Power generation device and charging system

A technology for power generation devices and charging systems, applied in circuit devices, battery circuit devices, generators/motors, etc., can solve the problems of affecting heat conduction efficiency, low power generation efficiency, uneven heat conduction, etc., so as to avoid wasteful loss and improve power generation. Efficiency, the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

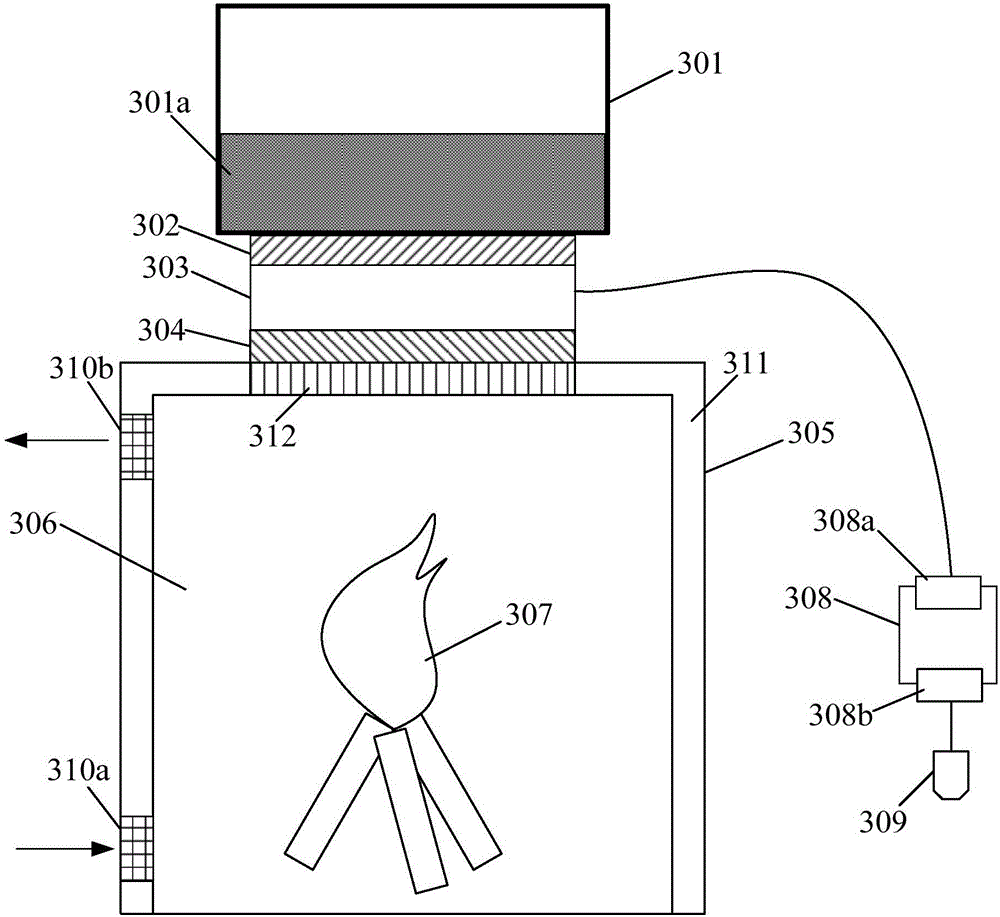

[0040] A structure of the power generation device provided by the embodiment of the present invention is as follows: image 3 As shown, the power generating device includes: a thermoelectric power generation part 303, a heat dissipation part 301, a heating part 305, a first heat conduction pad 302, a second heat conduction pad 304, a first electric energy output part 308 and a power supply interface 309; A thermal pad 302 includes a first surface and a second surface, the first surface and the heat dissipation end of the heat dissipation component 301 (ie image 3 The bottom of the heat dissipation component 301 (not shown in the figure) is bonded, and the second surface is bonded to the cold end of the thermoelectric power generation component 303; the second thermal pad 304 includes a third surface and a fourth surface , the third surface is bonded to the hot end of the thermoelectric power generation component 303, and the fourth surface is bonded to the heating end 312 of ...

