Preparation method of light-colored polyisocyanate curing agent

A technology of polyisocyanate and diisocyanate, which is applied in the field of preparation of light-colored polyisocyanate curing agent, can solve problems such as high reaction temperature, difficulty in monitoring reaction temperature, and uneven distribution of alcohol components, so as to control the color number of the product and prevent localized The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

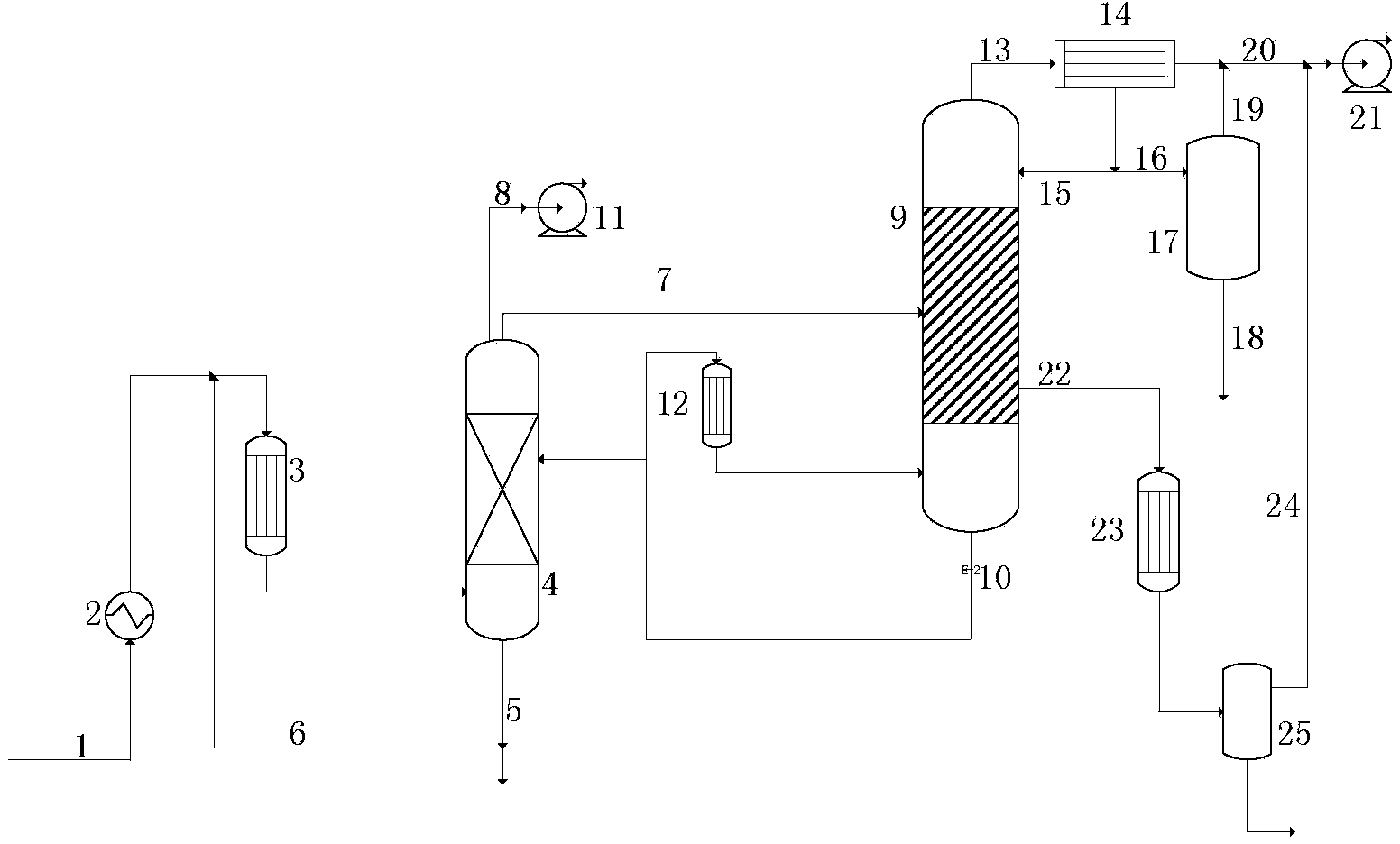

Method used

Image

Examples

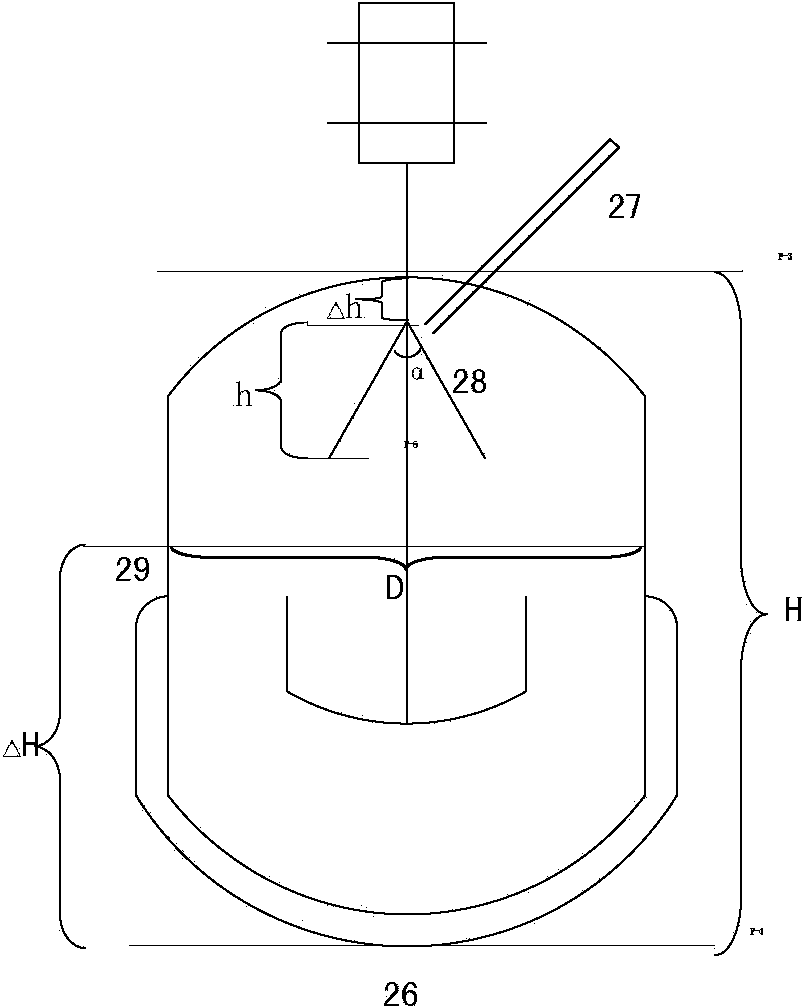

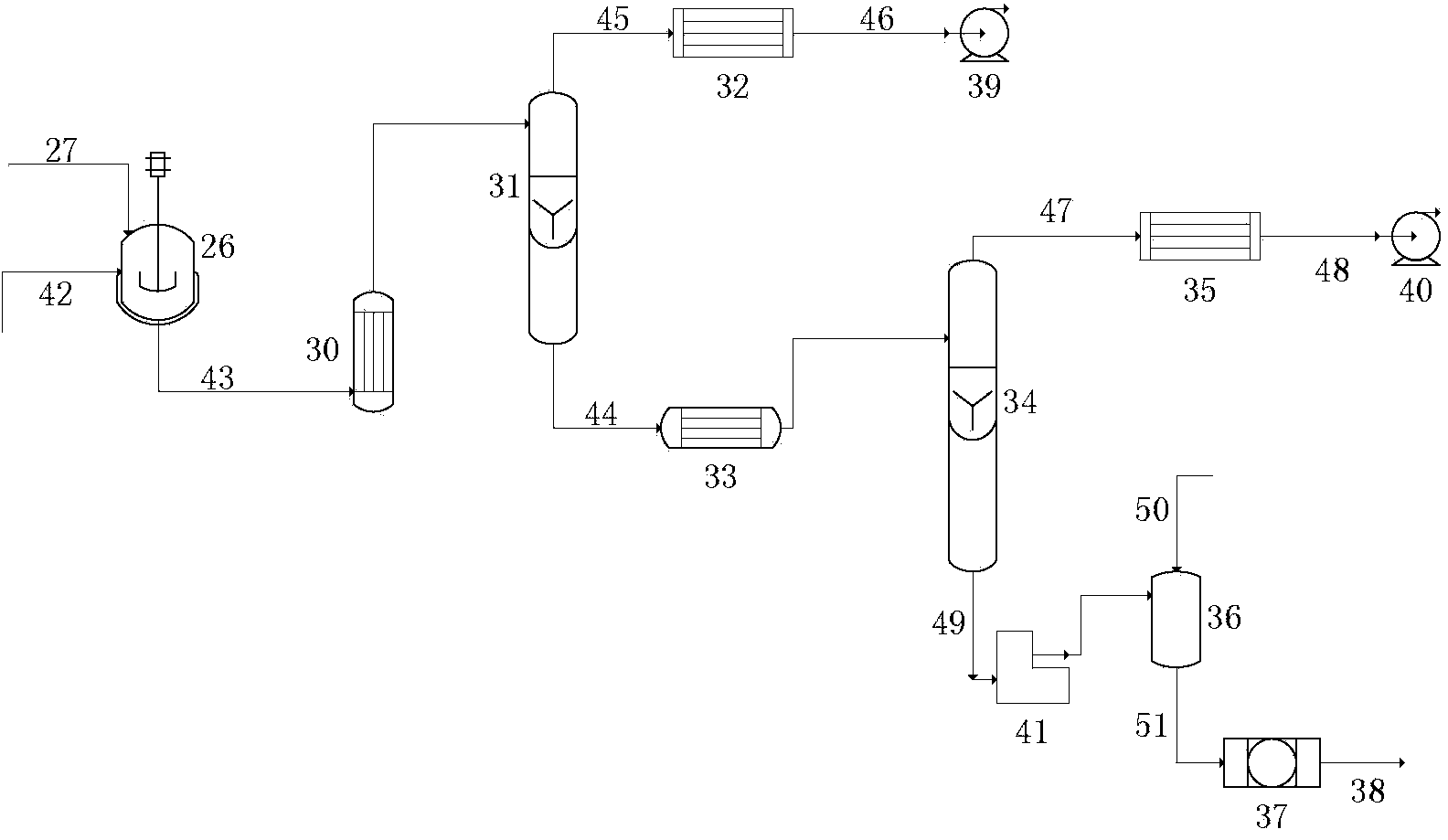

Embodiment 1

[0059] Trimethylolpropane with a carbonyl compound content of 0.02wt% is added dropwise to the conical liquid distribution pan and dispersed into the reactor containing 5Kg of toluene diisocyanate component (the liquid level is about 70% of the reactor