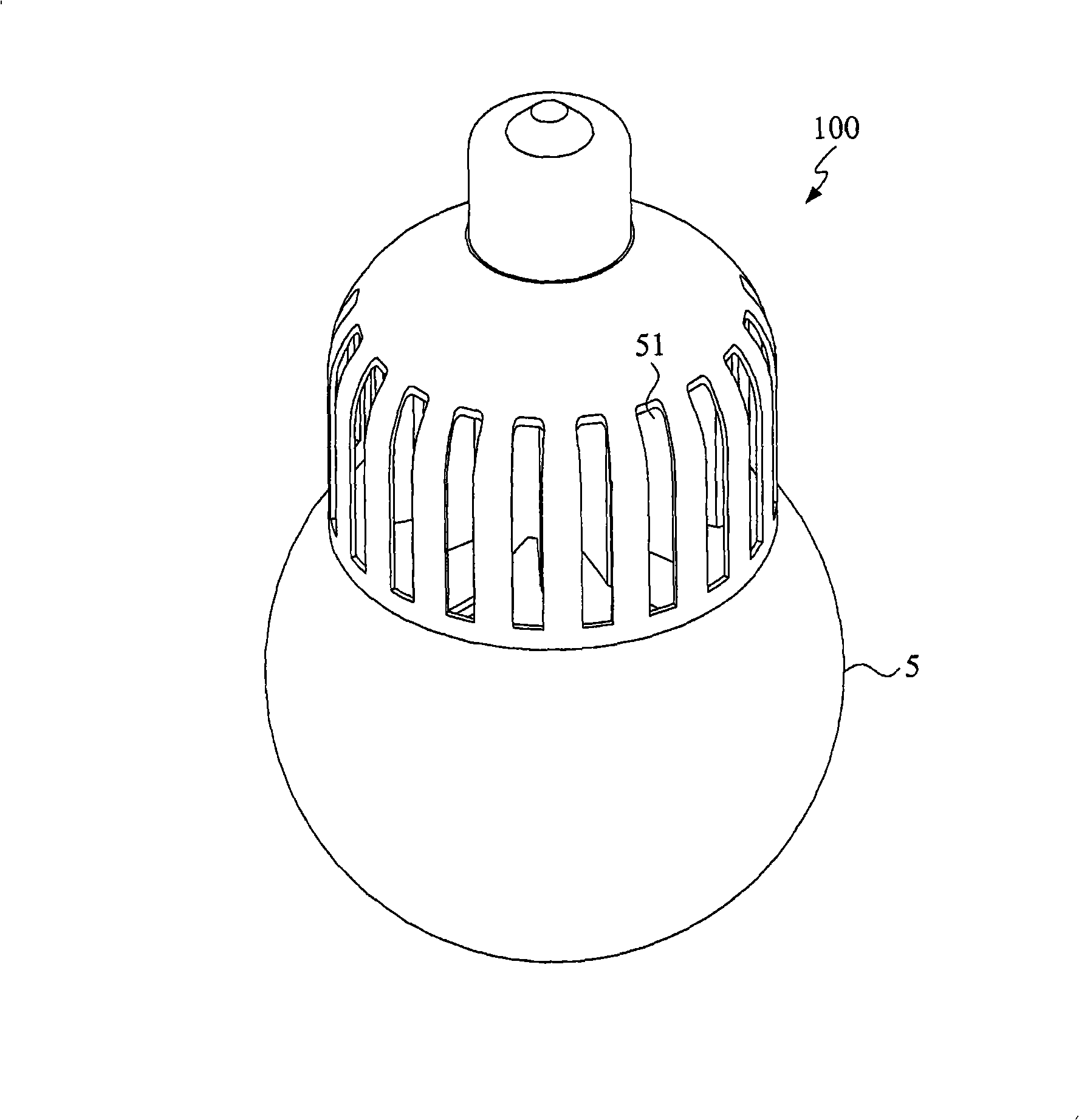

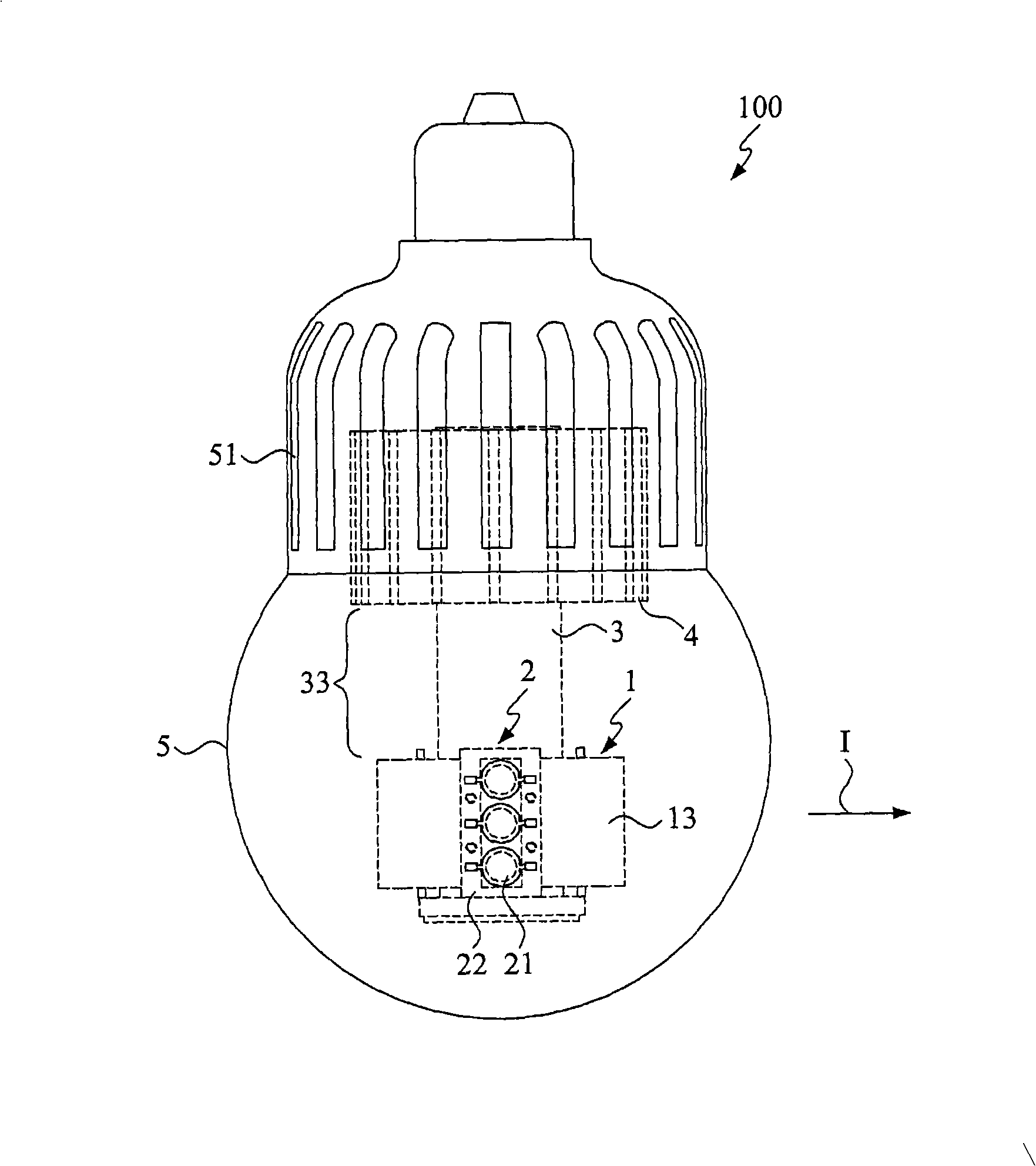

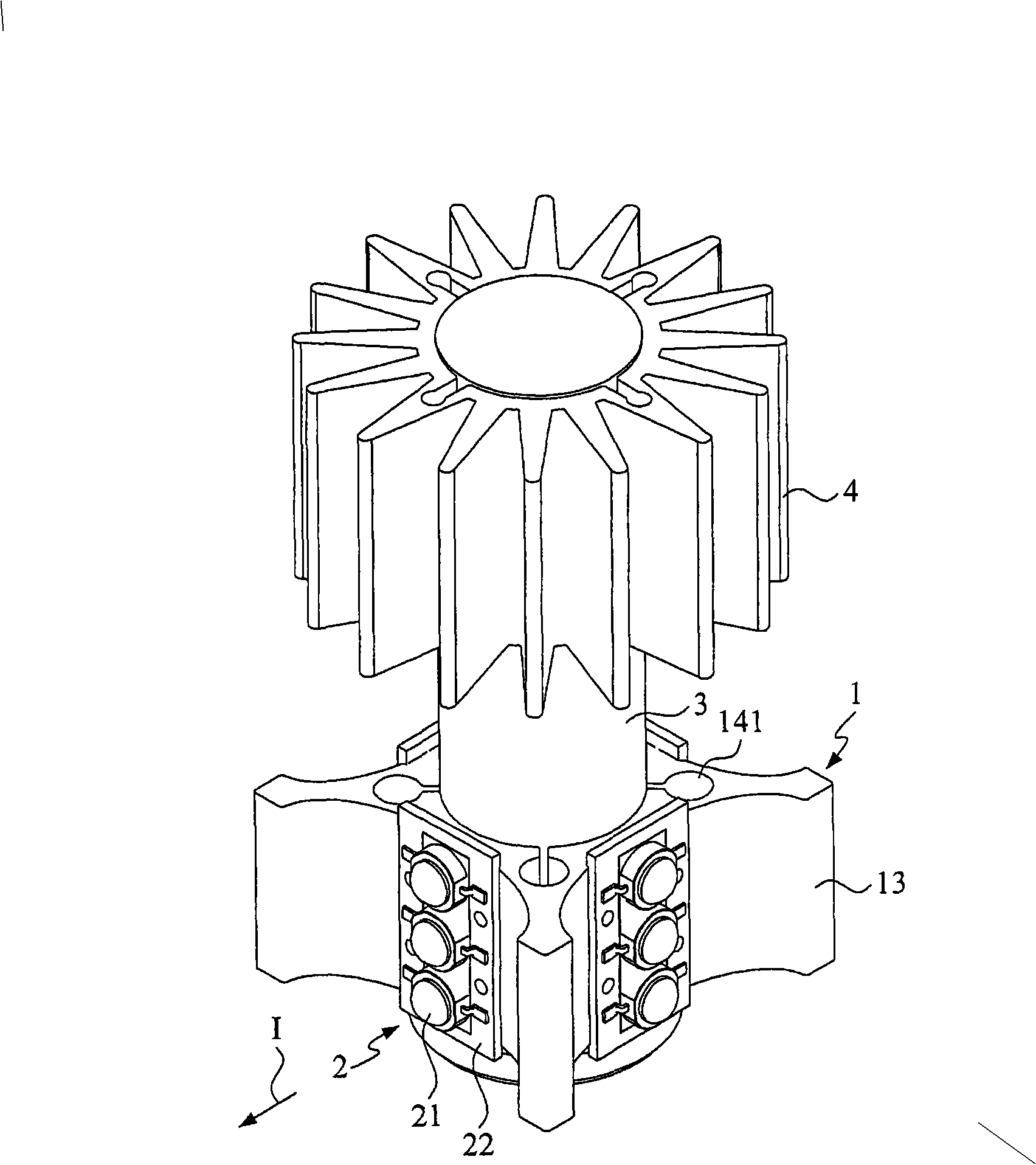

High power LED lighting lamp and radiating module thereof

InactiveCN101281902AAvoid stabilityAvoid damageSemiconductor/solid-state device detailsLighting heating/cooling arrangementsWorking fluidHeat transmission

The invention discloses a high power luminescent diode lamp and heat dissipation module thereof, which includes a LED heat transmission base, at least one LED array, at least one heat pipe and a heat dissipation module. The LED head transmission base has at least one LED collocation surface and at least one heat pipe trepanning. The LED array includes a plurality of LEDs, and each of the LEDs is arranged on the LED collocation surface at a preset angle. The heat pipe has a heated section, a condensation section and a transmission section, working fluid is contained in the heat pipe, and the heated section is nested in the heat pipe trepanning. The heat dissipation module is equipped in the condensation section of the heat pipe. Heat energy generated by the LED is transmitted to the heated section of the heat pipe by the LED heat transmission base, the working fluid of the heat pipe is heated to vaporize and flows to the condensation section through a transmission region, the heat dissipation module absorbs the energy carried by vaporized working fluid and dissipates the energy.

Owner:TAMKANG UNIVERSITY

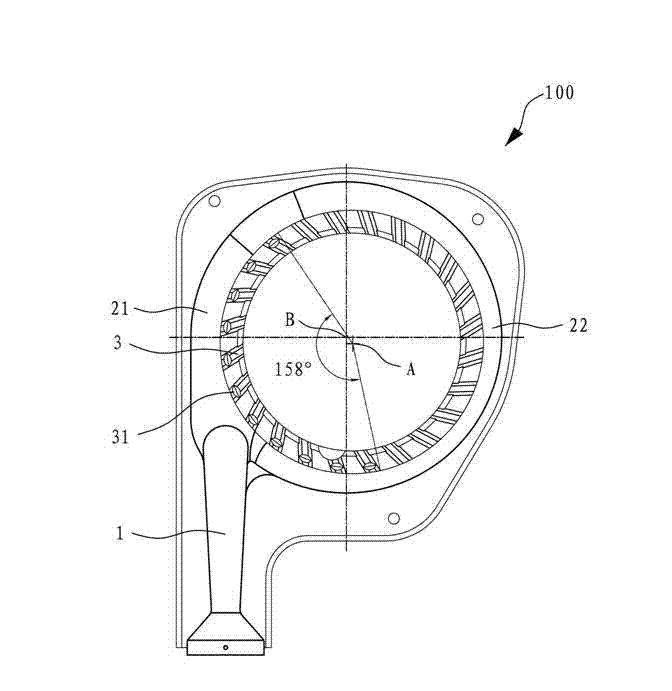

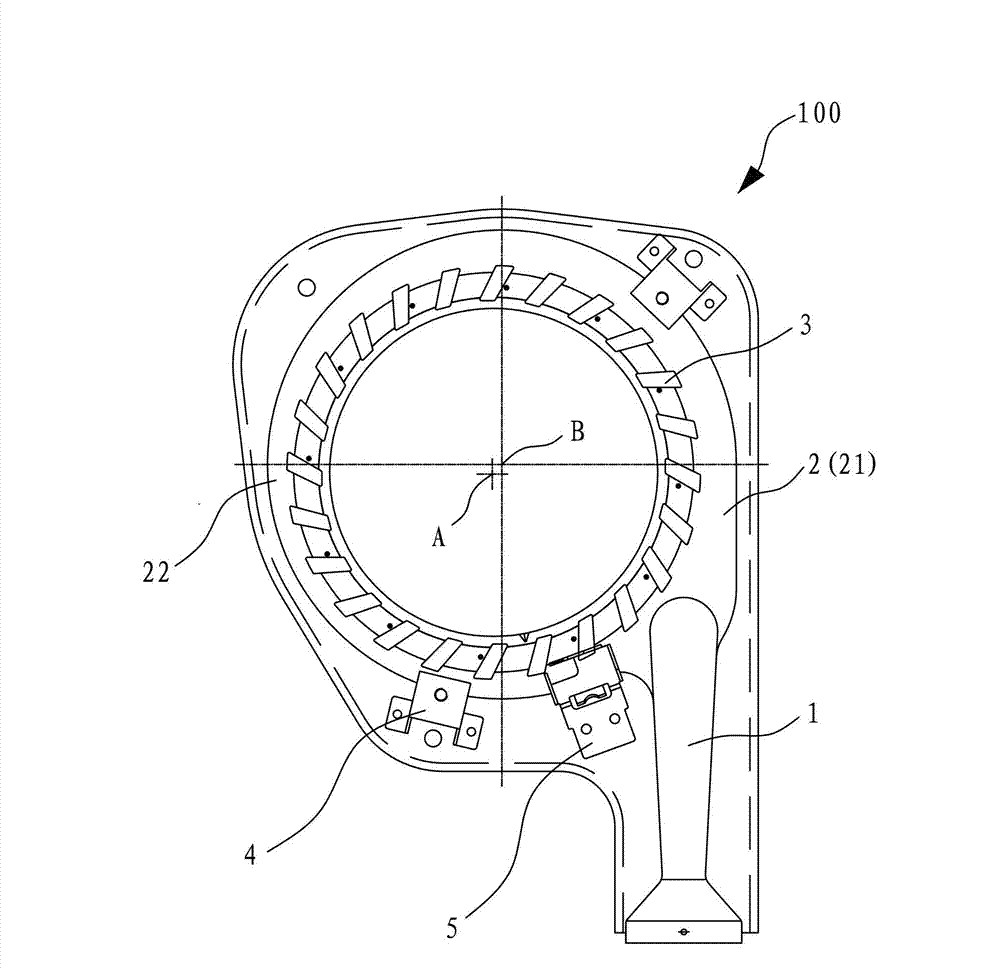

Environmental-combustion burner

InactiveCN102853424AMeet environmental protection requirementsIncrease volumeGaseous fuel burnerCombustorEngineering

The invention discloses an environmental-combustion burner which comprises an ingress pipe, a circular distribution pipe, and a plurality of flame holes. The ingress pipe guides in mixed gas of fuel gas and primary air. The circular distribution pipe is connected with the ingress pipe. The flame holes are arranged on the inner peripheral side of the circular distribution pipe. The circular distribution pipe is provided with a first gas cavity area close to the ingress pipe, and a second gas cavity area away from the ingress pipe. The center of a circle of the flame holes is eccentric to the center of a circle of the outer peripheral side of the circular distribution pipe and is close to the second gas cavity area. The length of flames generated in the flame holes in the first and second gas cavity areas of the environmental-combustion burner can be balanced, so that high temperature of a heated boiler bottom tends to be consistent. Local high temperature of the heated boiler bottom is avoided, carbon oxides and nitrogen oxides which are harmful to the environment and generated in combustion of the fuel gas are reduced effectively, and the combustion requirement of the burner for environment friendliness is met.