Embodiment 2

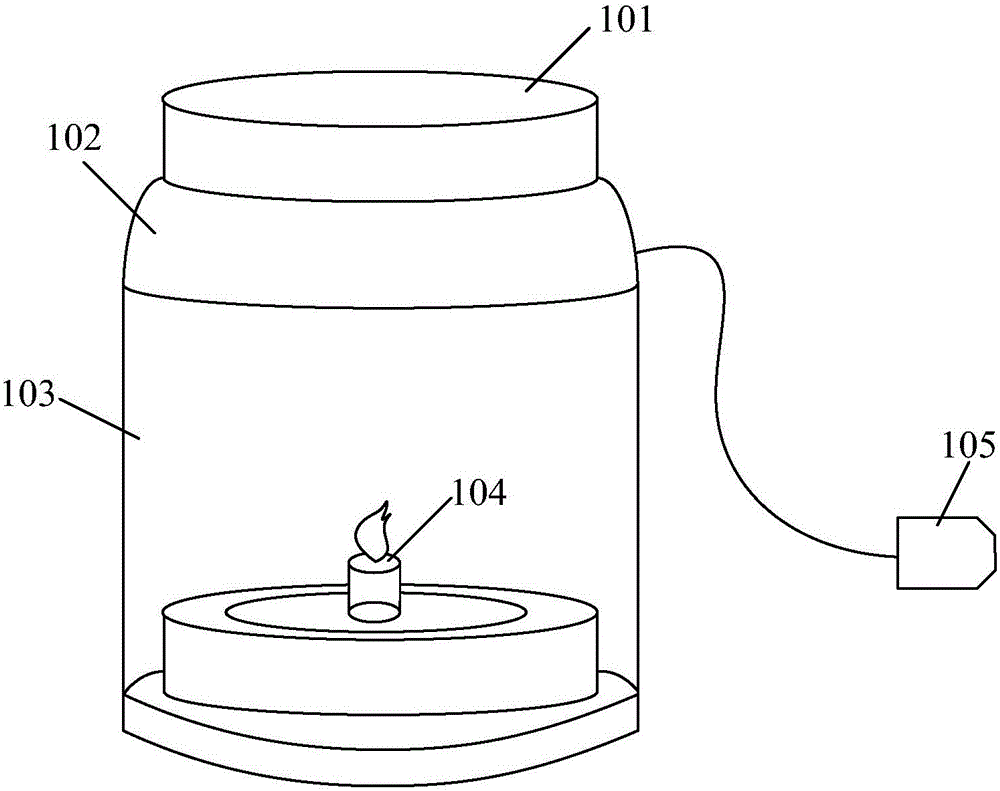

[0051] In the existing technology, such as figure 2 The thermoelectric power generation device shown only allows the output of electric energy by means of combustion and heating to realize power supply. The power supply method is single, and the use is not flexible enough, because in some cases, it is difficult to find suitable combustion materials in time, but electricity is urgently needed. For this reason, this embodiment is further improved on the basis of Embodiment 1 to provide another structure of the power generation device, such as Figure 4 As shown: in addition to the various components introduced in Embodiment 1, the power generating device also includes a second electric energy output component 313 connected to the power supply interface 309, which is used to accommodate the energy storage component 314 and control the energy storage The component 314 releases electric energy and realizes external power supply through the power supply interface 309 .

[0052] Du...

Embodiment 3

[0056] Apply the power generating device in Embodiment 2 or 3 to charge the batteries in electrical equipment such as mobile phones, GPS, smart bracelets, etc., to ensure the battery life of these electrical equipment, which is one of the most important uses in the field environment . For this reason, based on the power generating device in the second or third embodiment, this embodiment also provides a charging system, such as Figure 5 As shown, the charging system includes: a target battery 40 to be charged, a charging device 50 suitable for charging the target battery 40, and the above-mentioned power generating device 30, the power generating device 30 is connected to the charging device 50 for use To provide power for the charging device 50 .

[0057] In this embodiment, in order to realize the charging of the target battery 40 by the power generating device 30 more efficiently, in addition to improving the power generation efficiency of the power generating device 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com