height) The reaction is carried out in , the two satisfy the NCO / OH molar ratio of 4, the reactor diameter D is 20cm, the height H is 20cm, the distance △h between the distribution plate and the top of the reactor is 1cm, the height h of the distribution plate is 2cm, and the top angle of the distribution plate is α is 55°, holes are opened on the surface of the distribution plate, the hole diameter is 5mm, the opening ratio is 0.6, the rotation speed is 300rpm, the dropping time is 60min, the reaction temperature is 50°C, and the reaction time is 4h to obtain the prepolymer reaction liquid; the prepolymer reaction The liquid is separated by a two-stage thin-film evaporator, the primary temperature is 120°C, the absolute pressure...

Embodiment 5

[0067] Remove carbonyl compounds from trimethylolpropane and 1,4-butanediol respectively to obtain a mixed alcohol component with a carbonyl compound content of 0.02wt%. The mass ratio of trimethylolpropane to 1,4-butanediol is 3 : 1; the mixed alcohol component is dispersed in the reactor equipped with 60Kg of toluene diisocyanate component (its liquid level height is about 60% of the height of the reactor) by dropping it on the conical liquid distribution plate and reacting, The molar ratio of NCO / OH is 6, the diameter D of the reactor is 40cm, the height H is 70cm, the distance △h from the distribution plate to the top is 5cm, the height h of the distribution plate is 10cm, the top angle α of the distribution plate is 40°, the surface of the distribution plate Open holes with a pore diameter of 10mm, a porosity of 0.4, a rotational speed of 250rpm, a dropping time of 80min, a reaction temperature of 80°C, and a reaction time of 6h to obtain a prepolymer reaction solution; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com