Owner:福建省江南电器制造有限公司

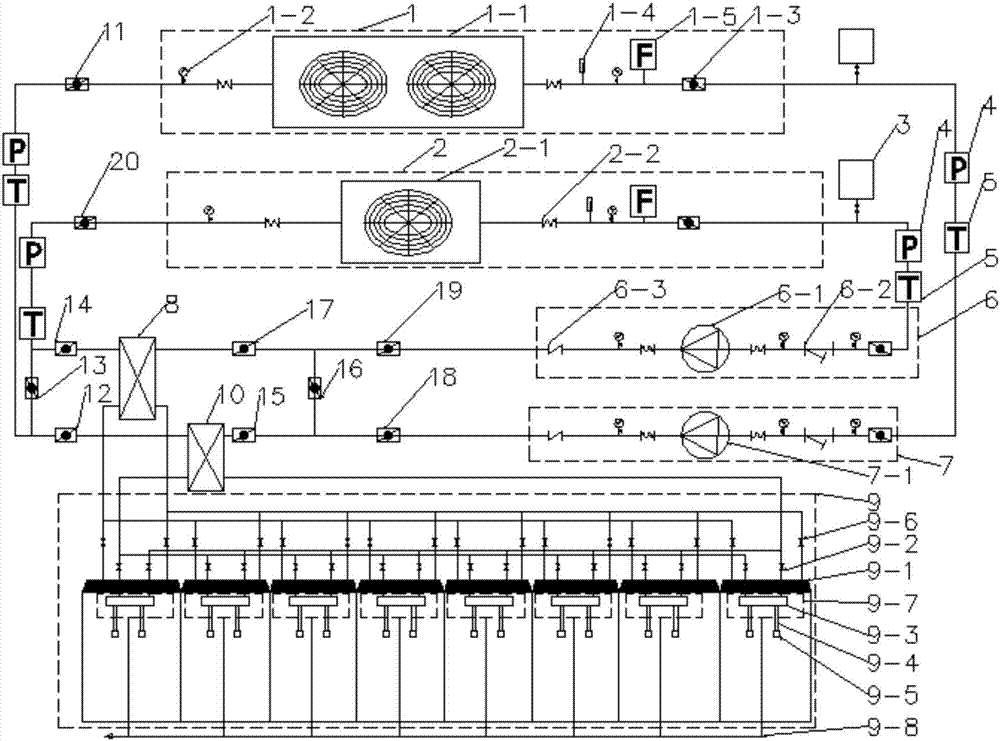

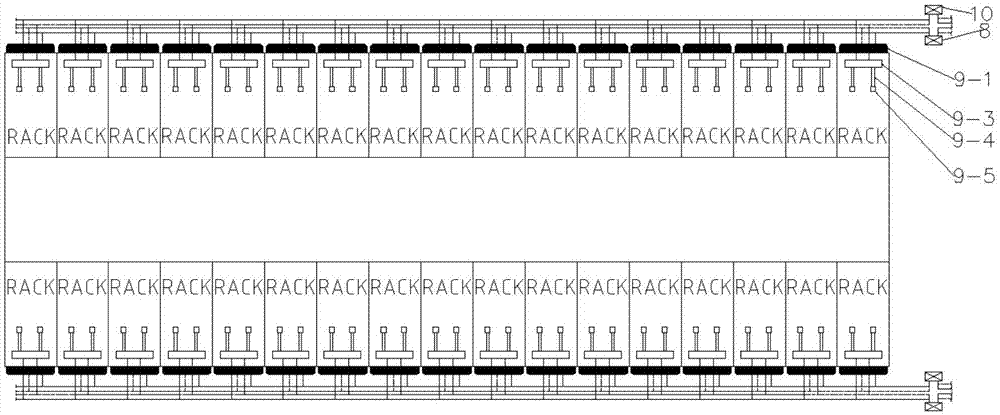

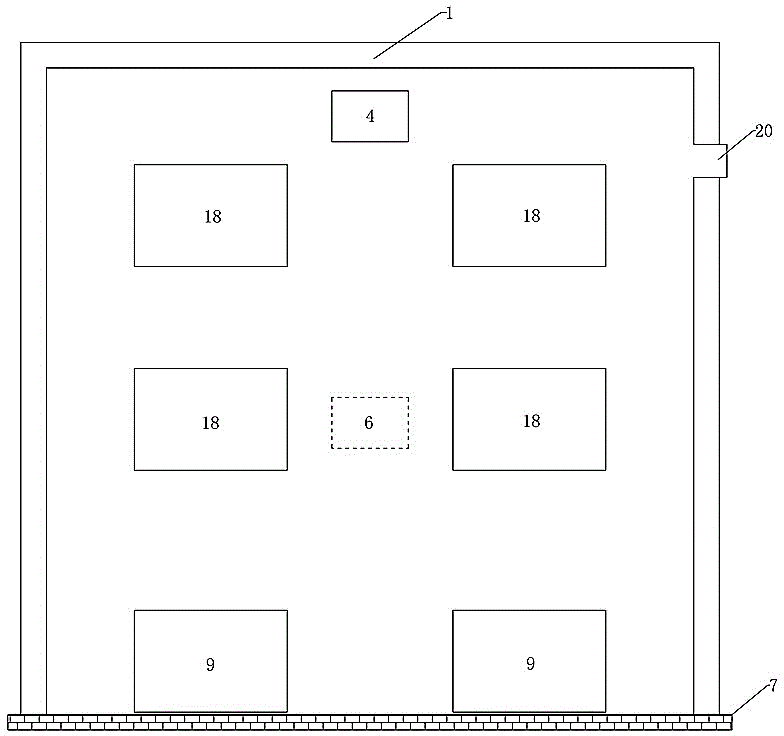

System for simultaneously realizing heat dissipation of CPU chip and server

ActiveCN107182191AImprove energy efficiency ratioImprove utilization efficiencyEnergy efficient computingCooling/ventilation/heating modificationsFree coolingEconomic benefits

The present invention discloses a system for simultaneously realizing the heat dissipation of a CPU chip and a server. An outdoor natural cooling unit and an outdoor mechanical refrigerating unit are sequentially connected with a voltage stabilizing unit, a pump set unit and a refrigerating capacity distributing and heat-exchange unit to form a loop respectively. The refrigerating capacity distributing and heat-exchange unit is connected with a CPU chip micro heat pipe radiating unit and a server back plate heat pipe radiating unit. The CPU chip micro heat pipe radiating unit is in contact with the CPU chip in the server. The server back plate heat pipe radiating unit is in contact with a heat dissipating port in the server. The system combines a natural cold source with the air-cooled water chiller unit cooling technology, so that the server is cooled by a heat pipe radiator near a heat source. Based on the reasonable organization of the air flow, the PUE can be effectively reduced and the energy efficiency utilization rate is improved. The problem of local hot spots due to the unreasonable air flow organization of a precise air conditioning unit can be solved. The space utilization rate of a machine room is improved and more cabinets and servers can be arranged in the machine room. Therefore, the economic benefit can be effectively improved and the space-saving effect is better.

Owner:SICHUAN SUP INFO INFORMATION TECH

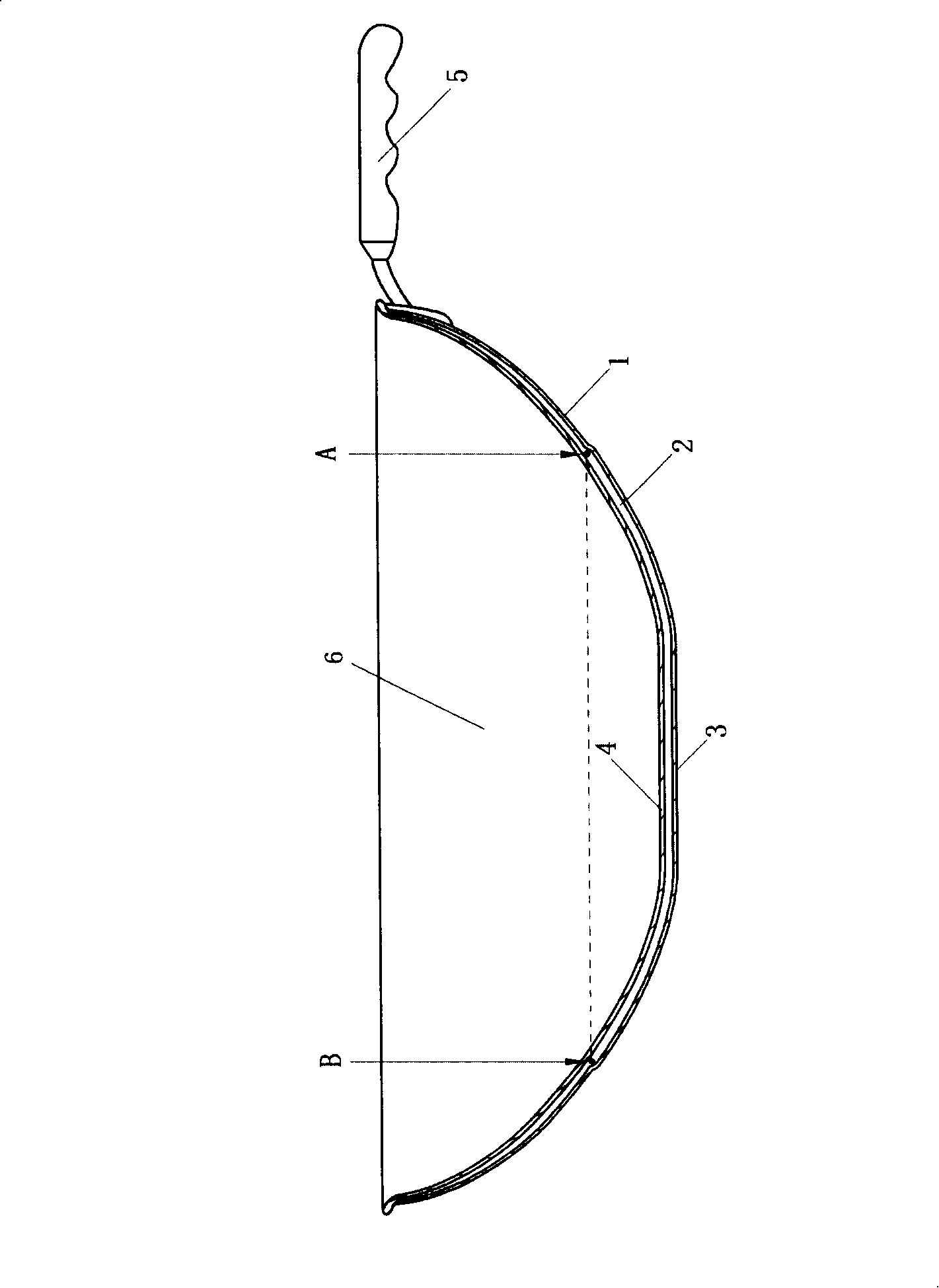

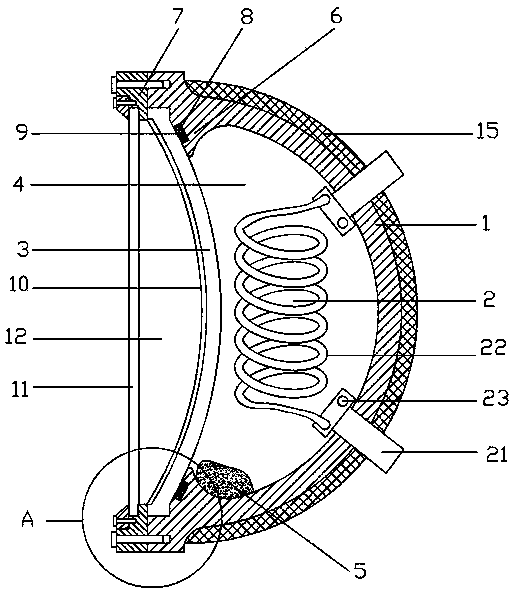

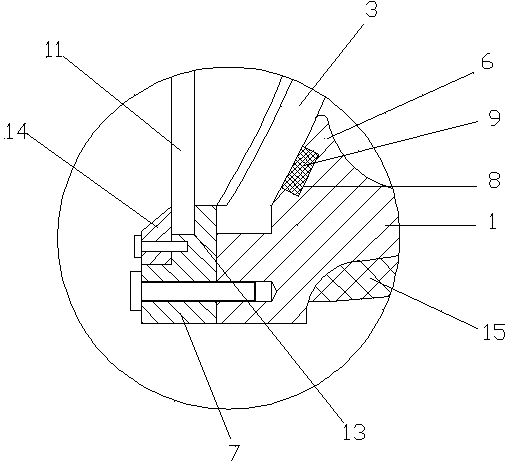

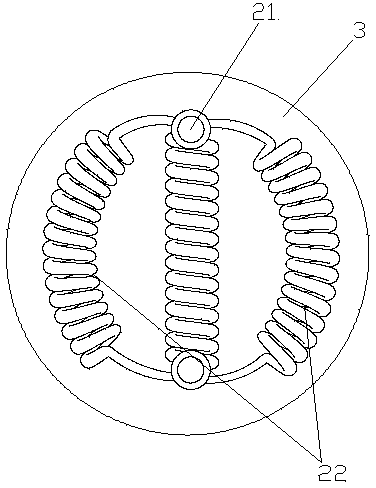

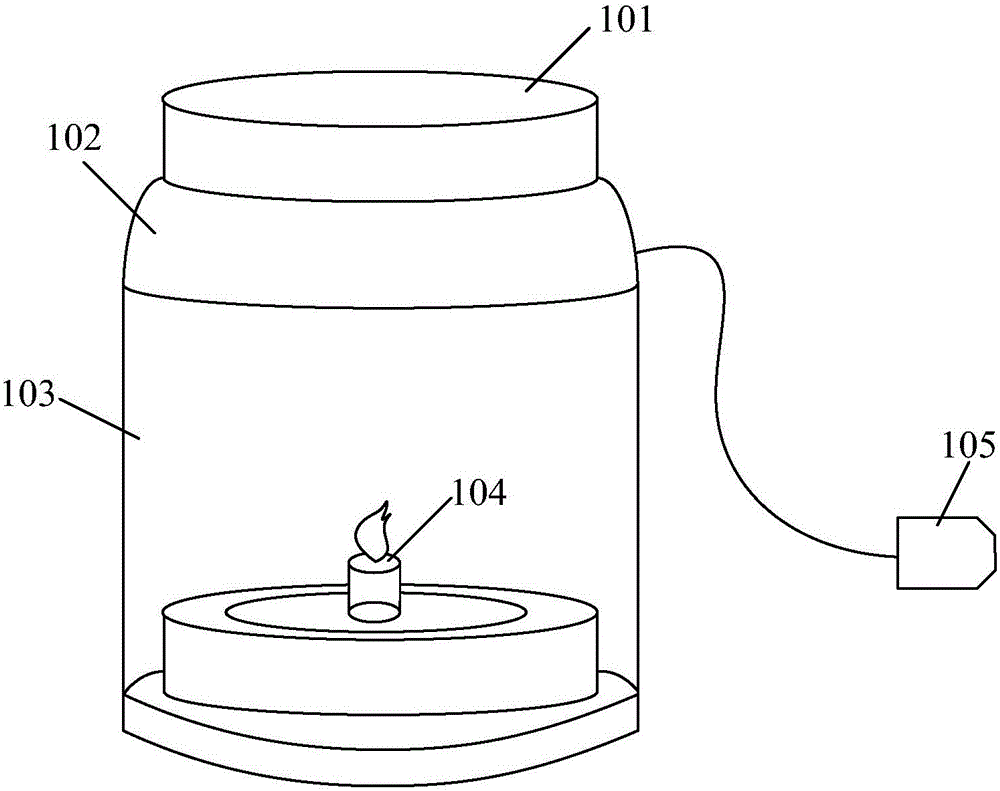

Stirling heat engine solar heat collector

ActiveCN103629829AUniform temperatureImprove heat absorption efficiencySolar heating energySolar heat devicesAbsorption rateStirling engine

The invention discloses a Stirling heat engine solar heat collector which comprises a heat collecting cover and a heat-exchanger tube arranged in the heat collecting cover. A heat collecting plate is arranged at the opening end of the heat collecting cover, a closed heat collecting cavity is defined by the heat collecting plate and the heat collecting cover, metallic sodium is arranged in the heat collecting cavity, the heat collecting cavity is filled with inert gas, and the two ends of the heat-exchanger tube respectively extend out of the heat collecting cover from the bottom of the heat collecting cover and are communicated with the heat end and the cold end of a Stirling air cylinder respectively. The heat collecting cover is in a hemispheroid shape, the heat collecting plate is a spherical surface plate, the outwards-protruding face of the heat collecting plate is towards the bottom of the heat collecting cover, the inner wall of the opening end of the heat collecting cover is extended to form a supporting ring, and the outer lateral face of the supporting ring is fitted with the periphery of the inner side of the heat collecting plate in a supported mode. The Stirling heat engine solar heat collector accordingly has the advantages that the temperature in the heat collecting cover is even, the heat absorption rate of the heat-exchanger tube is high, a Stirling heat engine can stably work, the service life is long, the temperature at the position around the inner lateral face of the heat collecting plate can be kept even through sodium fog, and the service life shortening caused by the local high temperature of the heat collecting plate is prevented.

