Horizontal type reversal combustion coal-fired water heating boiler

A hot water boiler and coal-fired technology, which is applied in the field of hot water boilers, can solve problems such as failure to seal the furnace and poor heat transfer effect of flue gas and hot water, and achieve the effect of avoiding local high temperature and uniform heat transfer on the water side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

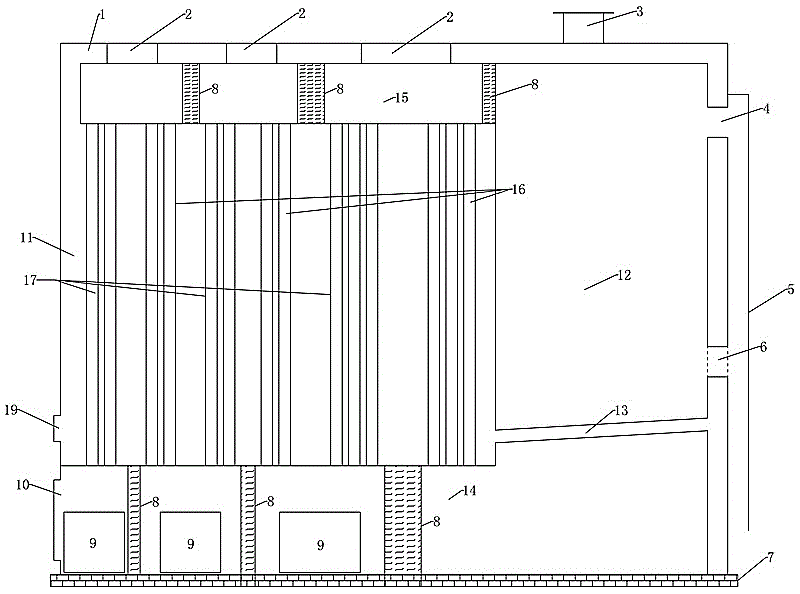

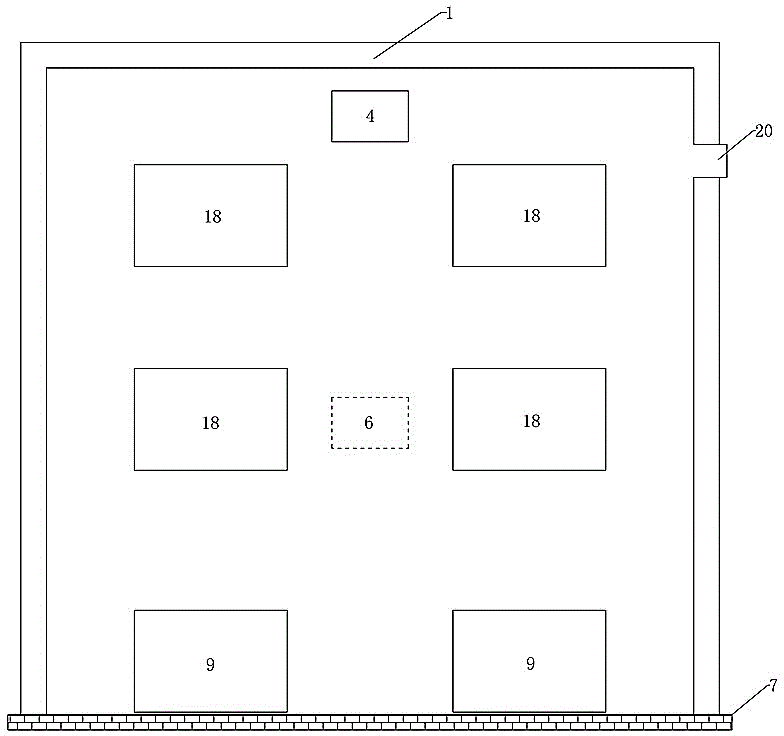

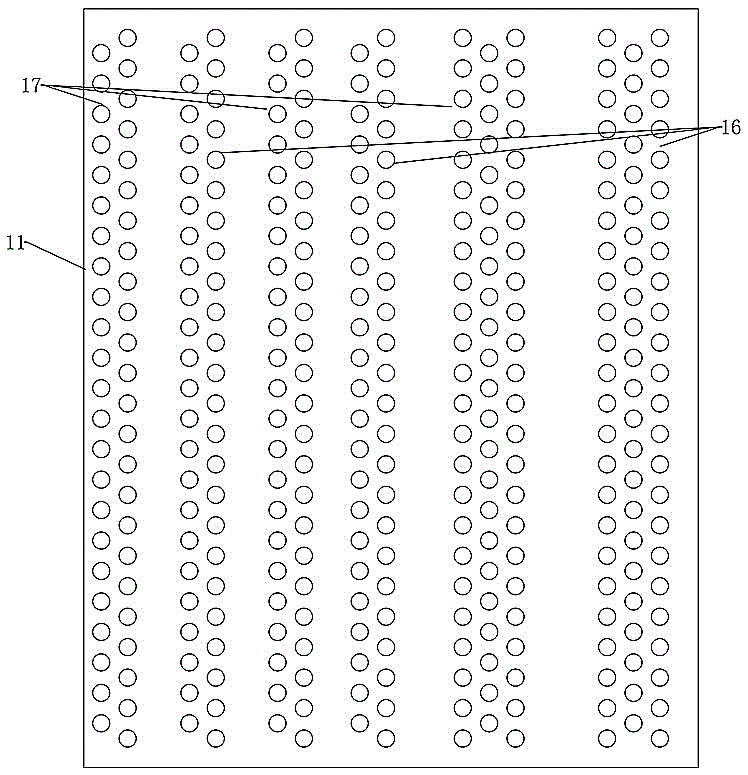

[0014] The accompanying drawings of the description show an embodiment of the present invention. The counter-firing boiler includes a water-cooled wall (1) composed of an inner tank and an outer tank, a combustion chamber (12) through which a water pipe (13) passes, a water tank (11) connected to a water-cooled wall (1), and a built-in six-pass The smoke tube bundle (16), (17), four coal inlets (18) are arranged on the side of the boiler. It is characterized in that the fresh air enters the combustion chamber (12) from the two air inlets (4) and (6) at the air inlet baffle (5), and the coal blocks are spread on the water pipes running through the combustion chamber to burn, and the solid charcoal volatilized is volatilized. Fall on the refractory brick surface (7) and burn fully. The smoke pipe bundles (16), (17) run through the water tank (11) longitudinally, and are connected in series through the burners (14), (15) etc. to form flue gas pipes, and finally the flue gas is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com