Environmental-combustion burner

A burner and environmental protection technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of short flame holes, high temperature at the bottom of the pot, and inability to achieve environmentally friendly combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

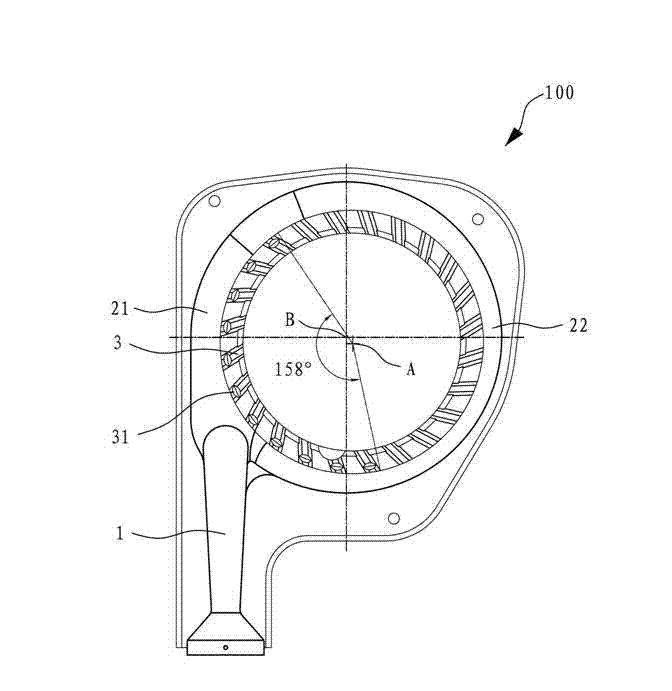

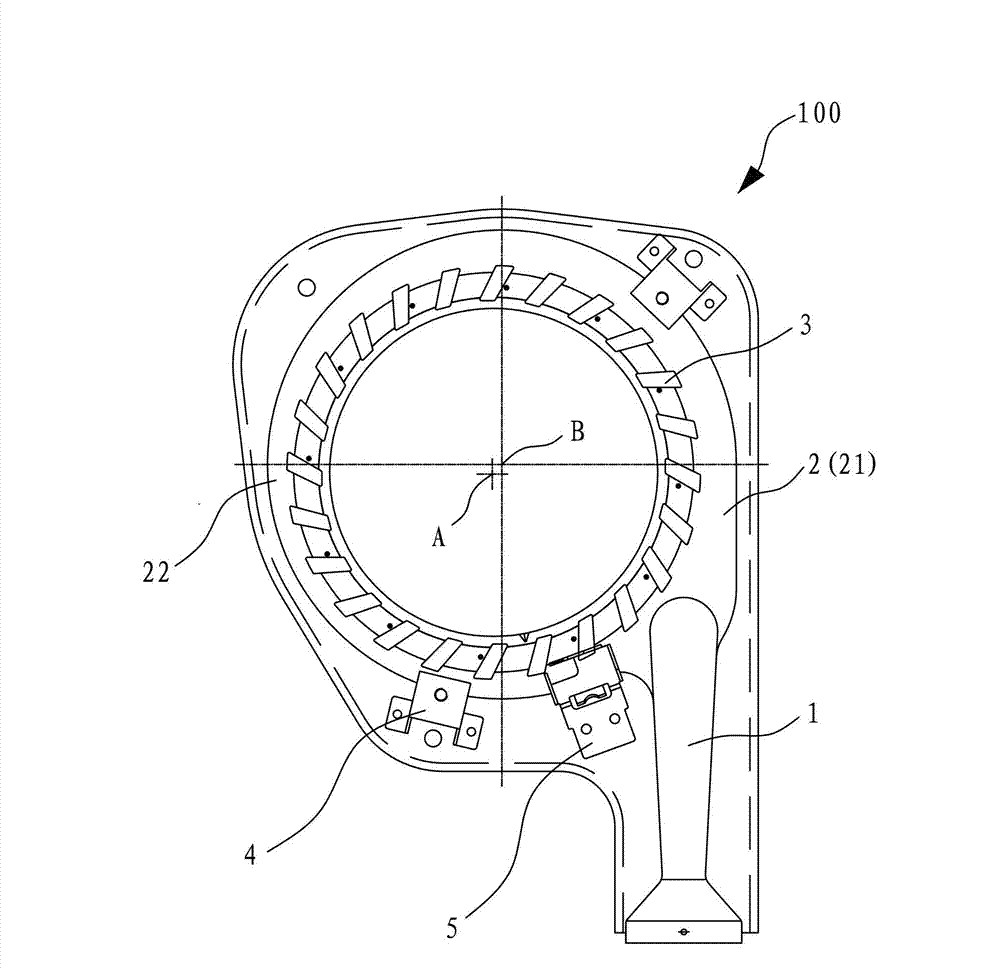

[0021] Such as figure 1 and figure 2 As shown, the present invention relates to an environmentally friendly burner, which is divided into a burner upper plate and a burner lower plate that can be covered together. Forming, the burner upper plate is also formed with an energy-gathering ring support 4 and a thermocouple support 5.

[0022] Wherein, the burner specifically includes an introduction pipe 1 for introducing a mixture of gas and primary air, an annular distribution pipe 2 connected to the introduction pipe 1, and a plurality of flame holes 3 arranged on the inner peripheral side of the annular distribution pipe 2, Specifically the same as the background technology, the flame hole 3 also includes an upper flame hole 3 and a lower flame hole 3, and the annular distribution pipe 2 has a first air cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com