Owner:斯特林威索AB

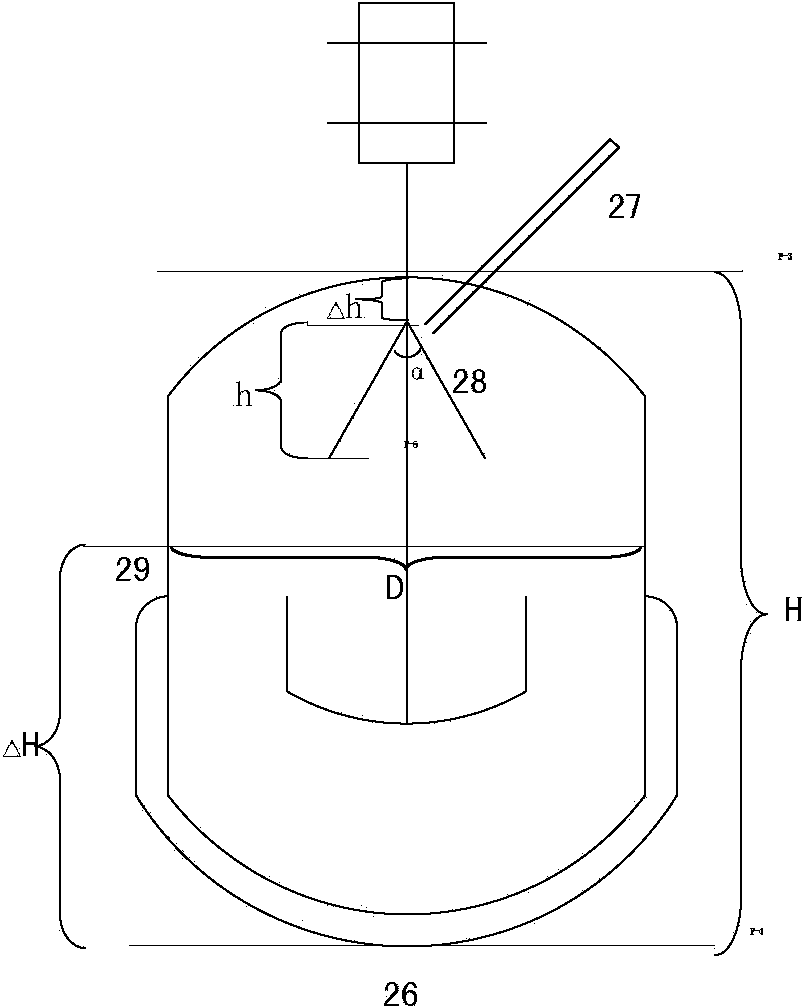

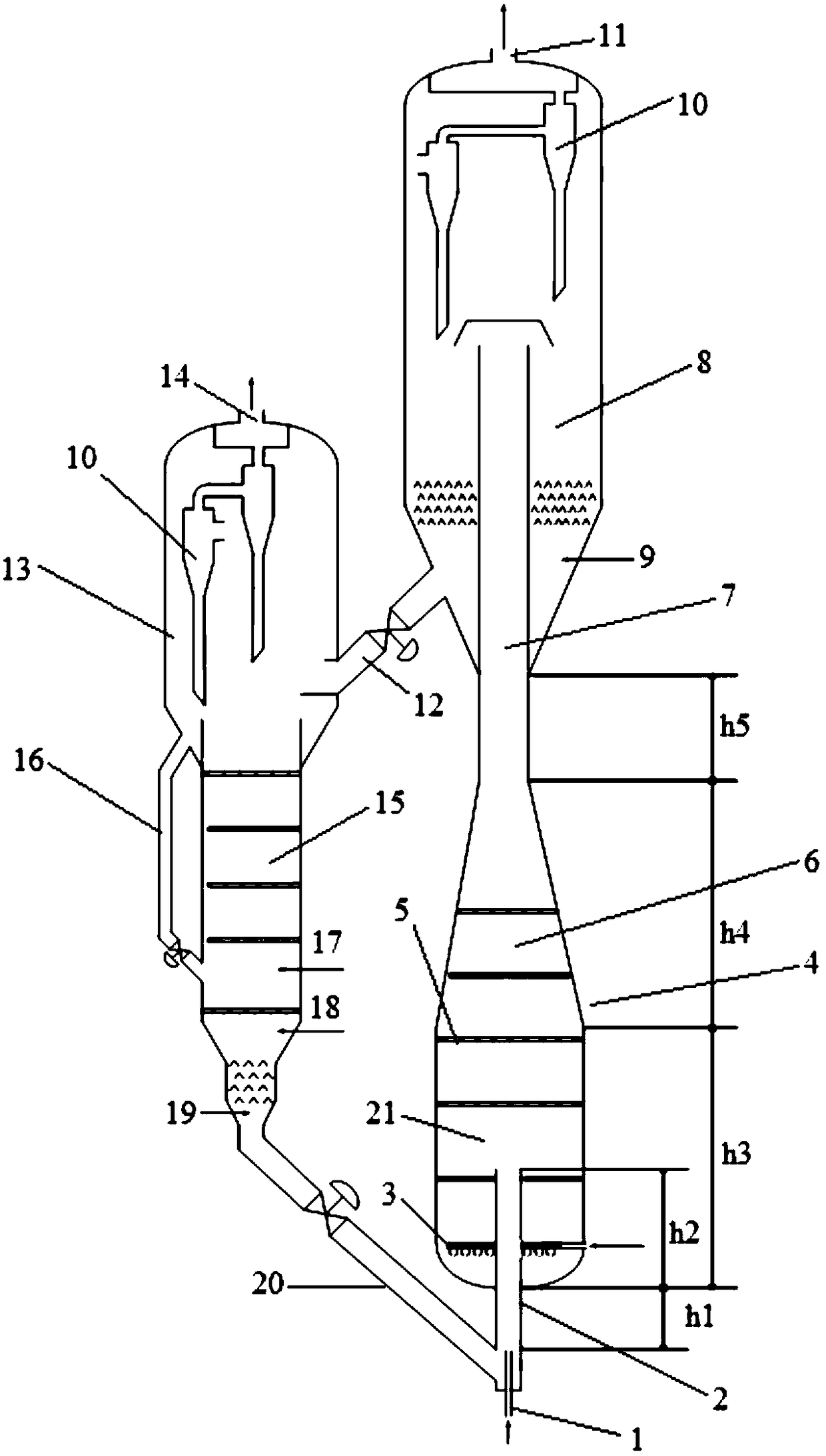

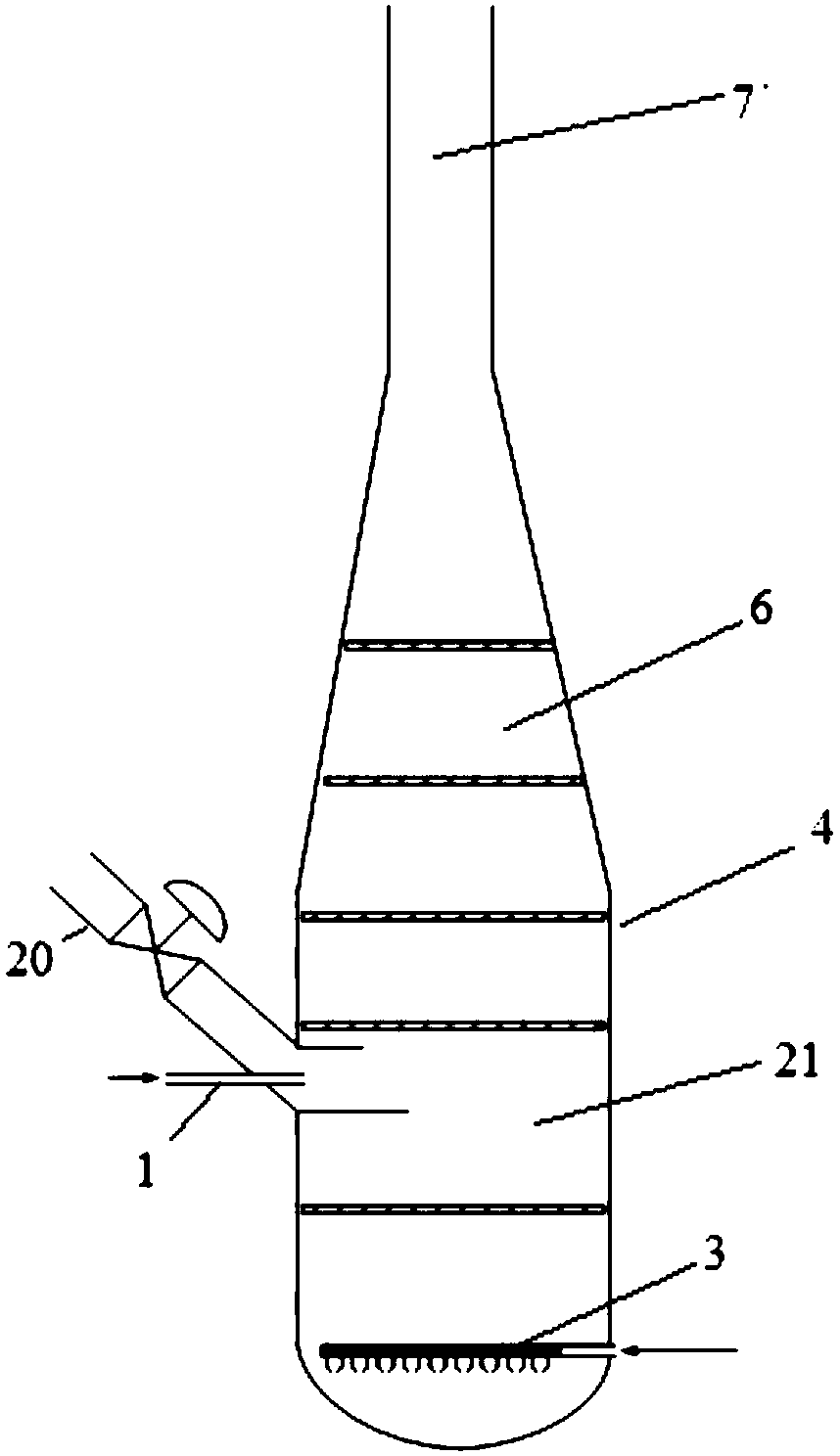

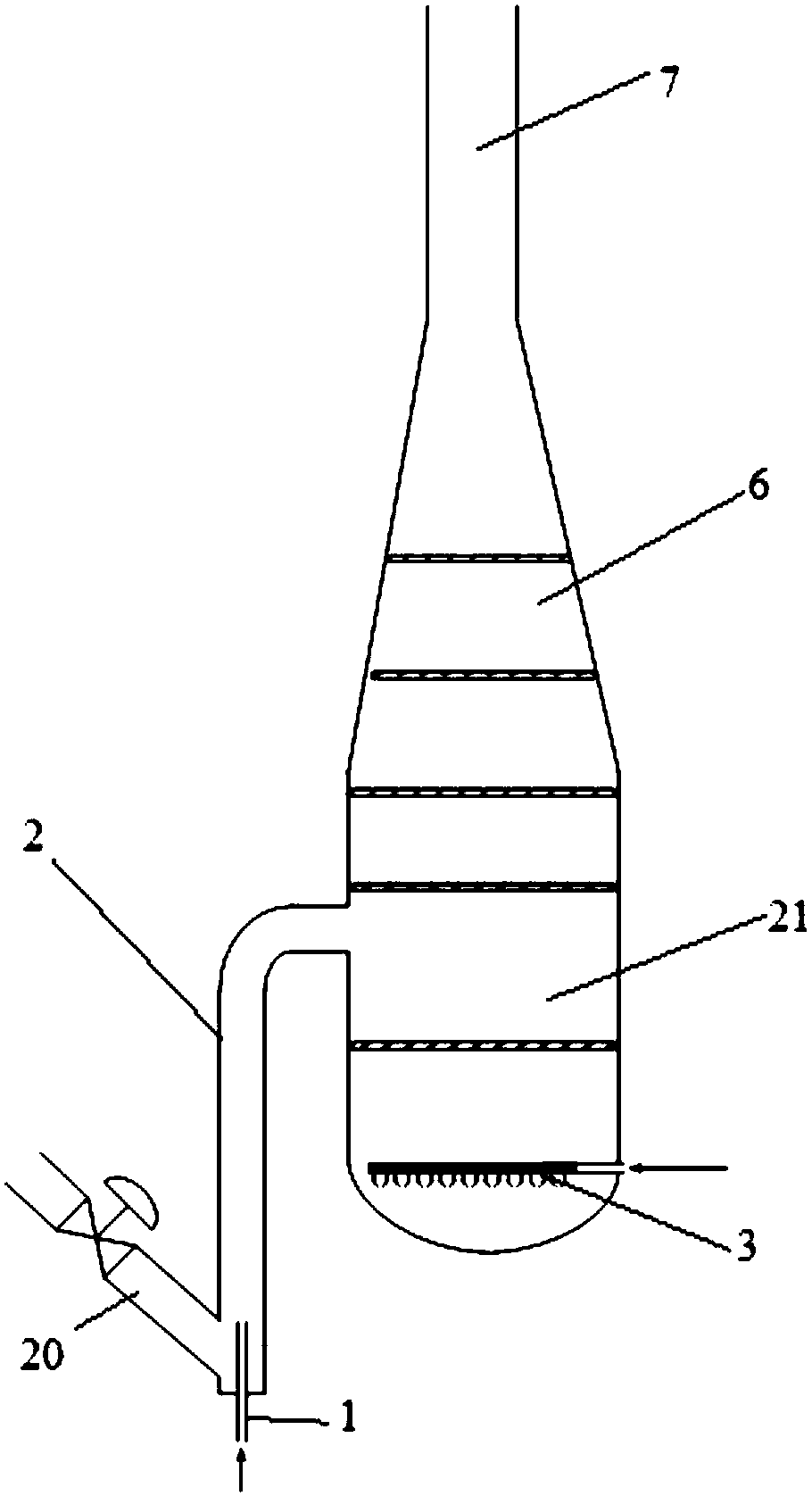

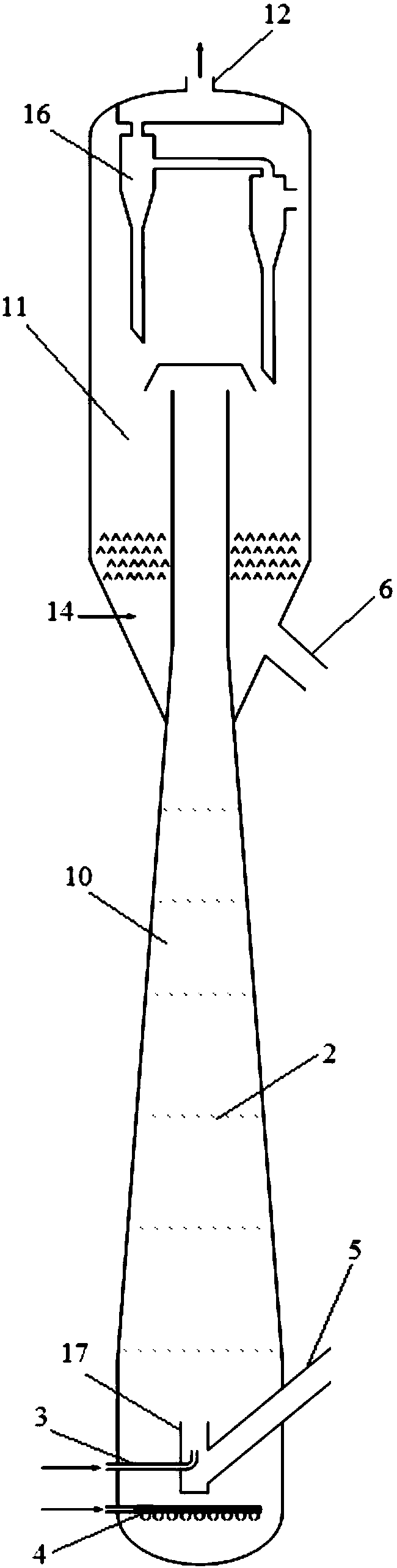

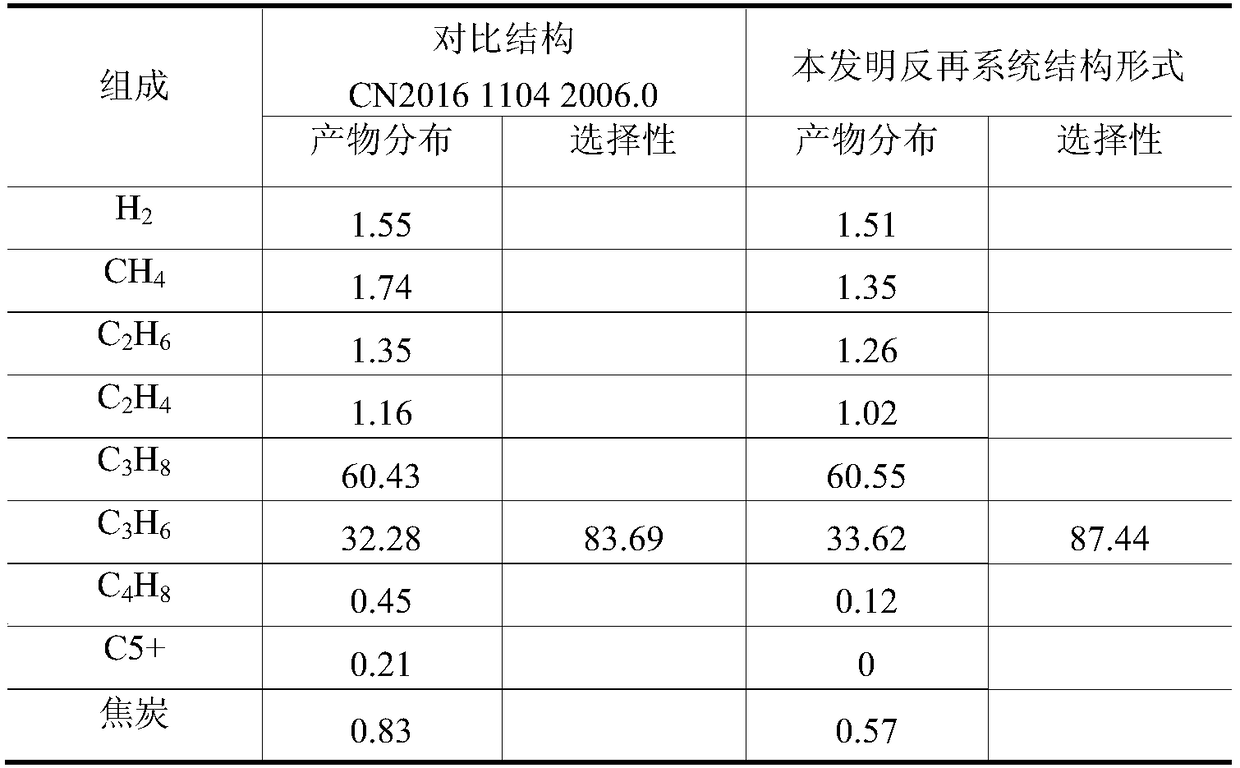

Circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking

ActiveCN109499486AReduce secondary conversionsTake advantage ofHydrocarbonsChemical recyclingAlkaneDehydrogenation

The invention provides a circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking. The device comprises a reactor and a reactor sedimentation section, wherein the reactor sedimentation section is positioned at the upper part of the reactor; the reactor comprises a diameter shrinkage section; the cross section diameter of the diameter shrinkage section is gradually decreased from bottom to top; a lifting pipe extends into the reactor from the lower part of the reactor; a catalyst regeneration inclined pipe is connected with the lifting pipe outside the reactor. The reaction device realizes the gradual diameter shrinkage along the fluid flowing direction; the secondary conversion of of olefin due to returning and mixing isreduced. Reactants and catalysts in the reactor realize the flow merging and upward flowing; the uniform distribution of temperature in the reactor can be effectively improved; the local high temperature is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

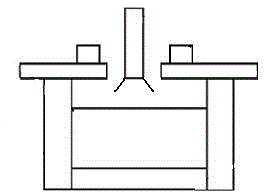

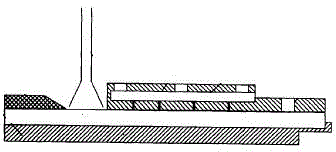

Integral optical glass forming mould

InactiveCN104817256ASolve the sticking problemSolving the Problem of Forming StreaksGlass pressing apparatusTemperature controlOptoelectronics

The invention discloses an integral optical glass forming mould, belongs to the field of an optical glass melting and forming technology, and mainly solves the problems that the glass metal sticky mold and moulded stripes can be easily caused when an optical glass strip is formed. The integral optical glass forming mould is characterized by mainly comprising a forming part and a cooling part, wherein the forming part is an integral forming groove, one end of the forming groove is opened, and an end working surface at another end of the forming groove is a concave working cambered surface; the bottom surface of the forming groove below the end working surface is a lower convex cooling cambered surface, the cooling part is a cooling cavity closely adhered to the cooling cambered surface, and a cooling hole is formed in the cooling cavity; a temperature control thermocouple is arranged above the forming part. The integral optical glass forming mould provided by the invention has the characteristics of the optical glass strip of stable production, high forming temperature and low forming viscosity, thereby being mainly used for the forming of lanthanide series optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

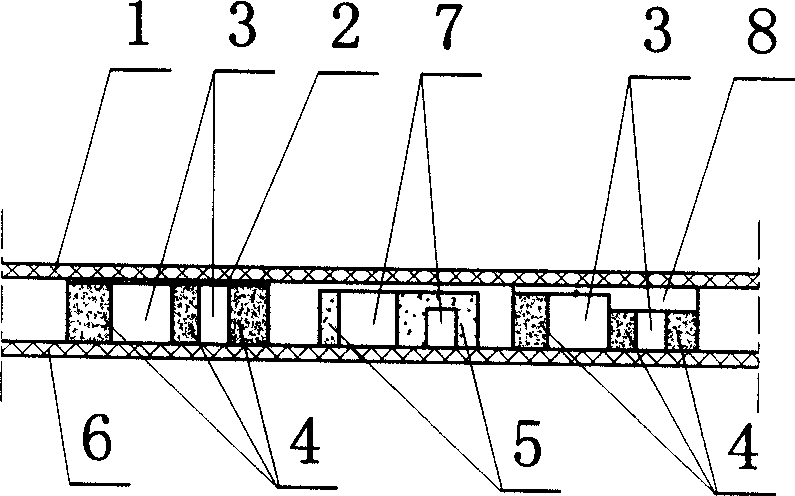

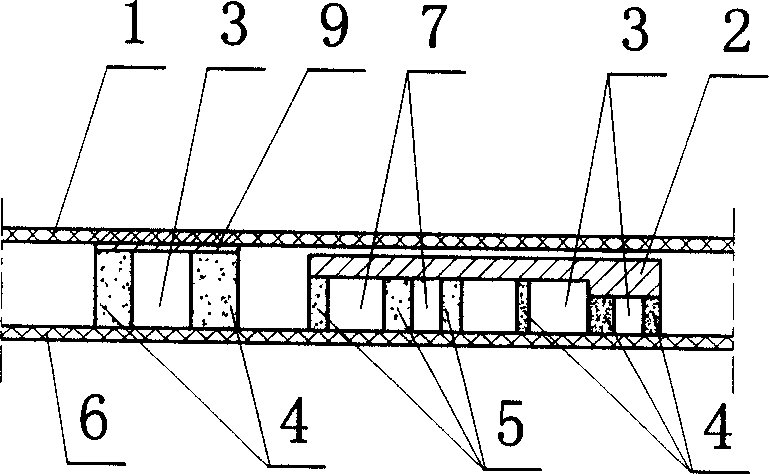

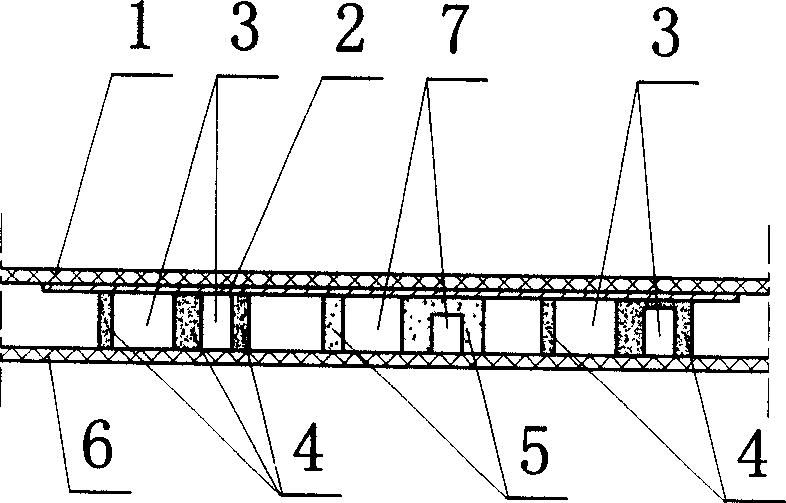

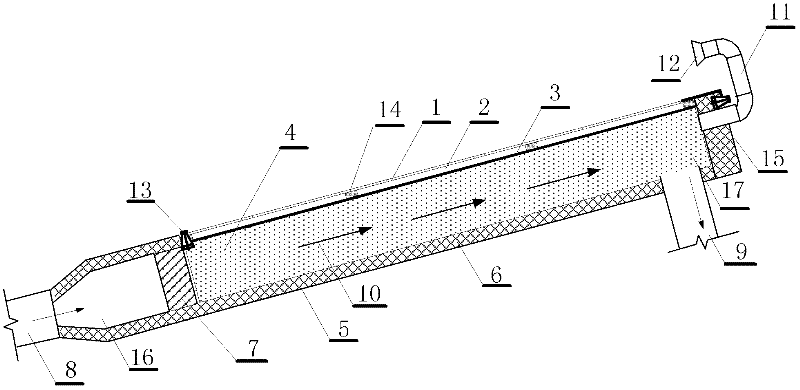

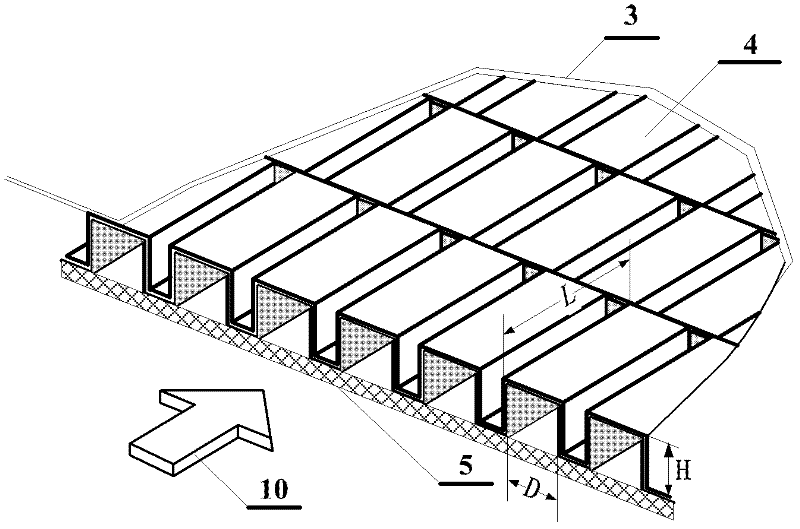

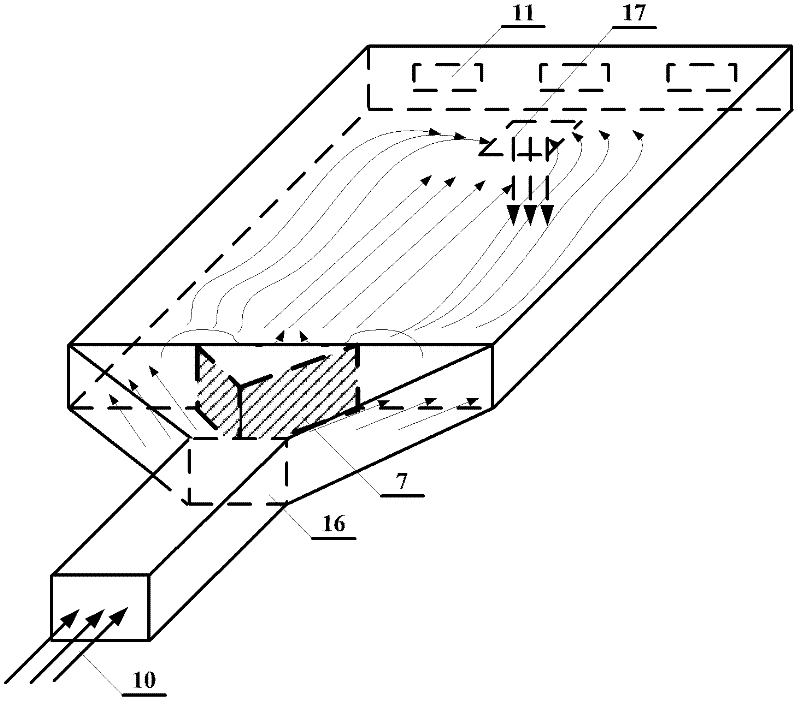

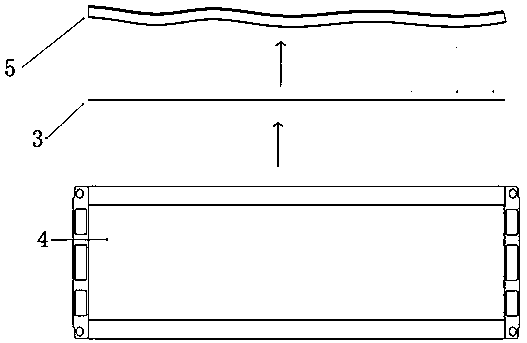

Solar air heat collection device with fluctuant strip fins

InactiveCN102353155AIncrease the heat exchange areaIncrease disturbanceSolar heating energySolar heat devicesCollection systemEngineering

The invention relates to a solar air heat collection device with fluctuant strip fins and belongs to the technical fields of solar utilization and energy conservation of buildings. The device comprises a transparent cover plate, a heat collecting pipe, a vent pipe, a sealed air layer and an air circulation channel. At least two groups of strip fins are arranged in the air circulation channel along the air circulating direction; two adjacent groups of strip fins are staggered; the cross sections of each group of strip fins have fluctuant sawtooth shapes; and a flow guide structure is arranged close to an air inlet in the air circulation channel. The solar air heat collection device greatly increases a heat exchange area between air and the heat collecting plate through the strip fins, improves heat exchanging efficiency, and optimizes the flow field of the air circulation channel through the flow guide structure. In the device, all components are made of common materials by common production processes, so that the device has the advantages of simple process, low cost and the like. The solar air heat collection system can be used in the fields of solar low temperature heat utilization such as heating, drying and the like, has low cost, is convenient to operate and maintain and has a wide application prospect.

