Bevel gear machining device for machining

A processing device and machining technology, applied in gear tooth manufacturing devices, mechanical equipment, metal processing equipment, etc., can solve problems such as low efficiency and poor deburring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

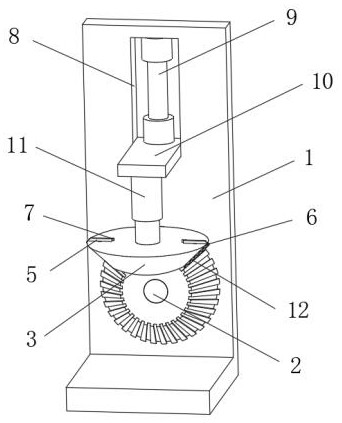

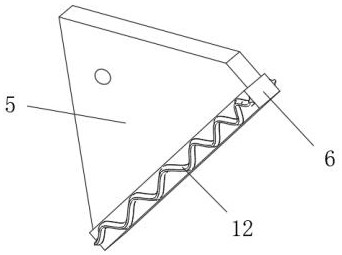

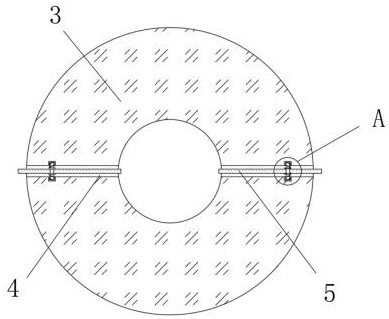

[0029] refer to Figure 1-4 , a bevel gear processing device for mechanical processing, comprising a fixed frame 1, the bottom of one end of the fixed frame 1 is rotatably connected with a horizontal positioning piece 2, and one end of the positioning piece 2 is rotatably connected with a rotating motor, and the fixed frame 1 is positioned on the positioning piece 2 is provided with a transmission part 3 that rotates horizontally, and the middle position of the top of the transmission part 3 is fixed with a driving motor 11, and the driving motor 11 is connected with a vertical displacement mechanism. Both sides of the outer wall of the transmission part 3 are provided with connecting grooves 4 , and the connecting piece 5 is connected by a spring between the inner walls of the two ends of the connecting groove 4, the top of the connecting piece 5 protrudes from the transmission part 3, and the position corresponding to the top of the transmission part 3 and the connecting piec...

Embodiment 2

[0037] refer to Figure 5-6 , a bevel gear processing device for mechanical processing, a chute 19 is provided at the middle position of the bottom of the fixed frame 1, and the chute 19 is arranged in parallel with the positioning member 2, and the inner wall of the chute 19 is slidably connected with a clamping plate 21, and the chute 19 One end of the bottom inner wall close to the positioning member 2 is provided with an embedding groove, the inner wall of the embedding groove is fixed with a magnetic block 20 , and the bottom of the clamping plate 21 is magnetically adsorbed to the magnetic block 20 .

[0038] When in use, when the bevel gear is installed on the positioning part 2, the vertically placed clamping plate 21 can be used to ensure the stability of the tooth groove position of the bevel gear, and ensure that the lowered transmission part 3 corresponds to the bevel gear, so as to ensure the stability of the device. actual use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com