Owner:TSINGHUA UNIV

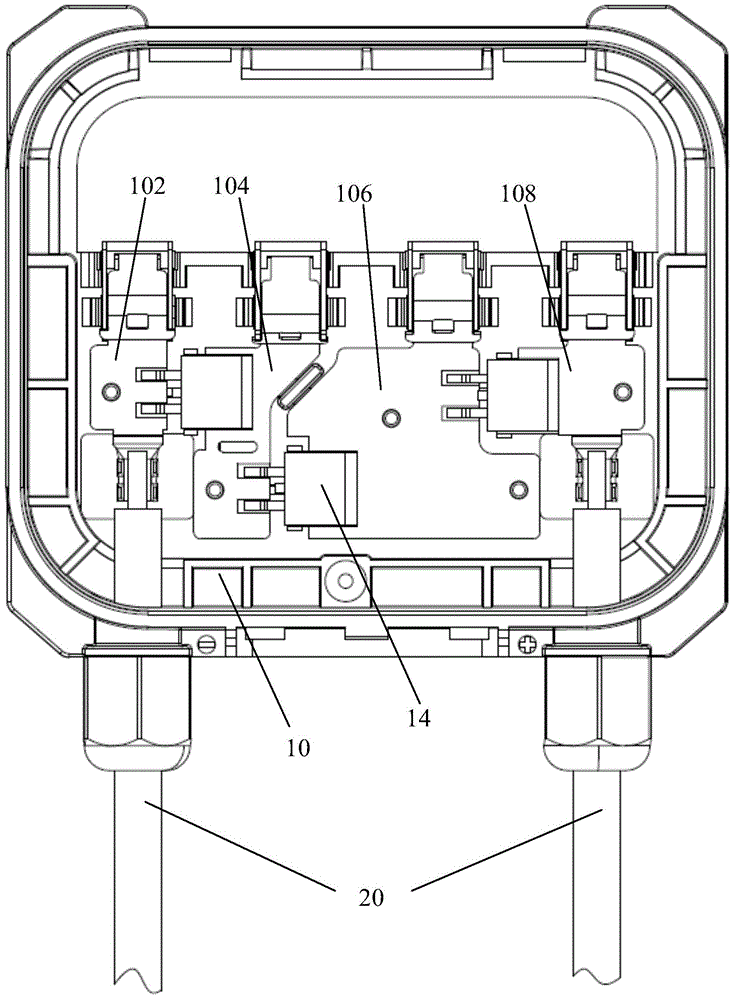

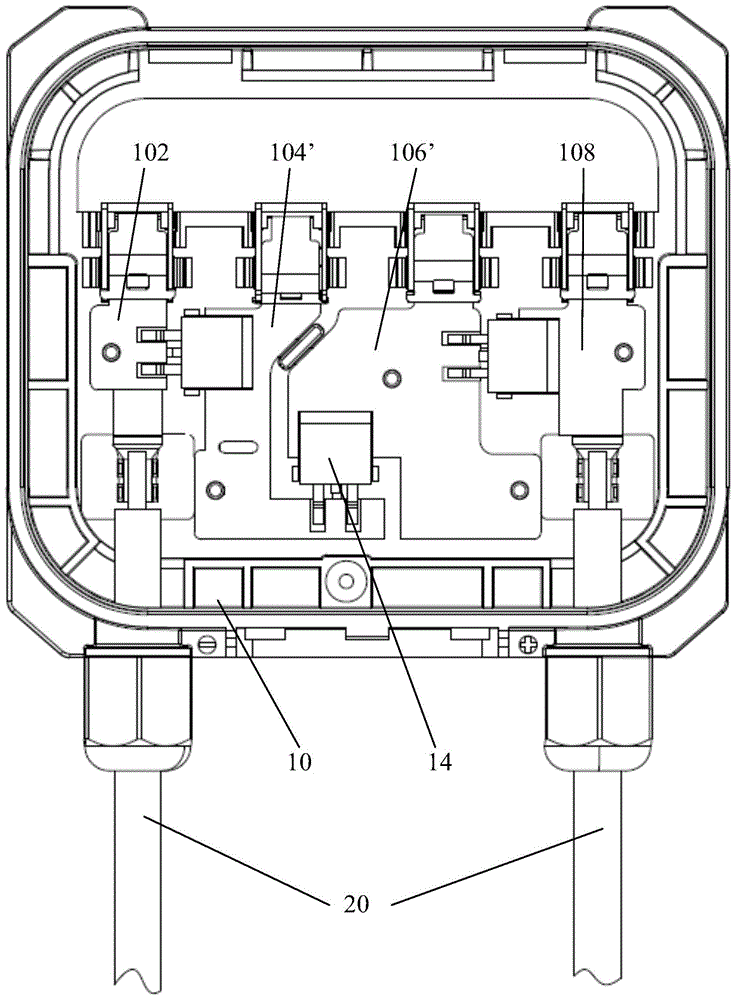

Photovoltaic module junction box with high heat dissipation performance

InactiveCN104467656AEfficient heat dissipationEven heat dissipationPhotovoltaicsPhotovoltaic energy generationElectricityElectrical polarity

The invention provides a photovoltaic module junction box with high heat dissipation performance. The junction box comprises a junction box body and electrical connecting wires, wherein a plurality of connection terminals connected with a photovoltaic module bus bar are arranged in the box body in sequence, the connection terminals comprise the first connection terminal, the second connection terminal, the third connection terminal and the fourth connection terminal, the second connection terminal, the third connection terminal and the fourth connection terminal are provided with SMD type diodes, the diodes are electrically connected with the adjacent connection terminals, the polarity is kept consistent after connection, and the plane area of the connection terminals arranged in the middle of the junction box is larger than that of the connection terminals located on the two sides of the junction box. According to the photovoltaic module junction box with high the heat dissipation performance, the connection terminals in different positions are designed to be in different sizes and different structures according to the distribution condition of the diodes in the junction box, and therefore heat dissipation in the junction box is efficient and uniform, local high temperature is avoided, and the service life of the junction box is guaranteed.

Owner:QC SOLAR SUZHOU CORP

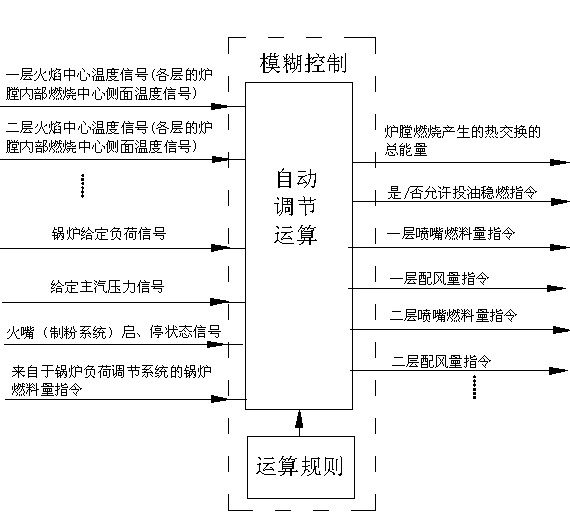

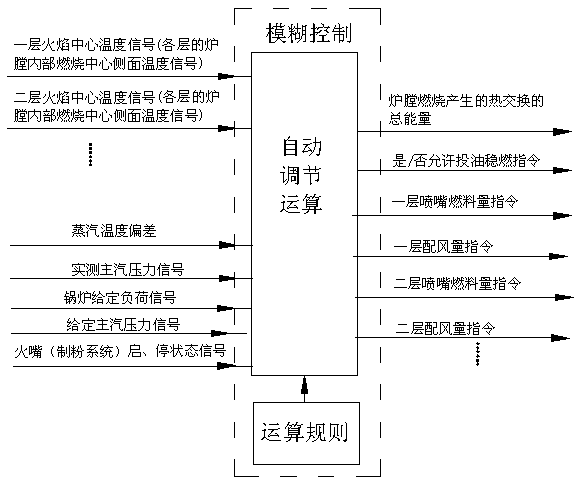

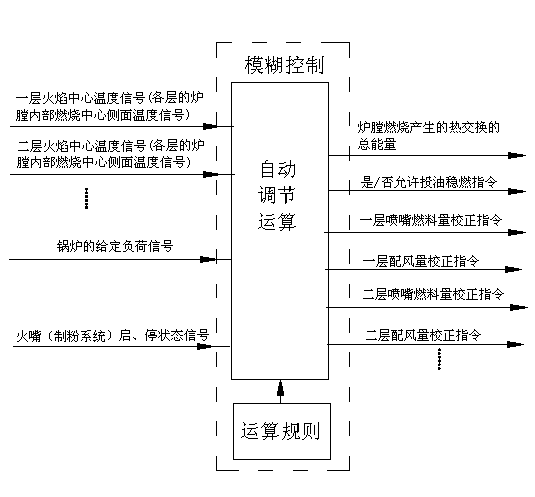

Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

ActiveCN103047678AAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationAutomatic controlCombustion

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

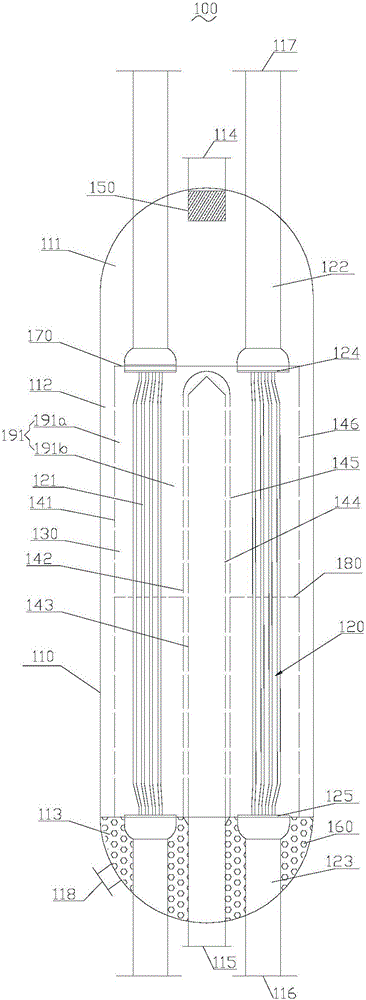

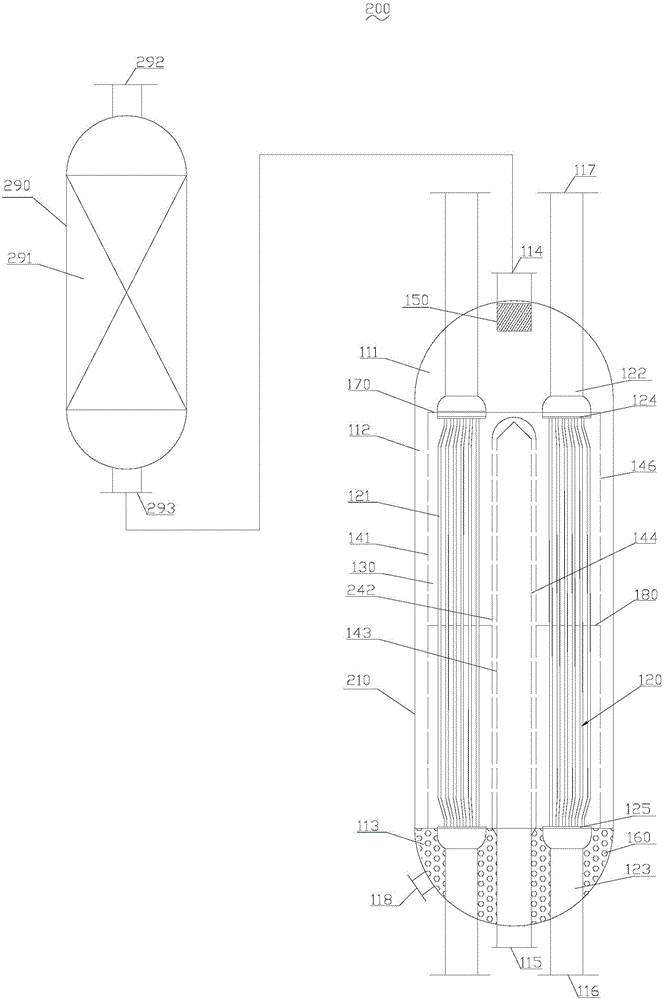

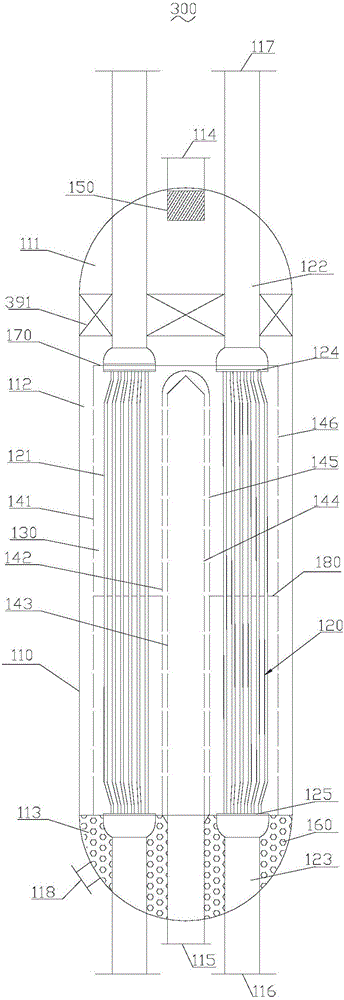

Steam rising type radial-flow reactor

ActiveCN105833804AReduce carbon depositionReduce riskChemical/physical processesWater vaporChemical reactor

The invention provides a steam rising type radial-flow reactor, and relates to the field of petrochemical and coal chemical reactors. The steam rising type radial-flow reactor comprises a reactor shell, a heat exchange tube bundle, a catalyst bed, a flow diversion barrel, a flow confluence barrel, a flow confluence pipe, a reaction material inlet, a water vapor outlet, a reaction material outlet, a cooling water inlet, a catalyst discharge opening and a heat insulation reaction section; the flow diversion barrel, the flow confluence barrel and the flow confluence pipe are sequentially sleeved and communicated; the catalyst bed is arranged in a gap between the flow diversion barrel and the flow confluence barrel; the heat exchange tube bundle passes through the catalyst bed; the bottom of the flow confluence pipe is communicated with the reaction material outlet; the heat insulation reaction section is communicated with the reaction material inlet; a catalyst is arranged in the heat insulation reaction section. According to the steam rising type radial-flow reactor provided by the invention, an effect that reaction gas radially passes through the catalyst bed is achieved; a flow area is large; a pressure drop is low, and temperature distribution is uniform; the local high temperature is avoided; the carbon deposit or inactivation risk of the catalyst is effectively reduced; steam is formed as a byproduct; economic benefits are good.

Owner:CHENGDU SEPMEM SCI & TECH

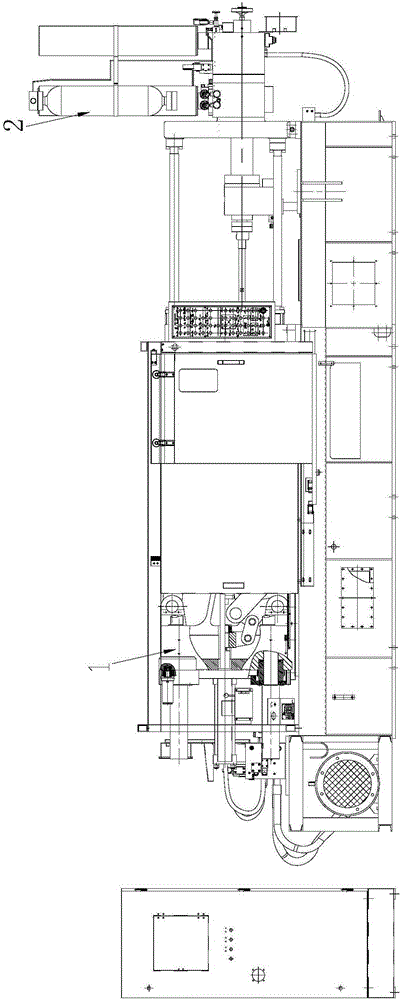

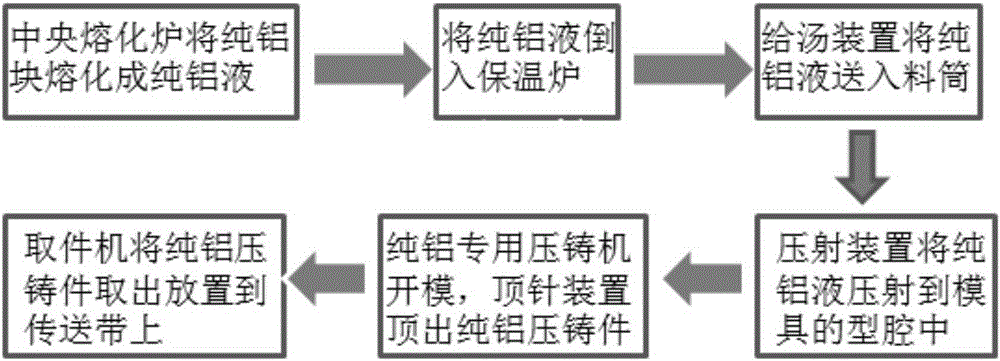

Pure-aluminium die casting equipment and pure-aluminium die casting technology

InactiveCN105234368AOvercome the problem of high resistance caused by poor liquidityImprove performanceDie castingElectro hydraulic

The invention is applicable to the technical field of pure-aluminium die casting, and discloses pure-aluminium die casting equipment and a pure-aluminium die casting technology. The pure-aluminium die casting equipment comprises a die-casting machine connected with a die-casting die; the die-casting machine comprises a material feeding barrel; the pure-aluminium die casting equipment further comprises a central melting furnace used for heating and melting an aluminium block, a heat preserving furnace used for performing heat preservation on molten aluminium, a molten aluminium feeding device used for conveying the molten aluminium into the material feeding barrel and a press-shooting device used for press-shooting the molten aluminium from the material feeding barrel to the die cavity of the die casting die; an ejecting device used for ejecting a formed product from the die cavity is arranged on one side of the die casting die; and the press-shooting device is provided with an electro-hydraulic proportional throttle valve with valve core position feedback. The above pure-aluminium die casting equipment is adopted in the pure-aluminium die casting technology. By adopting the pure-aluminium die casting equipment and the pure-aluminium die casting technology provided by the invention, the production qualification rate is high; the cost is low; and the requirement of markets on volume production of pure-aluminium parts is met.

Owner:SHENZHEN LEADWELL TECH CO LTD

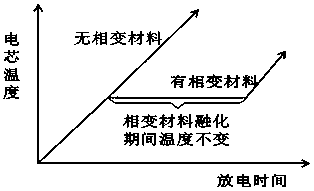

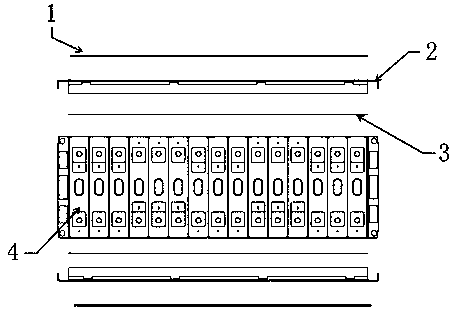

Power battery thermal management method and system based on phase change material

InactiveCN110808431APracticalSolve the disadvantages in cold and heat managementSecondary cellsPower batteryThermodynamics

The invention discloses a power battery thermal management method based on a phase change material. The battery cell of the power battery is surrounded by a PCM heat dissipation board. The thermal management method comprises a heat dissipation stage and a heating stage. In the heat dissipation stage, when the temperature of the battery cell reaches 35 DEG C, the PCM heat dissipation board absorbsthe heat generated during discharging of the battery cell and changes the form to reduce the temperature of the power battery. In the heating stage, when the temperature of the battery cell is lower than 35 DEG C, the PCM heat dissipation board conducts the stored heat to the battery cell to maintain the constant temperature state of the battery cell. The method has the characteristics of good heat dissipation and temperature equalization performance effects and simple system structure and is feasible for temperature management. Meanwhile, the method plays a very important role in the lightweight of battery PACK and the improvement of energy density. Besides, the utilization of phase change material effectively solves the disadvantages in air cooling and liquid cooling thermal management and greatly reduces the production cost and the use cost.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

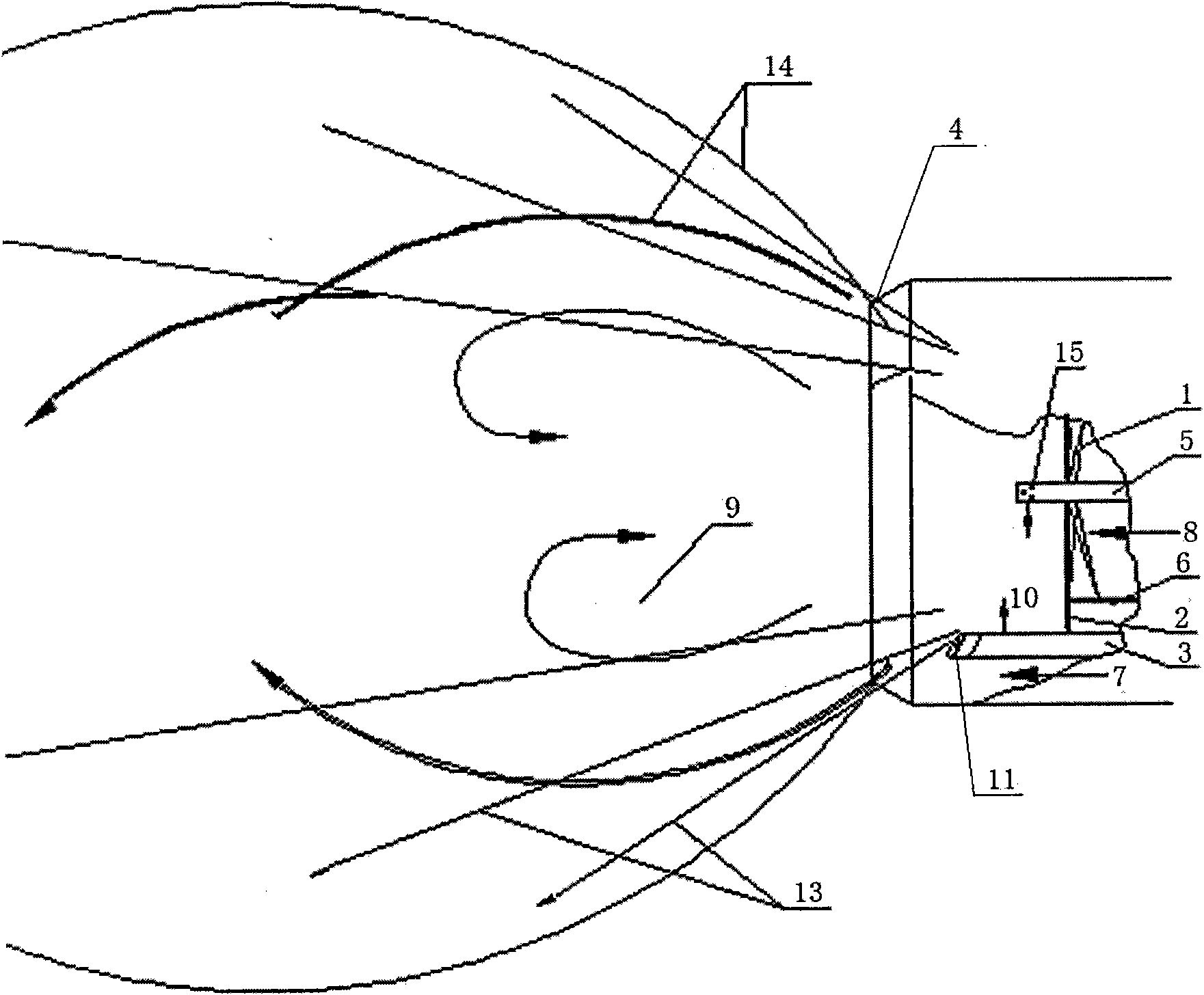

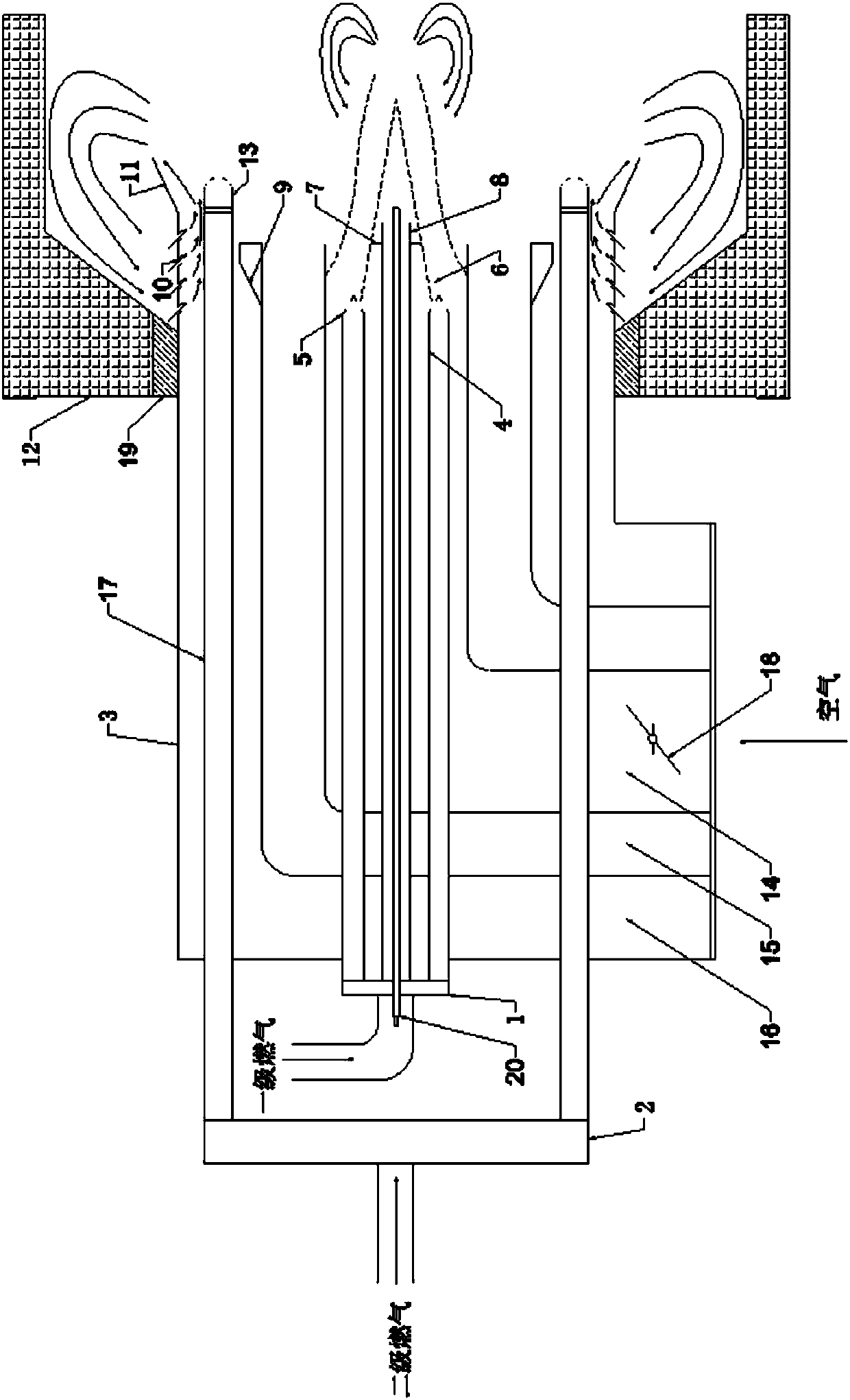

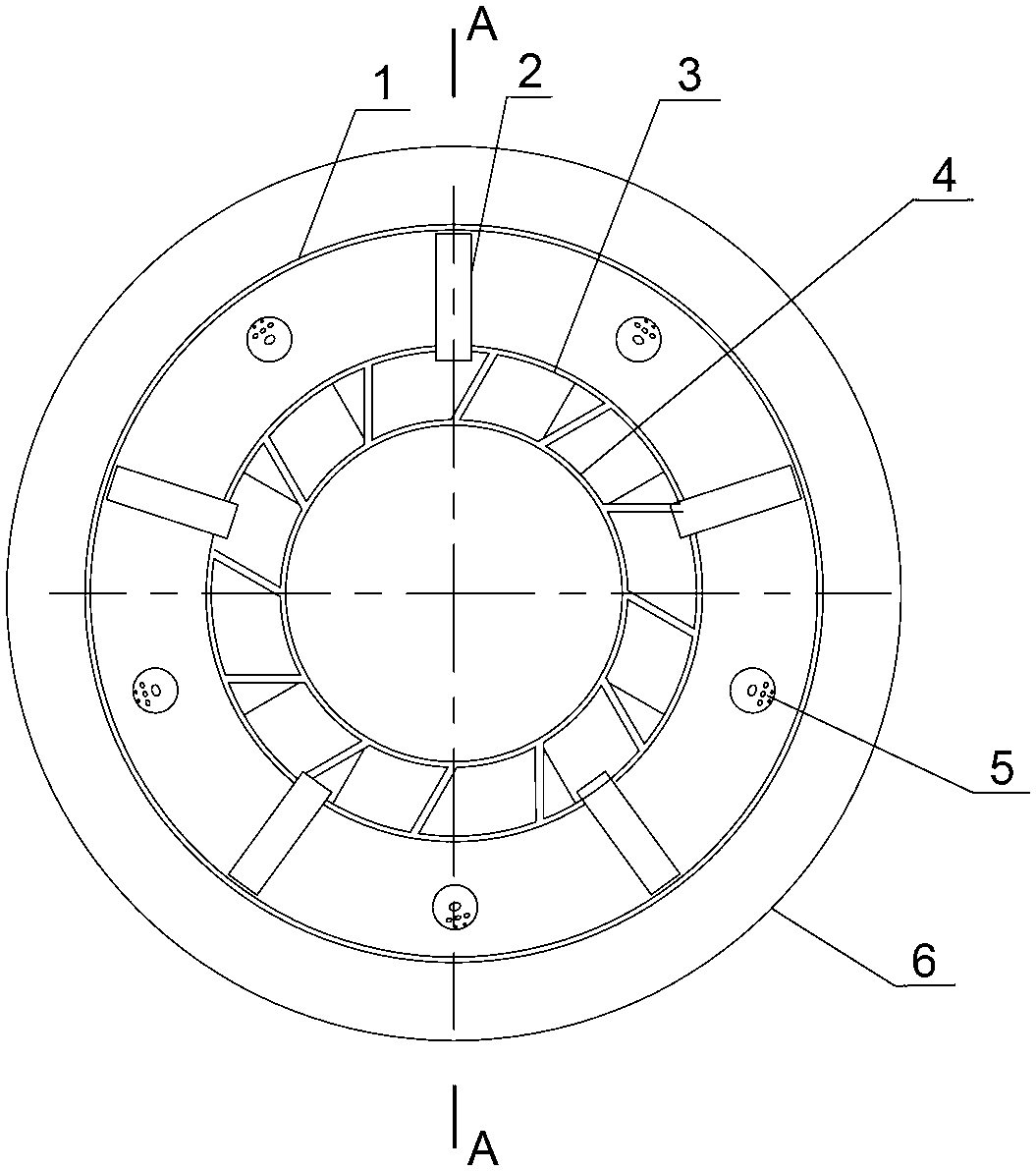

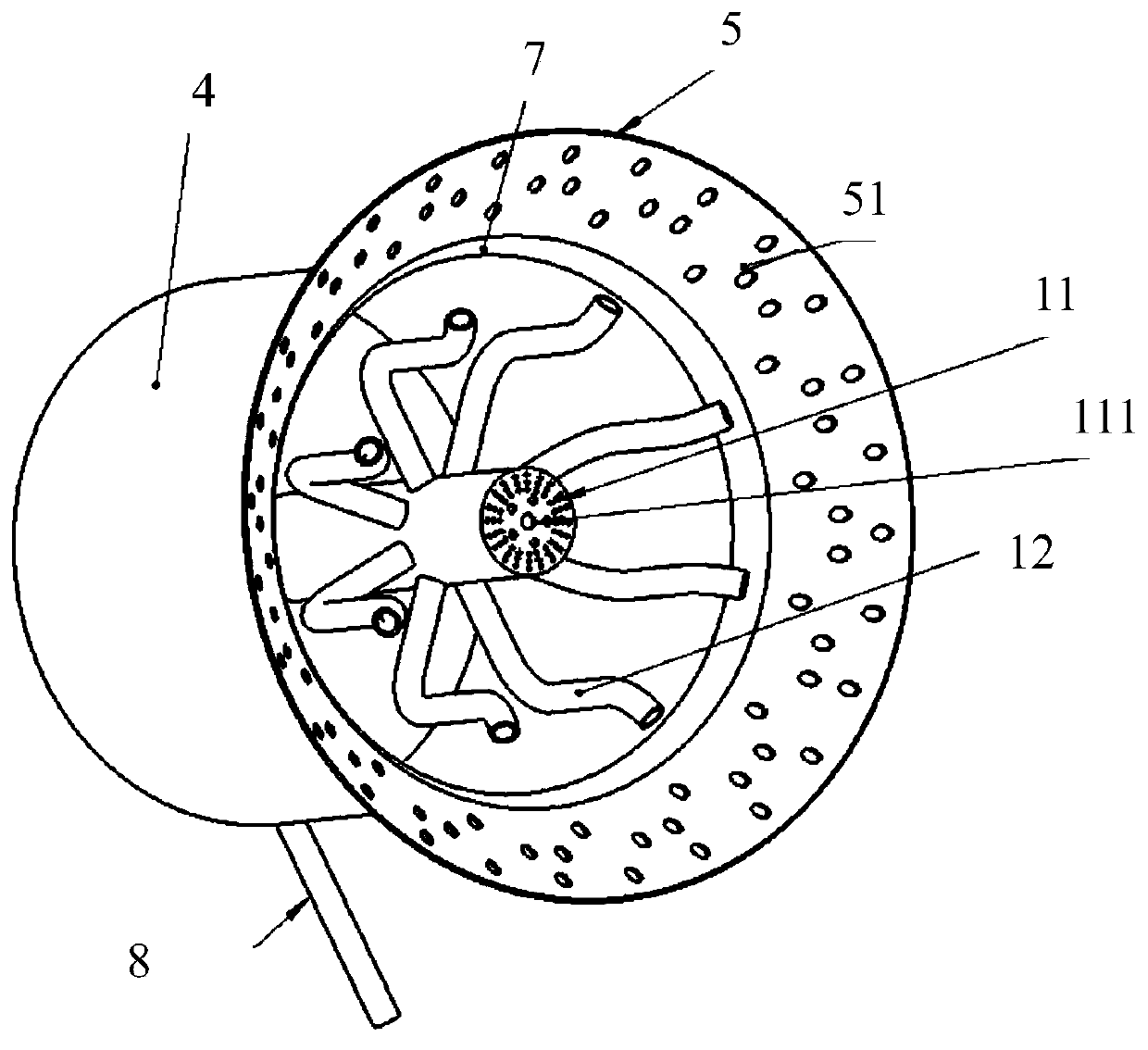

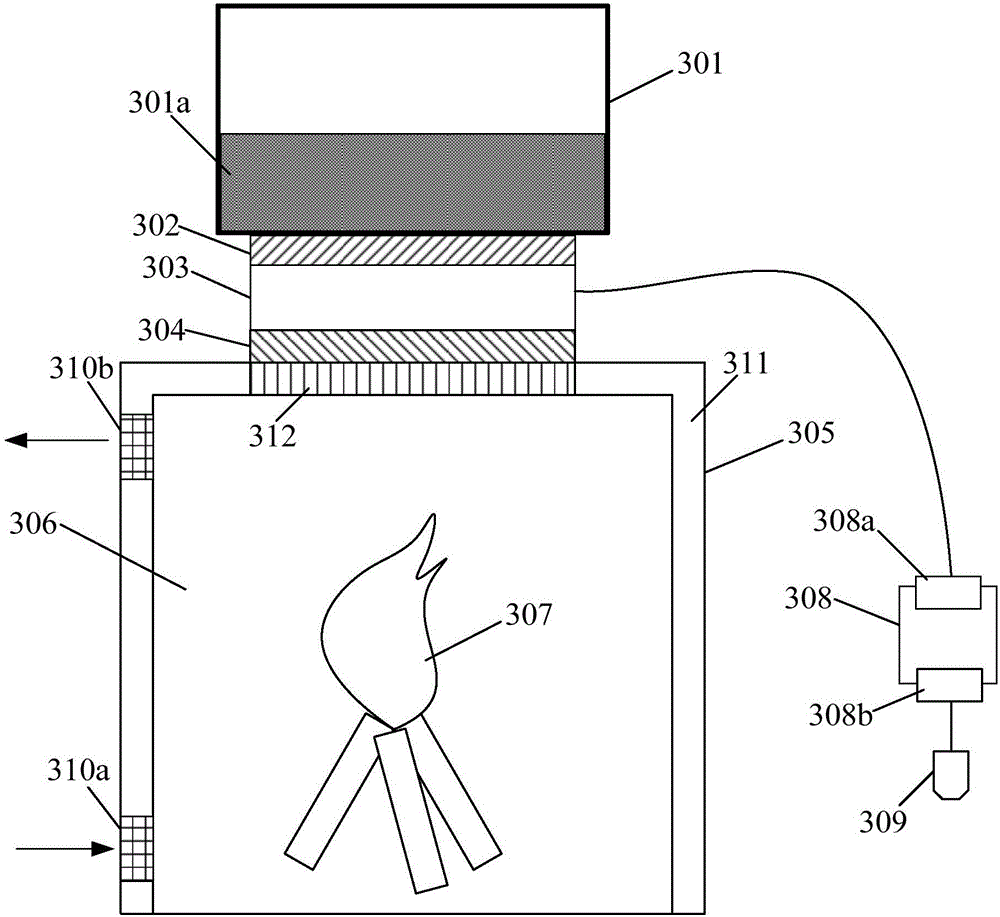

Fuel gas combustion device with ultra-low NOx emission amount and fuel gas distribution method

ActiveCN103267286AAvoid local high temperatureUniform heat loadGaseous fuel burnerPhysicsAutomotive engineering

The invention relates to a fuel gas combustion device with ultra-low NOx emission amount and a fuel gas distribution method, aims at enabling NOx emission amount to be smaller than 20ppm and meeting the low-emission requirement of a high-power combustor and belongs to the technical field of industrial boilers. The fuel gas combustion device with the ultra-low NOx emission amount is characterized in that a central barrel, a swirler, an inner throat and an outer throat are sequentially and coaxially arranged along the central axis of the combustion device outward, a first combustion air channel is arranged between the inner throat and the outer throat, a second combustion air channel is arranged between the inner side of the inner throat and the outer side of the central barrel, and a plurality of T-shaped fuel gas guns and a plurality of oblique-mouth fuel gas guns are arranged, staggered and evenly distributed in an equal-diameter mode. The fuel gas combustion device with the ultra-low NOx emission amount and the fuel gas distribution method have the advantages that fuel gas holes of the oblique-mouth fuel gas guns are outward, flame is formed in the first combustion air channel on the outer side of flame of the T-shaped fuel gas guns, accordingly a boiler furnace space is utilized to the most extent, the amount of produced NOx is little and is smaller than 20ppm, no CO is produced, and combustion is stable and reliable. The maximum power of one machine can reach to more than 70MW.

Owner:上海诺特飞博燃烧设备有限公司

Horizontal type reversal combustion coal-fired water heating boiler

The invention discloses a horizontal type reversal combustion coal-fired water heating boiler. The horizontal type reversal combustion coal-fired water heating boiler comprises a water cooling wall composed of an inner container and an outer container. A water pipe penetrates through a combustion chamber. A water tank is connected with the water cooling wall, and six-return-stroke smoke pipe bundles are arranged in the water tank. The horizontal type reversal combustion coal-fired water heating boiler is characterized in that fresh air enters the combustion chamber from two air inlets at an inlet air baffle; coal briquettes are laid on the water pipe to be combusted, and solid carbon separated out of the volatile component falls on refractory bricks and is combusted thoroughly. Generated smoke enters smoke pipes, the direction of the smoke changes when the smoke passes through each flame turning opening, and finally the smoke is discharged out of a smoke outlet. A chimney is additionally formed in the upper portion of the combustion chamber and used for positive combustion banking. Positive pressure reversal combustion is realized through the horizontal type reversal combustion coal-fired water heating boiler, the volatile component and the solid carbon of the coal are combusted separately, so that the combustion efficiency is improved, and emission of pollutants is lowered. The generated smoke passes through the smoke pipes and exchanges heat with water, so that the heat of the smoke is fully used. Conversion from reversal combustion to positive combustion is achieved and used for night banking, increase of coal consumption caused by frequent starting and stopping of the boiler is avoided, and the horizontal type reversal combustion coal-fired water heating boiler is compact in overall structure and convenient to install.

Owner:时亦飞

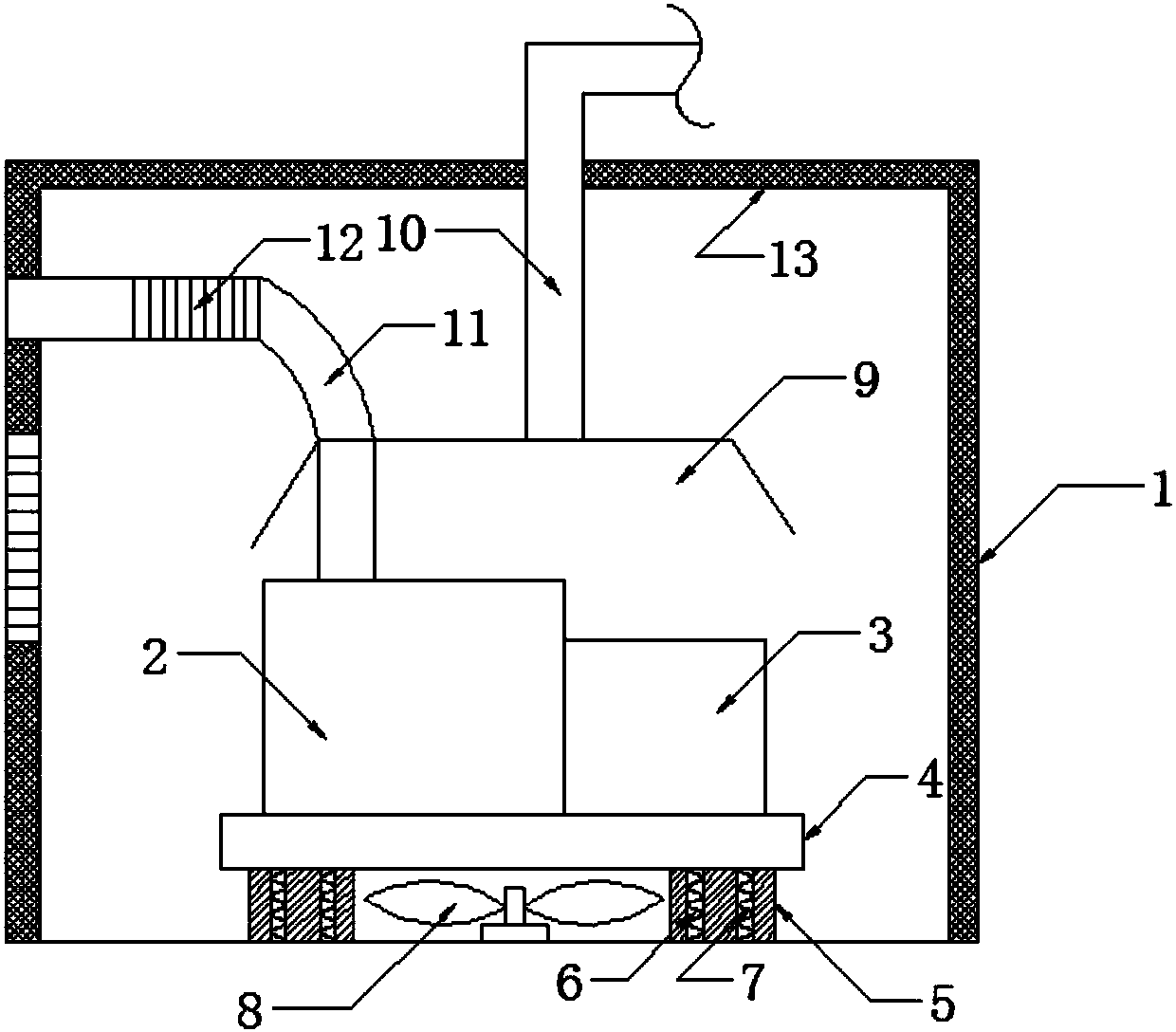

Environment-friendly and efficient power generating unit

InactiveCN107605593AReduce noiseImprove stabilityExhaust apparatusNon-rotating vibration suppressionActivated carbonCold air

The invention provides an environment-friendly and efficient power generating unit. A diesel engine and a power generator are disposed on a fixed base in a machine room of the power generating unit, and a grid plate is adopted as the fixed base; damping pads are arranged at the four corners of the fixed base; a plurality of vertically extending damping cavities are formed in the damping pads, anddamping springs extending in the same direction are arranged in any one damping cavity; a circulation fan is arranged at the bottom end of the fixed base; a cold air hood is arranged at the top ends of the diesel engine and the power generator and communicates with a central air conditioning system through a cold air delivery pipeline; and a sound absorption cotton layer is arranged on the inner wall of the machine room of the power generating unit, a window-shade is arranged in one side wall, and a solid activated carbon mesh partition plate is arranged in a flue gas exhaust pipeline of the diesel engine. The environment-friendly and efficient power generating unit has the beneficial effects of being low in noise, small in pollution and environmentally friendly.

Owner:TIANJIN CHENBAO ELECTROMECHANICAL TECH CO LTD

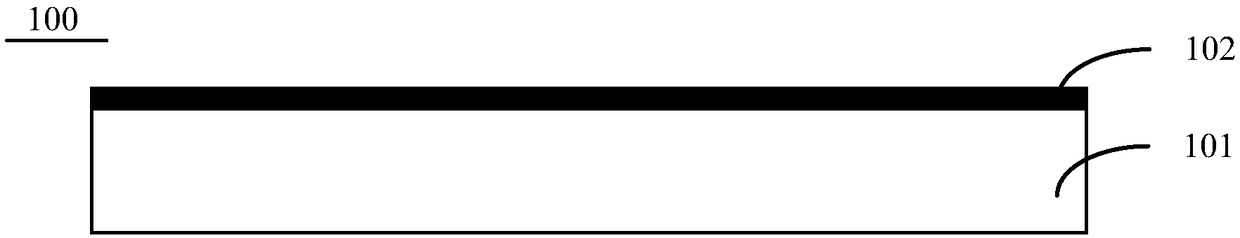

Heat dissipation structure, house and electronic device

ActiveCN108990365AAvoid local high temperatureImprove cooling efficiencyCooling/ventilation/heating modificationsEngineeringHeat conducting

The present disclosure relates to a heat dissipation structure, a housing and an electronic device. The heat dissipation structure includes a heat absorbing layer disposed close to a heat source for absorbing heat generated by the heat source. A heat conductive layer stacked and arranged with the heat absorbing layer for conducting heat absorbed by the heat absorbing layer to dissipate heat from the heat source; The heat dissipation structure proposed in the present disclosure can actively absorb heat at the heat source through the heat absorbing layer and disperse and cool the absorbed heat through the heat conducting layer, thereby avoiding local high temperature and contributing to improving heat dissipation efficiency at the heat source.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

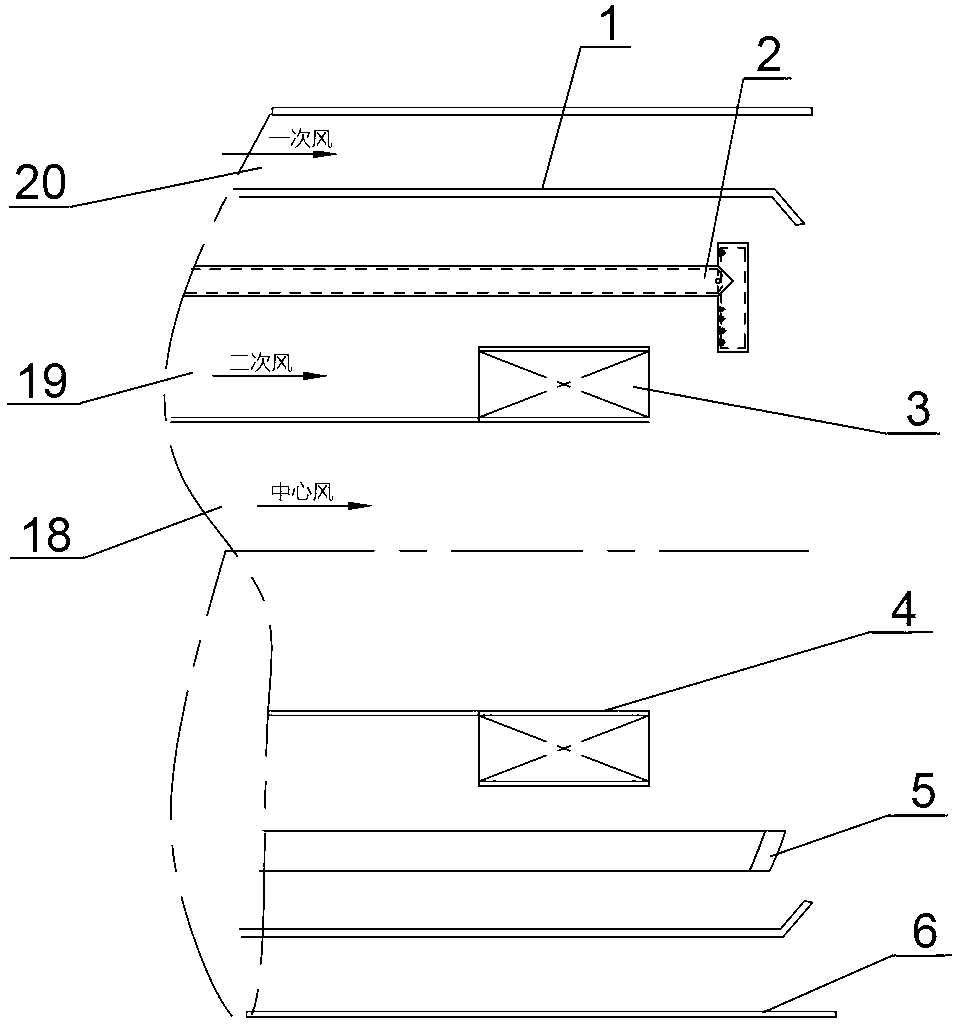

Graded low-nitrogen gas combustor based on rotational flow

The invention provides a graded low-nitrogen gas combustor based on rotational flow. The graded low-nitrogen gas combustor comprises a combustor barrel body, a connecting barrel body and a combustor hood which are sequentially arranged, the diameter of the combustor barrel body is smaller than that of the combustor hood, the diameter of the connecting barrel body is gradually increased in the direction from the combustor barrel body to the combustor hood, a rotational flow flame stabilizing disc is further arranged between a main fuel gas spray pipe and an auxiliary fuel gas spray pipe, the rotational flow flame stabilizing disc comprises a first cylinder and a second cylinder which are coaxially arranged, the first cylinder is arranged inside the second cylinder, a first rotational flow blade is arranged between the first cylinder and the second cylinder, a flame stabilizing disc end part is further arranged in the circumferential direction of the second cylinder, a second rotationalflow blade is arranged between the second cylinder and the flame stabilizing disc end part, and the distance between the first rotational flow blade and the combustor barrel body in the central axis direction is smaller than the distance between the second rotational flow blade and the combustor barrel body in the central axis direction. By means of the technical scheme, the mixing degree of gas can be enhanced, and therefore the key performance of a combustor is improved.

Owner:HUAQIAO UNIVERSITY

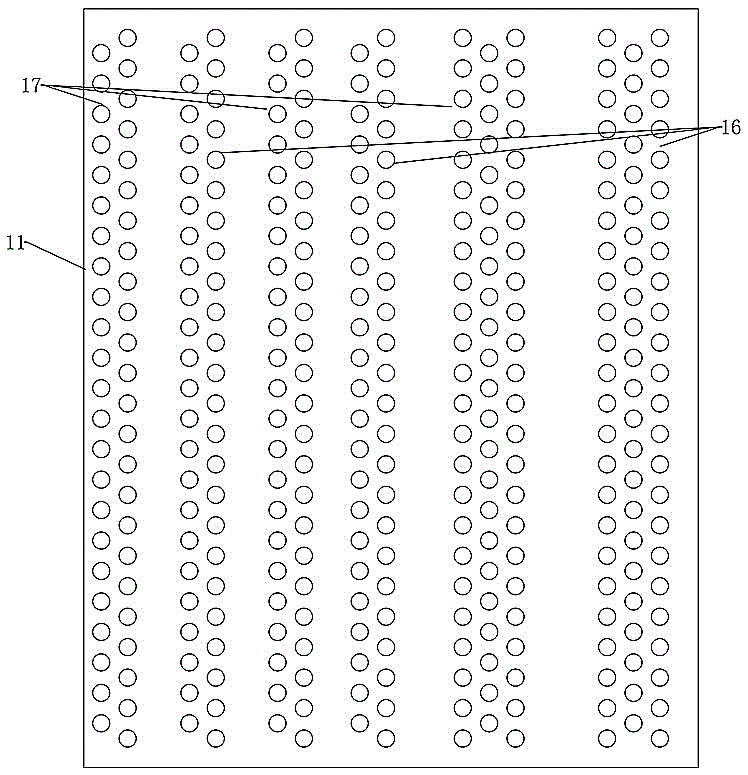

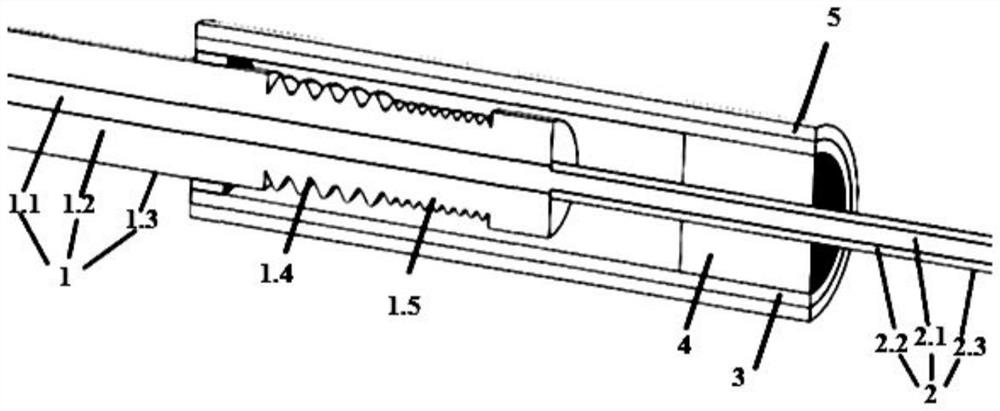

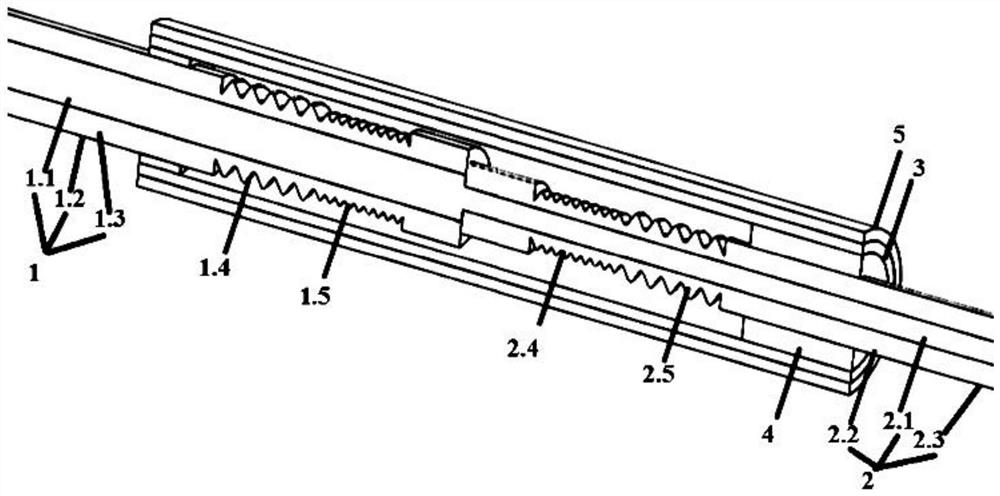

Cascade cladding light stripper and manufacturing method thereof

PendingCN111786247AAvoid local high temperatureIncrease powerCoupling light guidesActive medium shape and constructionMetallic enclosureEngineering

The invention discloses a cascade cladding light stripper and a manufacturing method thereof. The cladding light stripper comprises a first optical fiber, a second optical fiber, a quartz tube and a metal shell. According to the invention, cladding light is stripped layer by layer step by step through a plurality of cascaded cladding light stripping devices and a segmented corrosion method to guide away heat generated by the cladding light or the cladding light step by step and stage by stage, so that high-power cladding light stripping can be realized, local high temperature is effectively avoided, the cladding light stripper can be applied to a high-power optical fiber laser, and manufacturing difficulty is low.

Owner:宝宇(武汉)激光技术有限公司

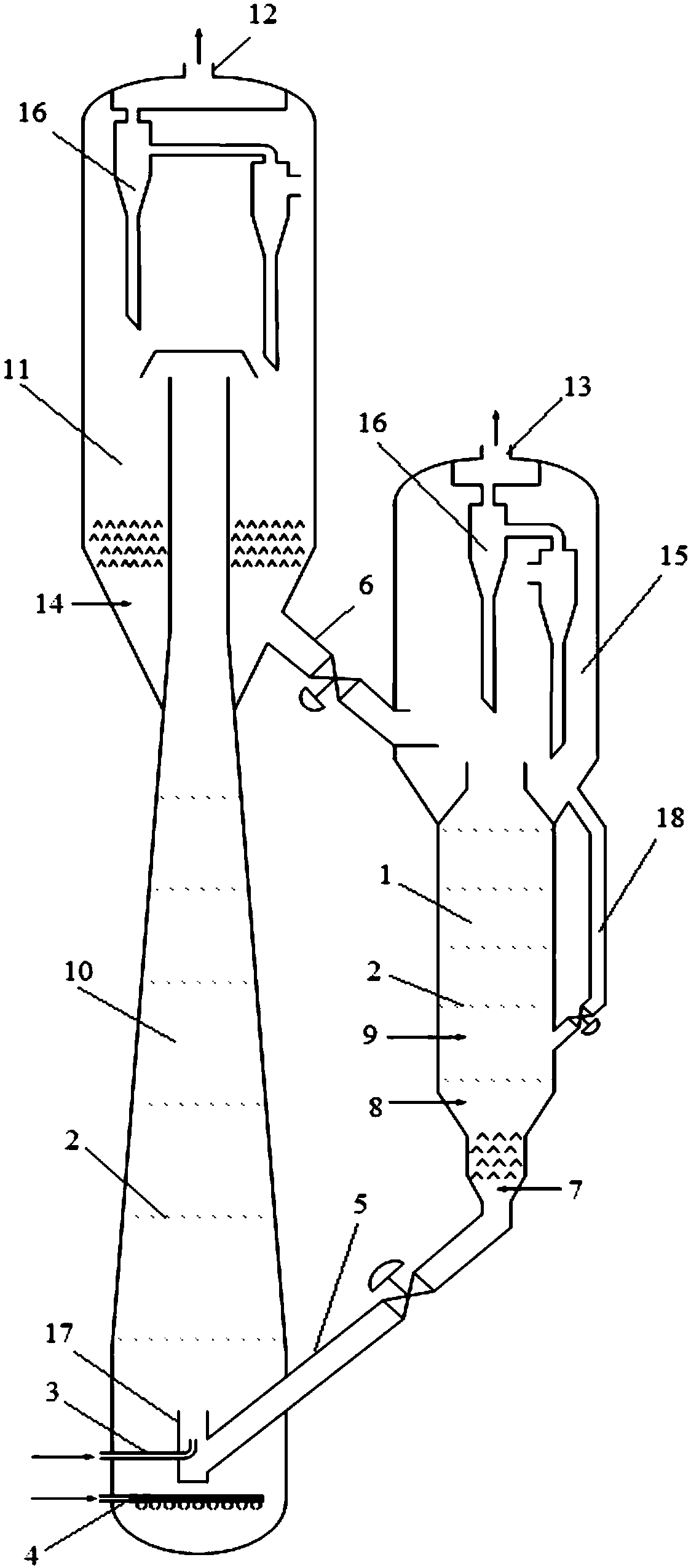

Reactor capable of reducing back mixing for preparing alkenes by dehydrogenation of alkanes and preparation method

ActiveCN108654526ATake advantage ofHigh selectivityHydrocarbonsChemical recyclingDehydrogenationAlkene

The invention relates to reaction apparatus for catalytic dehydrogenation of alkanes. The reaction apparatus comprises a reaction section and a reactor sedimentation section; the reactor sedimentationsection is positioned on the upper part of the reaction section; the diameter of the reaction section is gradually decreased from top to bottom; a catalyst regeneration tube aslant stretches into thereaction section, and the outlet end of the catalyst regeneration slant tube is positioned at the lower part of the reaction section; and a feeding distribution device is positioned below the outletend of the catalyst regeneration slant tube in the reaction section. The reactants and the catalyst in the reactor flow concurrently upwards, so that the uniformity of the temperature distribution inthe reactor can be effectively improved, local high temperature can be avoided, and then the thermal reaction is reduced. In addition, the diameter of the reactor is gradually decreased along the flowing direction of the fluid, and the secondary conversion of the alkenes caused by back mixing is reduced, so that the yield and the selectivity of alkenes are improved. A high-temperature regeneratoris directly sprayed into the bottom of the dense-phase bed of the reactor, so that rapid mixing of the high-temperature catalyst with the catalyst in the reactor is facilitated, and local high temperature in the bed layer is avoided. The dense-phase fluidized catalyst is beneficial to the ending of the transmission of free radicals, so that the thermal reaction is reduced, and the selectivity of preparing alkenes by the dehydrogenation of alkanes is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

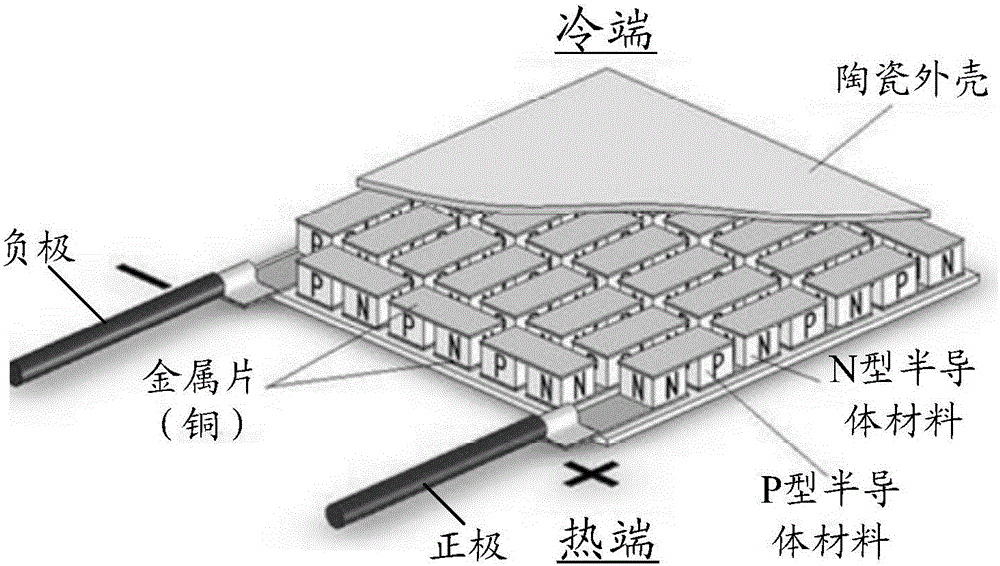

Power generation device and charging system

ActiveCN105914859AAvoid wastageImprove heating efficiencyBatteries circuit arrangementsElectric powerEngineeringElectric energy

The invention relates to a power generation device and a charging system. The power generation device is composed of a thermoelectric generating component, a heat radiating component, a heating component, a first heat conductive gasket, a second heat conductive gasket, a first electric energy output unit and a power supply interface. The first heat conductive gasket includes a first surface and a second surface; the first surface is in contact with a heat radiating end of the heat radiating component; and the second surface is in contact with a cold end of the thermoelectric generating component. The second heat conductive gasket includes a third surface and a fourth surface; the third surface and a thermal end of the thermoelectric generating component are in contact; and the fourth surface and a heating end of the heating component are in contact. The first heat conductive gasket and / or the second heat conductive gasket employ / employs flexible materials / a flexible material that can store energy and has a good uniform heat transferring performance. The first electric energy output unit connected with the thermoelectric generating component is used for outputting the electric energy generated by the thermoelectric generating component and carrying out external power supplying through the power supply interface. According to the technical scheme, uniform heat radiation during the heat conduction process can be guaranteed; a local high temperature phenomenon can be avoided; and the heat conduction efficiency and power generation efficiency can be improved.

Owner:ZHONGXIA NEW ENERGY SHANGHAI CO LTD

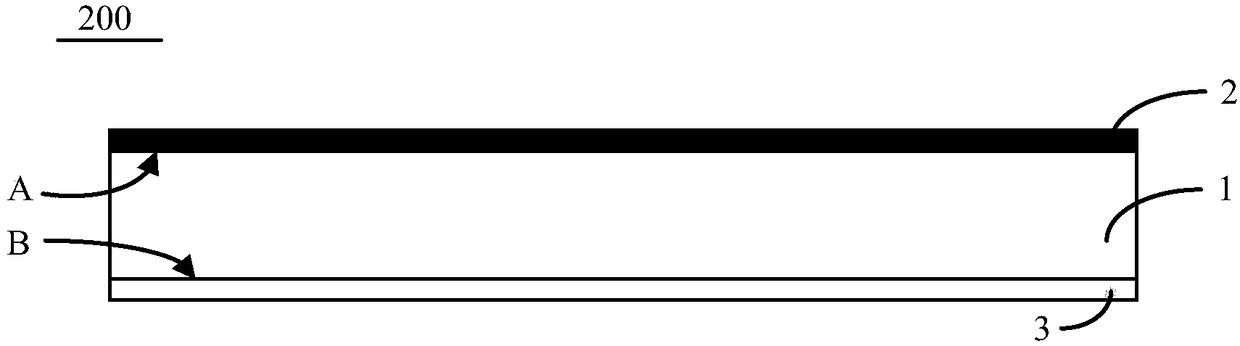

Copper clad laminates, printed circuit boards and electronic device

InactiveCN108990253AShorten the pathImprove cooling efficiencyCircuit thermal arrangementsHemt circuitsCopper foil

The present disclosure relates to copper clad laminates, printed circuit boards and electronic devices. The copper clad laminate comprises a base material layer and a copper foil layer laminated on atleast one surface of the base material layer, wherein the copper foil layer is used for manufacturing a target circuit pattern; The copper clad laminate further comprises at least one heat conductivelayer; The technical proposal of the invention can be provided with a heat conductive layer on the copper clad laminate or between adjacent copper clad laminates, so that when the copper clad laminate is processed into a printed circuit board and electronic components are installed, heat generated by the operation of the electronic components can be dispersed in all directions through the heat conductive layer to avoid local high temperature; Moreover, the heat transfer process does not need to pass through the air and other medium with large thermal resistance, which is conducive to improvethe heat dissipation efficiency of electronic equipment.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Method for improving reheating quality of crab cream and crabmeat through freezing conditioning

InactiveCN108353998AGood antibacterial effectImproves water retention and retentionMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingRadio frequencyBiology

The invention discloses a method for improving reheating quality of crab cream and crabmeat through freezing conditioning, and belongs to the technical feed of processing of aquatic products. The method comprises the steps of using crab cream and crab meat which are obtained by the processing course of steaming for cooking, stripping and the like as raw materials, adding a composite fresh keepingagent to the crab cream in a spraying manner, applying a recompounded water retaining agent for the crabmeat, performing vacuum packing on the treated crab cream or the crabmeat to obtain packed crabcream or packed crabmeat, placing the packed crab cream or the packed crabmeat in a blower instant freezer for low-temperature freezing for 2 hours, and then placing the frozen crab cream or the frozen crabmeat in a freezer of minus 18 DEG C for long-term preservation. The reheating course comprises early-stage frequency-conversion ultrasonic wave-soaking combined unfreezing and later-stage radio-frequency quick reheating. The method integrates fresh keeping, water retention and a reheating technique, so that the flavor and the quality frozen storage cooked crab cream can be improved to the maximum extent, the texture quality of the crabmeat is improved to the maximum extent, massive frozen crab cream and massive frozen crabmeat can be reheated once, and later-stage industrialized production is facilitated.

Owner:YANGZHOU YECHUN FOOD PRODN & DISTRIBUTION INC CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com